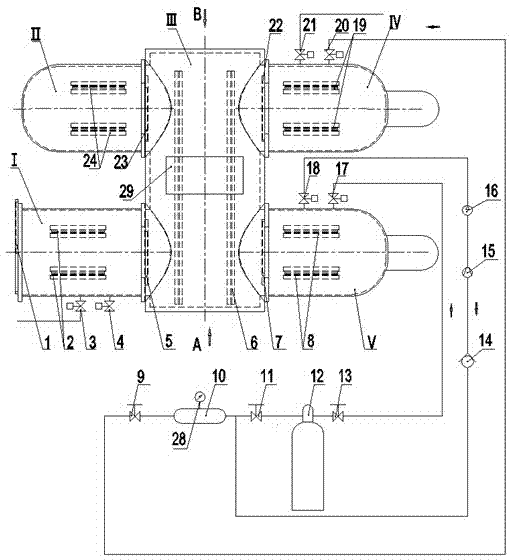

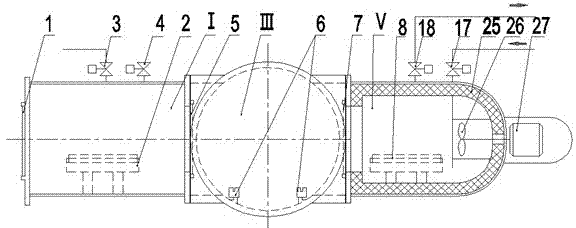

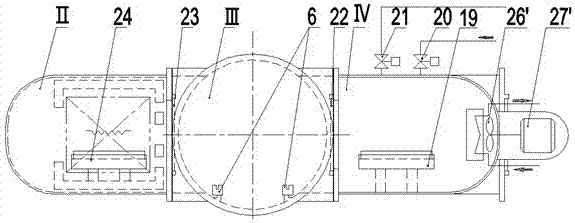

Vacuum heat treatment and subzero treatment integrated machine

A technology of vacuum heat treatment and cryogenic treatment, which is applied in the field of integrated equipment to achieve the effects of increasing productivity, improving quality, and saving electricity and nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Such as figure 1 As shown, when starting to work, open the first shut-off valve 9, the second shut-off valve 11, the third shut-off valve 13, observe the pressure gauge 28 on the gas storage tank 10, when the pressure shown by the pressure gauge reaches the work needs, close the first shut-off valve. Two cut-off valves 11. Then the first unsealed airtight door 1 is opened by computer control, and the material to be processed is sent to the first unloading table 2 in the material loading and unloading room I with a material truck, and the material truck is withdrawn, and then the first unsealed airtight door 1 is closed and opened. The second unsealed and sealed door 5, the third unsealed and sealed door 23, the fourth unsealed and sealed door 22, and the fifth unsealed and sealed door 7 open the first electromagnetic valve 3 to vacuumize the whole vacuum heat treatment and cryogenic treatment integrated machine. When the vacuum degree reaches the vacuum degree required...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com