Ship ballast water exchange device with mobile and telescopic snap-in barrier airbag

A ship ballast water, mobile telescopic technology, applied in water treatment devices, ship construction, ship parts, etc., can solve the problem that ballast water cannot be discharged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

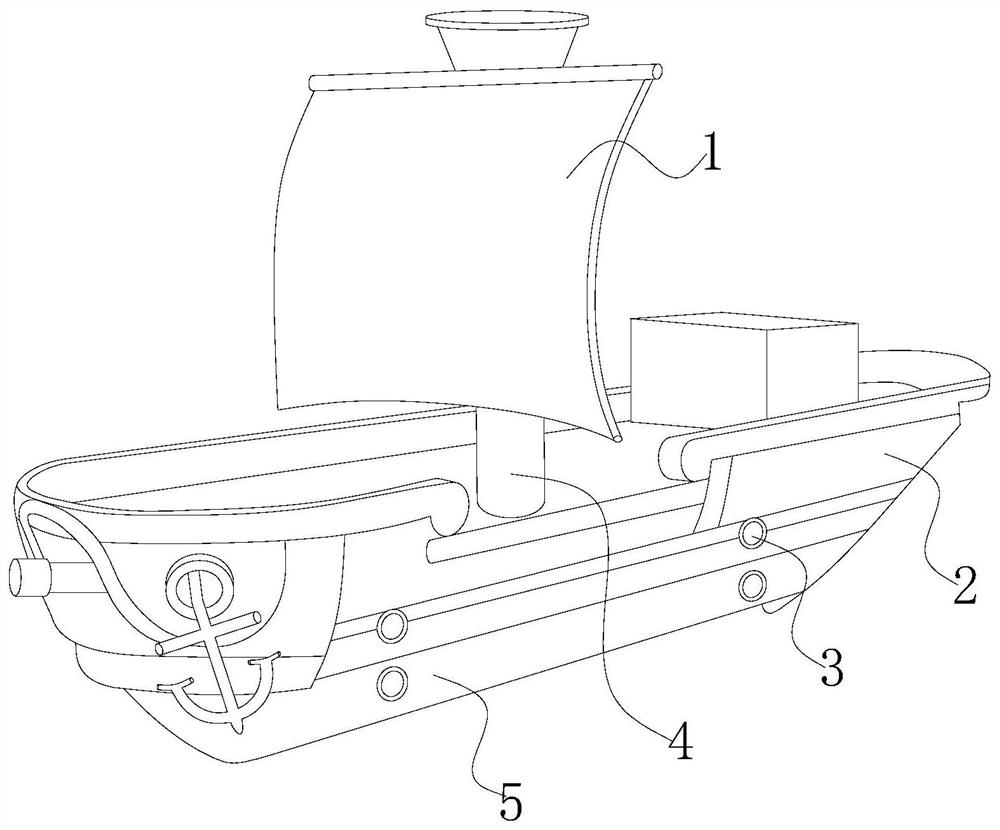

[0025] see Figure 1-Figure 7 , the present invention provides a mobile and telescopic ship ballast water exchange device with snap-fit barrier airbags, the structure of which includes a sail 1, a hull 2, a water treatment device 3, a sail fixing column 4, and a water-carrying chamber 5. The sail The fixed column 4 is fixedly installed on the hull 2, the sail fixed column 4 is provided with a sail 1, the sail fixed column 4 is fixedly connected with the sail 1, and the water-carrying chamber 5 is arranged on the hull 2 The bottom is an integral structure with the hull 2, and the water treatment device 3 is installed in the water-carrying chamber 5.

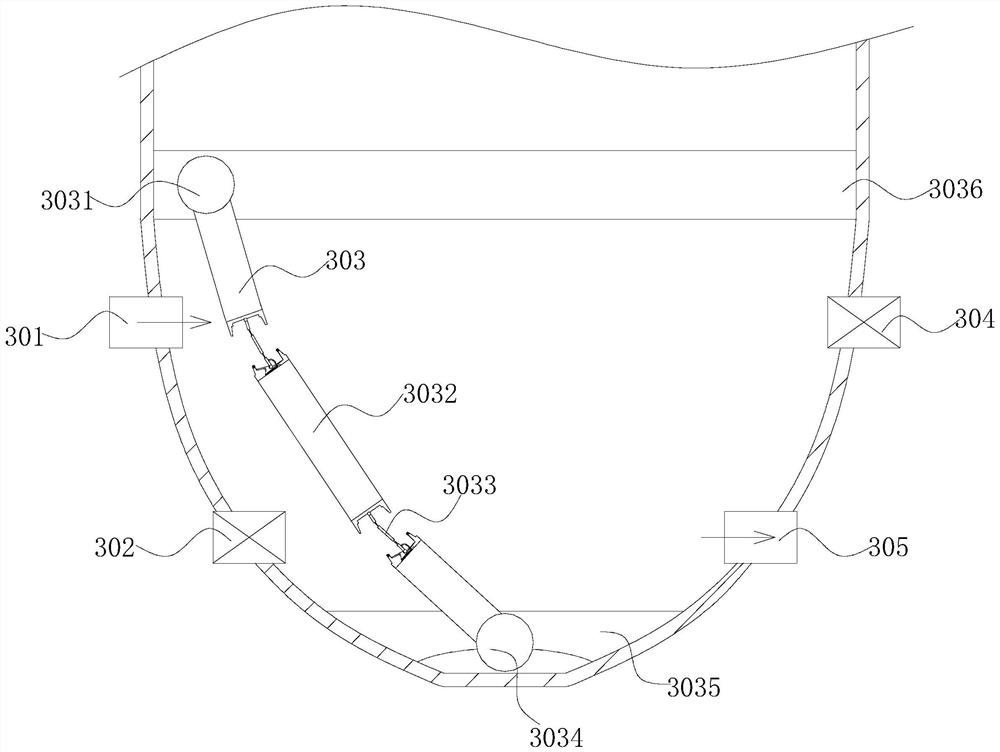

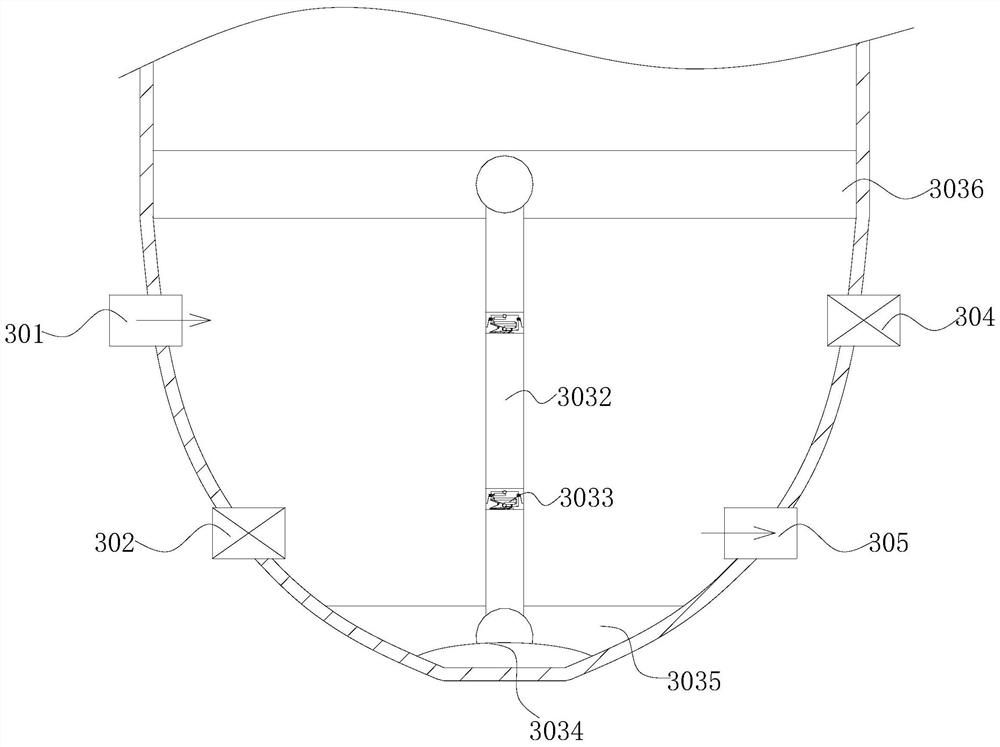

[0026] The water treatment device 3 is composed of a first water inlet 301, a first water outlet 302, a blocking device 303, a second water inlet 304, and a second water outlet 305. The first water inlet 301 and the second water inlet 304 is set up in a symmetrical structure, the first water inlet 301 and the second water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com