Pressure plate type lubrication pump for easy exhaust

A technology for lubricating pumps and pressure plates, which is applied in the direction of lubricating pumps, engine lubrication, and lubricating parts. It can solve the problems of gas in the pump, which is not easy to discharge, and affects the cleanliness of the environment. It achieves simple and compact structure and good exhaust effect. , keep clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

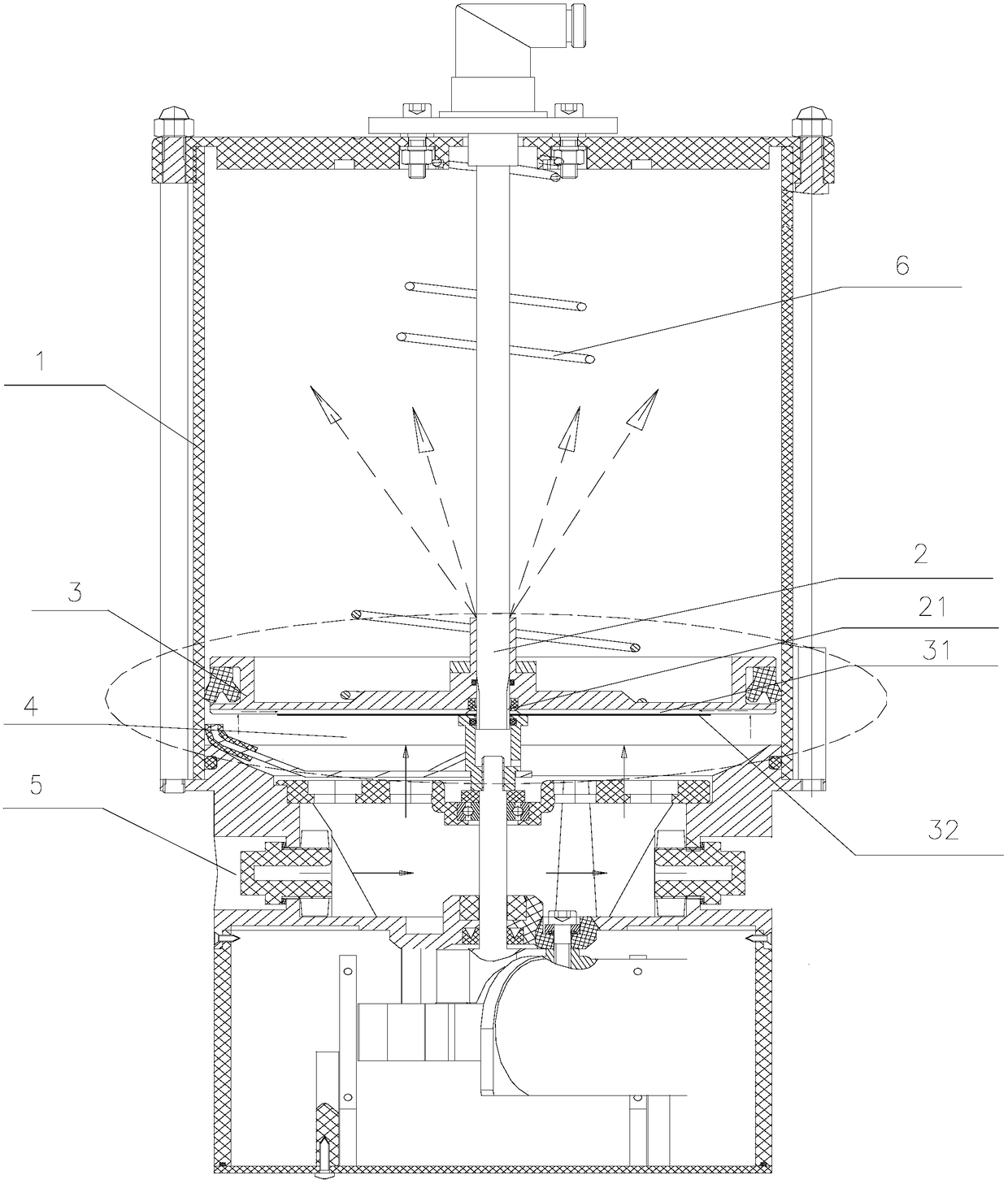

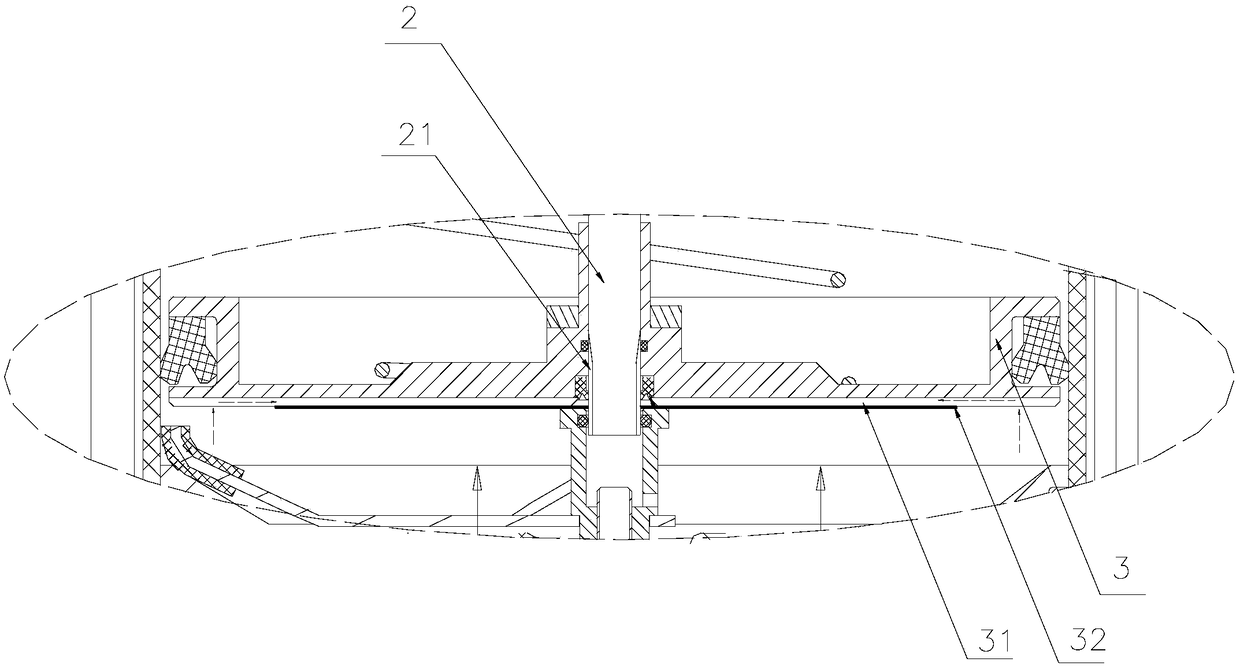

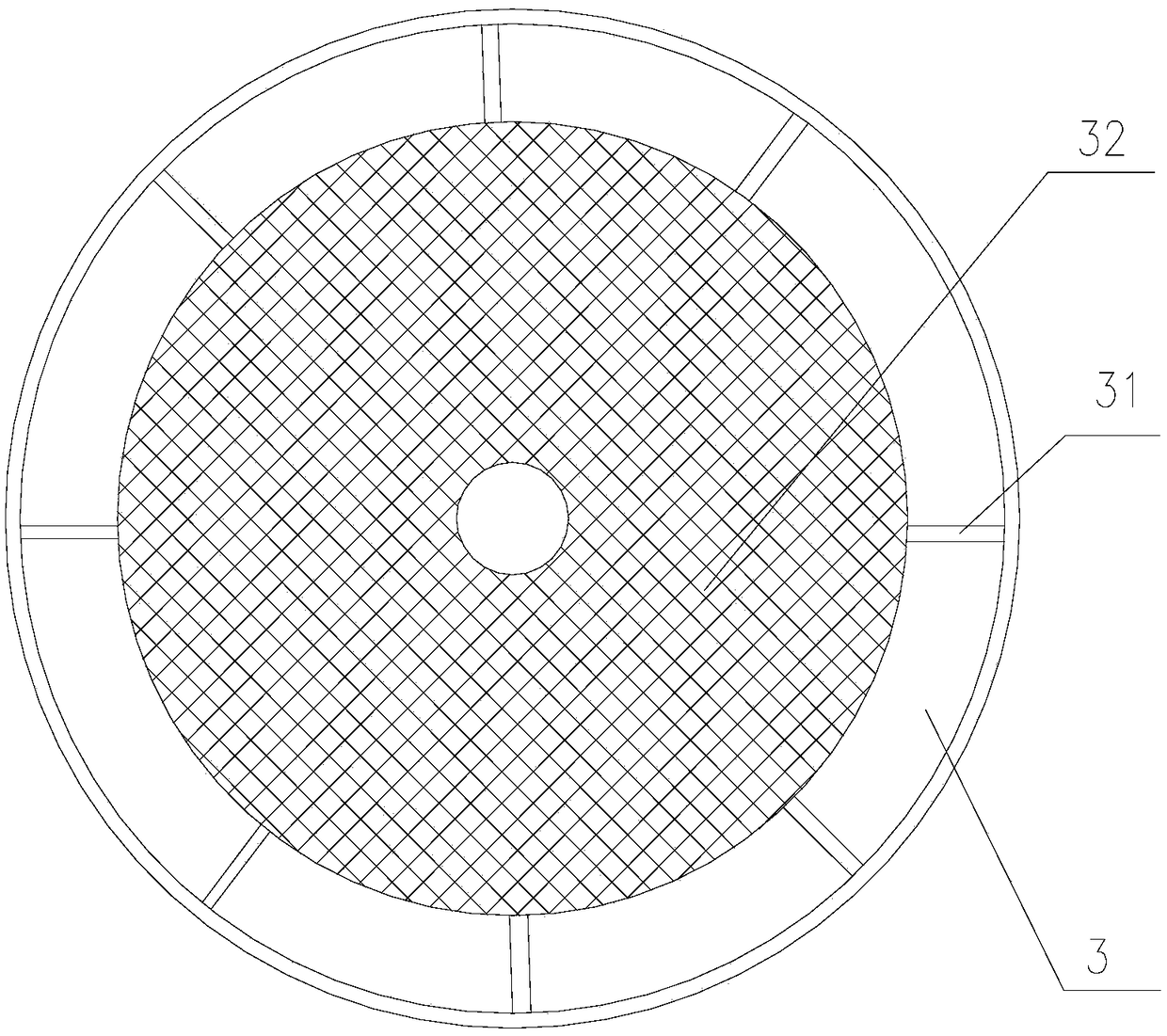

[0027] As shown in the figure, the pressure plate type lubricating pump convenient for exhausting in this embodiment includes an oil barrel 1 and an oil pump assembly. The oil barrel 1 is provided with a guide rod 2, and a pressure plate is arranged along the guide rod 2 for sliding fit. 3. The edge of the pressure plate 3 is slidingly sealed with the inner wall of the oil drum 1; the oil storage space 4 of the lubricating pump is provided with an exhaust channel, and the air inlet of the exhaust channel is located at the edge of the pressure plate 3; above the pressure plate is the exhaust The space below the pressure plate is the oil storage space of the lubricating pump; when the lubricating grease enters the oil barrel through the pump oil assembly, the air in the oil storage space will be squeezed to the edge of the pressure plate. In order to discharge all the air, the present invention will exhaust The air inlet of the channel is arranged on the edge of the pressure plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com