water heater drainage system

A technology of drainage system and water heater, applied in the directions of fluid heaters, lighting and heating equipment, etc., can solve the problems of inability to discharge, waste of cold water, inconvenient use, etc., and achieve the effect of avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

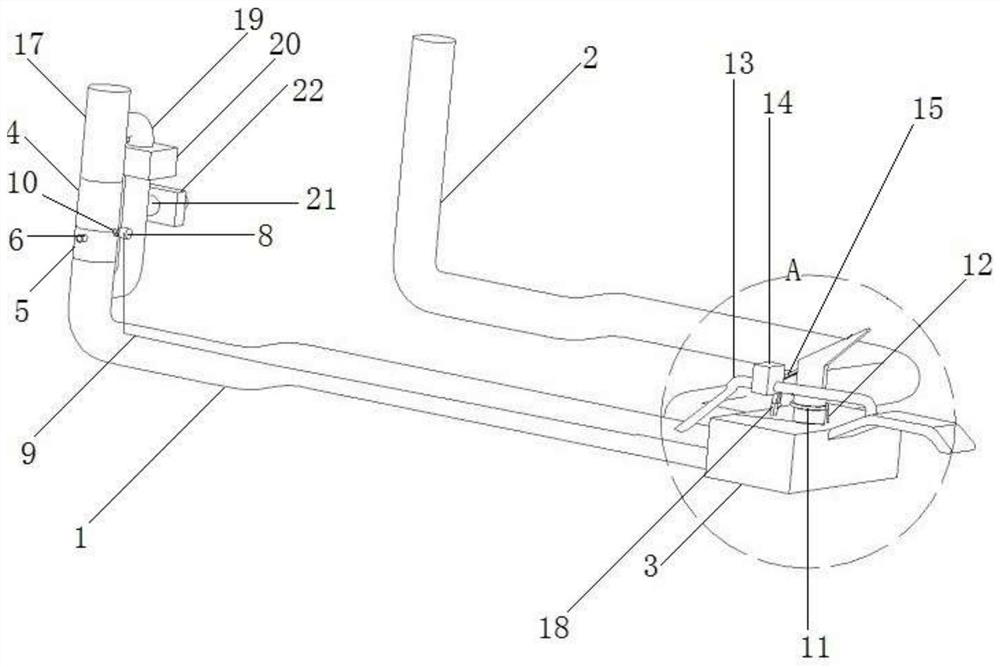

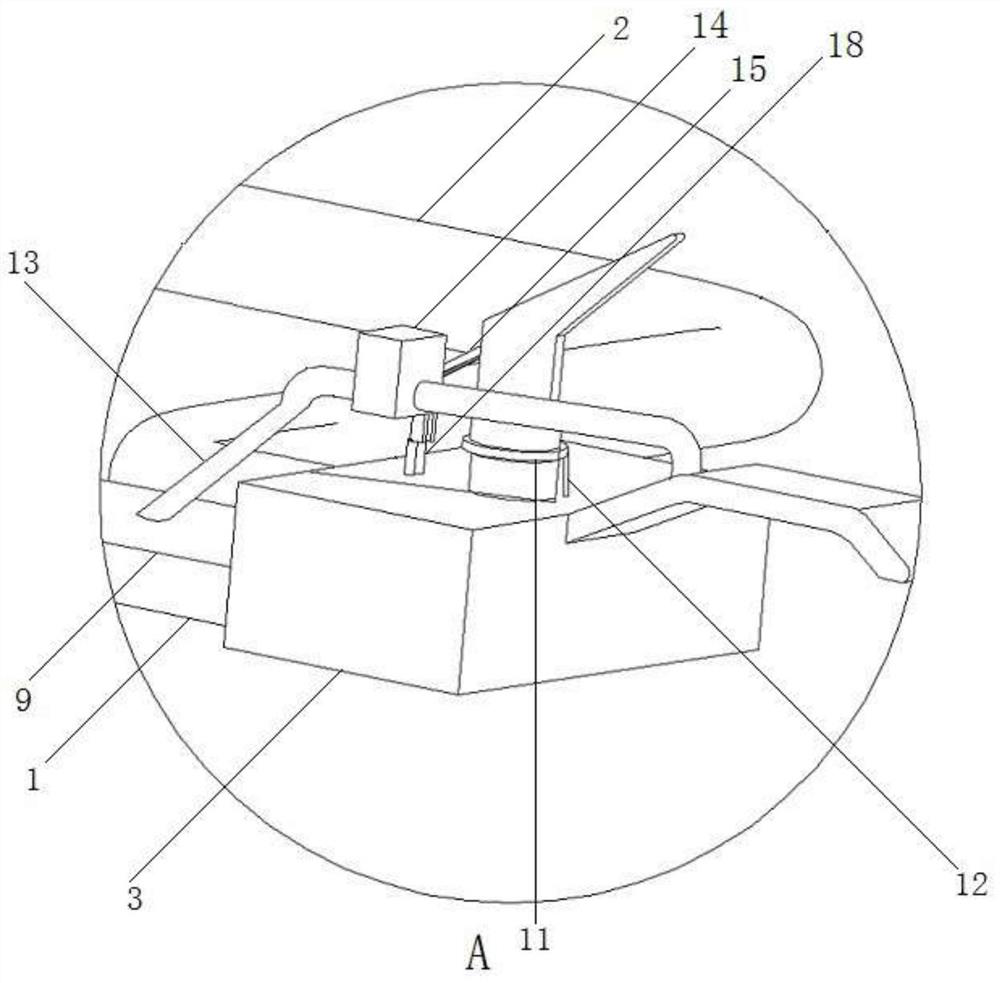

[0041] see Figure 1 to Figure 7 .

[0042] A drainage system for a water heater according to the present invention comprises a hot water pipe A1, a cold water pipe 2, and a water mixing valve 3, and one head of the hot water pipe A1 and the cold water pipe 2 is respectively connected to the hot water port and the cold water port of the water mixing valve 3 in airtight and fixed communication;

[0043] Among them, also include:

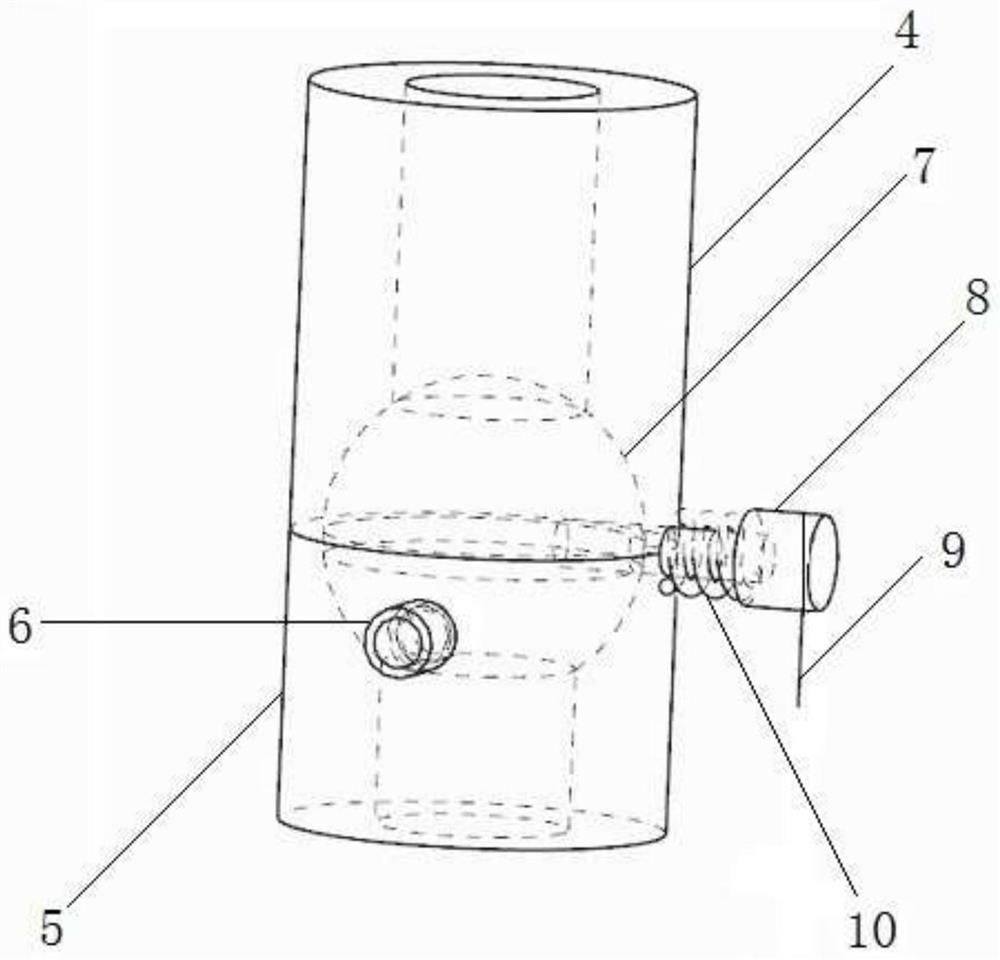

[0044] Joint pipe A4, joint pipe B5, hot water pipe B17, joint pipe A4 and joint pipe B5 are sealed and fixedly connected, the inner surface of joint pipe A4 and joint pipe B5 is a hemispherical surface, the upper end of joint pipe A4 is airtightly connected with hot water pipe B17, and the joint The lower end of the pipe B5 is airtightly connected with the hot water pipe A1;

[0045] The intake pipe 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com