Cinder breaking device for biomass boiler

A biomass boiler and slag breaking technology, which is applied to lighting and heating equipment, etc., can solve the problems of slagging, high content, and difficult to discharge slagging of biomass pellet fuel, and achieve the effect of improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

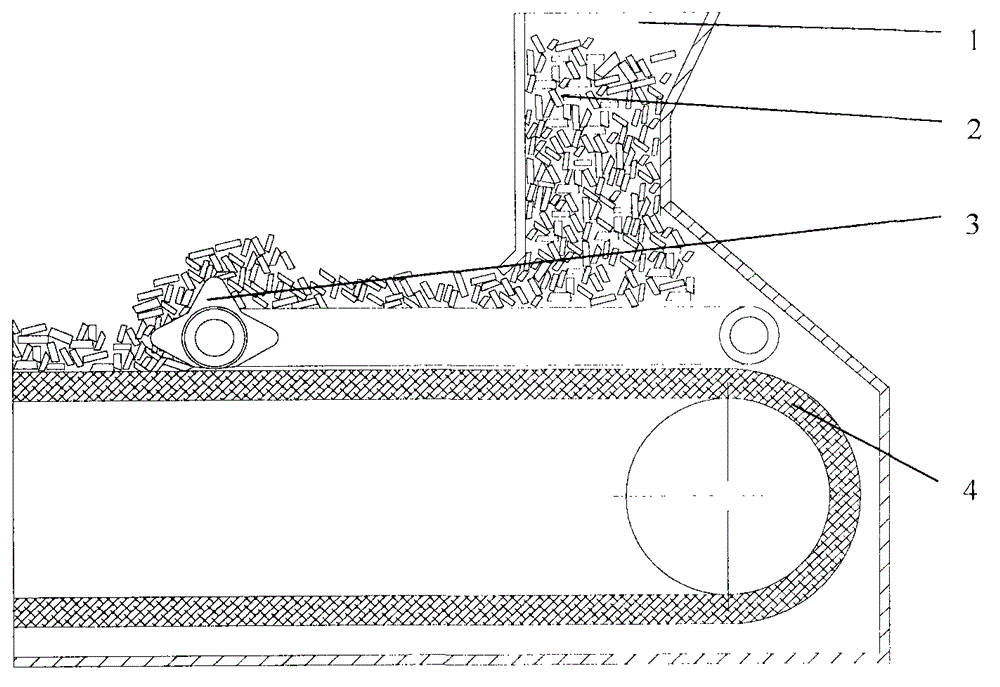

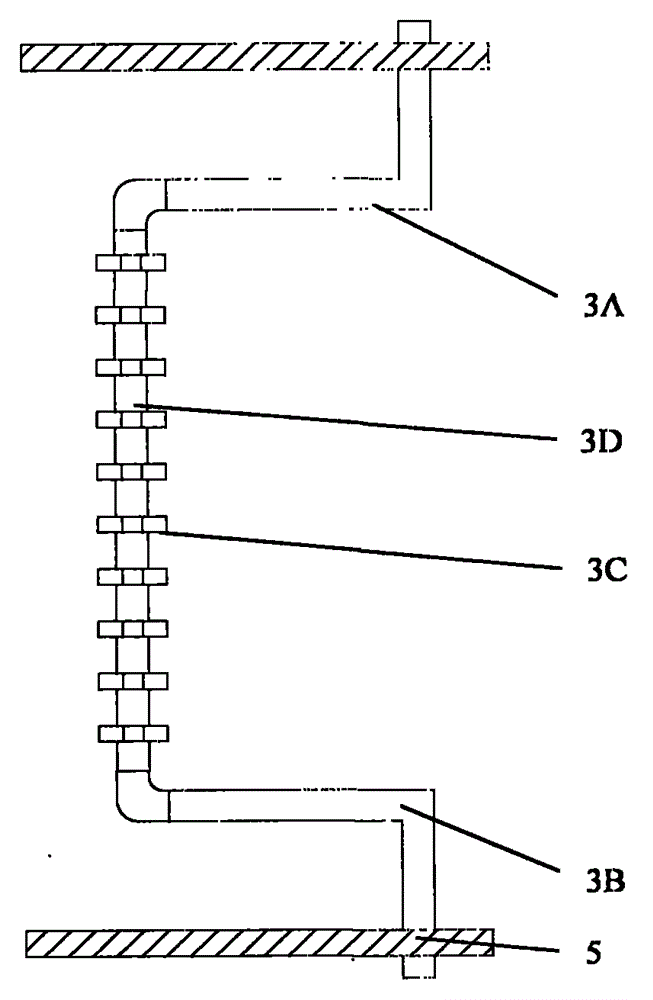

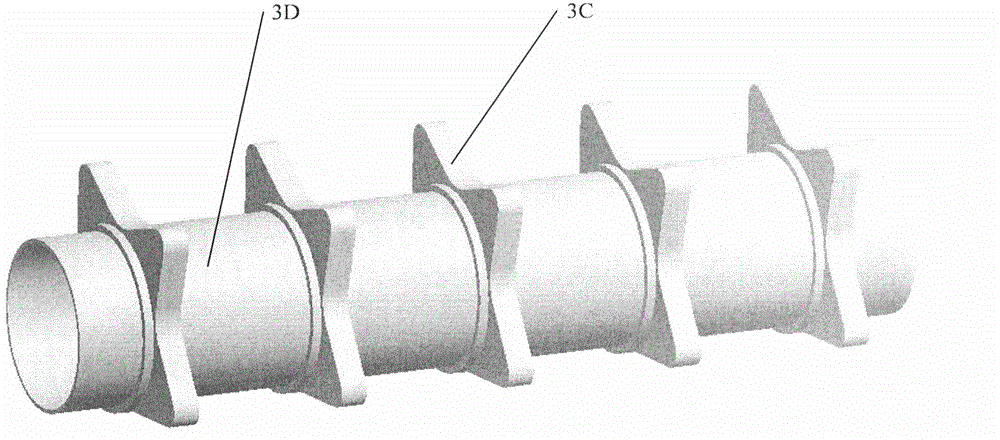

[0024] Example 1: Biomass boiler slag breaking device for corn stalk pellet fuel

[0025] The particle density of corn stalk pellet fuel is 1.2g / cm 3 , the highest ash content is 18.45%, the low calorific value is 13.01MJ / kg, and the softening temperature is 1167°C. The ash slag contains high Si and other alkali metal elements, Si content is 28%, and K content is 9%.

[0026] The corn stalk pellet fuel was burned in a biomass boiler without a slagging device. The slagging rate of the bottom ash was 48.94%. A small amount of coked ash on the grate chain is bonded to the grate; the corn stalk pellet fuel is placed in the biomass boiler equipped with a slag breaking device of the present invention for combustion, and the ash is found to be in small pieces after combustion, and the slag The maximum size of the block is 17.3mm, and only a small amount of ash remains on the grate chain, which shows that the biomass boiler slag breaking device can not only break the ash, but also pr...

Embodiment 2

[0027] Example 2: Biomass boiler slag breaking device for corn stalk pellet fuel containing additives

[0028] The corn stalk pellets containing additives were burned in a biomass boiler without a slagging device, and the slagging after combustion was serious. The slagging rate of the bottom ash was 26.17%. The slag was larger and harder than the straw pellets without additives. The fuel slag block is small, and the maximum size of the slag block is 32.5mm. It is observed that a small amount of coked ash sticks on the fire grate chain; Combustion in the biomass boiler, after combustion, it was found that the size of the ash and slag block became smaller, and the maximum size of the slag block was 15.2mm. It was observed that only a small amount of ash remained on the grate chain, which indicated that the biomass boiler slag breaking device could not only break the ash and slag. , and it can prevent the ash from sticking on the chain grate, and the effects of slag breaking and ...

Embodiment 3

[0029] Embodiment 3: Biomass boiler slag breaking device for wood pellet fuel

[0030] Wood pellet fuel particle density 1.18g / cm 3 , the highest ash content is 1.01%, the low calorific value is 16.83MJ / kg, the softening temperature is 1332°C, the Si content in the ash is 10%, and the K element content is 4%.

[0031] The wood pellet fuel is burned in a biomass boiler without a slagging device. The slagging rate after combustion is not serious, and the bottom ash slagging rate is 0. It is observed that there is only a small amount of ash on the grate chain; the wood pellet fuel is placed in the Combustion in a biomass boiler equipped with a slagging device of the present invention is basically the same as that of a biomass boiler without a slagging device after combustion, and the effects of slag breaking and slag removal in the implementation examples are not obvious, indicating that for wood pellet fuels with low ash content, It is not necessary to increase the slag breakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com