Oil-sand separator and method for removing sand and sealing

A technology of separator and oil sand, which is applied in the direction of earthwork drilling, production fluid, wellbore/well parts, etc., which can solve the problems of labor-intensive, low work efficiency, long processing time, etc., and achieve environmental pollution and work efficiency High, good sand removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

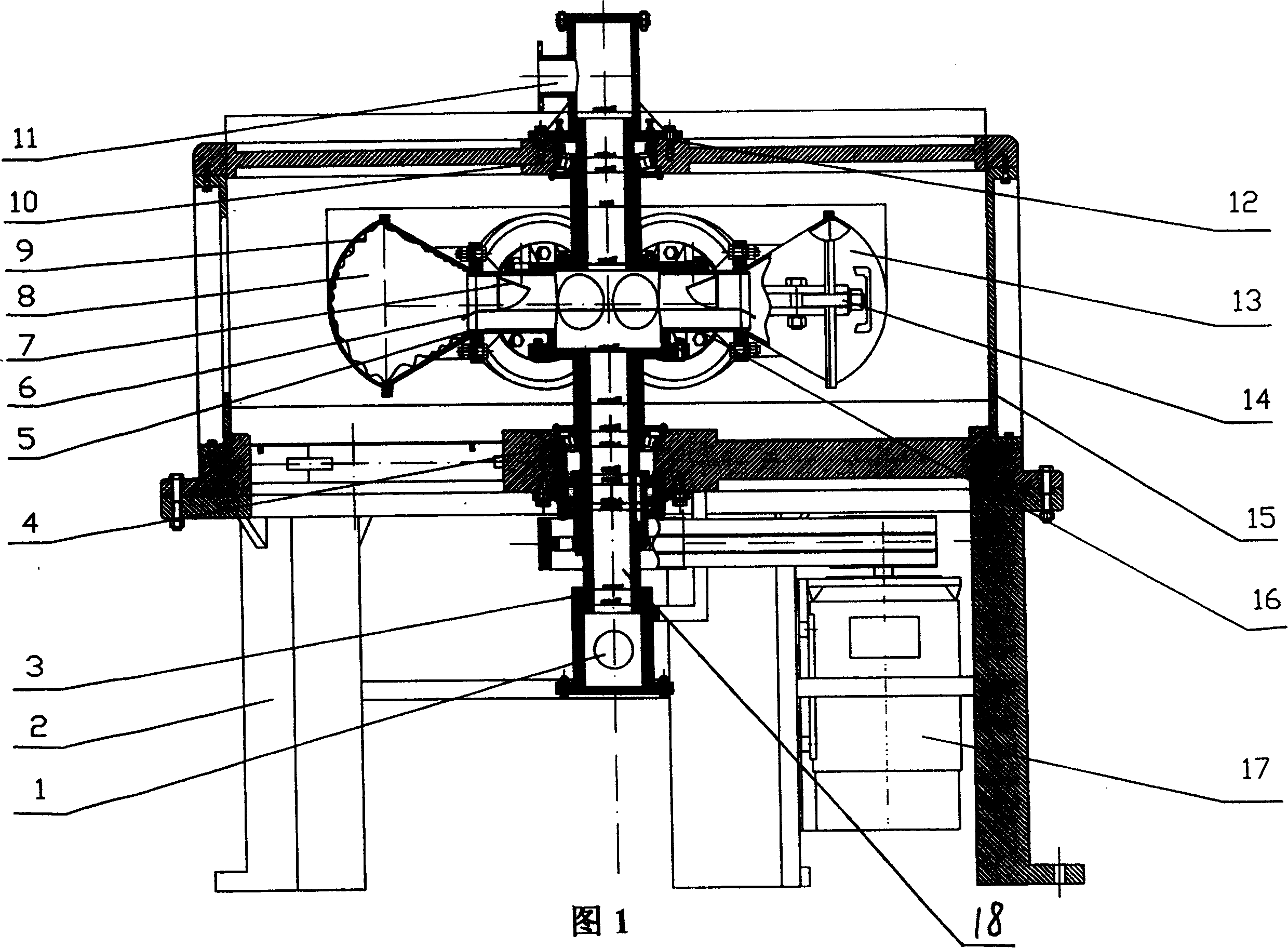

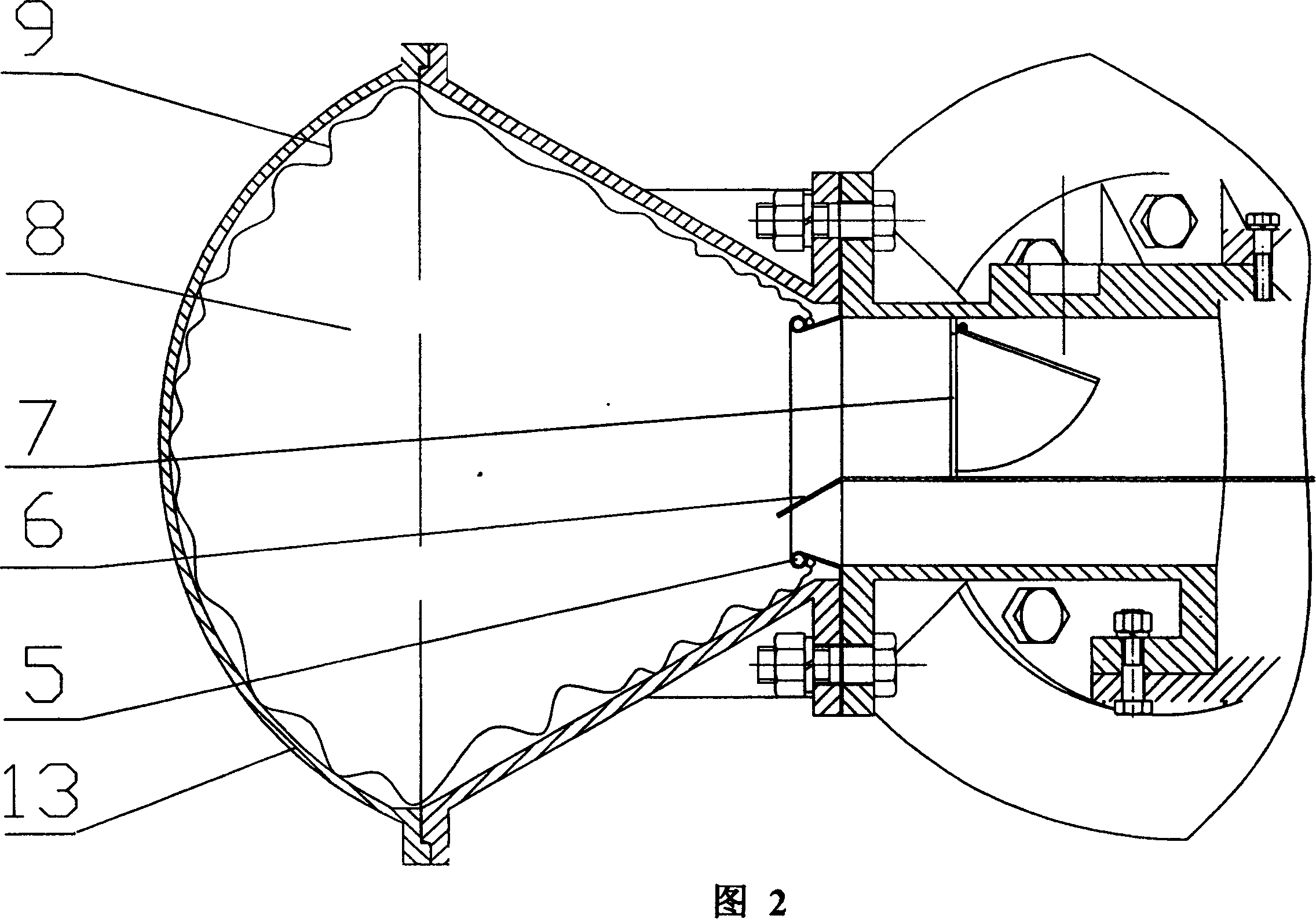

[0012] Separator of the present invention is made up of base 2, upper and lower bearing 10,4, drum 16, drum shaft 18 etc. Referring to accompanying drawing 1 , the bracket 15 is fixedly installed on the base 2 .

[0013] The drum shaft 18 is a hollow shaft, supported and installed in the center of the bracket 15 by the upper bearing 10 and the lower bearing 4, and its upper end is connected with the upper joint. It is connected with the lower joint, and the contact between the lower joint and the drum shaft 18 is provided with a sealing ring 3 . An oil outlet 11 is arranged on the upper joint, and the oil outlet 11 communicates with the upper joint. The lower joint is provided with an oil inlet 1, and the oil inlet 1 communicates with the lower joint. The rotating drum 16 is connected with the rotating drum shaft 18 and placed horizontally at the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com