A method for continuously synthesizing O, S-dimethylphosphorothioate based on a tubular reaction device

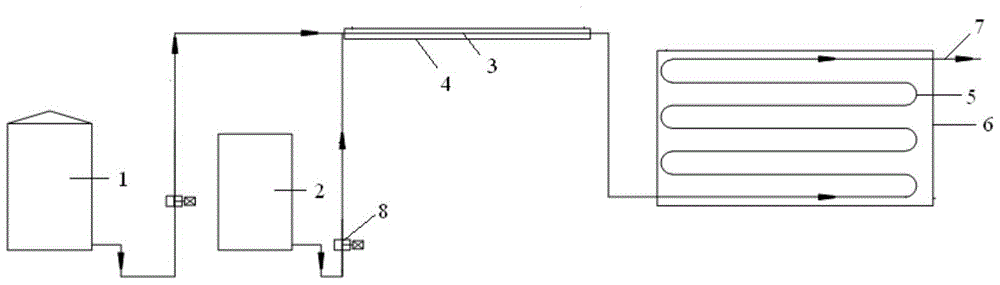

A technology of dimethylphosphorothioate and tubular reaction device, applied in chemical/physical/physicochemical stationary reactors, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc., capable of solving The production capacity of a single reactor is small, the product quality and yield are unstable, and the production process is prone to problems such as material flushing, which meets the requirements of large-scale industrial production, is easy to automatically control, and has the effect of small equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

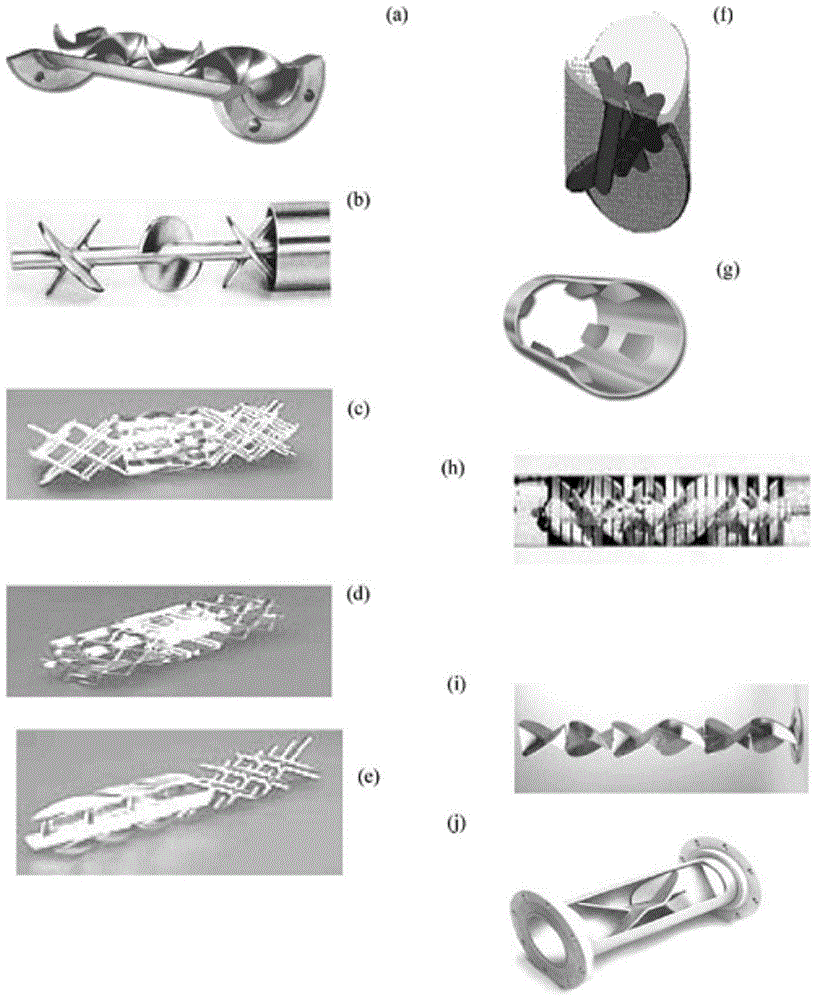

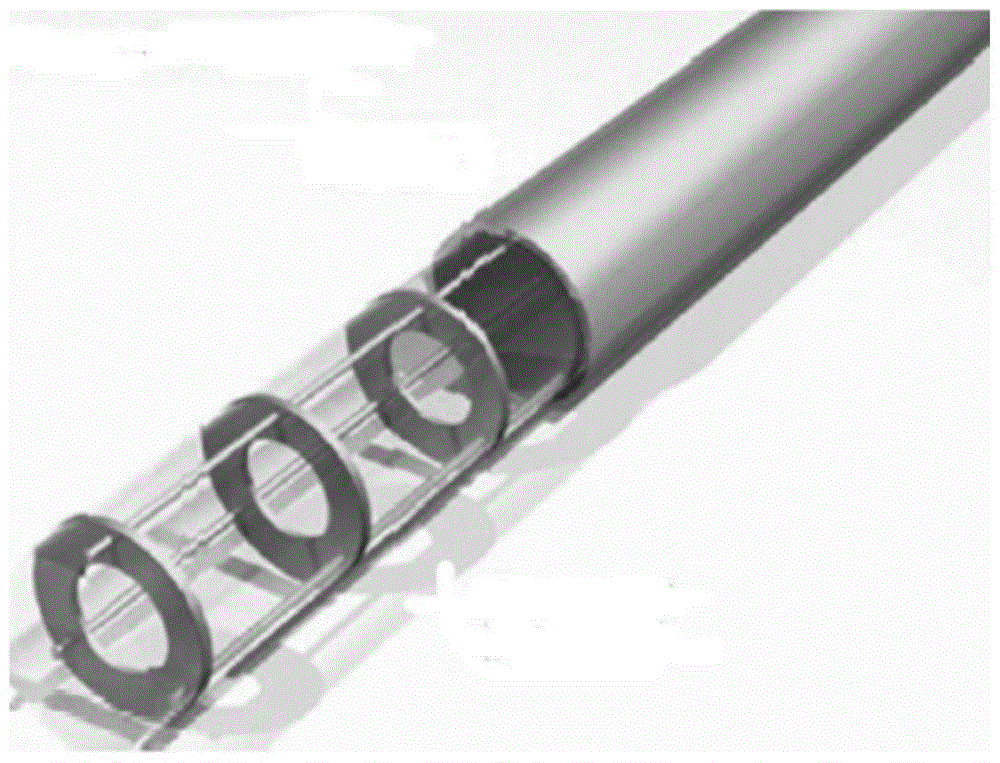

[0032] O, O-dimethylphosphorothioate and dimethyl sulfate are respectively metered by piston metering pumps, and then enter the first section of the tubular reactor, which is equipped with a static mixer inside and outside the tube. Jacketed cooling jacket. The mass ratio of dimethyl sulfate to O, O-dimethylphosphorothioate is 5.3:100. The flow rate of the material in the first section of the tubular reactor is 1m / s, the residence time is 6 minutes, and the temperature of the first section of the tubular reactor is 40°C to 45°C. Then enter the second section of the tubular reactor. The second-stage tubular reactor is provided with an annular central baffle, and the second-stage tubular reactor is submerged in a container with a coolant, and the flow rate of the material in the second-stage tubular reactor is 0.01m / s. The time is 8 hours, and the temperature of the second-stage tubular reactor is 40°C to 45°C. At the reaction outlet, the content of O,S-dimethylphosphorothioa...

Embodiment 2

[0034] O,O-dimethylphosphorothioate is metered with dimethyl sulfate by a piston metering pump respectively, and then enters the first section of the tubular reactor. A static mixer is installed inside the tubular reactor, and a static mixer is installed outside the tube. There is a jacketed cooling jacket. The mass ratio of dimethyl sulfate to O, O-dimethylphosphorothioate is 6:100. The flow rate of the material in the first section of the tubular reactor is 0.1m / s, the residence time is 60 minutes, and the temperature of the first section of the tubular reactor is 35°C to 40°C. Then by entering the second-stage tubular reactor, the second-stage tubular reactor is provided with a central circular baffle, and the second-stage tubular reactor is submerged in a container with a coolant, and the second-stage tubular reactor The flow rate of the material in the reactor is 0.01m / s, the residence time is 7 hours, and the temperature of the second-stage tubular reactor is 40°C-45°C....

Embodiment 3

[0036] O,O-dimethylphosphorothioate is metered with dimethyl sulfate by a piston metering pump respectively, and then enters the first section of the tubular reactor. A static mixer is installed inside the tubular reactor, and a static mixer is installed outside the tube. There is a jacketed cooling jacket. The mass ratio of dimethyl sulfate to O, O-dimethylphosphorothioate is 5:100. The flow rate of the material in the first section of the tubular reactor is 0.05m / s, the residence time is 30 minutes, and the temperature of the first section of the tubular reactor is 35°C to 40°C. Then it enters the second-stage tubular reactor, and the second-stage tubular reactor is provided with a porous baffle, and a cooling jacket with a jacket is arranged outside the pipe. The flow rate of the material in the second section of the tubular reactor is 0.001m / s, the residence time is 7 hours, and the temperature of the second section of the tubular reactor is 40°C-45°C. At the reaction ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com