Travelling type grain dewatering and drying machine

A walking and drying machine technology, which is applied in the fields of saving seeds by drying, adapting to climate change, etc., can solve the problems of inability to meet the needs of farmers, waste of manpower and material resources, and inconvenient movement, so as to reduce the labor intensity of workers and achieve fast drying speed. , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

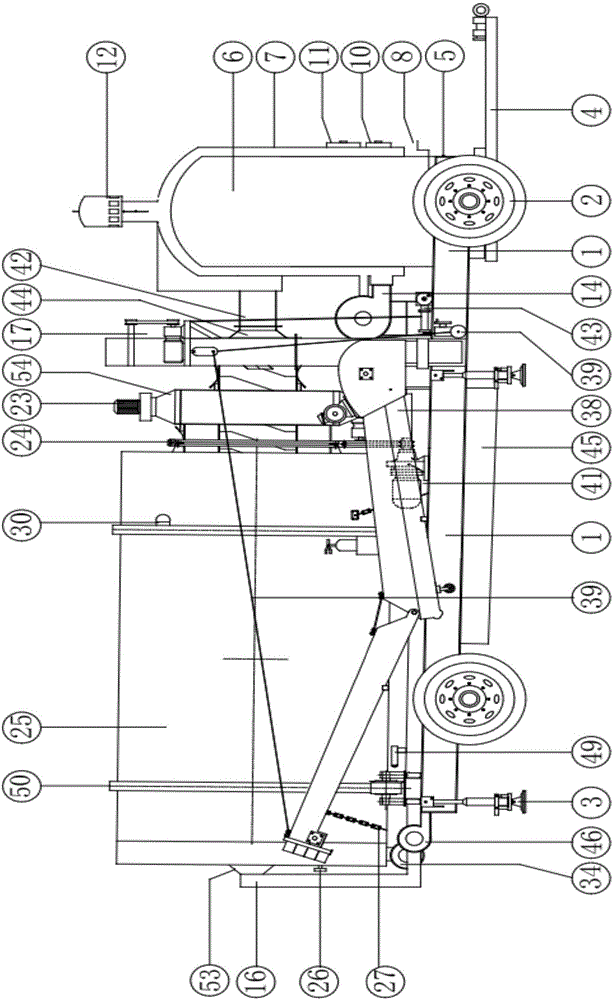

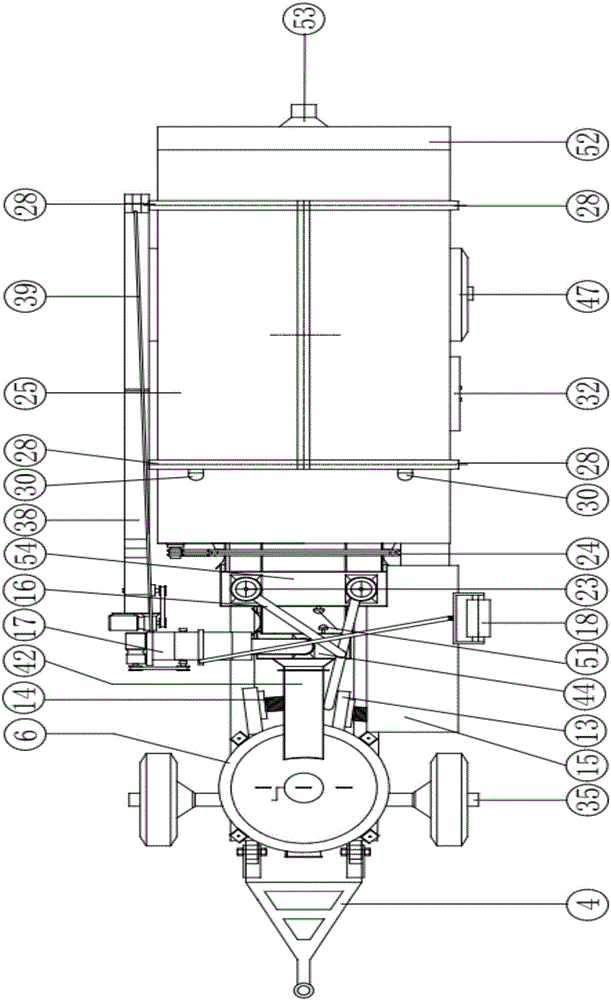

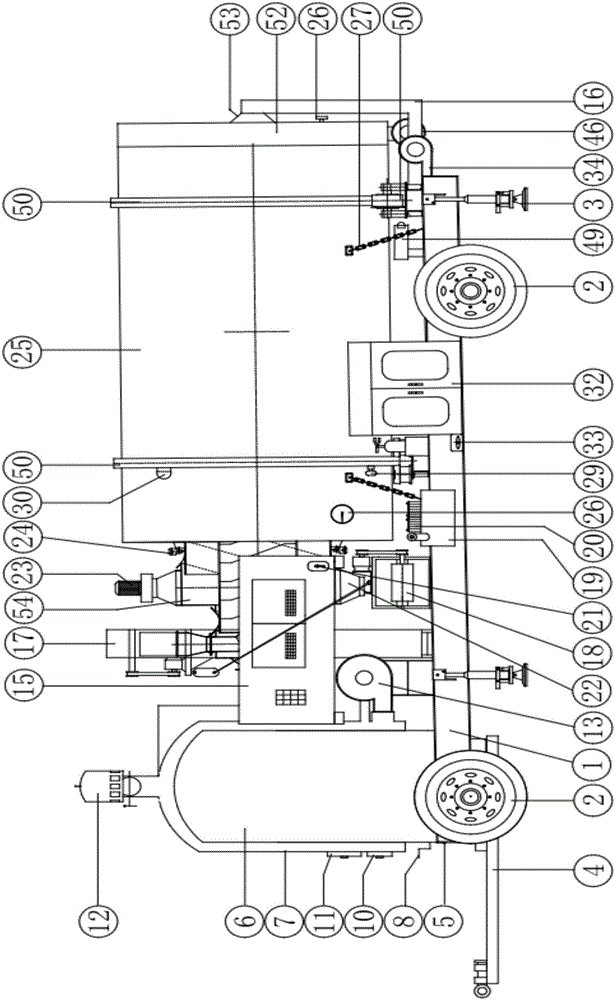

[0024] see Figure 1-12 , a walking type grain dehydration dryer, including a walking chassis assembly 1, a hot air stove 6, a six-pack drying bin 25, a retaining wheel component 50, a generator set 15, a fan-shaped grain scraper 38, and a multi-angle discharger 18 And intelligent frequency conversion control cabinet 32, described walking chassis assembly 1 is made up of walking wheel 2, traction frame 4, turntable direction front axle 35, electric drive hub brake rear axle 47, travel motor 48 and H-shaped frame 36, turntable direction The front axle 35 and the electric drive hub brake rear axle 47 are respectively provided with two and four traveling wheels 2, and the front end of the front axle 35 in the direction of the turntable is provided with a traction frame 4 and a brake quick connector 5, and the electric drive hub brake rear axle 47 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com