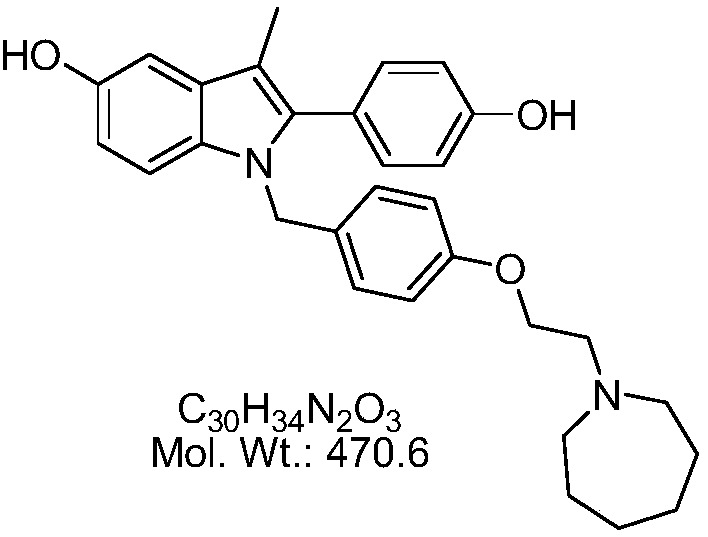

A kind of preparation method of bazedoxifene acetate

A technology of bazedoxifene acetate and acetic acid, which is applied in the field of medicine, can solve the problems of high equipment requirements, industrial scale-up, complicated operation, etc., and achieve the effects of high reaction efficiency, short reaction time and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

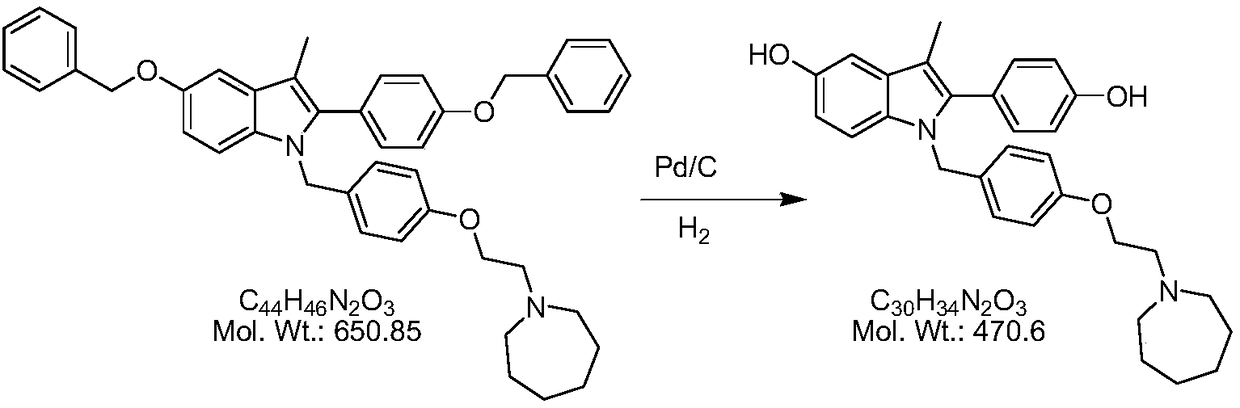

[0026] 1) Preparation of slurry: Dissolve 100 g of compound I completely in 500 ml of ethanol, add 3 g of Raney nickel at room temperature, stir evenly, and obtain a slurry for later use.

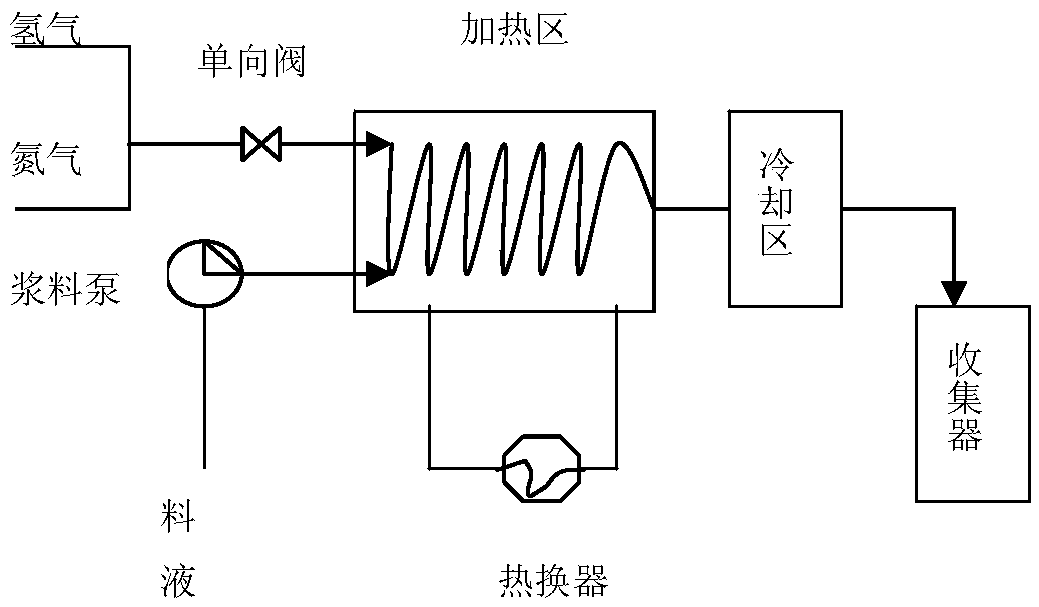

[0027] 2) Microreactor reaction: Use nitrogen to fully replace the air in the heating zone of the microreactor, then preheat the heating zone of the microreactor to an internal temperature of 30°C, then pass in hydrogen, and control the pressure at 0.2-0.3MPa to complete the step 1) The slurry is pumped into the heating zone of the microreactor through the slurry pump to control the temperature at 30°C and react for 3-8s; after the reaction is completed, pass through the cooling zone (the cooling zone is cooled by circulating water), and then collect the reaction solution;

[0028] 3) Generate bazedoxifene acetate: remove the insoluble matter by filtration, slowly add 10 g of acetic acid dropwise to the filtrate, and a white solid will slowly precipitate out. After the dropwise addition, coo...

Embodiment 2

[0030] 1) Preparation of slurry: Dissolve 500g of compound I completely in 4000ml of ethanol and ethyl acetate (3:1) mixture, add 20g of Raney nickel at room temperature, stir well, and set aside;

[0031] 2) Micro-reactor reaction: Use nitrogen to fully replace the air in the micro-reactor, preheat the micro-reactor to an internal temperature of 40°C, feed hydrogen, control the reaction pressure at 0.3-0.4MPa, and pump the slurry into the micro-reactor by the slurry pump In the reactor, control the temperature in the heating area at 40°C for 1-5s; after the reaction is completed, pass through the cooling area to cool (the cooling area is cooled by circulating water), and then collect the reaction liquid;

[0032] 3) Remove insoluble matter by filtration, slowly add 50g of acetic acid dropwise to the filtrate, and a white solid will slowly precipitate out. After the dropwise addition, cool down to 10°C-20°C, keep warm for crystallization for 1h, filter with suction, and air-dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com