Coal-fired nitrogen reduction method for cement kiln

A cement kiln and nitrogen reduction technology, applied in cement production, clinker production, etc., can solve the problems of cement production cost increase, unfavorable circular economy, unfavorable environmental protection, etc., to reduce the use of fuel, protect the ecological environment, and reduce pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

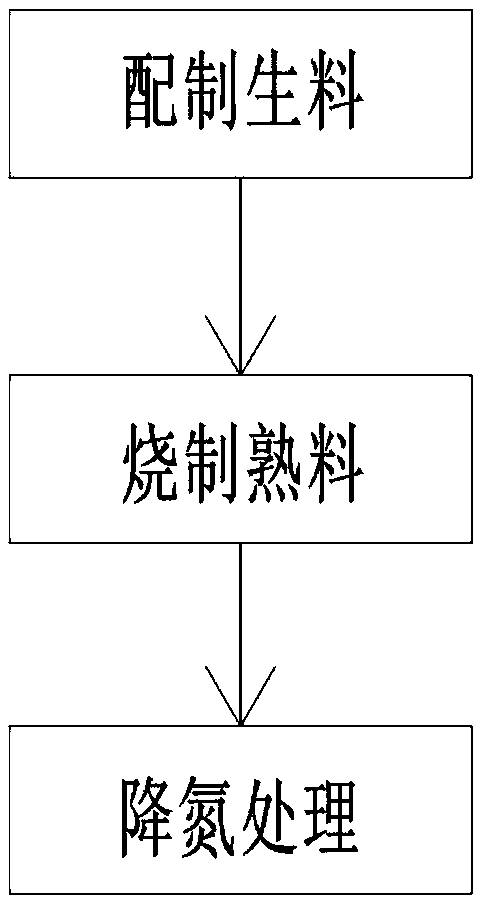

Image

Examples

Embodiment 1

[0021] A method for reducing nitrogen by burning coal in a cement kiln, comprising the steps of:

[0022] S1 preparation of raw meal, raw meal preparation according to the weight percentage of raw materials, the composition is: limestone 60-85%, sandstone 8-20%, steel slag 8-20%, tailings 5-15%, clay 15-35%, white cloud Stone 3-7%.

[0023] S2 burns clinker, using main coking coal as fuel, the sulfur content of main coking coal is 0.5-0.6%, and the volatile content of combustible base is 18-24%. On the basis of ensuring the firing effect, the temperature of entering the furnace for controlling the shrinkage of the smoke chamber should be as low as possible, and the temperature of entering the furnace for controlling the shrinkage of the smoke chamber should not be higher than 1100°C, so as to increase the reducing atmosphere.

[0024] S3 nitrogen reduction treatment, ammonia water is used to carry out nitrogen reduction treatment at the outlet of combustion tail gas.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com