Device and method for reducing discharging of boiler NOx in powder mode

A technology for boilers and furnace fumes, which is applied in the field of reducing boiler NOx emissions by pulverizing, can solve the problems of reducing the load of tail gas denitrification system, reducing the use of catalysts and reducing agents, and harsh reaction conditions, etc., to achieve the goal of suppressing NOx Production amount, reduction of NOx content, effect of oxygen content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the present invention on a large coal-fired boiler will be further described in detail below, but the implementation of the present invention is not limited thereto.

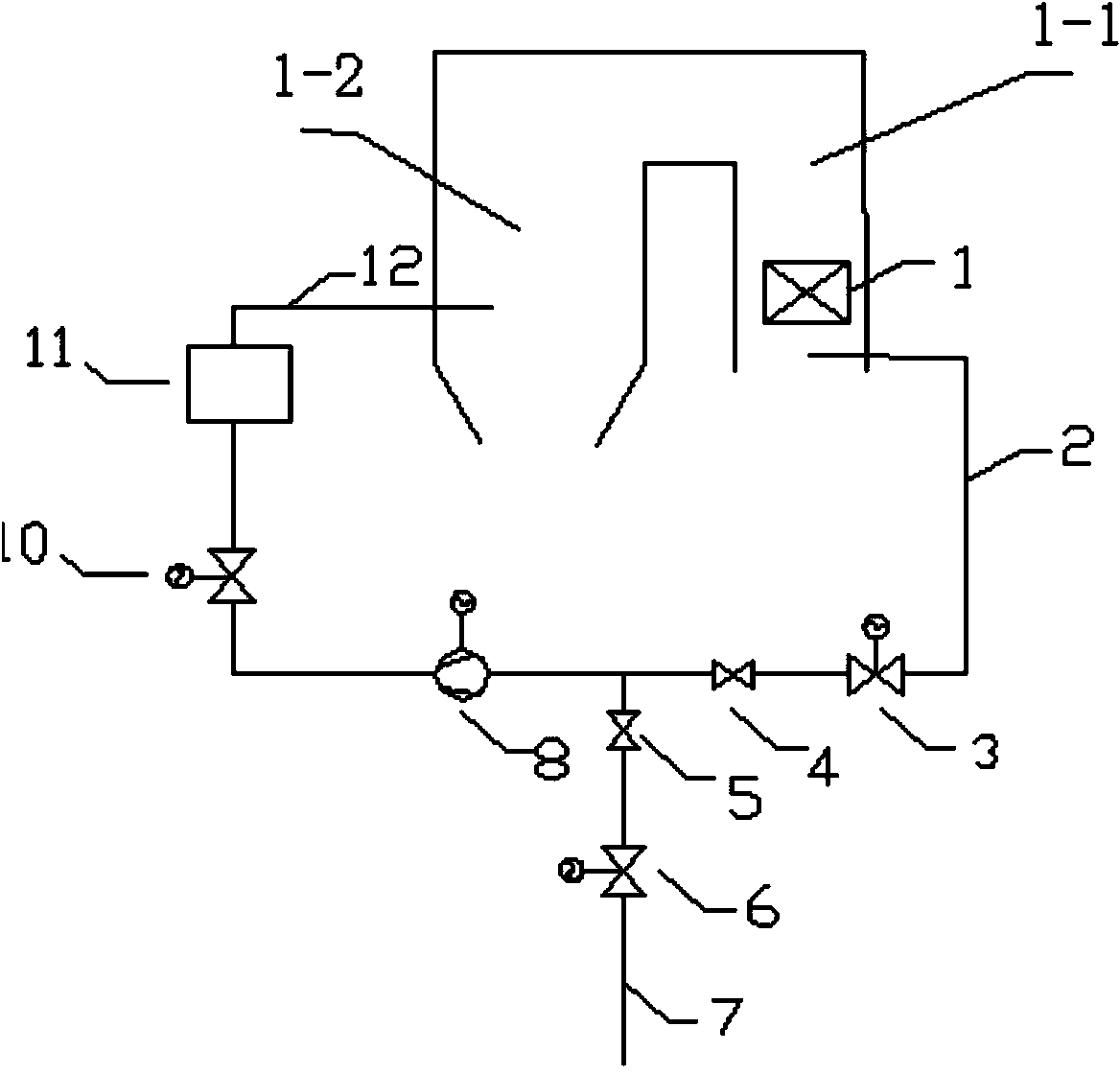

[0025] Such as figure 1 shown. The device for reducing boiler NOx emission by the pulverizing method of the present invention includes a first flue gas pipeline 2 and a second flue gas pipeline 7;

[0026] The initial end of the first flue gas pipe 2 is placed behind the economizer 1 in the flue 1-1, and the end 12 of the first flue gas pipe 2 is placed in the furnace 1-2; the first flue gas pipe 2, the first electric valve 3, the first check valve 4, the furnace smoke fan 8, the third electric valve 10, and the coal mill 11 are connected in series in sequence;

[0027] After the initial end of the second flue gas pipeline 7 is connected to the induced draft fan and before the desulfurization tower, a second electric valve 6 and a second check valve 5 are connected in seri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com