Method for treating copper slag by rotary hearth furnace

A rotary hearth furnace and copper slag technology, applied in the field of metallurgy, can solve the problems of low iron grade, no recovery of zinc element, low metal recovery rate and other problems in grinding products, achieve less dust content, improve reduction efficiency and metallization rate, The effect of high zinc oxide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

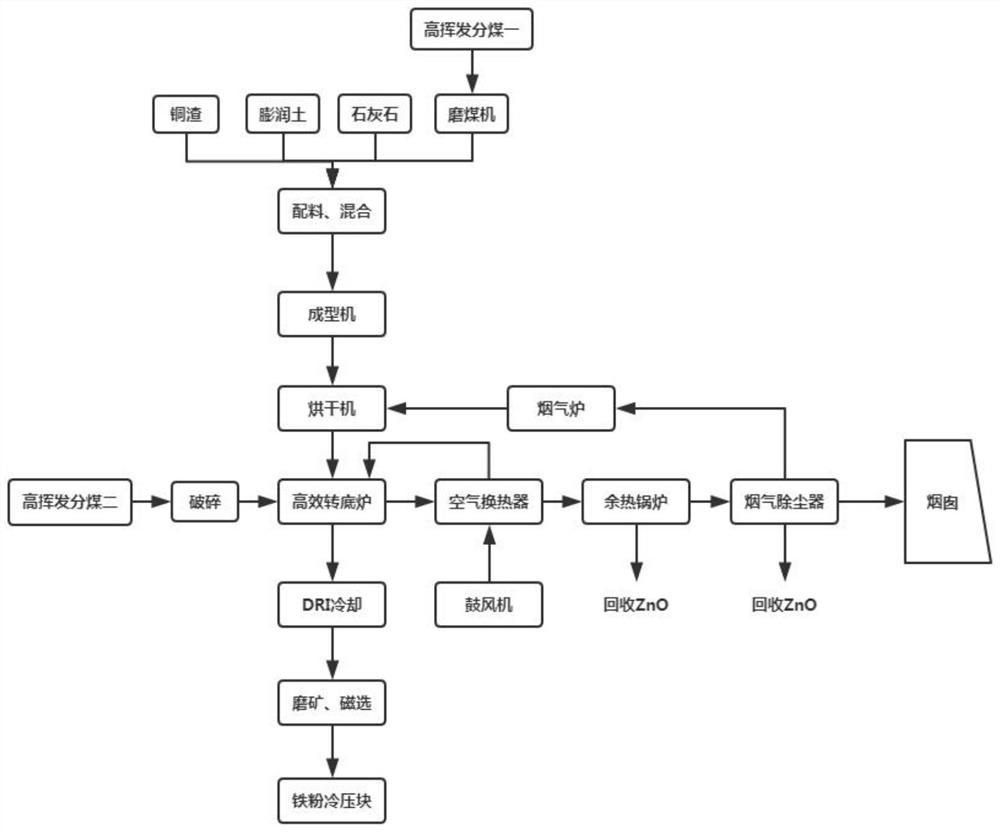

Image

Examples

Embodiment 1

[0044] The copper slag contains 41.63wt% of TFe, 2.15wt% of Zn, 33.12wt% of SiO2, 2.23wt% of CaO and 3.36wt% of Al2O3.

[0045] A novel copper slag processing method comprises the following steps:

[0046] (1) Raw material processing: Select high-volatile coal with volatile content of 30-50% and ash content <10%, and divide it into two parts—high-volatile coal one and high-volatile coal two, and high-volatile coal one and high-volatile coal The limestone is ground to a particle size of 100-200 mesh, and the high-volatile coal is crushed to a particle size of 5-25mm.

[0047] (2) Batching and mixing: select 100 parts of copper slag, 15 parts of high volatile coal, 10 parts of limestone, and 2 parts of bentonite, mix according to proportion.

[0048] (3) Molding: prepare the mixed material into a wet molding material with a water content of 10% and a particle size of 20mm.

[0049] (4) Material drying: dry and dehydrate the wet molding material, and the moisture content of the...

Embodiment 2

[0056] The copper slag contains 41.63wt% of TFe, 2.15wt% of Zn, 33.12wt% of SiO2, 2.23wt% of CaO and 3.36wt% of Al2O3.

[0057] A novel copper slag processing method comprises the following steps:

[0058] (1) Raw material processing: Select high-volatile coal with volatile content of 30-50% and ash content <10%, and divide it into two parts—high-volatile coal one and high-volatile coal two, and high-volatile coal one and high-volatile coal The limestone is ground to a particle size of 100-200 mesh, and the high-volatile coal is crushed to a particle size of 5-25 mm.

[0059] (2) Batching and mixing: select 100 parts of copper slag, 18 parts of high volatile coal, 10 parts of limestone, and 3 parts of bentonite, mix according to proportion.

[0060] (3) Molding: prepare the mixed material into a wet molding material with a water content of 10% and a particle size of 20mm.

[0061] (4) Material drying: dry and dehydrate the wet molding material, and the moisture content of th...

Embodiment 3

[0068] The copper slag contains 41.63wt% of TFe, 2.15wt% of Zn, 33.12wt% of SiO2, 2.23wt% of CaO and 3.36wt% of Al2O3.

[0069] A novel copper slag processing method comprises the following steps:

[0070] (1) Raw material processing: Select high-volatile coal with volatile content of 30-50% and ash content <10%, and divide it into two parts—high-volatile coal one and high-volatile coal two, and high-volatile coal one and high-volatile coal The limestone is ground to a particle size of 100-200 mesh, and the high-volatile coal is crushed to a particle size of 5-25mm.

[0071] (2) Batching and mixing: select 100 parts of copper slag, 20 parts of high volatile coal, 10 parts of limestone, and 3 parts of bentonite, mix according to proportion.

[0072] (3) Molding: prepare the mixed material into a wet molding material with a water content of 10% and a particle size of 20mm.

[0073] (4) Material drying: dry and dehydrate the wet molding material, and the moisture content of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com