Patents

Literature

71results about How to "Fully restored" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mura defect detection method based on sample learning and human visual characteristics

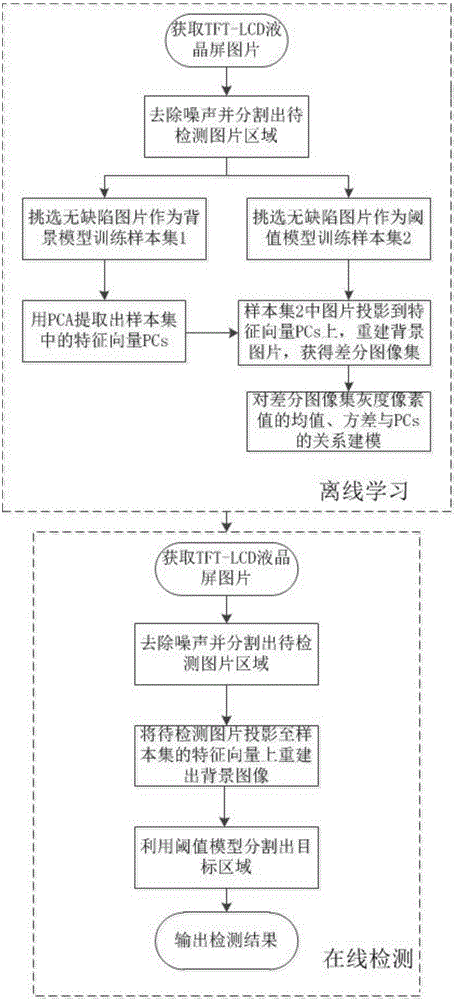

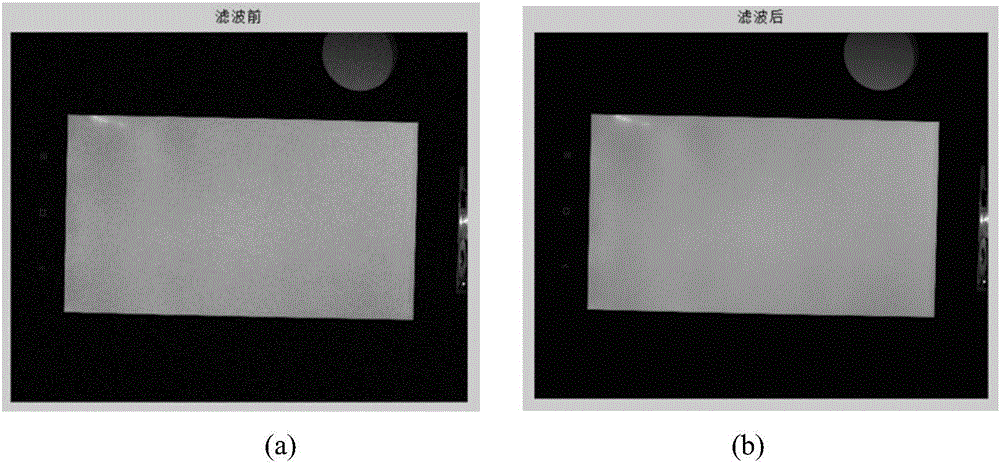

ActiveCN106650770AAccurate segmentationEfficient removalCharacter and pattern recognitionHough transformRelational model

The invention discloses a mura defect detection method based on sample learning and human visual characteristics, which belongs to the TFT-LCD display defect detection field. According to the invention, the method comprises the following steps: firstly, utilizing the Gaussian filter smoothing and Hough transform rectangle to preprocess the TFT-LCD display image, removing a large amount of noise and segmenting the image areas to be detected; then, using the PCA algorithm to conduct learning to a large amount of defect-free samples; automatically extracting the differential characteristics between the background and the target and re-constructing a background image; and then, thresholding the differential characteristics between a testing image and the background; through the reconstructing of the background and the threshold calculating, jointly creating a model. According to the invention, based on the training sample learning, a relationship model between the background structure information and the threshold value is established; and a self-adaptive segmentation algorithm based on human visual characteristics is proposed. The main purpose of the invention is to detect different mura defects in a TFT-LCD, to raise the qualification rate and to increase accuracy for the detection of mura defects.

Owner:NANJING UNIV

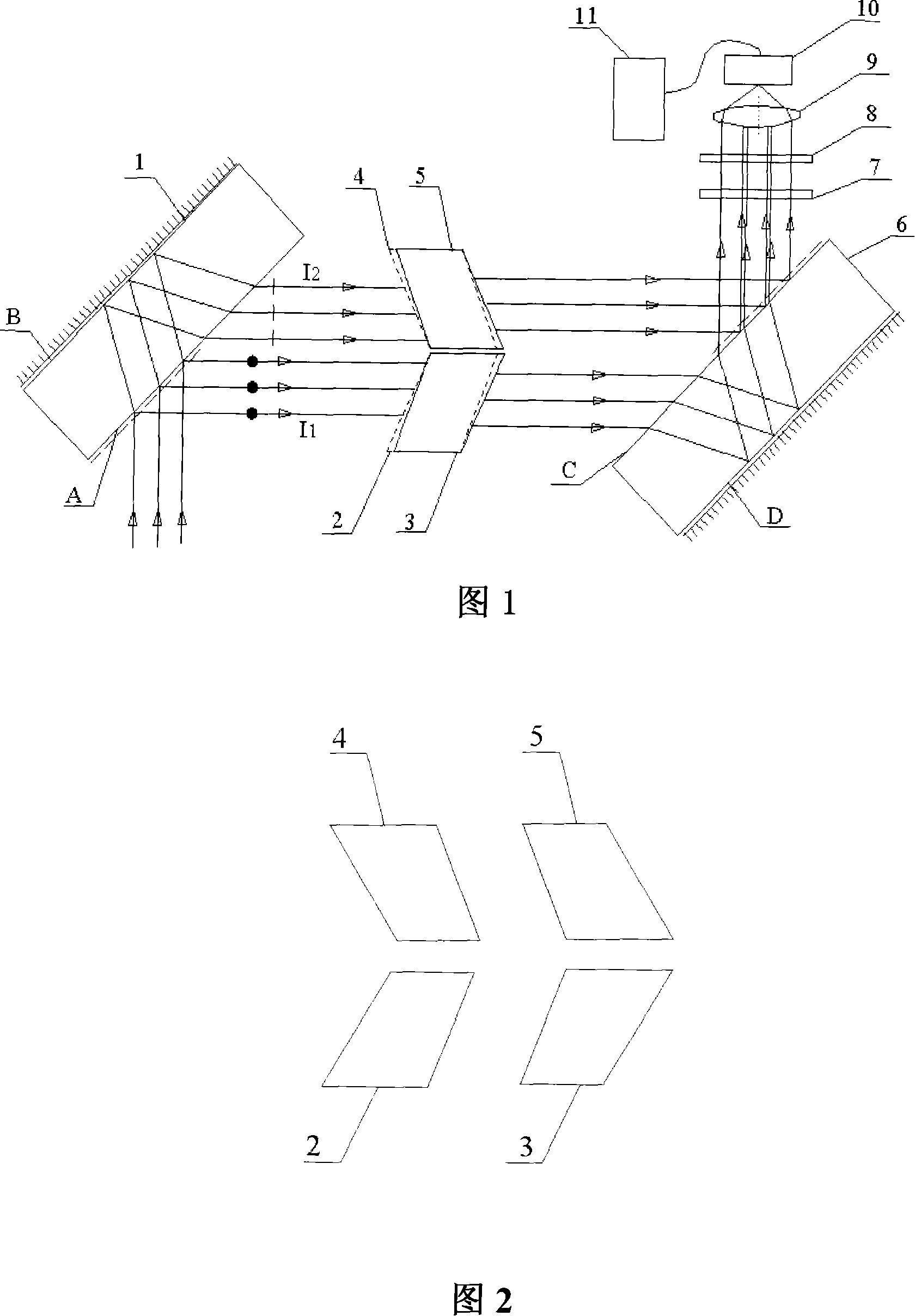

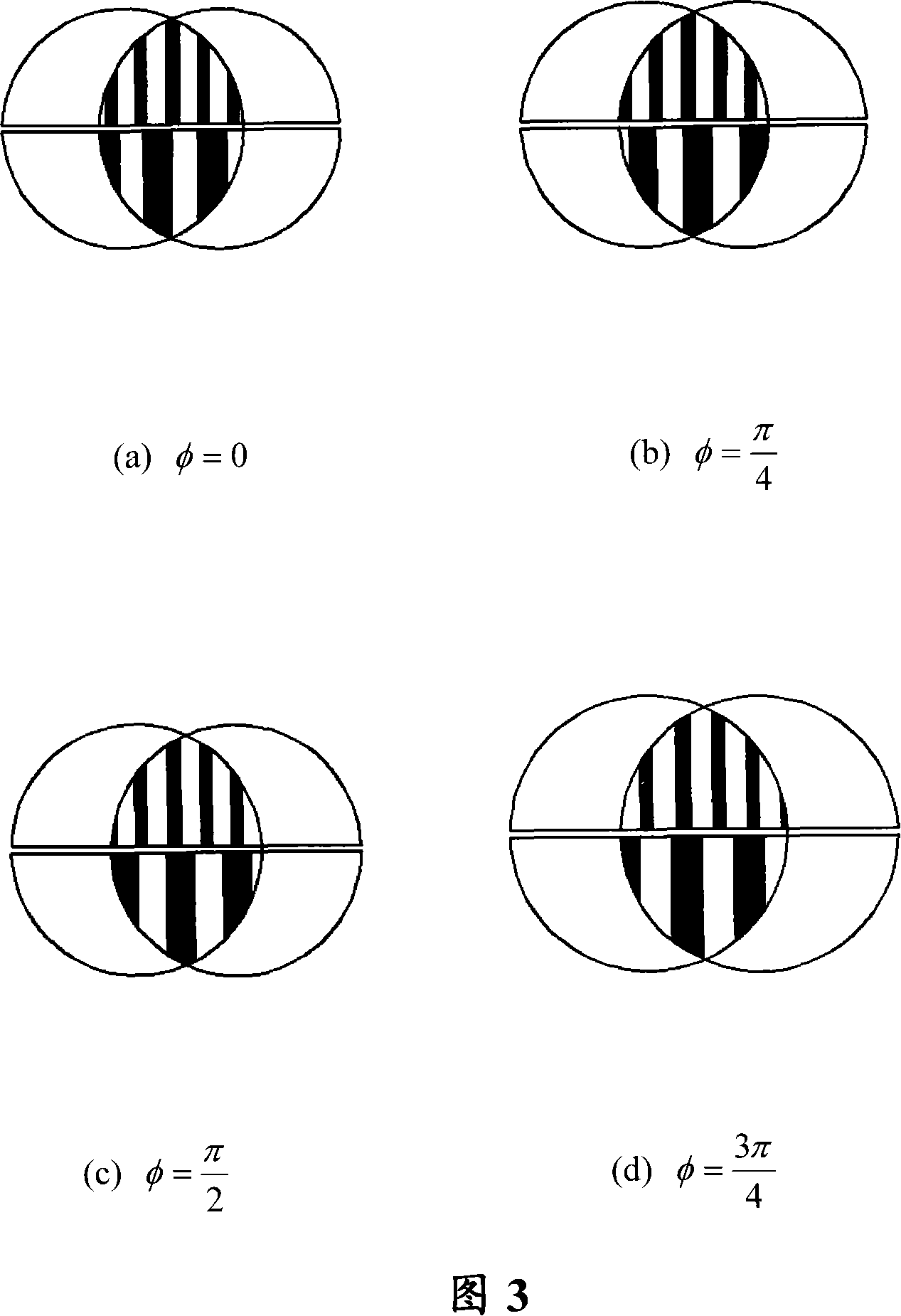

Polarization phase shifting double shearing interference wave face measuring apparatus and inspect method thereof

InactiveCN101140186AFully restoredComplete measurementOptical measurementsPolarising elementsPhase shiftedParallel plate

The invention relates to a polarization phase-shifting double-shear interference wave surface measuring instrument and a detection method, wherein the measuring instrument orderly comprises a first Yamin parallel plate, a left lower wedge-shaped optical plate, a left upper wedge-shaped optical plate, a right lower wedge-shaped optical plate, a right upper wedge-shaped optical plate, a second Yamin parallel plate, a polarization phase shifter, an imaging mirror group and an image sensor along the forward direction of light beam, and the output end of the image sensor is connected with a computer. The invention not only keeps all characteristics of the double-shear interference wave surface measuring instrument, but also has the advantages of the high sensitivity, the accurate measurement of random symmetrical wave surfaces and the supply of complete wave surface profile.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

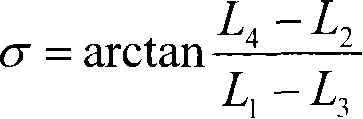

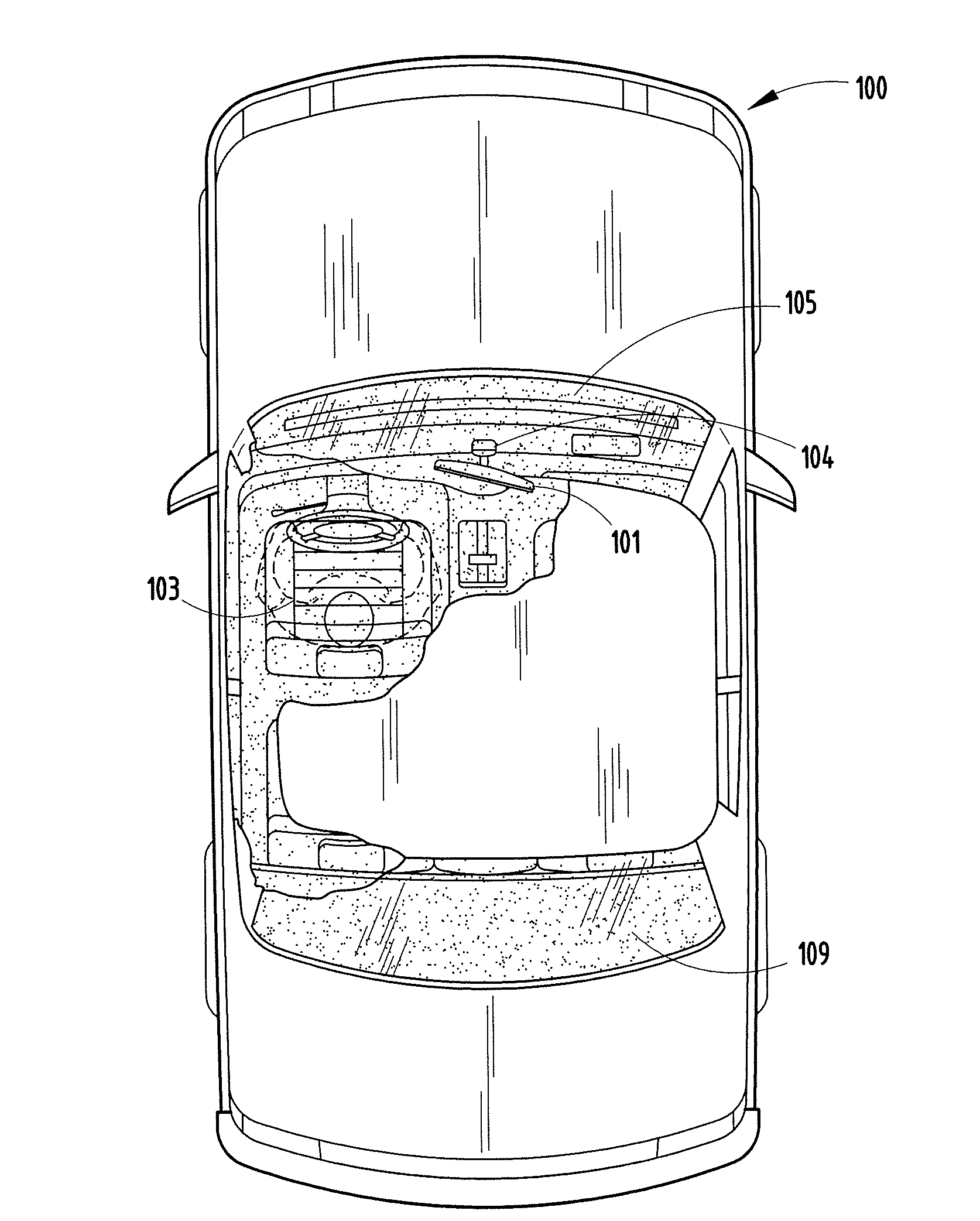

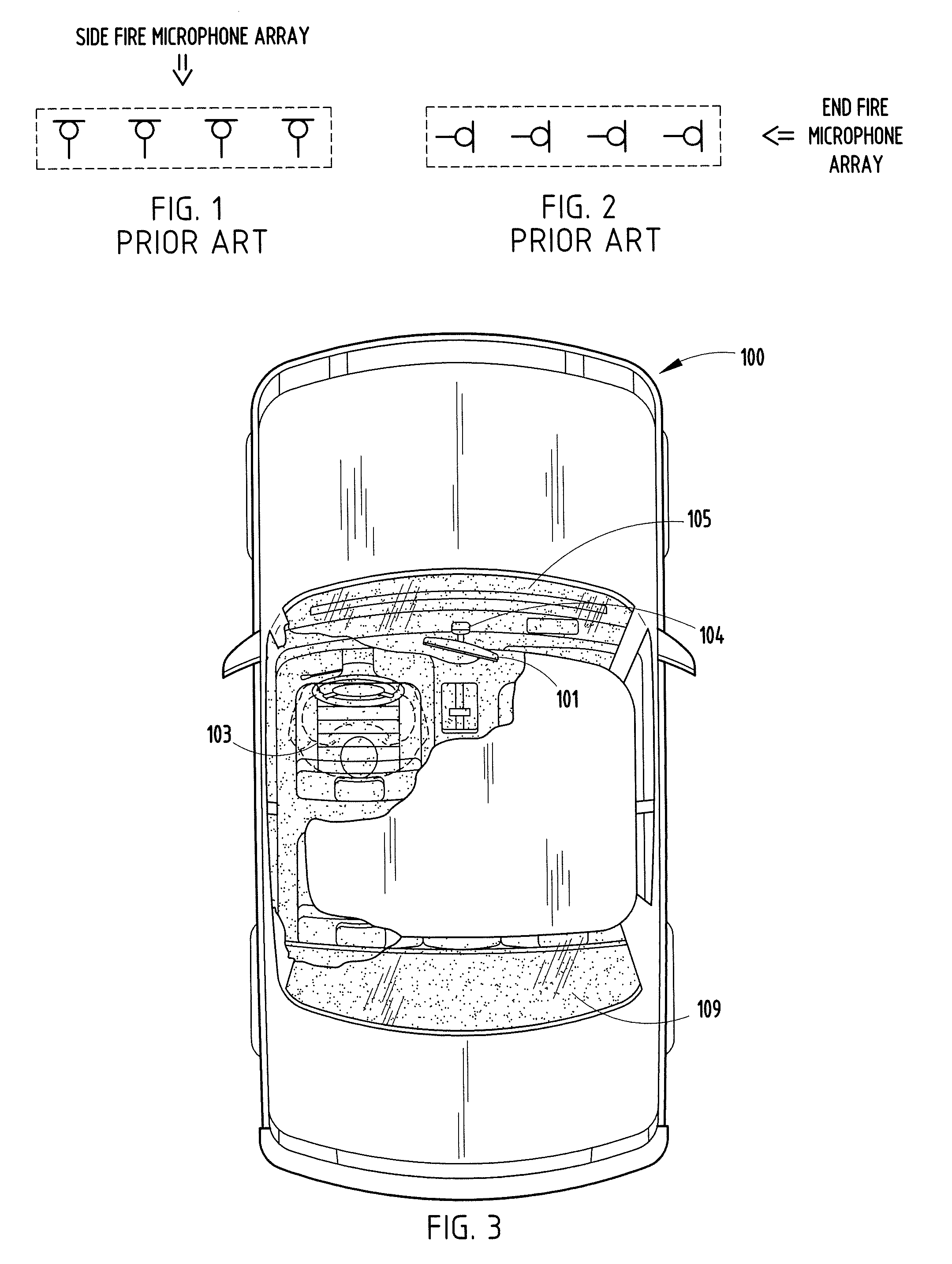

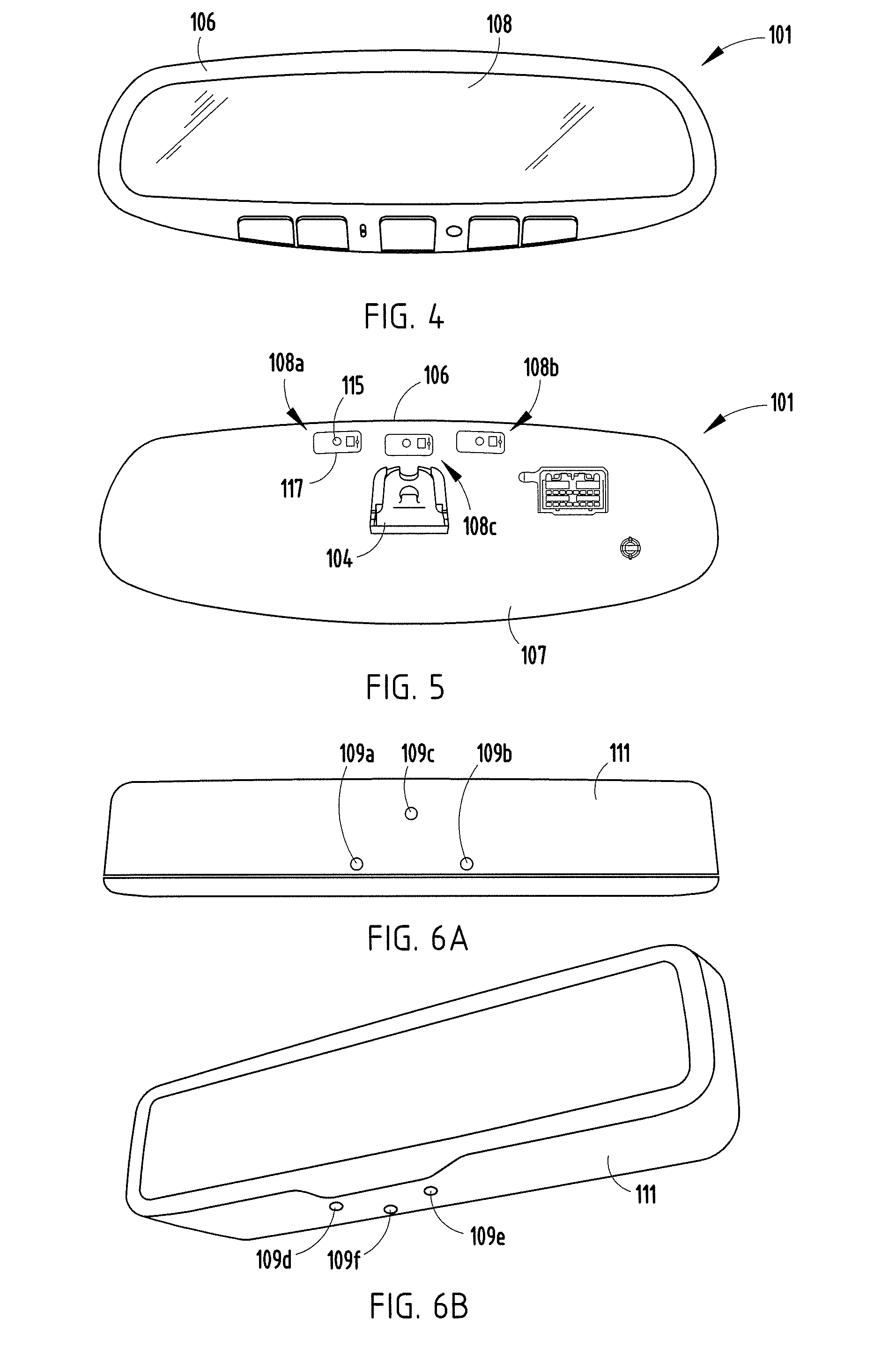

Vehicular microphone assembly using fractional power phase normalization

ActiveUS20100124339A1Increase in significanceHighly effective filterPiezoelectric/electrostrictive microphonesMicrophonesEngineeringDigital signal processor

A triangular microphone assembly (101) for use in a vehicle accessory includes a mirror housing (106) adapted for attachment to the interior of the vehicle. A mirror is disposed in an opening of the mirror housing (106) and a plurality of virtual digital microphones (108a, 108b, 108c) are arranged in a substantially triangular configuration in the mirror housing (106). A digital signal processor (DSP) (537) is used for receiving signals from the plurality of digital microphones (108a, 108b, 108c) such that the digital microphones exhibit directional characteristics for reducing undesirable noise in at least one direction by normalizing the phase of the received signals as a function of signal frequency.

Owner:GENTEX CORP

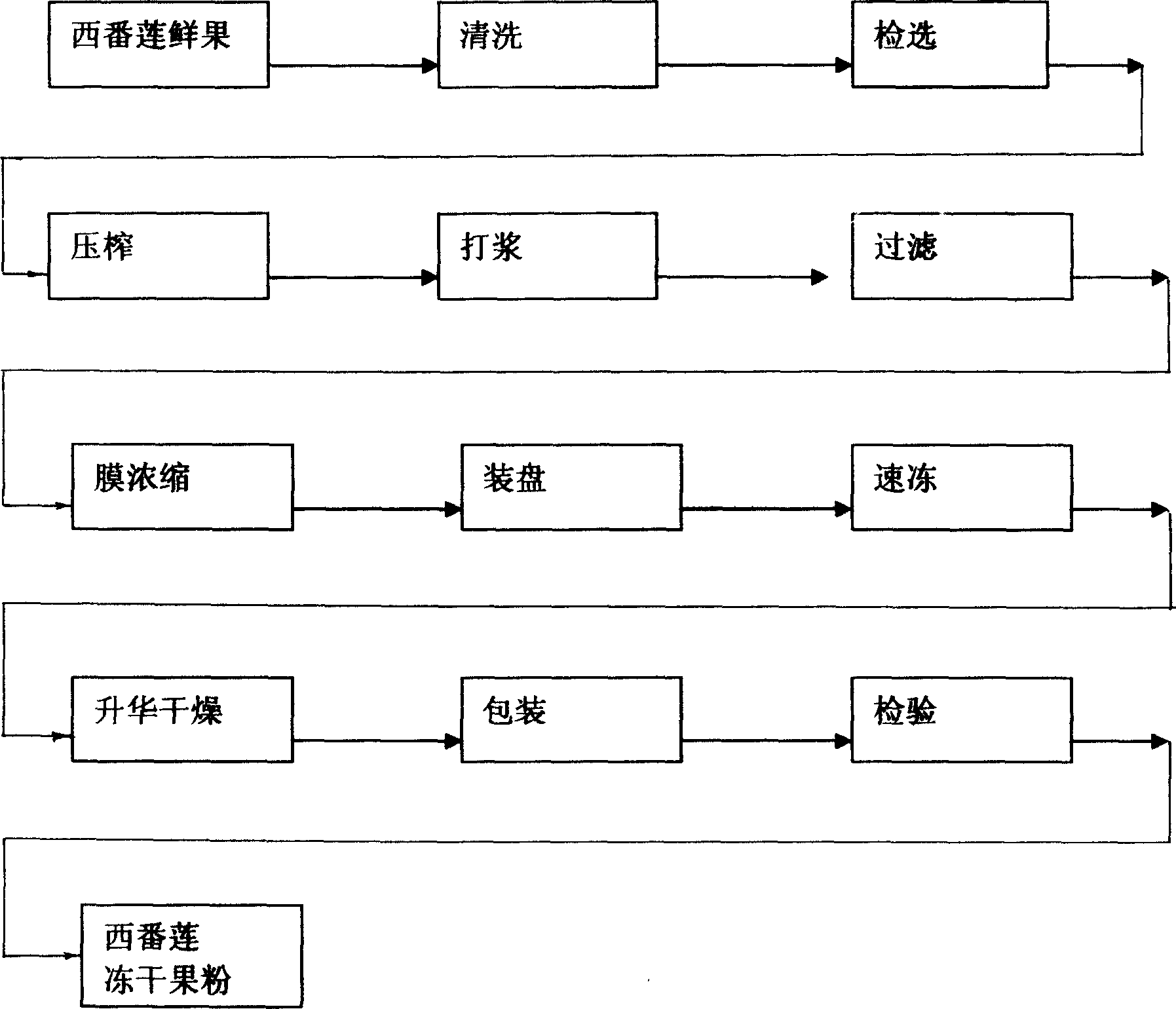

Process for producing natural fruit-juice perfume synergist using passion flower as raw material

The invention is a process for using passionflower as primary material to produce natural fruit juice flavoring agent, it acquires the solid passionflower frozen fruit juice powder through film condensing and freezing and drying technologies. The soluble solid 12-16 degrees Bx raw pulp is condensed to 30-35 degrees Bx through filtering film, and then they are frozen to -30deg.C--35deg.C for 2-4 hours, the process can reserve the fragrant smell, flavor and nutriment of passionflower raw pulp, the product is convenient to be stored, transmitted and used, it can be used as raw material and additives for beverage, icecream, cake, healthy keeping product and so on.

Owner:江城绿色版纳生态食品有限公司 +1

Chemical metallurgical method for comprehensive treatment and utilization of red mud

InactiveCN108118141AFull restorationGuaranteed conversion of carbonation structureAmmonium carbonates/bicarbonatesNanotechnologyRed mudSlag

The invention relates to a chemical metallurgy method for comprehensive treatment and utilization of red mud. Lignite is used as a reducing agent for Fe2O3 in the red mud, limestone is taken as a dispersant and a conversion agent for Al2O3 in the red mud, and the lignite and the limestone are finely ground and uniformly mixed with the red mud for carrying out reduction magnetization and conversionroasting. Fe3O4 and Fe obtained by the magnetization are subjected to magnetic separation enrichment to obtain an iron concentrate, and second reduction magnetization can be further carried out on the iron concentrate and then precision magnetic separation is performed to prepare reduced iron powder. After the magnetic separation, Al2O3 is converted into Al2(CO3)3 aluminum-rich slag for performing oxidative cooking and desilication to dissolve Al2(CO3)3. Silicon slag containing a small amount of aluminum and calcium can be used as a raw material of ceramic or white cement. An Al2(CO3)3 solution is used for synthesizing NH4Al(OH)2CO3(inverted arrow) with ammonia water. After carrying out solid-liquid separation, solid-phase NH4Al(OH)2CO3 is dried and roasted and reduced to obtain nano-active alumina; liquid-phase (NH4)2CO3 is concentrated and crystallized and then dried to obtain a sodium carbonate by-product.

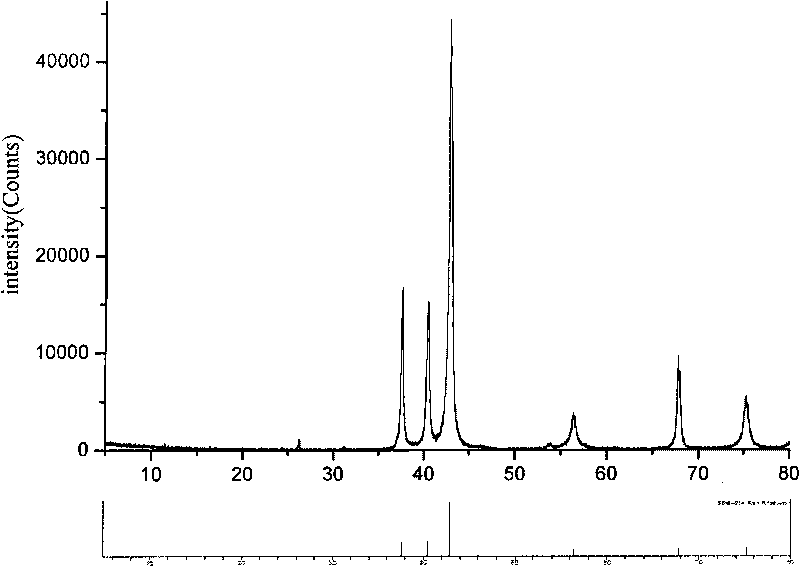

Preparation method of superfine rhenium powder

InactiveCN101700574ALower decomposition temperatureLow reduction temperatureVolumetric Mass DensityCrystallinity

The invention discloses a preparation method of superfine rhenium powder, taking high-purity ammonium rhenate as a raw material and comprising the following steps: heating the high-purity ammonium rhenate at an oxidizing atmosphere to decompose into high valence rhenium oxide Re2O7; and then reducing Re2O7 by H2 or CO to obtain superfine rhenium powder. The superfine rhenium powder obtained by the method of the invention has the advantages of low impurity content, sphere or sphere-like structure, even particle size distribution, high crystallinity, low oxygen content, good fluidity, high tap density and the like.

Owner:CENT SOUTH UNIV +1

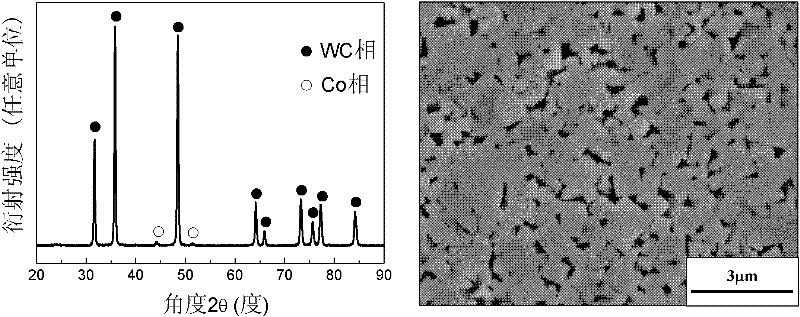

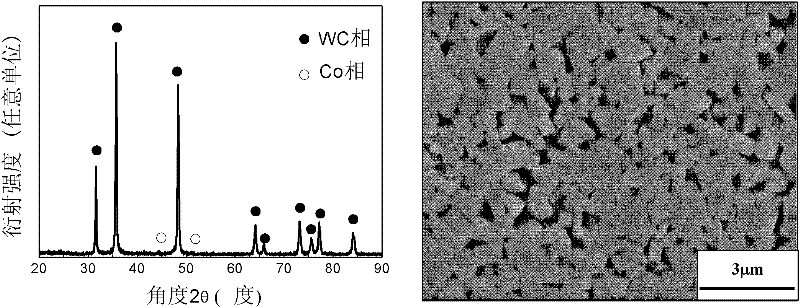

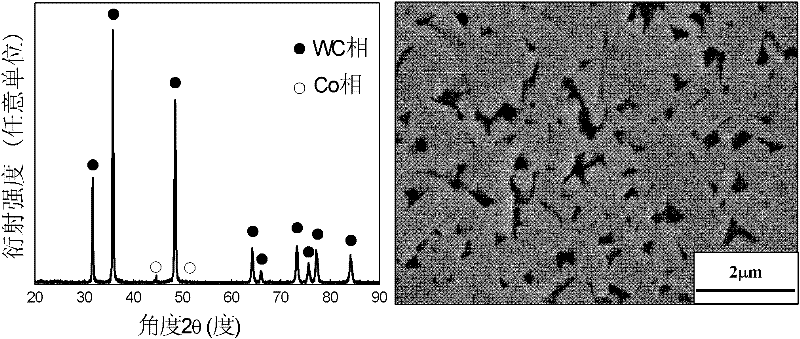

Industrial production method for synthesizing cemented carbide block material in situ

ActiveCN102517483AReduce the introduction of impuritiesExcellent performanceMaterial qualityCemented carbide

The invention discloses an industrial production method for synthesizing a cemented carbide block material in situ, belonging to the technical field of cemented carbide. The industrial production method comprises the steps of: utilizing WO 2.9, Co3O4 and carbon black as raw materials, calculating a dosage ratio of the three raw materials by considering the evaporation capacity and wastage of Co and carbon wastage caused by carrying powder in an oxidizing gas during the preparation process according to the demand of a final Co content, ball grinding the raw materials to mix the same, and calculating the mass of the necessary raw material powder according to the material mass reduction and the sintering wastage coefficient k of the WC and Co powder during the sintering process; and utilizing the low sintering pressure at the primary application stage of a hot press sintering technique, a vacuum sintering technique or a low pressure sintering technique, periodically maintaining the temperature and periodically increasing the pressure to obtain the cemented carbide block material. The industrial production method of the invention has the advantages of simple technique steps, short process, energy saving and environmental friendly properties, and capability of realizing the large scale industrial production of the cemented carbide.

Owner:BEIJING UNIV OF TECH

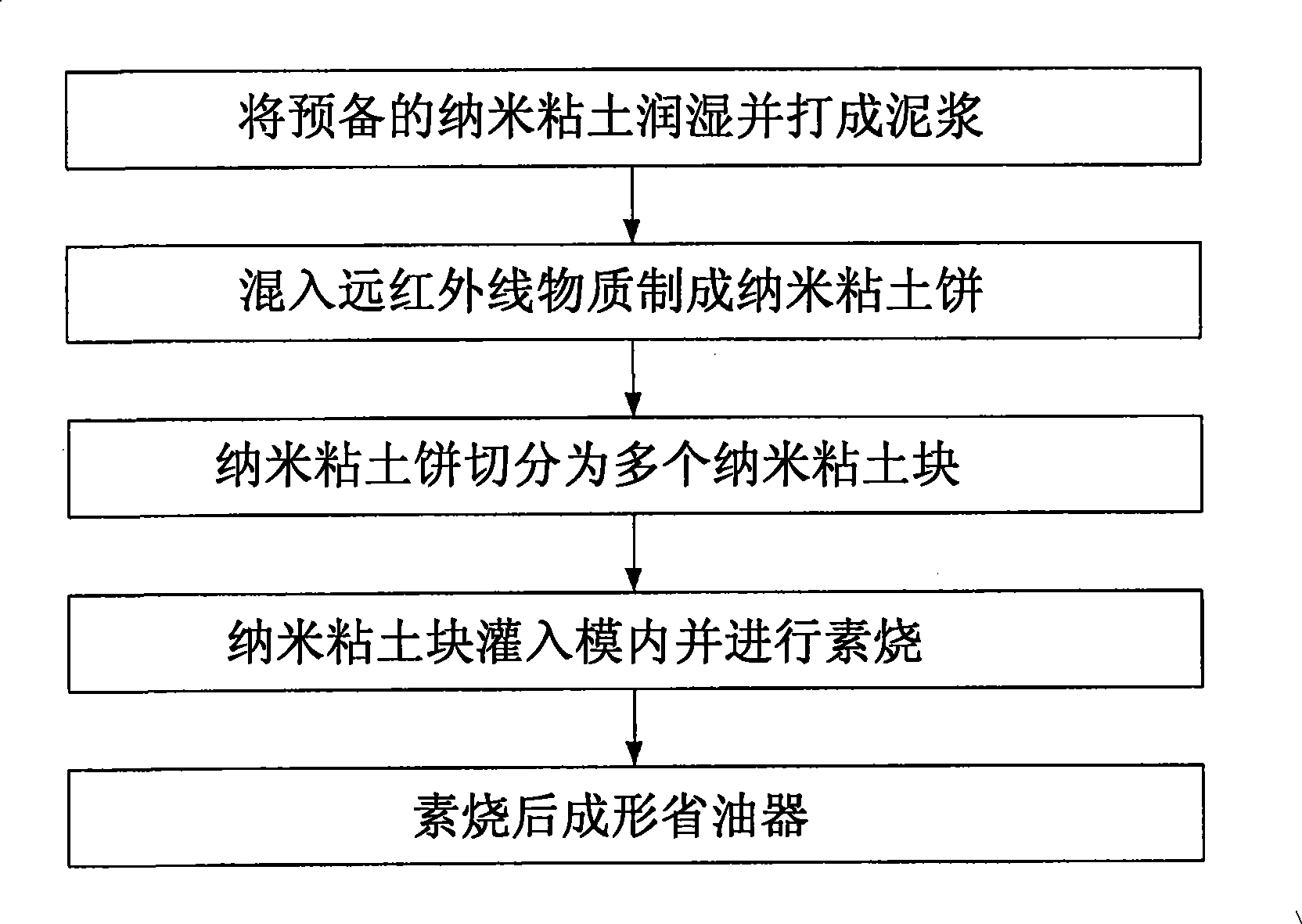

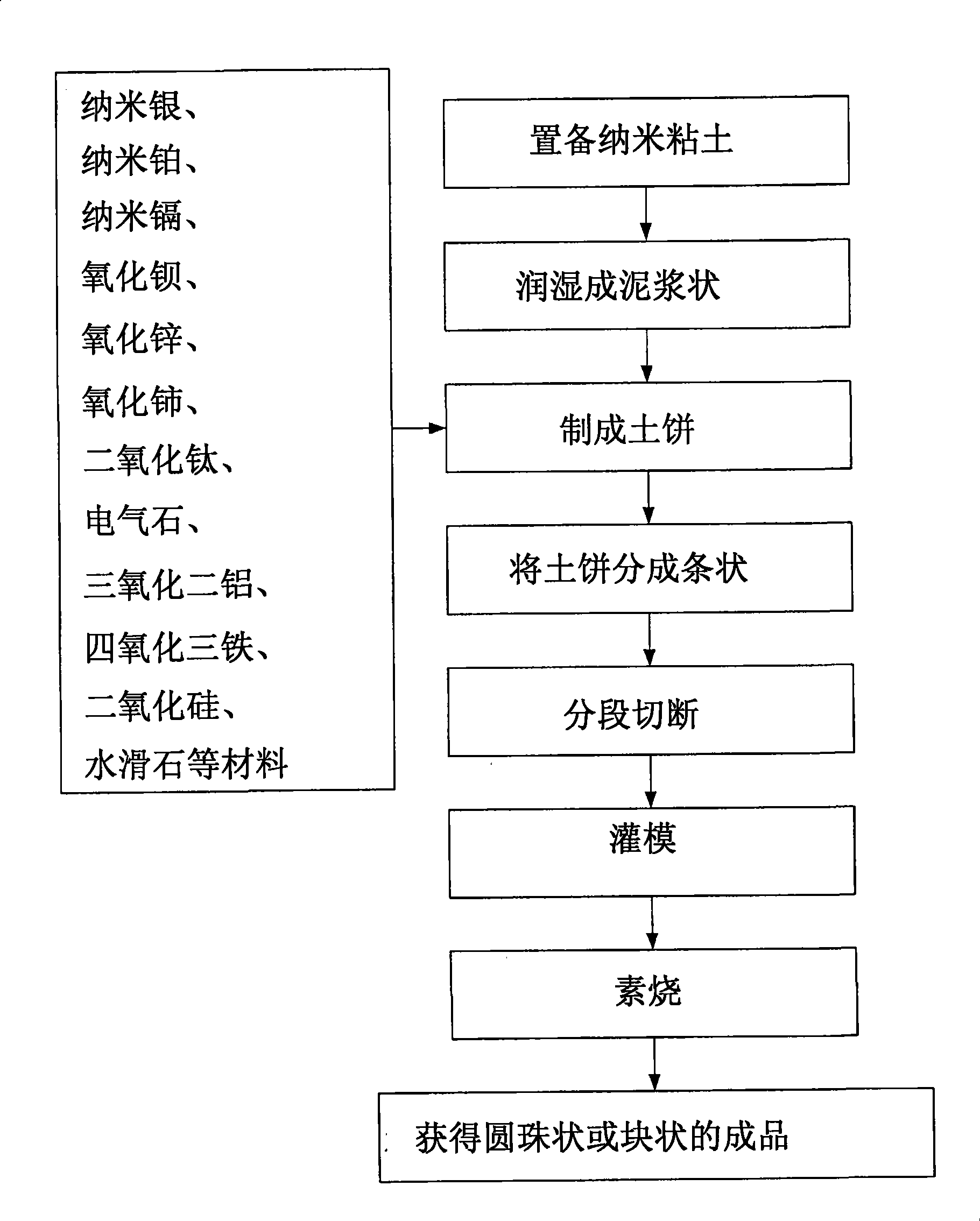

Method for making combined economizer made of ceramic material

InactiveCN101382101AImprove mechanical propertiesImprove heat resistanceCombustion-air/fuel-air treatmentMachines/enginesCombustionComposite ceramic

The invention relates to a method for manufacturing an oil economizer made of composite ceramic materials, wherein the oil economizer is manufactured by means of biscuiting of a nano-clay mixed with far-infrared substances, and is mainly characterized in that the wet nano-clay is pulped into slurry and mixed with the far-infrared substances into a nano-clay pie, and the pie is cut into a plurality of nano-clay blocks which are poured into a die to undergo the biscuiting so as to form the oil economizer. Therefore, after being put into an oil tank, the oil economizer can improve the combustion efficiency of the combustion engine, and improve the durability of the oil economizer at the same time.

Owner:ABA NANO TECH

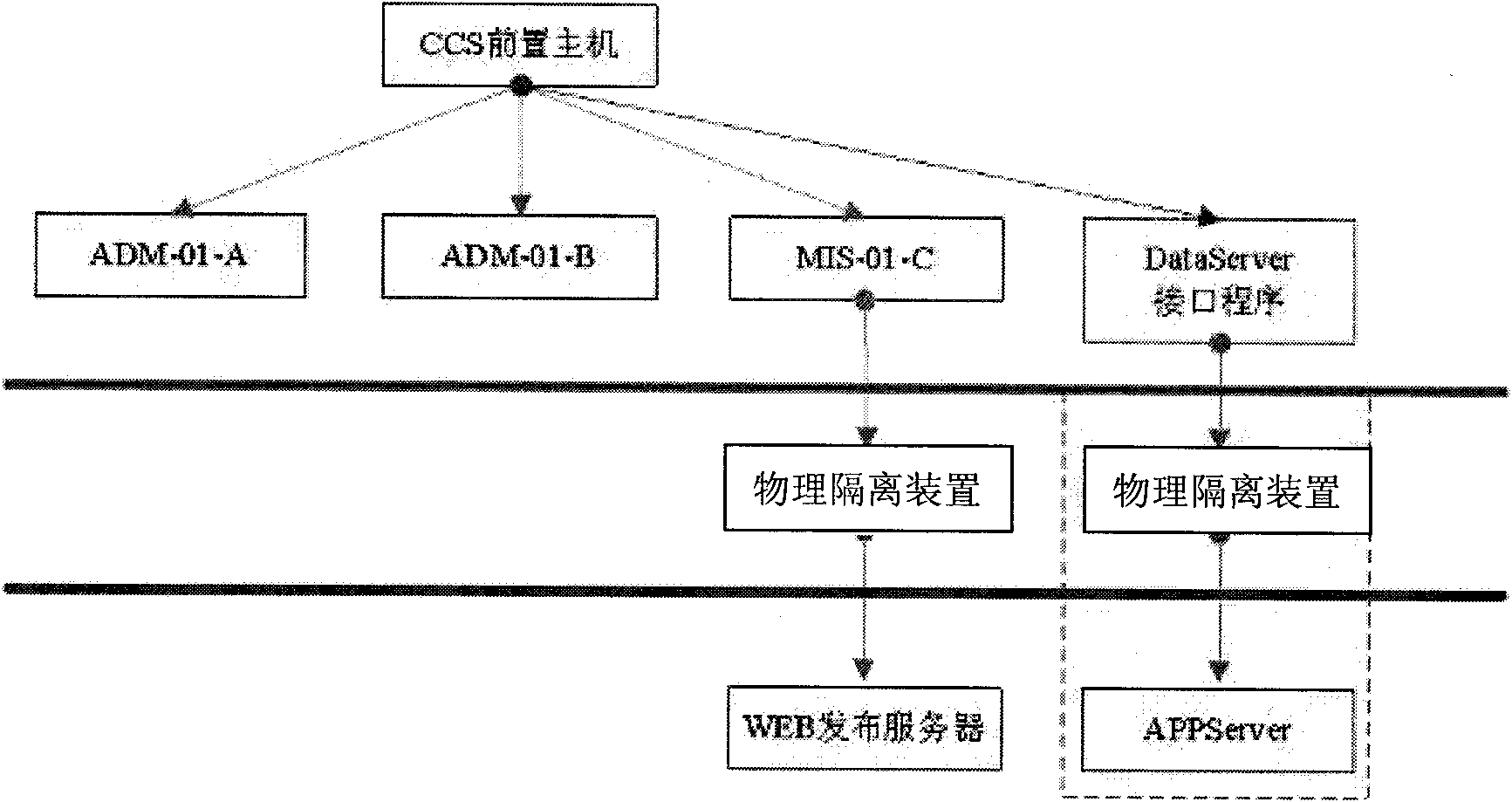

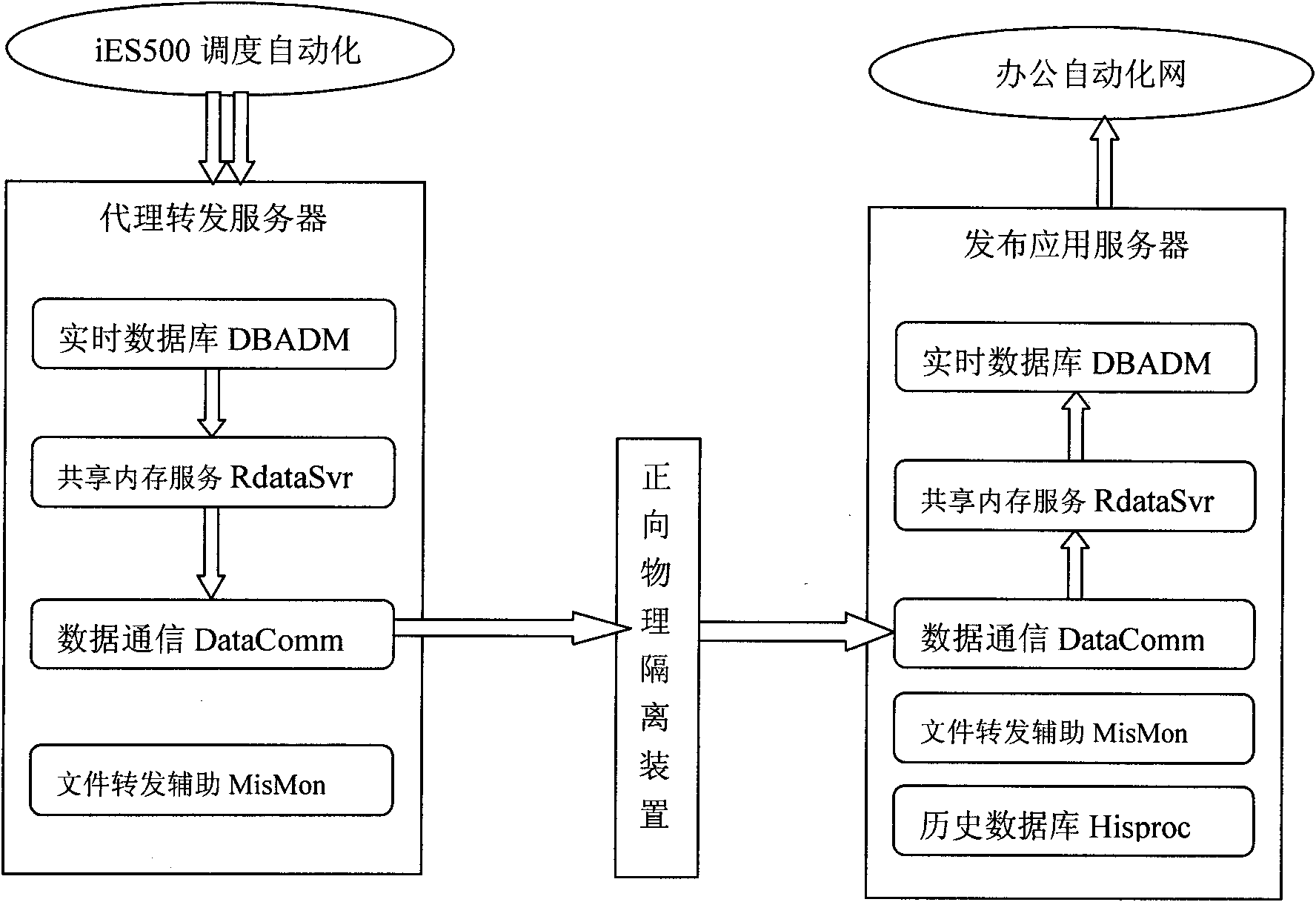

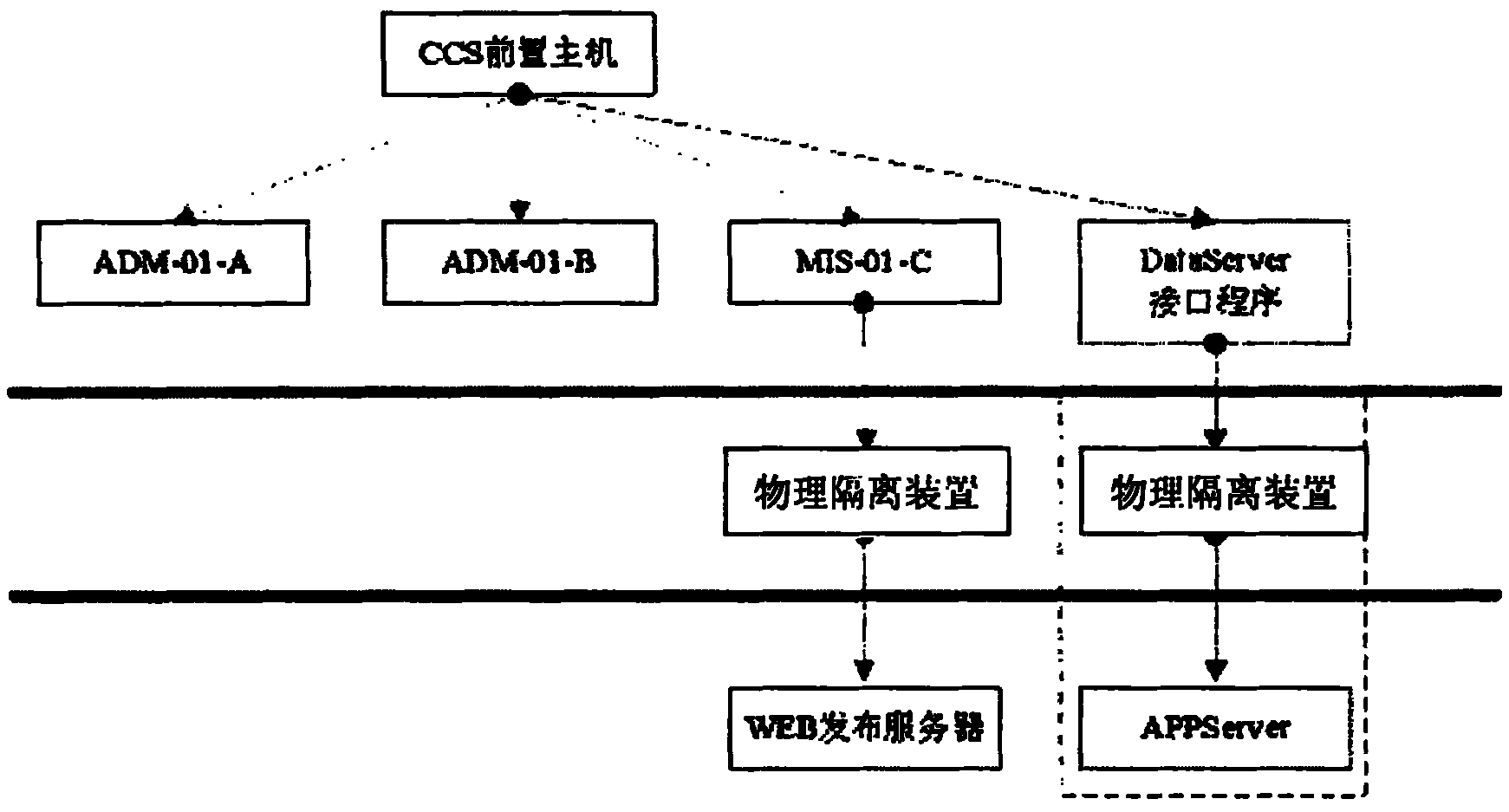

Ies500 automatic real-time data and information system transmission interface

ActiveCN101848241AIsochronous transferReal-time synchronous communicationTransmissionWeb serverCore system

The invention discloses an ies500 automatic real-time data and information system transmission interface, which is characterized in that the transmission interface is provided with a double-link structure of a real-time data link and a file link, and the work content of the intranet for maintaining a data base can also be automatically and synchronously transmitted to the outer net at the same time of real-time data transmission of the intranet; an allopatric server is positioned in a soft bus on a dispatching workstation, and a modification triggering device is set in an intranet server; a historical data base synchronous module is arranged on a data server, and the synchronization of an inner historical data base and an outer historical data base of an isolation system is completed at the fixed time; a three-layer application system structure of a data base server, a web server and a browser is adopted; and the results of the in-side meter checking are written into marketing MIS through a web service interface. The invention mainly ensures the safe and stable operation capability of the dispatching automatic core system, can ensure the automatic synchronization of data inside and outside the isolation system to the largest degree, and can reduce the repeated work, so the invention ensures factuality, convenience and high reliability of the data recovery of the dispatching automatic system on the outer net.

Owner:国网安徽省电力有限公司合肥供电公司 +1

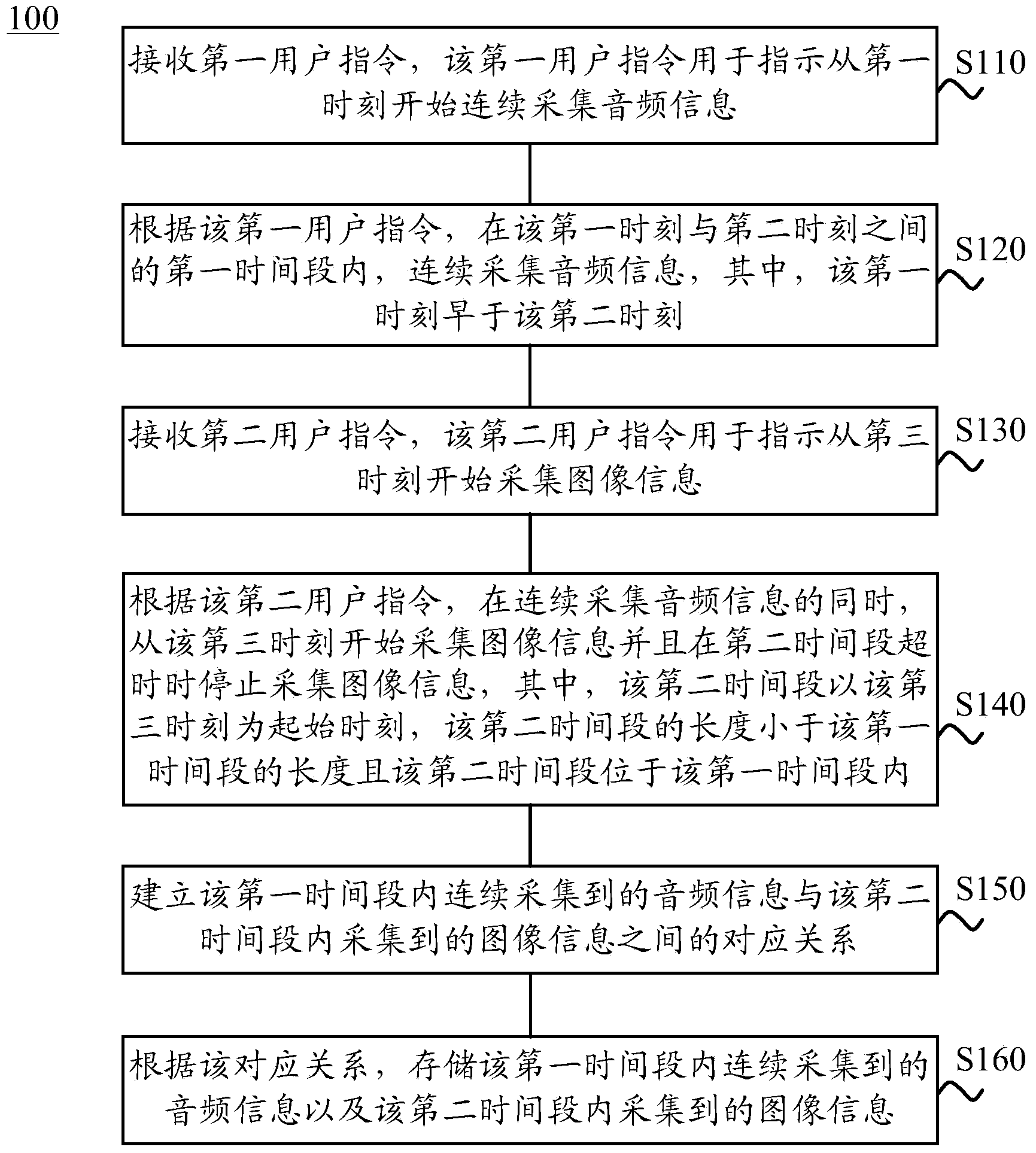

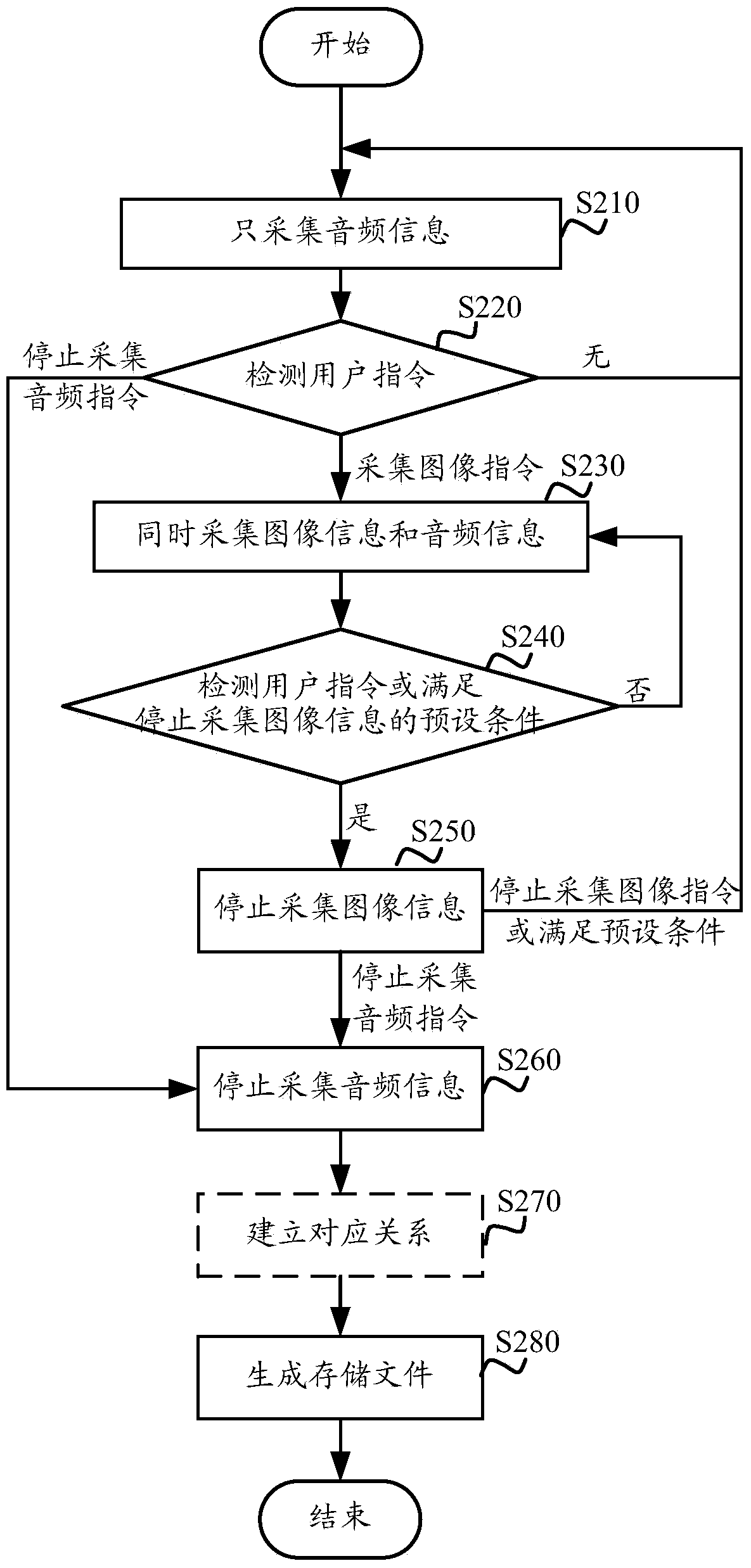

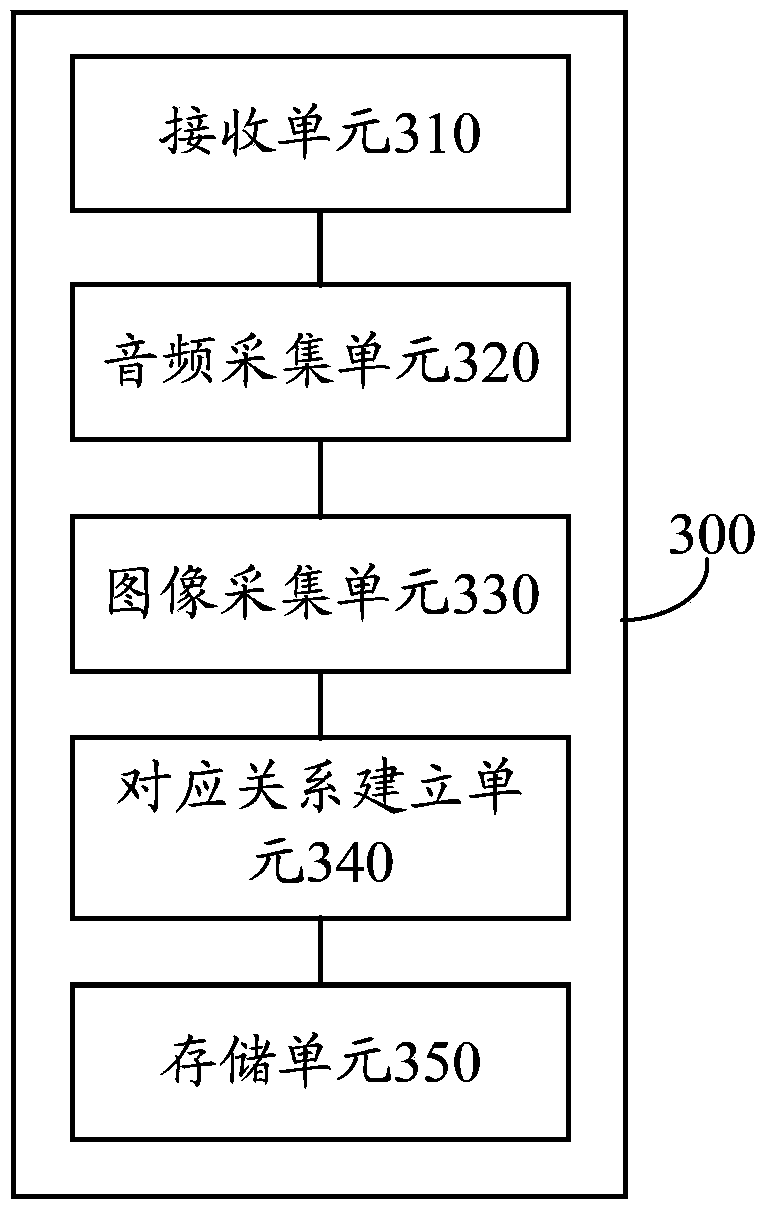

Method and device of processing audio frequency and image information as well as terminal equipment

ActiveCN104023176AImprove experienceSave storage spaceTelevision system detailsColor television detailsTime segmentTerminal equipment

The invention discloses a method and a device of processing audio frequency and image information as well as terminal equipment. The method comprises the following steps of: receiving a first user command, which is used for indicating continuous collection of the audio frequency information from a first moment; continuously collecting the audio frequency information within a first time bucket between the first moment and a second moment according to the first user command; receiving a second user command, which is used for indicating collection of the image information from a third moment; collecting the image information from the third moment according to the second user command and stopping collecting the image information when the time is over at a second time bucket; establishing corresponding relation between the audio frequency information, which is continuously collected in the first time bucket, and the image information, which is collected in the second time bucket; and storing the audio frequency information and the image information according to the corresponding relation. According to the method of processing the audio frequency and the image information, which is disclosed by the invention, a meeting scene can be more completely restored while the meeting scene is recorded for a long time.

Owner:HUAWEI TECH CO LTD

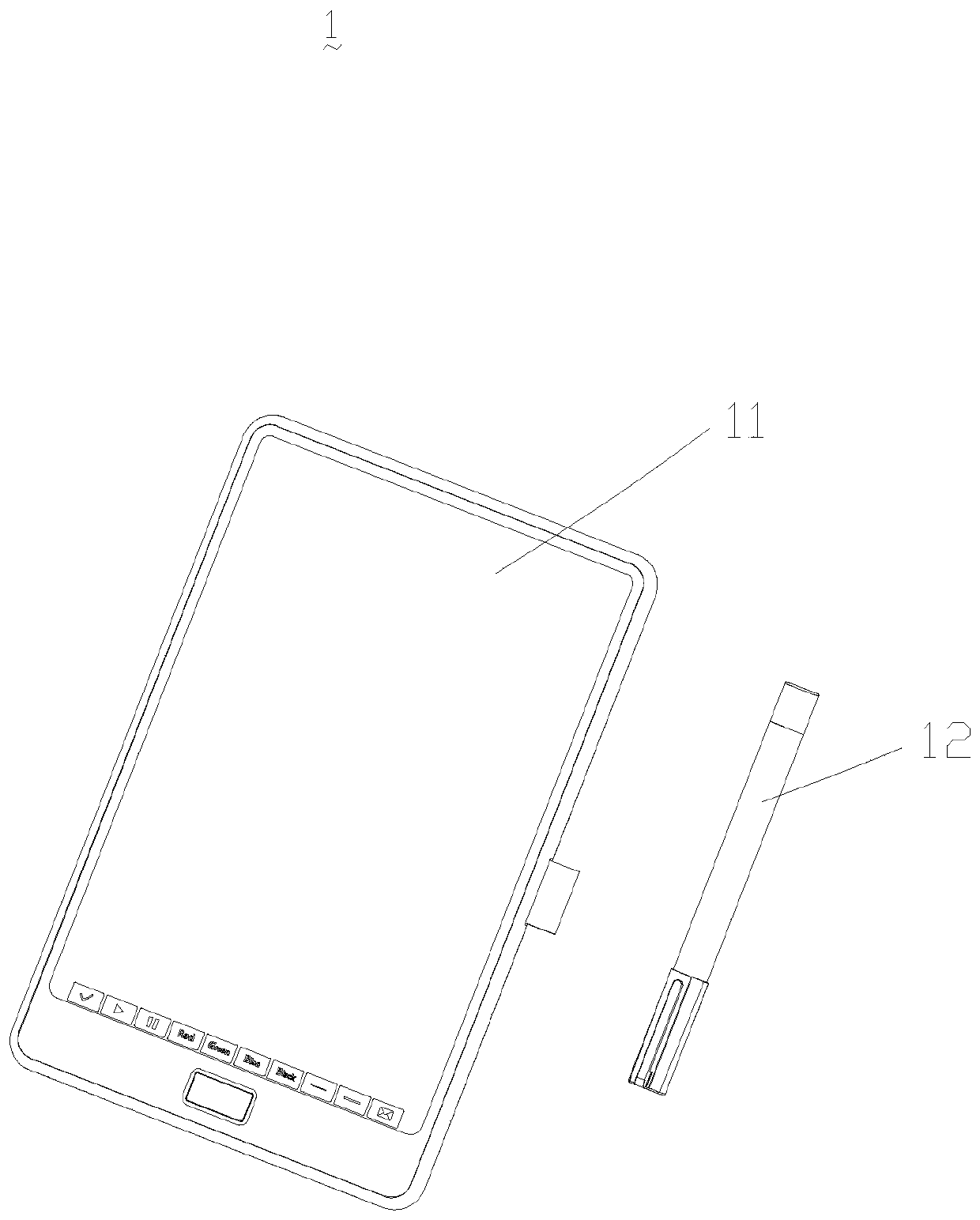

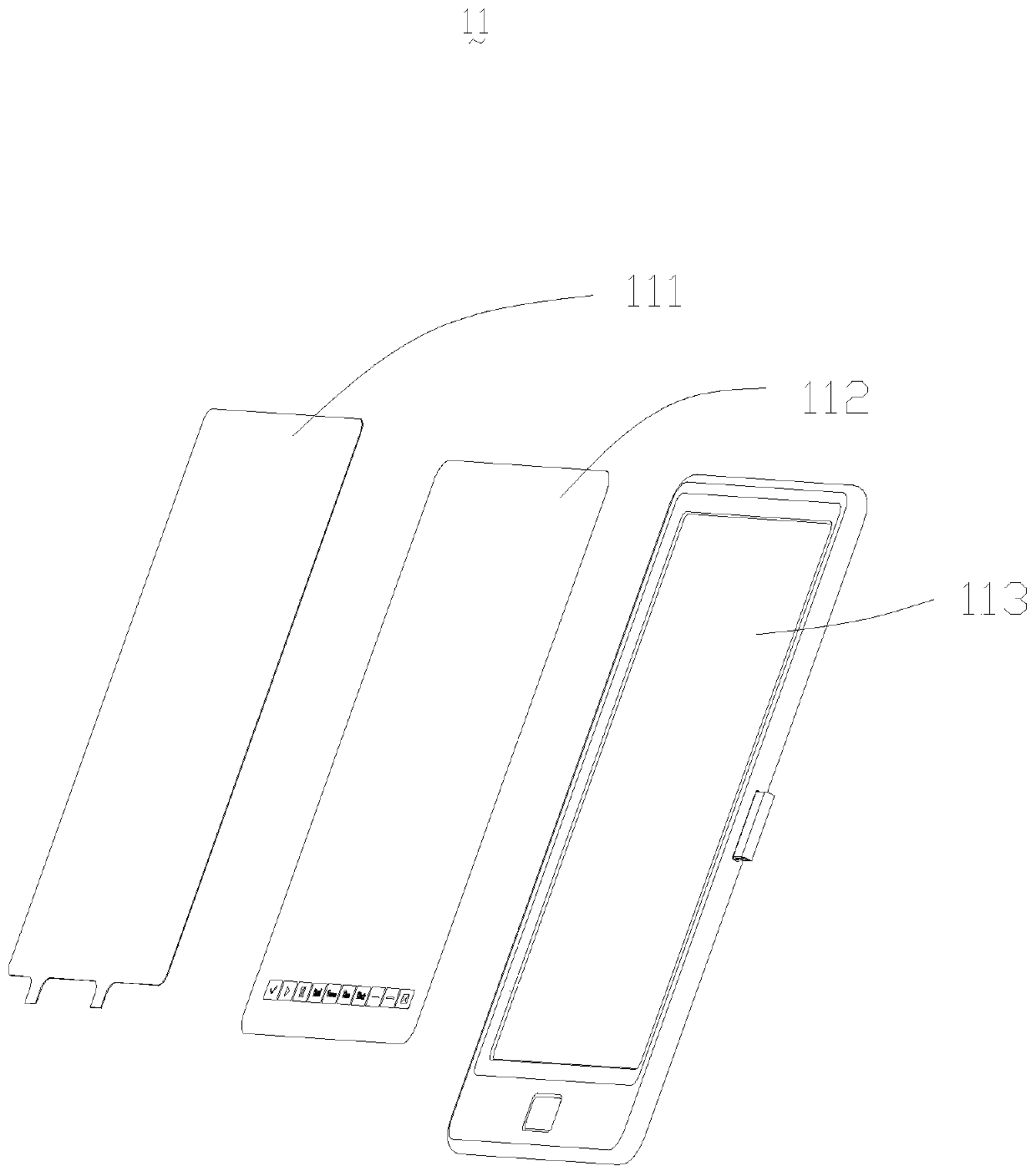

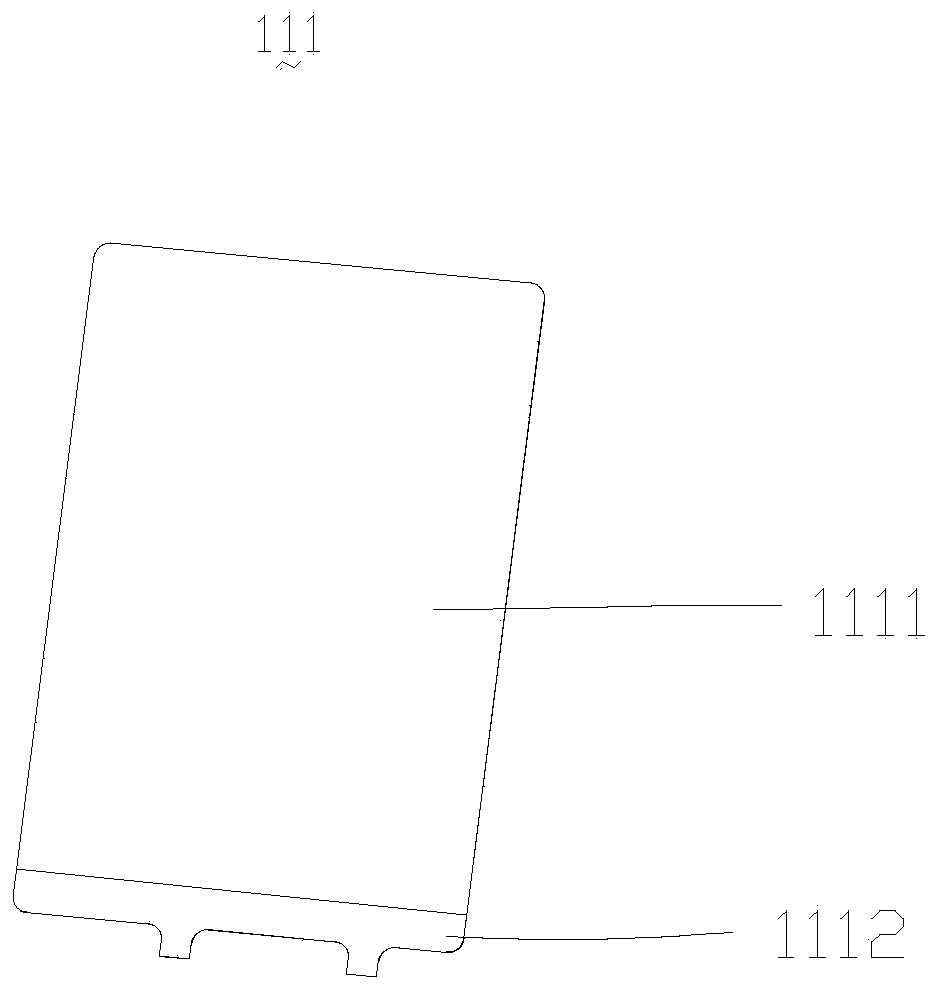

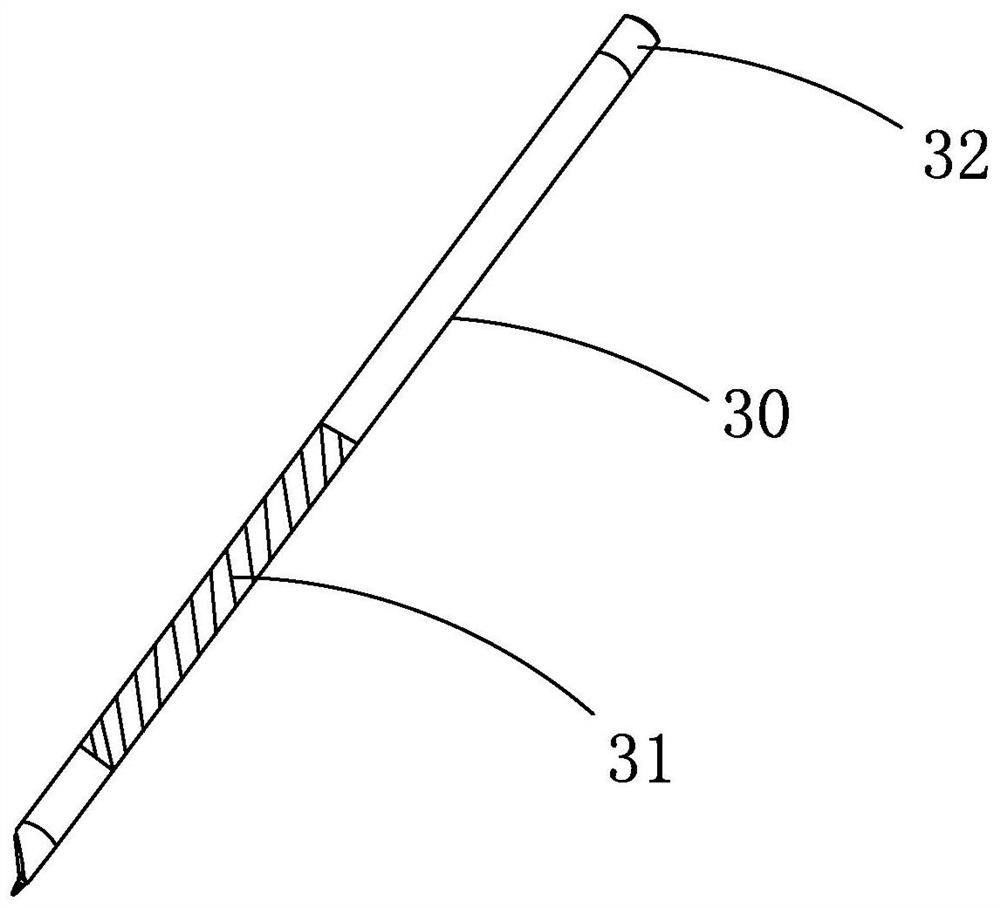

Handwriting board set and system

InactiveCN111274836AVersatileFully restoredWriting boardsOther databases queryingHandwritingDot matrix

The invention relates to a handwriting board set which comprises a handwriting pen and a handwriting board, dot matrix codes are arranged on the handwriting board, and when the handwriting pen carriesout writing operation on the handwriting board, the handwriting pen obtains data information of the dot matrix codes. A dot matrix code is arranged on a handwriting board; a database is arranged in the handwriting pen; through cooperation of the handwriting pen and the handwriting board, the dot matrix codes obtained by the handwriting pen are directly compared with a database in the handwritingpen, coordinate data of the position where the handwriting pen is located are obtained in real time, the content written by a user can be recognized more accurately, sensitivity and accuracy are higher, and the writing operation of the user can be restored more completely. The invention further provides a handwriting board sleeving system, the handwriting board sleeving system comprises electronicequipment and a handwriting board sleeve, and the electronic equipment and the handwriting pen can communicate with each other.

Owner:SHENZHEN NEWYES TECH LTD

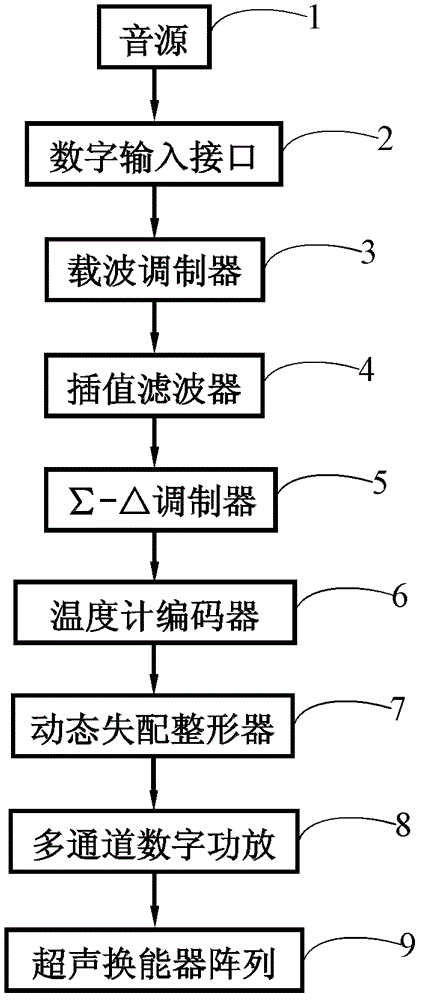

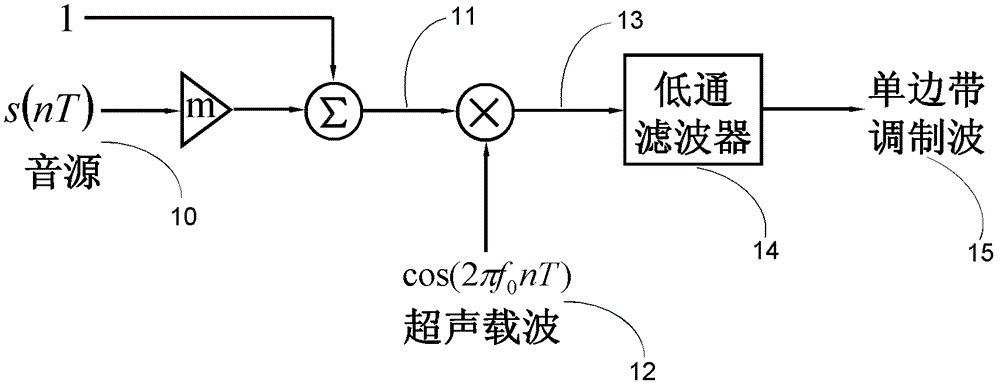

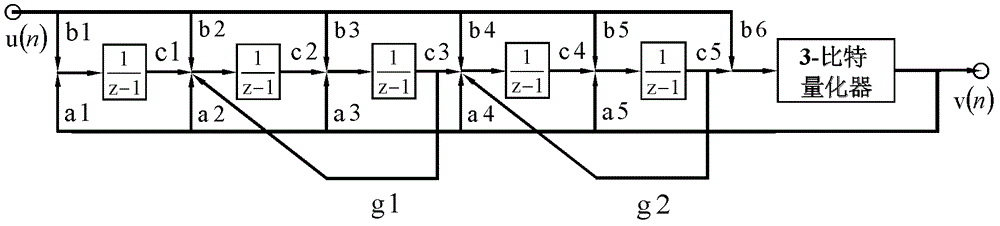

A digital super-directional loudspeaker system

ActiveCN103167380BGo digitalFlexible and convenient data interactionTransducer circuitsSound sourcesSonification

The invention relates to a full-digitalized super-directivity speaker system based on multi-bit sigma-delta modulation. The system comprises a sound source, a digital input interface, a carrier wave modulator, an interpolation filter, a sigma-delta modulator, a thermometer encoder, a dynamic mismatch reshaper, a multi-channel digital amplifier and an ultrasonic transducer array. The system can achieve full digitalization of a system signal transmission link, highly integrated design can be carried out conveniently, system size and power consumption are reduced, system manufacturing complexity and cost are lowered, system electro-acoustic conversion efficiency is improved, and the system has low electromagnetic radiation level and good antijamming capability at the same time, can well lower the harmonic distortion level for demodulating a sound source signal, and greatly improve articulation clearness of conveyed information and acoustic level. The system has a good sound field control ability, provides a good realization method for voice private conveying, and can better meet development requirements of digitalization and networking at the same time.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Reduction state hydrogenation catalyst and preparation method thereof

ActiveCN111375413AImprove hydrogenation activityFully restoredCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonAlkaline earth metal

The invention discloses a reduction state hydrogenation catalyst and a preparation method thereof. The reduction state hydrogenation catalyst comprises a hydrogenation active metal component, an auxiliary agent and a carrier, wherein the hydrogenation active metal component is nickel oxide, the auxiliary agent is one or more of IIA group alkaline earth metal, IB group transition metal, IIB group transition metal, VIII group transition metal and lanthanide series metal, and the carrier is petroleum coke-based activated carbon. The preparation method comprises the following steps: uniformly mixing petroleum coke, metal soluble salt containing hydrogenation activity, metal soluble salt containing auxiliaries and an activating agent, and activating same; carrying out steam treatment on the obtained sample; cooling, introducing oxygen-containing gas for treatment, and finally washing and drying to obtain the reduction-state hydrogenation catalyst. According to the catalyst, petroleum coke-based activated carbon is used as a carrier, so that dispersion of active metal components is facilitated, more high-hydrogenation activity centers are easy to form, and the catalyst has higher hydrogenation activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

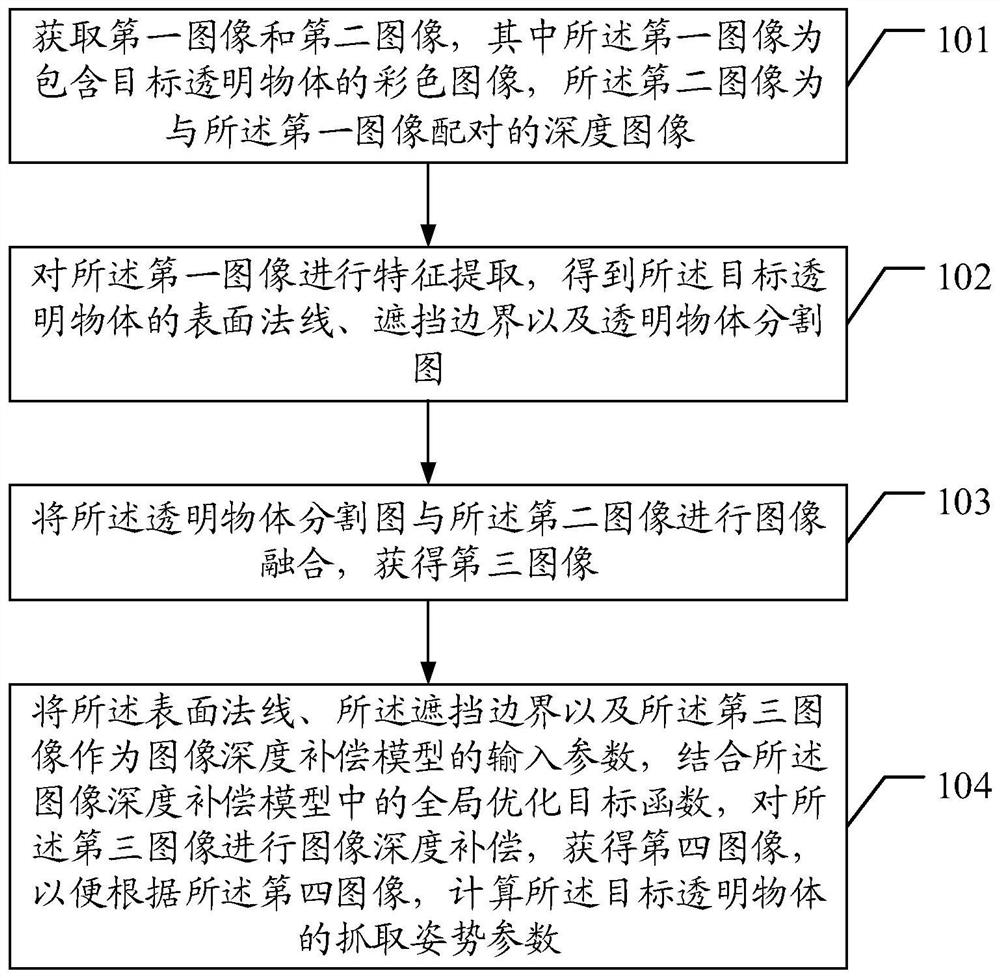

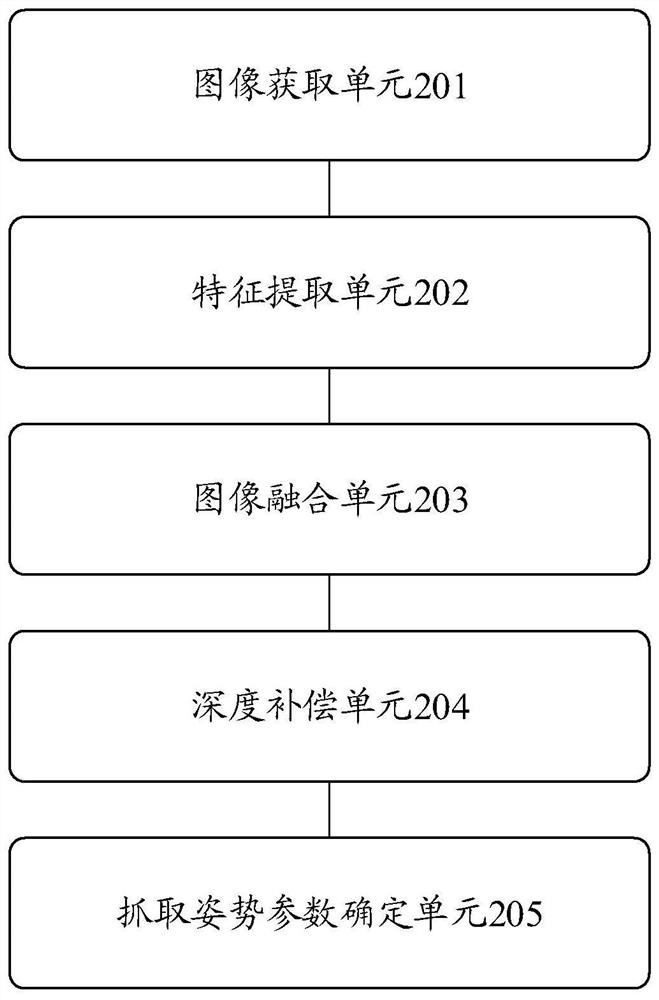

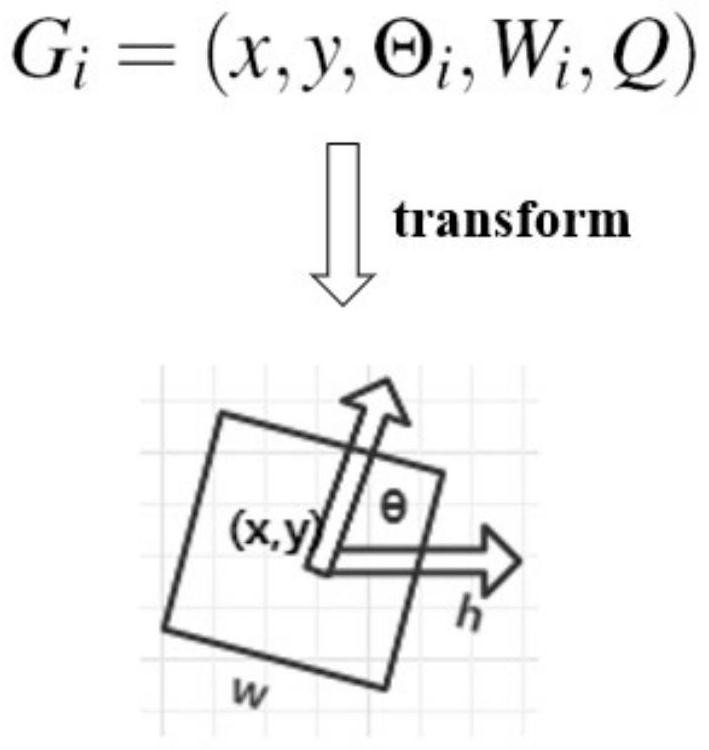

Transparent object grabbing control method and device, terminal and storage medium

PendingCN113160313AFully restoredSolve technical problems with low accuracyImage enhancementImage analysisColor imageComputer science

According to the transparent object grabbing control method and device, the terminal and the storage medium provided by the invention, the missing depth region is filled through the surface normal based on the color image containing the target transparent object in combination with the global optimization algorithm, Meanwhile, the shape of the transparent object is compensated according to the depth discontinuity displayed by the shielding boundary; and depth parameter compensation is carried out on the depth image, so that the image capable of completely restoring the depth information of the transparent object is obtained, and the technical problem of low prediction accuracy of the capture frame of the transparent object in the prior art due to the lack of the depth information is solved.

Owner:GUANGDONG UNIV OF TECH

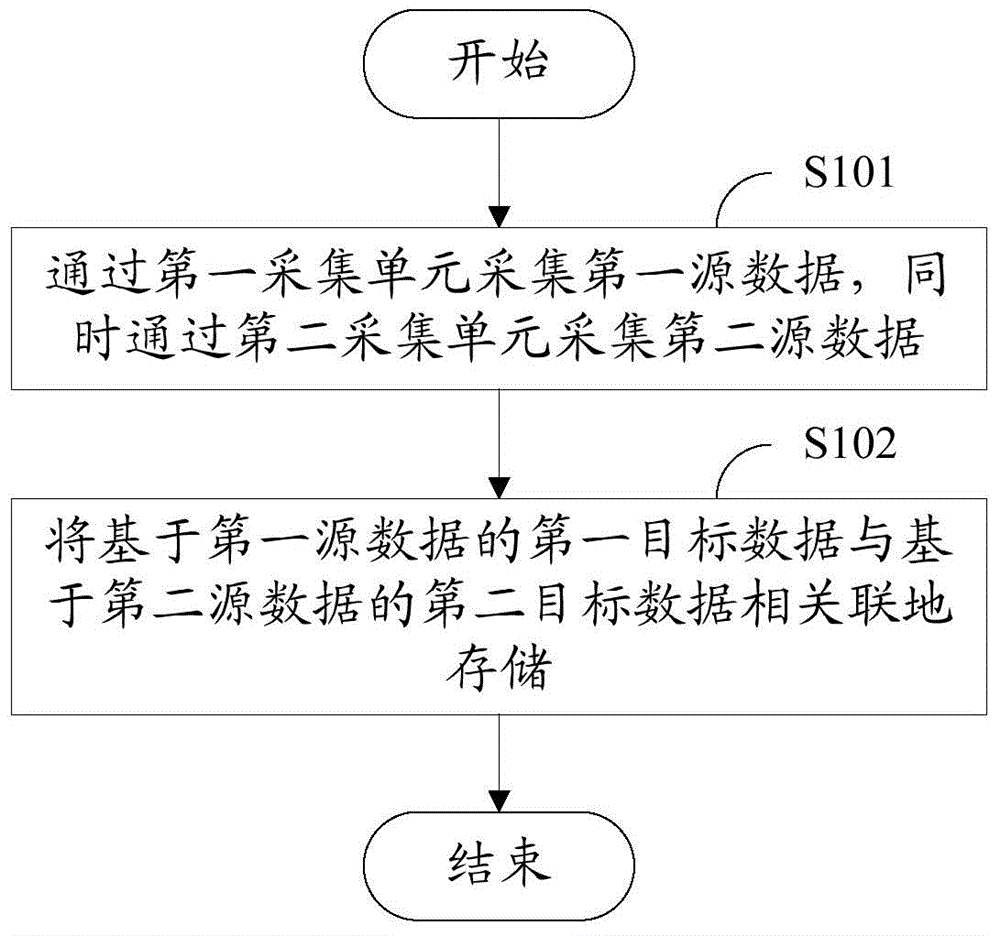

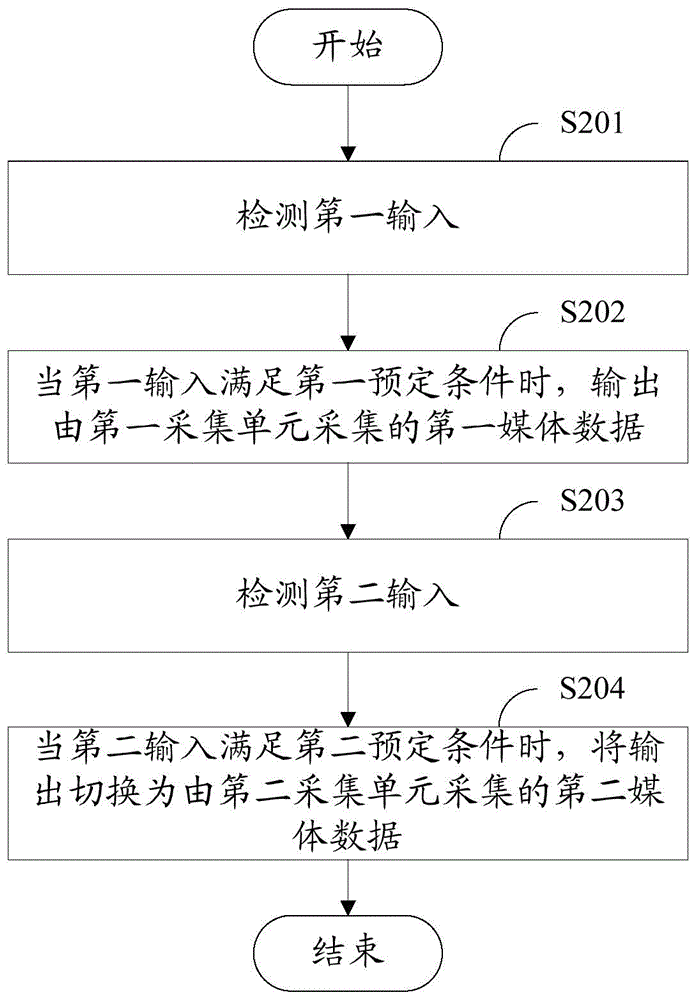

Information processing method and information processing equipment

ActiveCN104375755ARich experienceFully restoredTelevision system detailsColor television detailsTime parameterReal-time computing

An information processing method and device applied to an electronic device are provided. The electronic device includes a first collecting unit located on a first surface and a second collecting unit located on a second surface. The method includes detecting a first input; outputting a first media data collected by the first collecting unit when the first input satisfies a first predetermined condition; detecting a second input; and switching the output into a second media data collected by the second collecting unit when the second input satisfies a second predetermined condition, wherein the first media data and the second media data have the same media type, the first media data corresponds to a first collecting time parameter, the second media data corresponds to a second collecting time parameter, and the first collecting time parameter is the same as the second collecting time parameter.

Owner:LENOVO (BEIJING) CO LTD

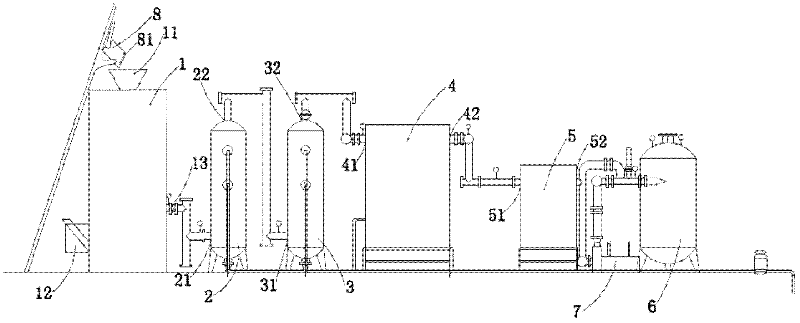

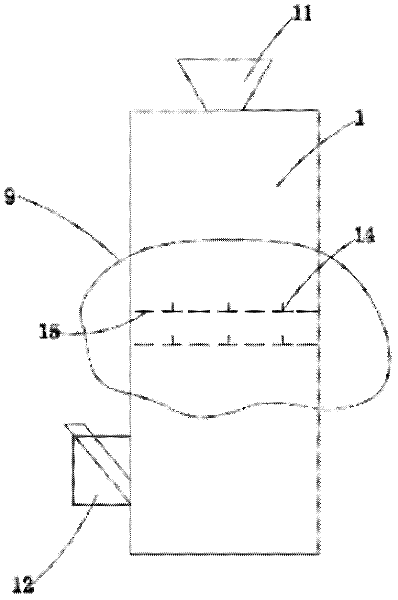

Production equipment for continuous preparation of combustible gas using biomass fuel

The invention discloses production equipment for continuously preparing combustible gas by utilizing biomass fuel, which comprises a biomass gasification furnace, two stages temperature reducing dust removal spray towers, a tar purifier, a gas and water separator and a buffer tank, wherein a material inlet at the upper end of the biomass gasification furnace is provided with a feeding device; a grate is arranged in the biomass gasification furnace; the biomass gasification furnace is provided with a dust discharge device; the biomass gasification furnace is connected with the first temperature reducing dust removal spray tower; the first temperature reducing dust removal spray tower is connected with the second temperature reducing dust removal spray tower; the second temperature reducingdust removal spray tower is connected with the tar purifier; the tar purifier is connected with the gas and water separator; and the gas and water separator is connected with the buffer tank; and a gas pressurization blowing and draught fan is connected between the gas and water separator and the buffer tank. The invention can continuously produce gas, meet the requirement of continuous gas production and remove dust, tar and water of the combustible gas obtained after biomass is gasified and has higher purity and production yield.

Owner:宁波双翼能源科技有限公司

Product and method for direct vanadium alloying of molten steel

The invention discloses a product and method for direct vanadium alloying of molten steel, and belongs to the technical field of metallurgy. By means of the product and the method, a vanadate vanadium compound, a reduction and carbonization agent and a nitrogen increasing agent during synchronous vanadium-nitrogen alloying are crushed and mixed uniformly, the mixture is packaged into a closed reactor serving as a carbon steel shell to be prepared into a sealed monomer product, the sealed monomer product is added into a transfer hot steel ladle or baking hot steel ladle waiting for tapping before and after steel ladle hot repair, steel ladle heat storage is directly used for carbothermal pre-reduction and carbonization of vanadium in the vanadate compound, reduction of vanadium and subsequent molten steel vanadium or vanadium-nitrogen alloying are further completed in the subsequent tapping process so as to replace a finished ferrovanadium alloy or vanadium-nitrogen alloy, vanadium increase of the vanadium compound on the molten steel or synchronous vanadium increase and nitrogen increase of the molten steel are completed, and therefore direct vanadium or vanadium-nitrogen alloying is carried out on the molten steel through carbothermal reduction by adopting a two-step method of vanadate and other compounds.

Owner:MAANSHAN XINGDA METALLURGICAL NEW MATERIAL +1

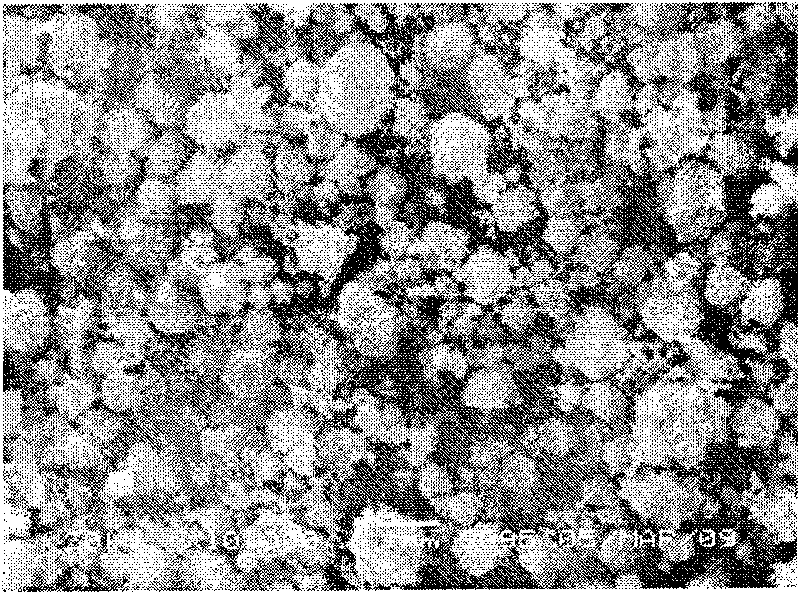

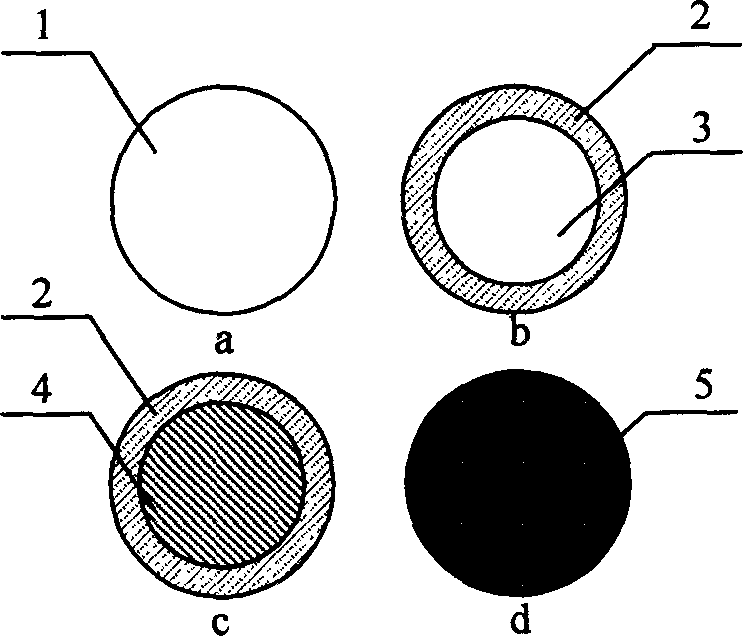

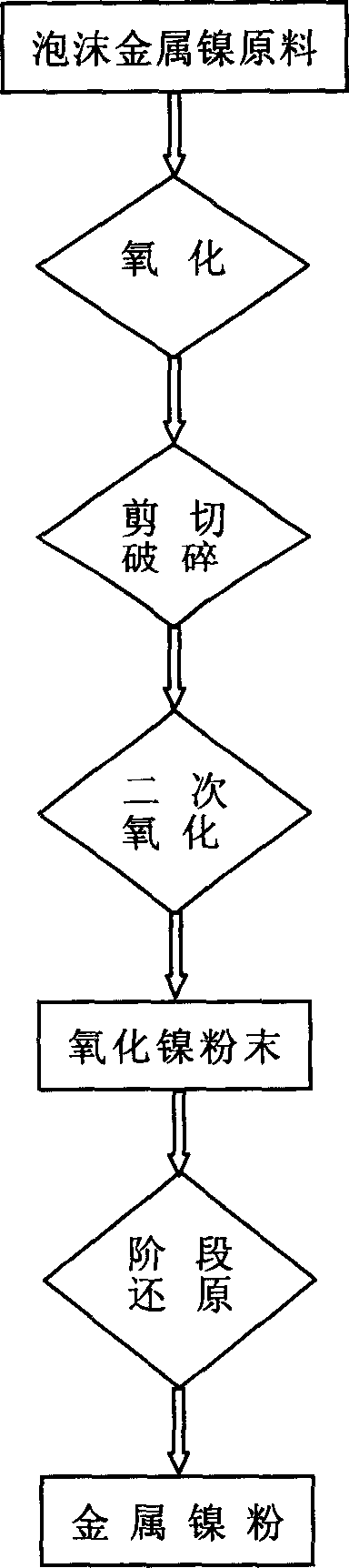

Method for preparing high performance metallic nickel powder using reoxidation process

The invention relates to a method which is adopted the re-oxidation technology to prepare the metal nickel powder with high performance. It is gained the oxidation product of the metal nickel packed by the brittle nickel oxide after the foamed metal nickel raw material is conducted the dynamic gyration oxidation treatment. The oxidation product is conducted multistage shearing crushing by the multistage shearing crusher. Then the crushed powder is conducted the re-oxidation treatment to gain the nickel oxide powder with fine grain. The nickel oxide powder is conducted reduction treatment in stages by cracked ammonia. Thus the high quality metal nickel powder with high purity, fine grain, and small loosing ratio is produced. The technology can be widely applied to all of the metal powder preparations adopted the oxidation reduction method. The advantage of The invention discloses that the high quality metal nickel powder with fine grain can be prepared by the reduction in stages after the re-oxidation of the oxidation intermediate product. The produced metal nickel powder can be widely applied to the sintered metal product (hard alloy, diamond tool, nickel iron alloy product, nickel base product) stainless steel product, battery, and chemical industry product, and so on. The features of the invention are that the non contaminant is discharged; it is good for the environmental protection; the process flow and the cost are reduced.

Owner:长沙市维优金属材料有限公司

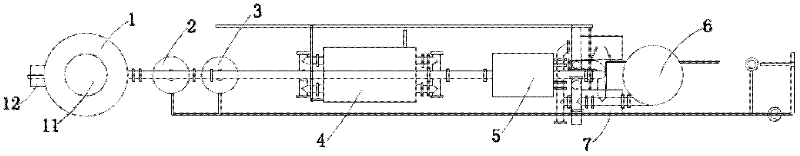

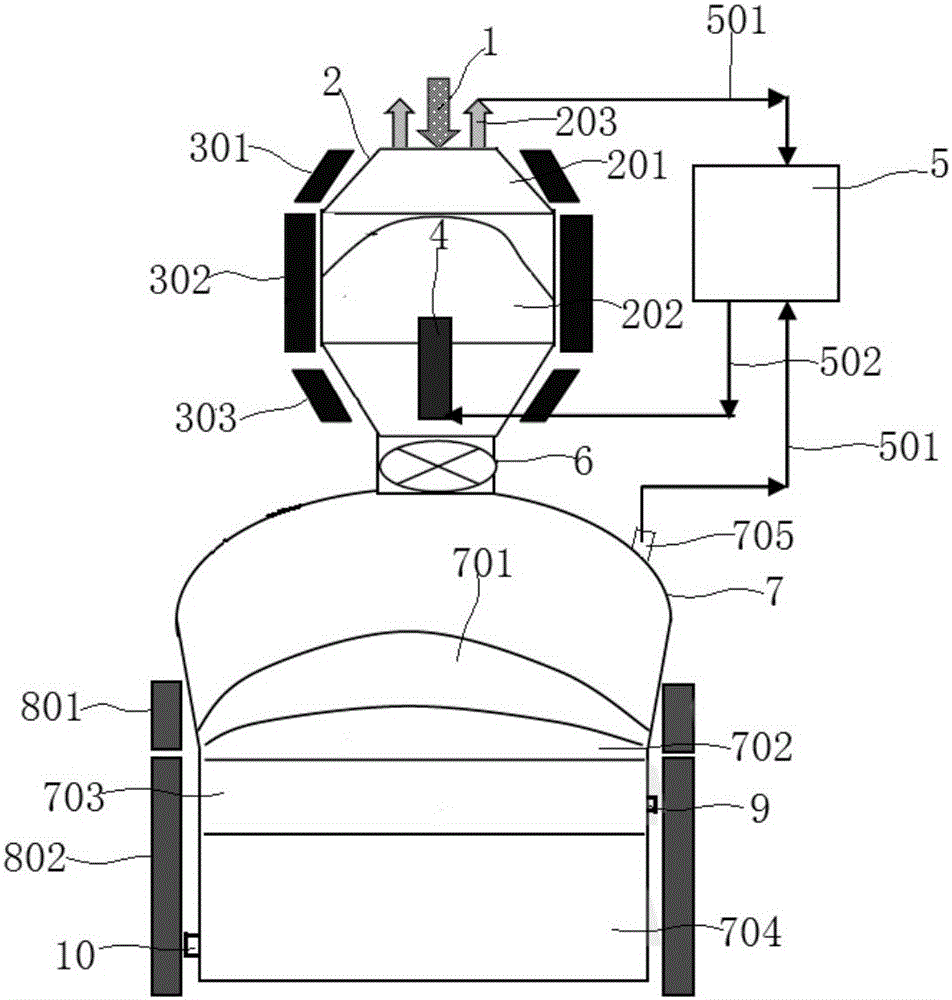

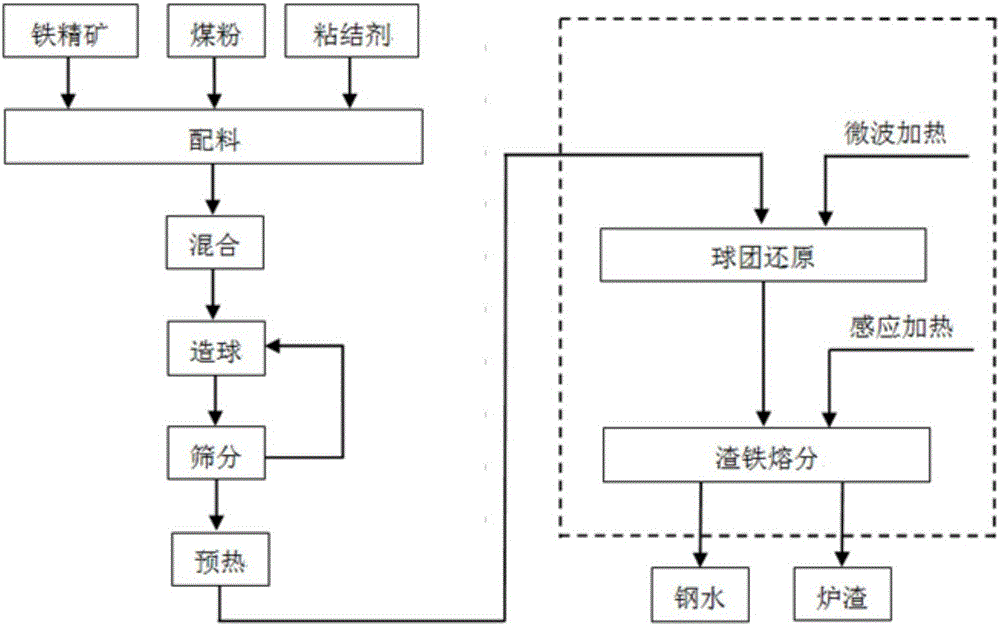

Device for continuously producing molten steel by performing microwave and induction heating on carbon-containing pellets

ActiveCN105755197AIncrease metallization rateImprove breathabilitySmelting processContinuous production

The invention discloses a device for continuously producing molten steel by performing microwave and induction heating on carbon-containing pellets, and belongs to the technical field of iron and steel metallurgy. The device for continuously producing the molten steel by performing microwave and induction heating on the carbon-containing pellets disclosed by the invention comprises a steel refining furnace body; the steel refining furnace body comprises an upper microwave reducing furnace and a lower induction smelting separating furnace; the microwave reducing furnace is used for heating and reducing the carbon-containing pellets; the induction smelting separating furnace is used for performing an iron slag smelting separating reaction; the microwave reducing furnace is communicated with the induction smelting separating furnace through a material discharging valve. By adoption of the technical scheme of the invention, the problems of furnace slag foaming, insufficient reduction of the carbon-containing pellets, and low metallization ratio in the existing steel smelting process can be effectively solved, and the quality of the finally obtained molten steel is ensured.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for preparing high performance metallic nickel powder using electrochemical passivation-loosing process

The invention relates to method which is adopted the electrochemistry purification-loosing to prepare the metal nickel powder. It prepares the high performance metal nickel powder by adopting the electrochemistry purification-loosing processing technology at first, then the oxidation reduction technology. The method is adopts the metal nickel plate with high purity to gain the foamed metal nickel with high porosity and purity after the processing of the electrochemistry purification-loosing. The foamed metal nickel is conducted oxidation treatment with dynamic gyration. The brittle nickel oxide foam is gained after the oxidation. Then the foamy nickel oxide is conducted multistage shearing crushing; the nickel oxide powder with different granularity is gained after the classification by sedimentation method. The nickel oxide powder is conducted reduction treatment in stages by cracked ammonia. Thus the high quality metal nickel powder with high purity, fine crystal grain, and small loosing ratio is produced. The advantages of the invention are that the non contaminant is discharged; it is good for the environmental protection; the process flow and the cost are reduced; and it can ensure the production of gaining the metal nickel powder with high performance. The metal nickel powder with high performance produced by the preparation method can be widely applied to the sintered metal product (hard alloy, diamond tool, nickel iron alloy product, nickel base product) stainless steel product, battery, and chemical industry product.

Owner:长沙市维优金属材料有限公司

Fish feed containing Chinese herbal medicine formula and preparation method of fish feed

InactiveCN106343268AImprove immunityFast growthFood processingClimate change adaptationDiseasePlant disease

The invention discloses a fish feed containing a Chinese herbal medicine formula. The fish feed comprises the following components in parts by weight: 4-6 parts of green tea, 5-7 parts of residues of Fructus Hippophae, 2-4 parts of Radix Et Rhizoma Rhei, 1-3 parts of Cortex Phellodendri, 2-3 parts of Radix Scutellariae, 1-3 parts of Cortex Eucommiae, 6-8 parts of branches and leaves of Melia azedarach L., 1-2 parts of garlicin, 2-4 parts of vitamin, 110-130 parts of silkworm chrysalis, 70-90 parts of fish meal, 340-360 parts of bean pulp, 60-80 parts of peanut residues, 190-210 parts of wheat bran, 160-180 parts of corn and 8-12 parts of salt. The invention further provides a preparation method of fish feed containing the Chinese herbal medicine formula. The fish feed does not have side effect, does not have chemical drug residues, does not damage micro-ecological balance in water, further can enhance fish immunity, prevents diseases, reduces morbidity, effectively reduces use amount of medicines, and guarantees safety of quality of aquatic water.

Owner:上林县维度食品有限公司

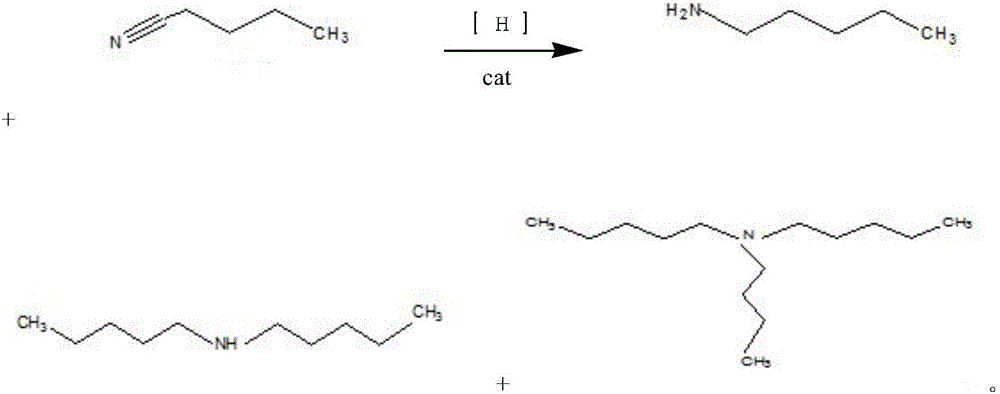

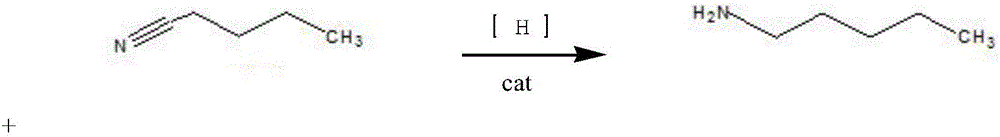

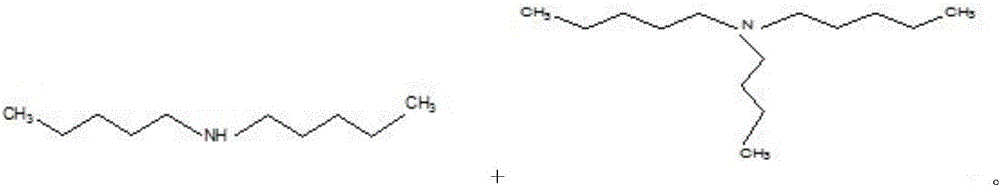

Synthesis method for nickel-base composite catalyst used for synthesizing n-amylamine from pentanenitrile

InactiveCN106582656AFully restoredAvoid reunionOrganic compound preparationAmino compound preparationSolventNanometre

The invention relates to a synthesis method for a nickel-base composite catalyst used for synthesizing n-amylamine from pentanenitrile. The synthesis method includes the steps of: 1) dissolving soluble nickel salt in a solvent to prepare a solution; 2) impregnating a moulded carrier having a pore structure in the solution in the step 1) to produce a catalyst precursor; 3) reducing the catalyst precursor; 4) drying the reduced catalyst precursor to produce the nickel-base composite catalyst. In the method, the pH of a reductant solution is controlled to be a proper range of 8-14, so that Ni<2+> can be reduced completely and a moderated reduction rate can be maintained, thereby producing metal nickel particles in nano scale. The synthesis method can prevent agglomeration due to growth of the metal nickel particles, thereby producing high-activity supported nickel-base composite catalyst.

Owner:浙江优创材料科技股份有限公司

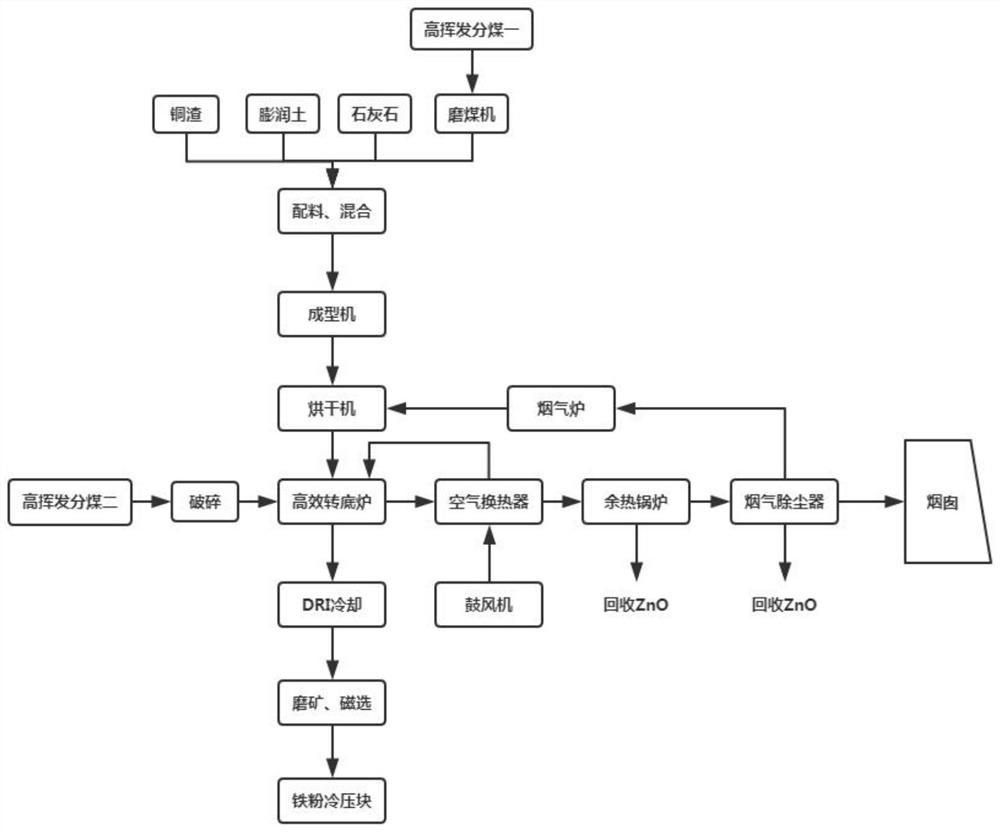

Method for treating copper slag by rotary hearth furnace

ActiveCN113736940AEfficient reductionLow reduction temperatureProcess efficiency improvementIron powderFlue gas

The invention relates to a method for treating copper slag by a rotary hearth furnace. The method comprises the steps of raw material treatment, burdening, mixing, forming, material drying, roasting reduction, flue gas treatment, finished product cooling, ore grinding, magnetic separation and iron powder cold pressing, and adopts a hydrocarbon combined reduction technology to reduce iron oxide into metal iron, reduce zinc oxide into metal zinc, volatilize, oxidize and collect, so that Fe2SiO4 in the copper slag can be efficiently reduced, the metallization rate of direct reduction iron of an intermediate product can reach 90% or above, the zinc removal rate reaches 95% or above, and the iron recovery rate of the whole process reaches 85% or above; the hydrocarbon combined reduction technology is adopted, the reduction temperature is low, and the energy consumption is low. according to the process, the reduction temperature is 800-1230 DEG C; hydrogen is adopted as a main reducing agent in the later stage of reduction, a by-product is water, green and environment-friendly effects are achieved, and the carbon emission amount of treated copper slag per ton is 50-70% of that of a carbon metallurgy rotary hearth furnace process; and the reduction coal in the process is low-rank coal instead of anthracite, so that the cost is low.

Owner:THERMONERGY HIGH TECH CO LTD

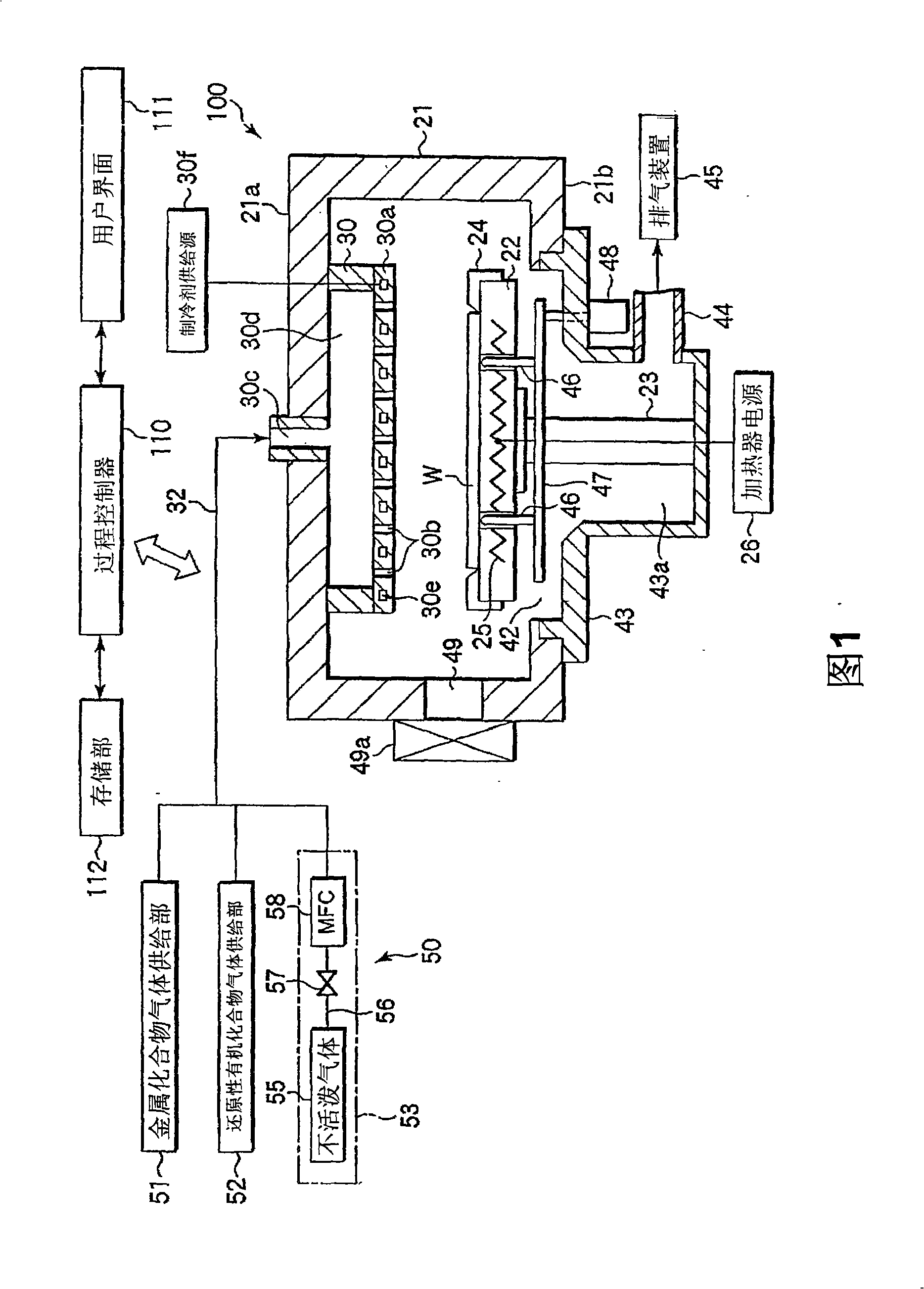

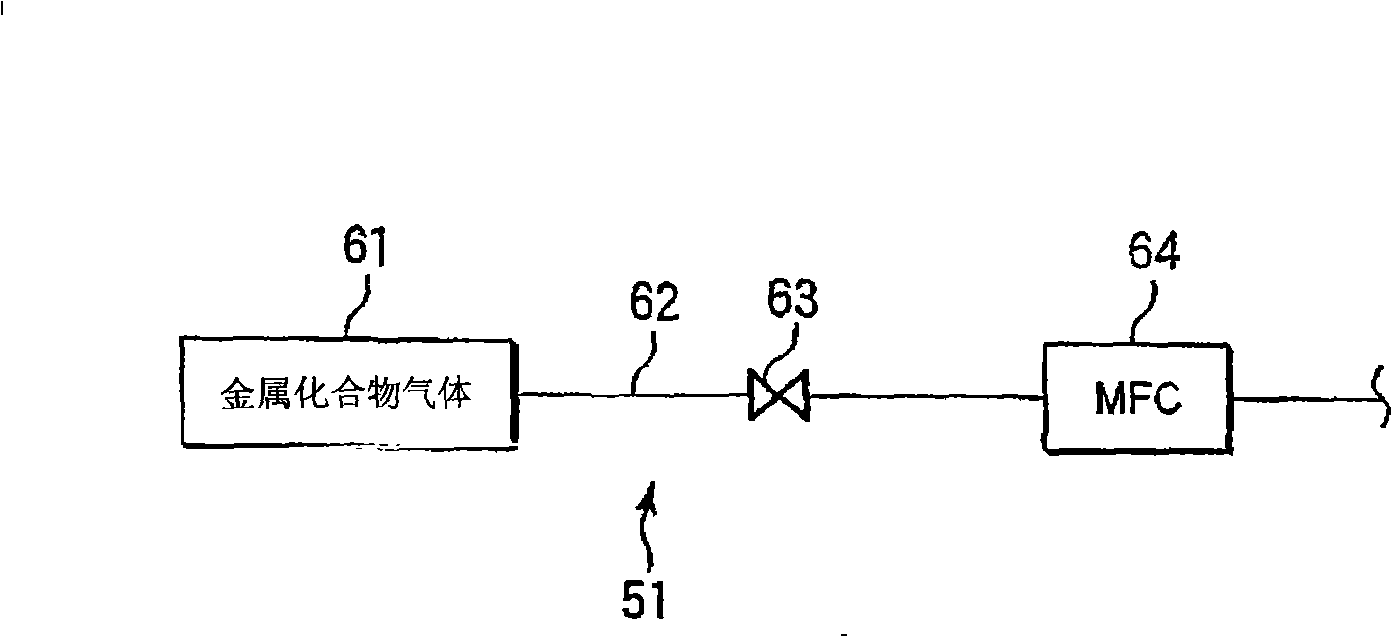

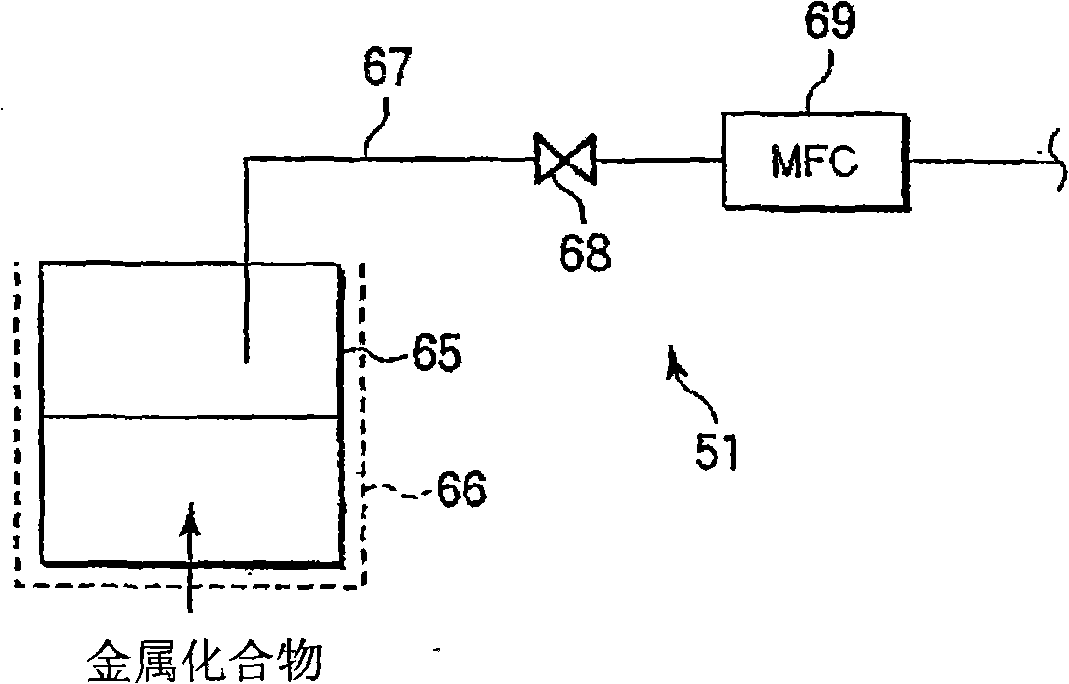

Cvd film forming method and cvd film forming apparatus

InactiveCN101495673AFully restoredReduce the temperatureSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorEngineering

The invention relates to a CVD film deposition process and apparatus. A wafer (W) is arranged on a susceptor (22) in a chamber (21), and a metal film is formed on the surface of a wafer (W) by continuously supplying the chamber (21) with a metal compound gas from a metal compound gas supplying section (51) and a reducing organic compound gas from a reducing organic compound gas supplying section (52) of a gas supplying mechanism (50).

Owner:TOKYO ELECTRON LTD

A kind of method for preparing graphene by redox

The invention relates to the technical field of graphene, in particular to a method for preparing graphene by oxidation reduction. The method comprises the following steps: (1) oxidizing and exfoliating graphite to prepare oxidized graphene; (2) adding the oxidized graphene in an aqueous solution of haloid and reacting; (3) forming electrolyte by using a solution obtained from the step (2), taking metal as a cathode, taking a noble electrode as an anode, and electrolyzing the electrolyte for 0.5-1.5 hours under the condition that the voltage is 1V-1.5V to obtain the graphene on the surface of the cathode. The prepared graphene is good in conductivity, is small in environmental pollution, and is simple and practicable, and the quality of the obtained graphene material is high.

Owner:湖南烯源新材科技有限公司

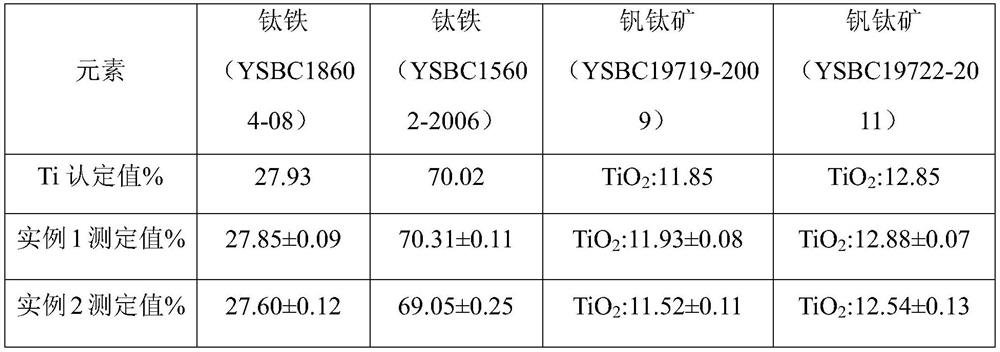

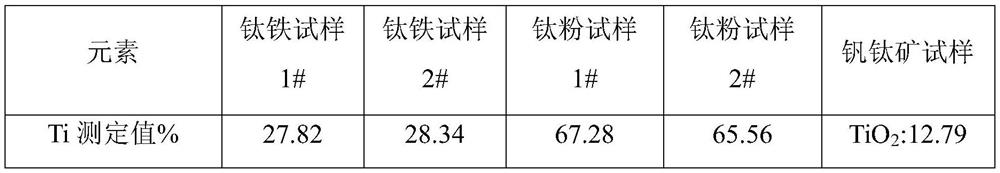

Method for determining titanium in titanium alloy powder

PendingCN111830195AImprove measurement accuracySimple and efficient operationChemical analysis using titrationMaterial analysis by observing effect on chemical indicatorFerrous metallurgyTitanium

The invention discloses a method for determining titanium in titanium alloy powder, and belongs to the technical field of ferrous metallurgy analysis. According to the method provided by the invention, after the sodium hydroxide-sodium peroxide is adopted to melt the sample, the titanium is determined by using an oxidation-reduction volumetric method, the method is high in determination accuracy,simple and convenient to operate and particularly suitable for determining a high-content titanium sample, the determination range is 10.0-80.0% of Ti, and the method can be popularized and used in alarge range.

Owner:BAOTOU IRON & STEEL GRP

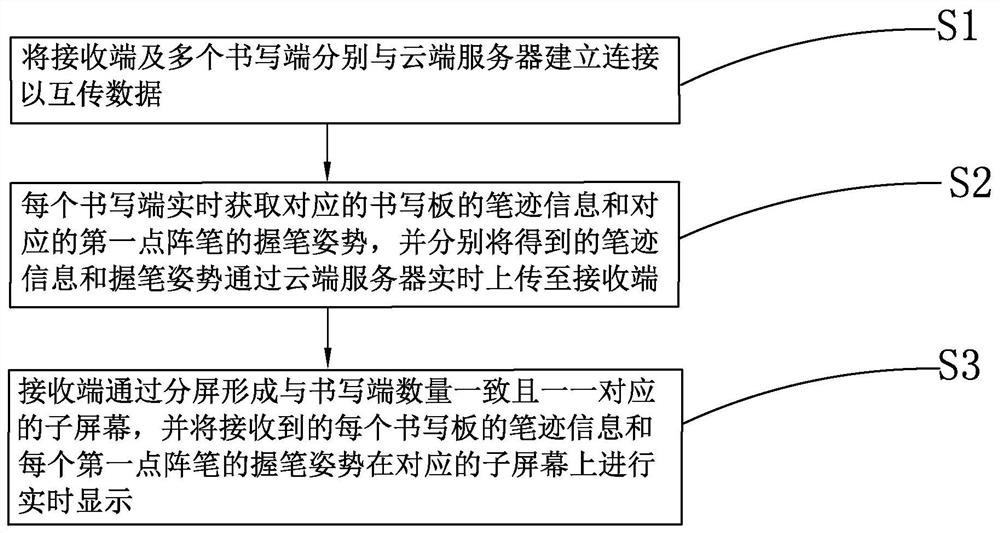

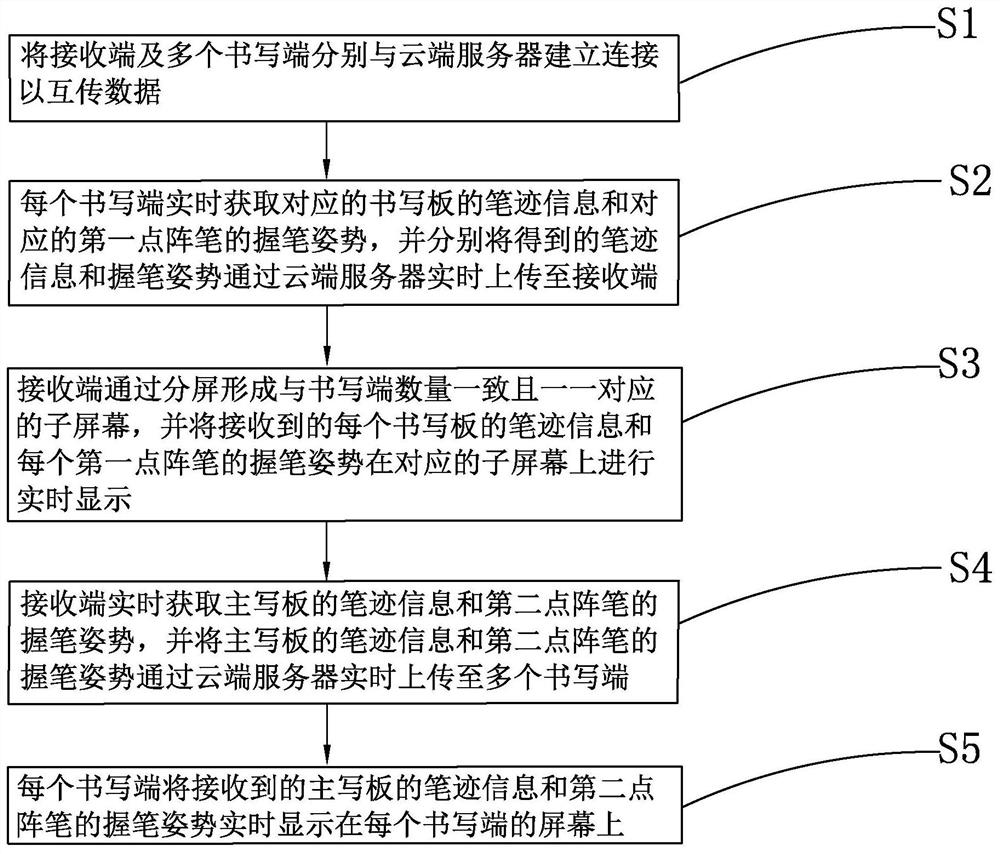

Multi-screen remote real-time writing presentation method

PendingCN112799626AImprove interactive experienceAvoid copying each otherExecution for user interfacesDigital output to display deviceHandwritingEngineering

The invention provides a multi-screen remote real-time writing presentation method. According to the method provided by the invention, each writing end is in communication connection with a writing board and a first dot matrix pen, the first dot matrix pen writes on the writing board to form handwriting information, and a receiving end and the plurality of writing ends are respectively connected with a cloud server to mutually transmit data. Each writing end obtains the handwriting information of the corresponding writing board and the pen holding posture of the corresponding first dot matrix pen in real time and uploads the obtained handwriting information and pen holding posture to the receiving end through the cloud server in real time, and the receiving end forms sub-screens which are consistent with the writing ends in number and are in one-to-one correspondence with the writing ends through screen splitting; the received handwriting information of each writing board and the pen holding posture of each first dot matrix pen are displayed on the corresponding sub-screen in real time, so that a user of a receiving end can observe the writing process of all writing end users on each sub-screen in real time, and the limitation of distance and region is relieved; and the interaction effect between the users is greatly enhanced.

Owner:深圳柔果信息科技有限公司

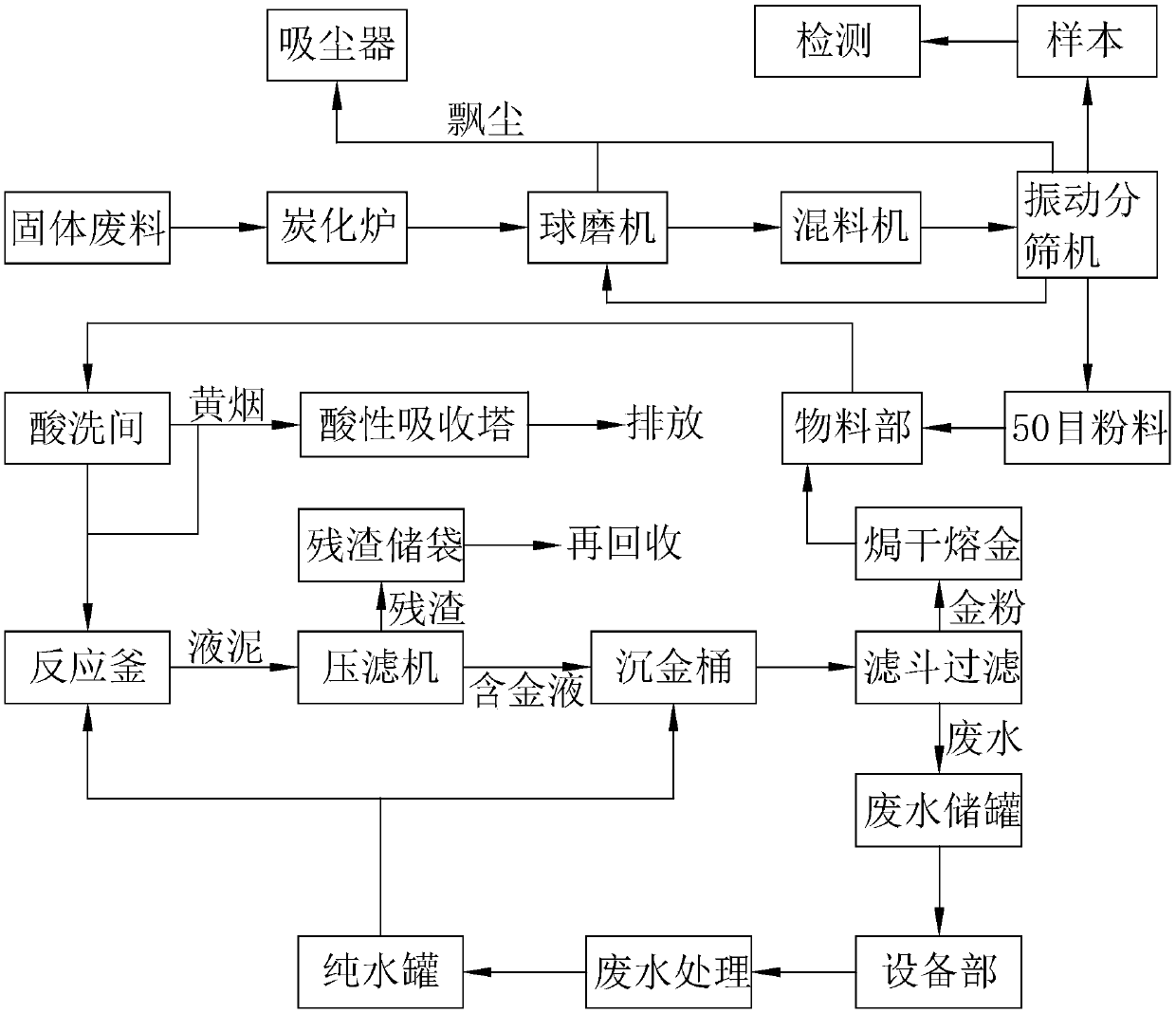

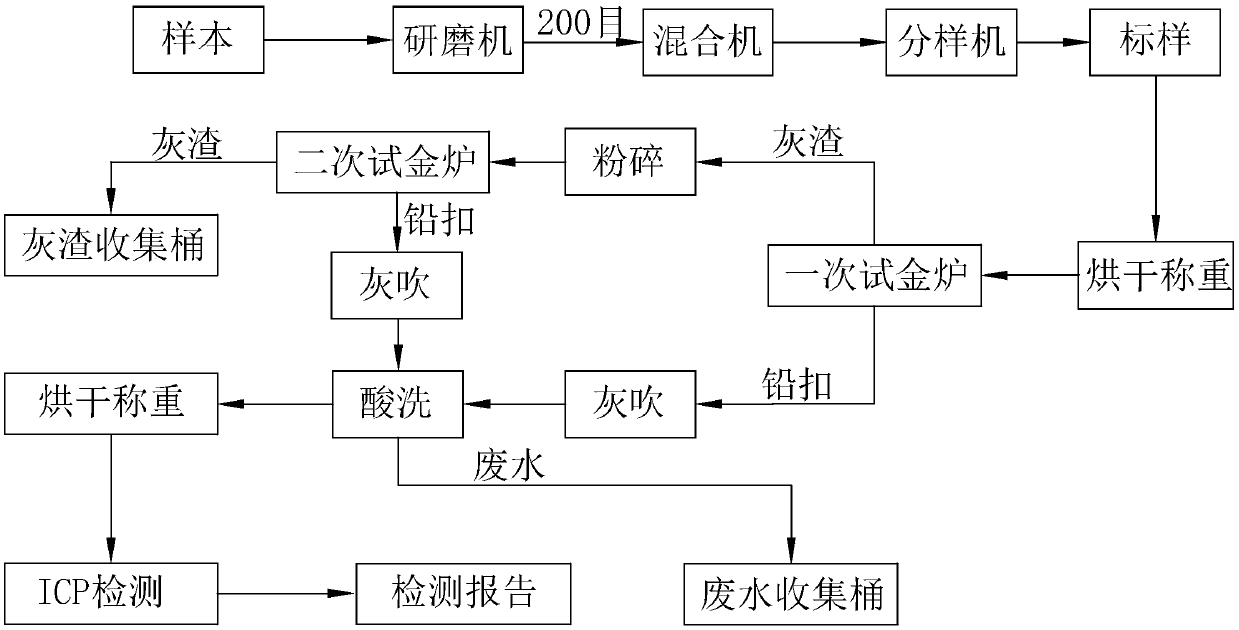

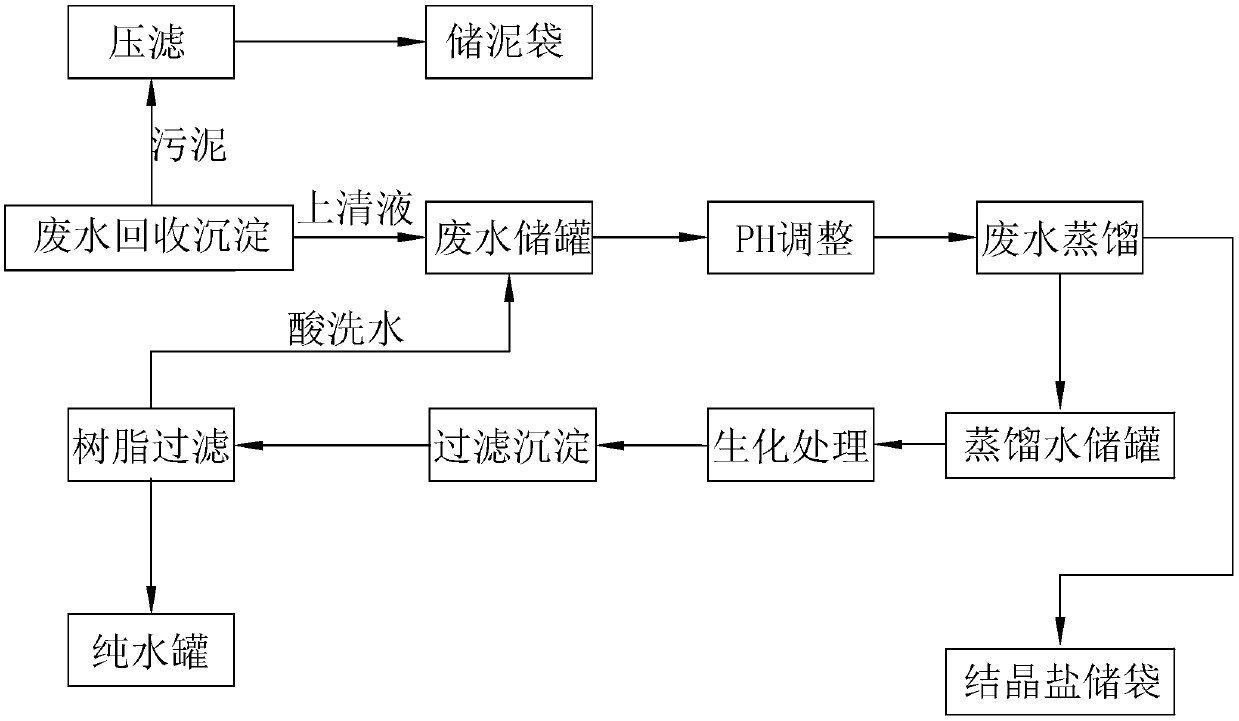

Process for recovering gold from solid waste

The invention discloses a process for recovering gold from a solid waste. The process includes the steps of first, the solid waste is placed in a carbonization furnace for burning and a material is obtained after the burning; after being measured, the material is put into a ball mill to be ground so as to obtain a granular material; then, the granular material is fed to a mixer for mixing and thenconveyed to a vibrating sieve for sieving to obtain a powder; the powder is put into a reaction kettle, steam is fed and aqua regia is added for acid pickling to obtain a paste; the paste is fed to apressure filter for pressure filtration to obtain a gold-containing liquid and residue respectively; the gold-containing liquid is fed into a gold-precipitating bucket, a reductant is added and stirring is performed for reduction, and filtering is performed by using a filter cone to obtain gold powder and waste water; and the gold powder is baked dry and ingot melting is performed to obtain goldingots. Before the dissolution by the aqua regia, the granular material is firstly fed to the mixer for mixing to make the granular material more homogeneous, then screened through the vibrating sieveto select the powder of appropriate size and finally subjected to subsequent dissolution and reduction, so as to make the subsequent acidification and reduction more thorough and complete. Therefore,the gold recovery rate is effectively increased.

Owner:深圳市金正龙科技有限公司

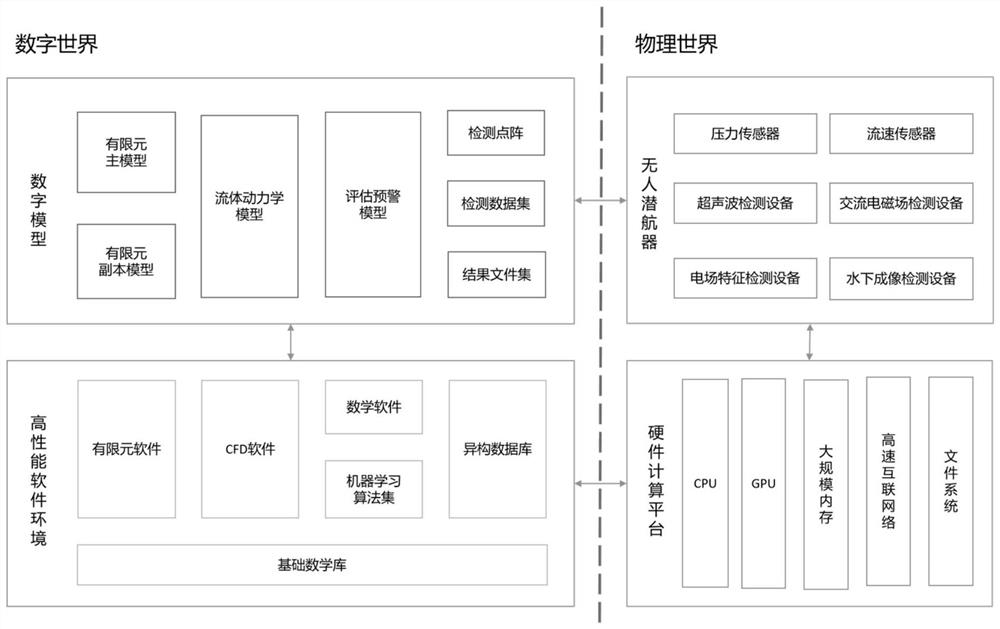

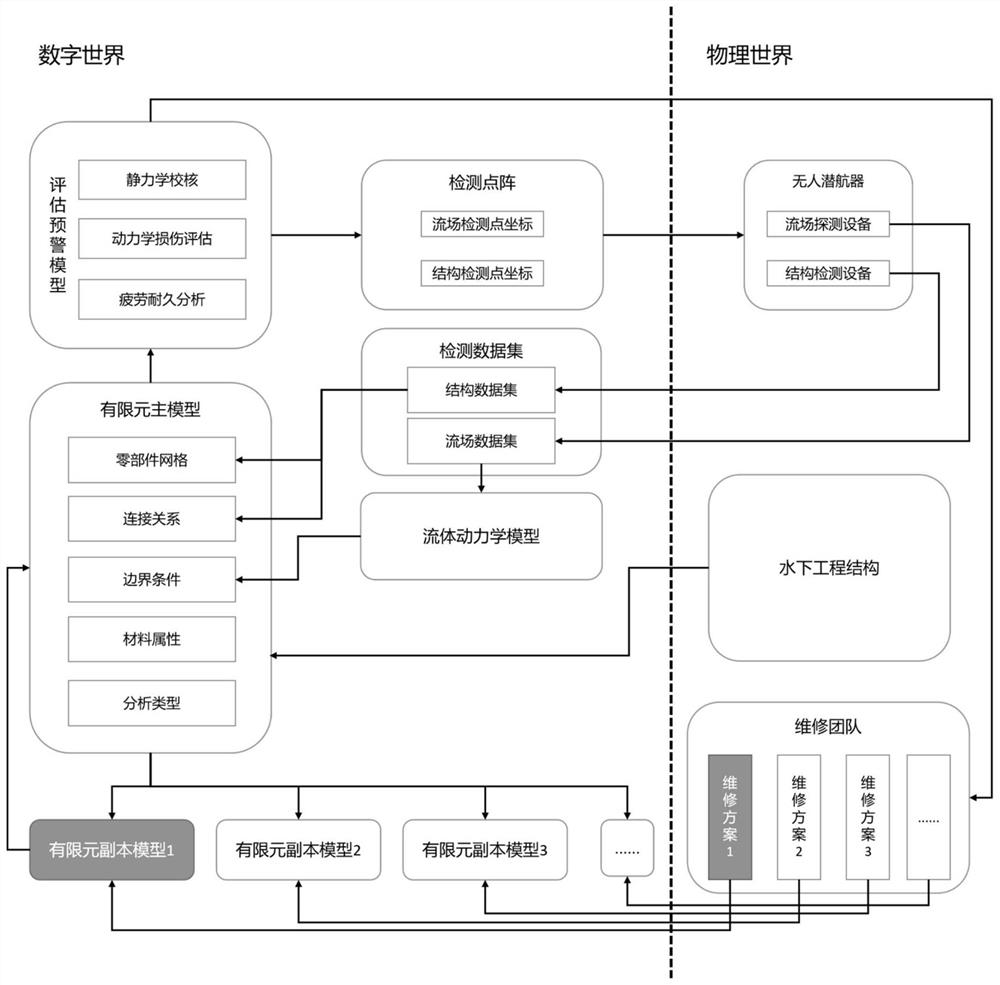

Underwater engineering structure intelligent detection method and system based on digital twinning

PendingCN114547725AAchieve exact restorationRealize precise perceptionGeometric CADMeasurement devicesEvaluation resultData set

The invention discloses an underwater engineering structure intelligent detection method and system based on digital twinning, and the method comprises the steps: building a finite element main model according to a design scheme and actual working conditions of an underwater engineering structure; performing assessment and early warning on the underwater engineering structure based on the finite element main model, and if the assessed structure performance does not reach the standard, sending out warning information and skipping to the maintenance step; if the structural performance reaches the standard, generating a detection dot matrix according to an evaluation result; performing flow field detection and structure detection on the underwater engineering structure based on the detection dot matrix to obtain a detection data set; and according to the detection data set, updating the finite element main model, and carrying out evaluation and early warning on the underwater engineering structure again. The invention provides a method for establishing an underwater engineering structure digital twinborn body, data acquisition of a flow field and nondestructive testing of the structure are carried out based on an unmanned underwater vehicle, a digital twinborn system with a finite element main model as a core is constructed, and monitoring, evaluation and early warning of underwater structure performance are realized.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

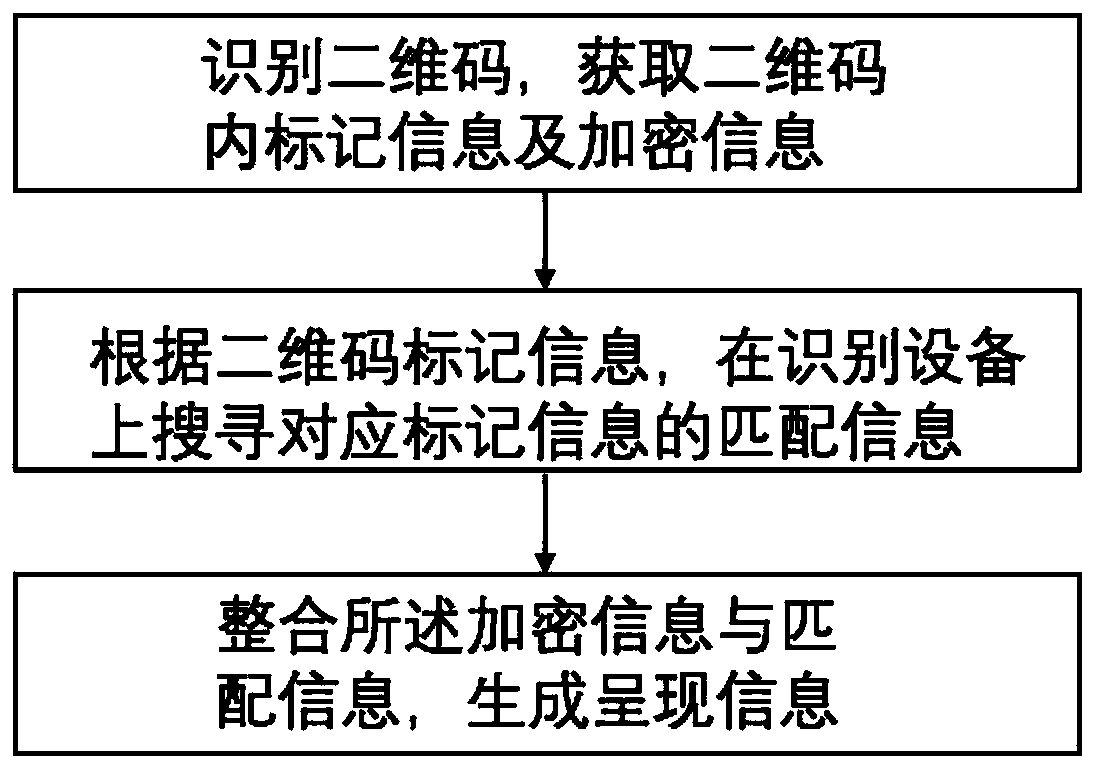

An information presentation method and device based on a two-dimensional code

ActiveCN109948760ASolve costly technical problemsAchieve data protectionCo-operative working arrangementsRecord carriers used with machinesData informationEncryption

The invention relates to the field of data identification, in particular to a two-dimensional code technology. The invention provides an information presentation method based on a two-dimensional code, and the method comprises the steps: 1, identifying the two-dimensional code, and obtaining the marking information and encryption information in the two-dimensional code; Step 2, according to the two-dimensional code mark information, searching matching information corresponding to the mark information on identification equipment; and step 3, integrating the encrypted information with the matching information to generate presentation information. The technical problem of high two-dimensional code information acquisition cost in the prior art is solved, the data information is vividly restored, and data protection, offline display and cost reduction are realized.

Owner:UNI2K INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com