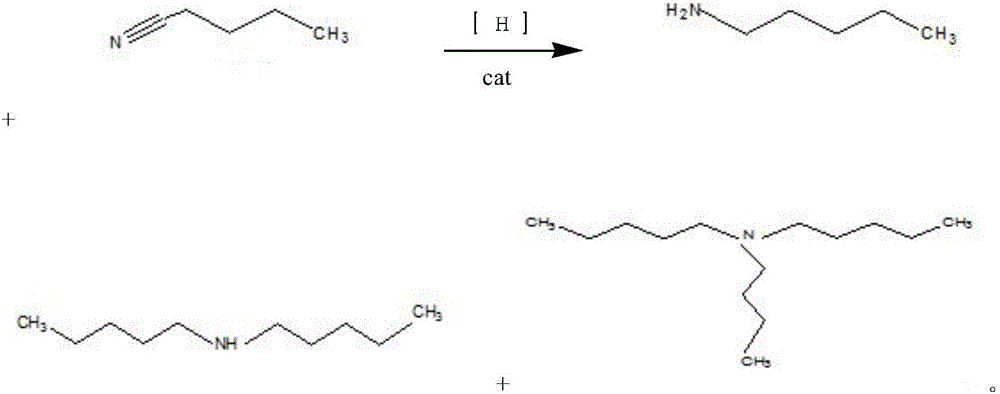

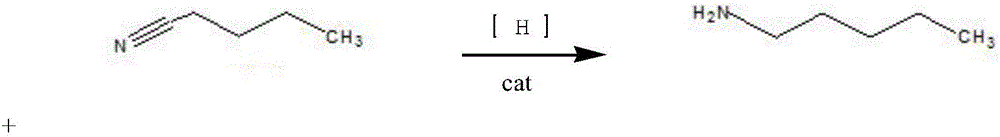

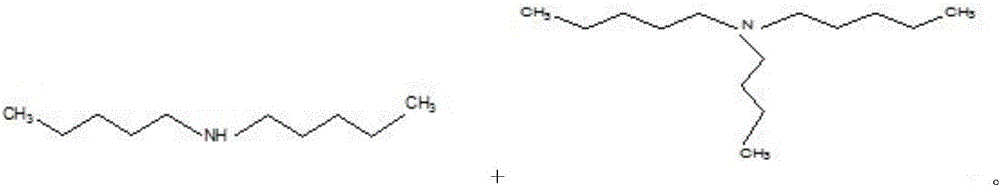

Synthesis method for nickel-base composite catalyst used for synthesizing n-amylamine from pentanenitrile

A technology of composite catalyst and synthesis method, which is applied in the field of synthesis of nickel-based composite catalyst, can solve the problems of increased cost, low yield, high cost of raw materials, etc., and achieve the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

[0022] Embodiment 1 and 2: the preparation of nickel-based composite catalyst

[0023] The catalyst carrier used in the following examples 1-6 is purchased from the market, and only the titanium-modified activated alumina carrier and the silica carrier are used as examples in the examples 1-6:

Embodiment 1

[0025] (1) Preparation of soluble nickel salt solution: Weigh 300g of nickel nitrate and put it into a 1L beaker, add 150ML deionized water and 150ML absolute ethanol, stir to dissolve; add additives EDTA 5g, diethylamine 15g, 20g of triethylamine, 5g of surfactant PEG800, 5g of PEG100005g were stirred and dissolved for later use;

[0026] (2) Preparation of the catalyst precursor: put 600 g of the purchased titanium-modified alumina carrier into the above room temperature solution and soak for 2 days and 2 nights, then take it out and ventilate and dry it in an oven at 80±1°C to obtain 700 g of the precursor for use;

[0027] (3) Catalyst precursor reduction: put 100g of the precursor into a 2L reaction kettle, put in 0.05mol / l sodium borohydride solution to cover the precursor, add a small amount of sodium hydroxide to adjust the pH to 14, start stirring and raise the temperature to 70±1℃ Down reaction, reaction is complete after 2 hours;

[0028] (4) Filter the reduced cat...

Embodiment 2

[0030] (1) Preparation of soluble nickel salt solution: Weigh 300g of nickel nitrate and put it into a 1L beaker, add 150ML deionized water and 150ML absolute ethanol, stir to dissolve; add additives EDTA 5g, diethylamine 15g, 20g of triethylamine, 5g of surfactant PEG800, 5g of PEG100005g were stirred and dissolved for later use;

[0031] (2) Preparation of catalyst precursor: Put 600g of the purchased large-pore silica carrier (particle size 1-3mm) into the above room temperature solution for 2 days and 2 nights, take it out and ventilate and dry it in an oven at 80±1°C Get 700g of precursor for later use;

[0032] (3) Catalyst precursor reduction: put 100g of the precursor into a 2L reaction kettle, put in 0.05mol / l sodium borohydride solution to cover the precursor, add a small amount of sodium hydroxide to adjust the pH to 14, and start stirring to raise the temperature to 70±1°C Down reaction, reaction is complete after 2 hours;

[0033] (4) Filter the reduced catalyst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com