Method for determining titanium in titanium alloy powder

A titanium alloy powder and titration technology, which is applied to the determination of titanium in titanium alloy powder and the determination of titanium in insoluble titanium alloy powder, can solve the problem that the iron alloy sample cannot be completely melted, it is not suitable for the determination of high content of titanium, and the accuracy is low. Problems, to avoid splash loss, easy to operate, easy to observe the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The method for determining titanium in titanium alloy powder provided by the present invention comprises the following steps:

[0040] 1) Wash several corundum crucibles and place them in a low-temperature electric furnace for drying. Weigh about 2.0 g of sodium hydroxide in the corundum crucible. Put the crucible into a 300°C muffle furnace and melt it, then take it out and put it in a desiccator for cooling. to room temperature.

[0041] 2) Weigh about 0.1500g of insoluble titanium powder sample into the above corundum crucible, add about 1.5g of sodium peroxide, stir the sodium peroxide and the sample, mix the two, and then cover about 1.0g of peroxide Sodium, along with reagent blank and titanium iron standard sample calibration test.

[0042] 3) Melt the corundum crucible containing the sample in a muffle furnace at 700±10°C for 10min, take it out and cool it to room temperature, wipe the bottom of the crucible with filter paper, put the crucible into a 400mL beak...

example 1

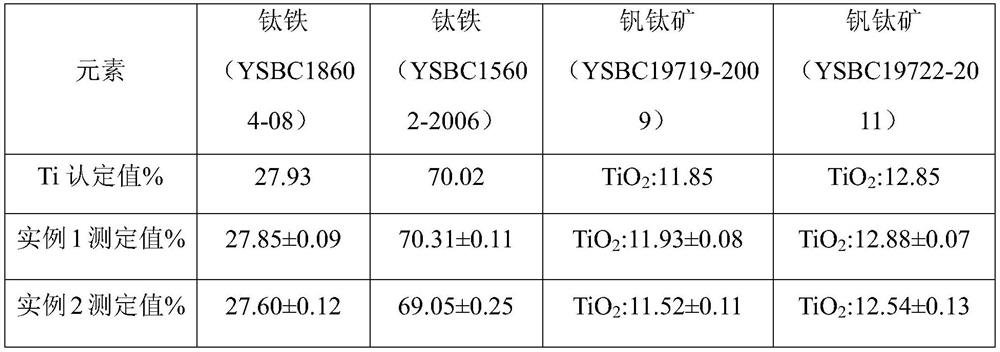

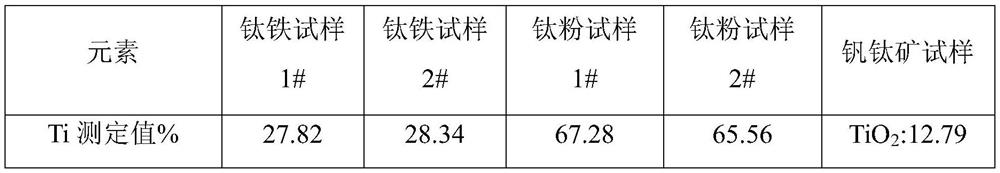

[0052] Weigh standard samples of ferrotitanium (YSBC18604-08), ferrotitanium (YSBC15602-2006), vanadium titanite (YSBC19719-2009), vanadium titanite (YSBC19722-2011) and measure them according to the above method. The results are shown in the following table. 1.

example 2

[0054] Weigh standard samples of ferrotitanium (YSBC18604-08), ferrotitanium (YSBC15602-2006), vanadium ore (YSBC19719-2009), vanadium titanite (YSBC19722-2011) according to the above method (except step 2) different, In the method of this example 2, step 2) is: Weigh about 0.1500g of the sample into the above corundum crucible, add about 2.5g of sodium peroxide, stir the sodium peroxide and the sample, make the two evenly mixed, and will be used soon The amount of sodium peroxide used to mix with the sample at one time) was measured, and the results are shown in Table 1 below.

[0055] Table 1: Sample Assay Results

[0056]

[0057] As can be seen from the above table 1 results, with respect to the method of example 2 (the only difference with the method provided by the invention is that the sodium peroxide of the usage amount is added at one time and mixed with the sample), the method of example 1 (that is, the method provided by the invention) is adopted. ) has higher a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com