Process for recovering gold from solid waste

A solid waste and process technology, applied in the field of gold recovery technology in solid waste, can solve the problems affecting the comprehensiveness and thoroughness of aqua regia dissolution method extraction, uneven particle size, and low gold recovery rate, etc. Extraction and recovery efficiency, reducing raw material waste, and improving the effect of recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

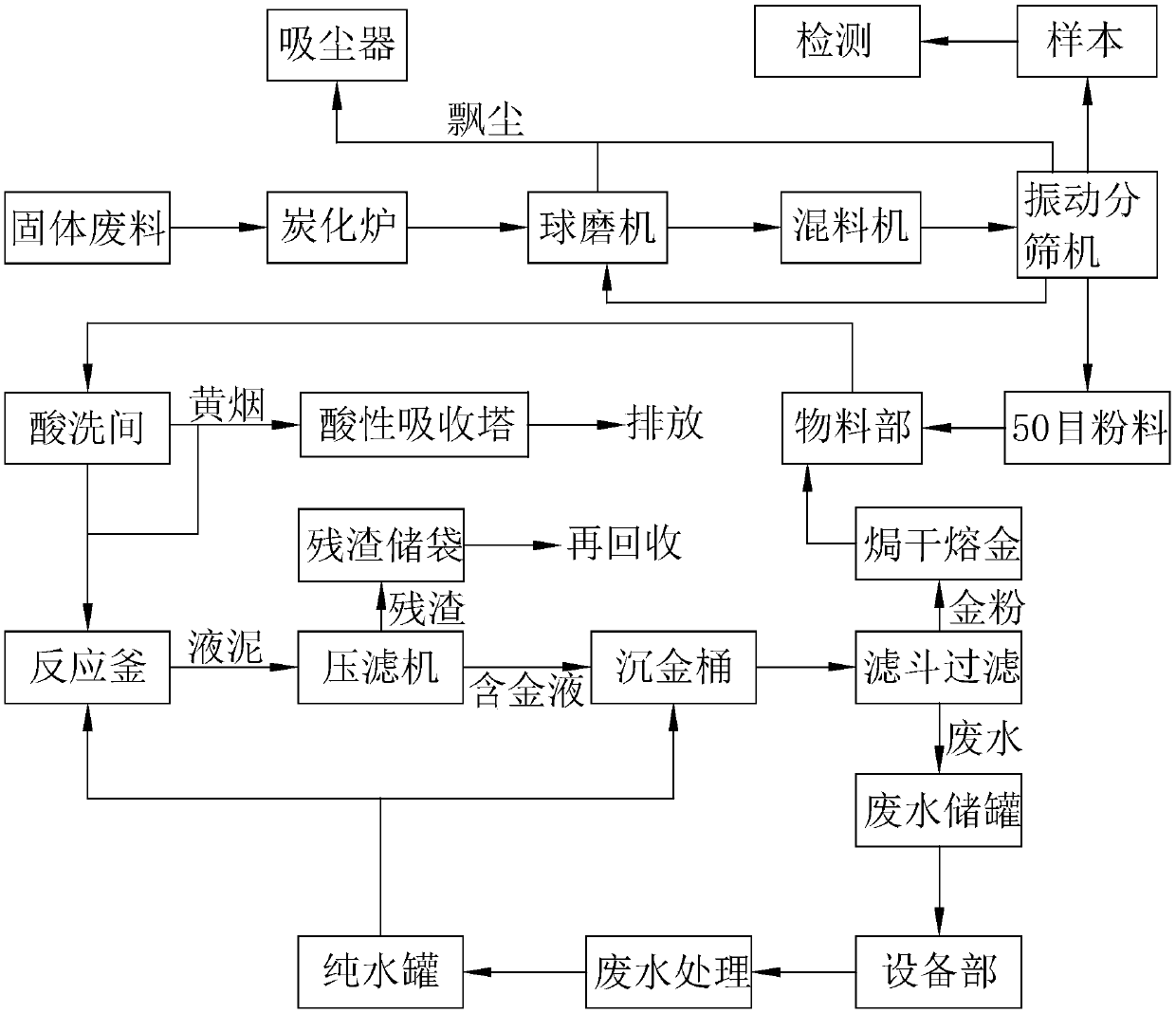

[0050] A recovery process for gold in solid waste, such as figure 1 As shown, firstly, the solid waste is weighed and put into the carbonization furnace for combustion to obtain burnt materials. After the burnt materials are weighed and weighed, they are put into the ball mill for grinding to form granular materials. These granular materials are fed by vacuum. The transfer storage tank is connected to the mixer, and the granular material enters the mixer to achieve mixing. The V-shaped mixer is selected in this embodiment, so that the granular material is mixed After the material is more uniform, it is then sieved by a vibrating sieving machine, and the particle mixture is taken from the vibrating sieving machine as a sample for subsequent testing operations; the powder below 50 mesh is screened by the vibrating sieving machine and transported to the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com