Method for making combined economizer made of ceramic material

A technology of ceramic materials and manufacturing methods, applied in the direction of charging system, machine/engine, engine components, etc., can solve the problems of non-durability, small surface area, poor reaction effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to achieve the above purpose and effects, the technical means and structures adopted by the present invention are described in detail in conjunction with the accompanying drawings for the preferred embodiments of the present invention. The features and functions are as follows for a complete understanding.

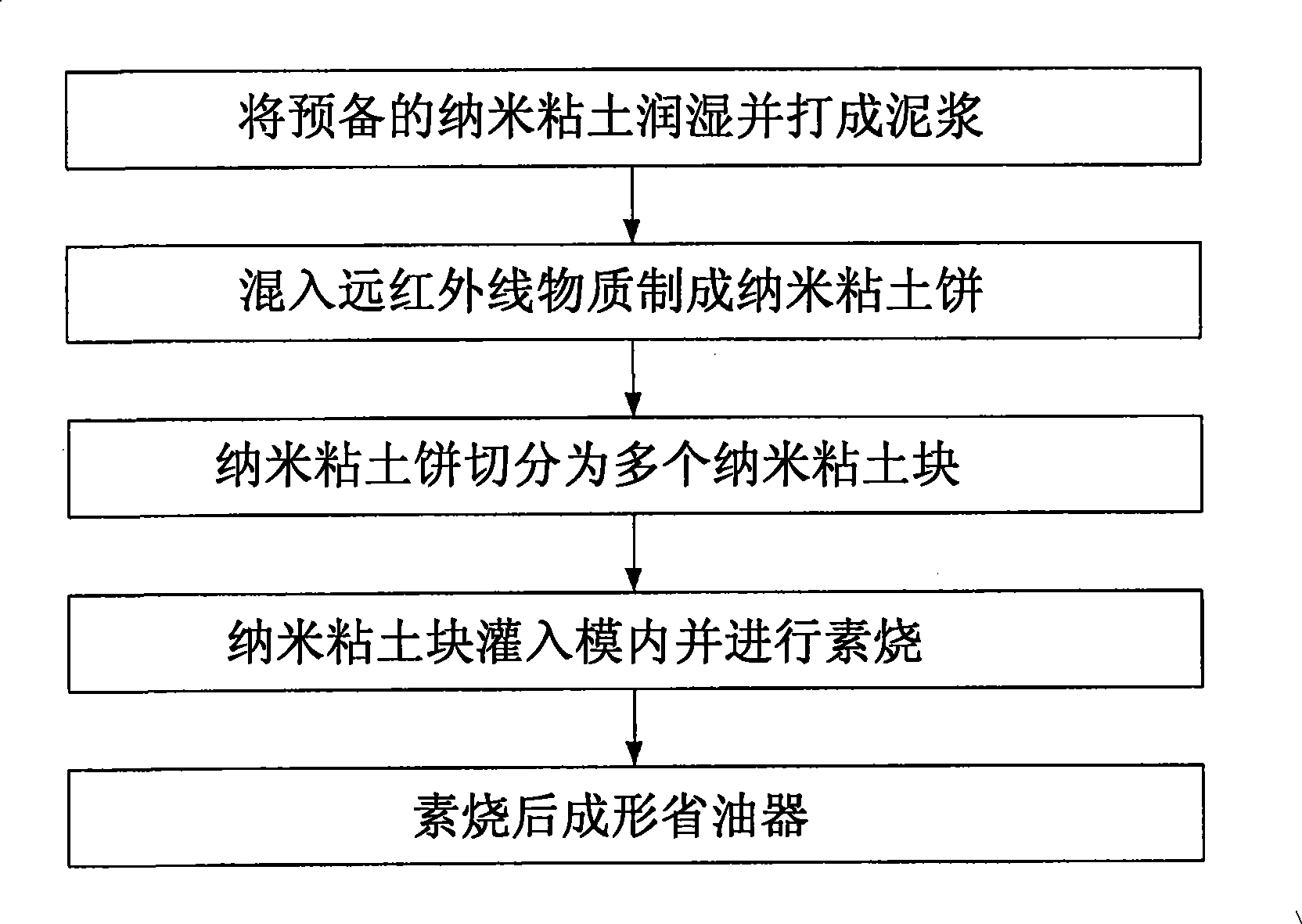

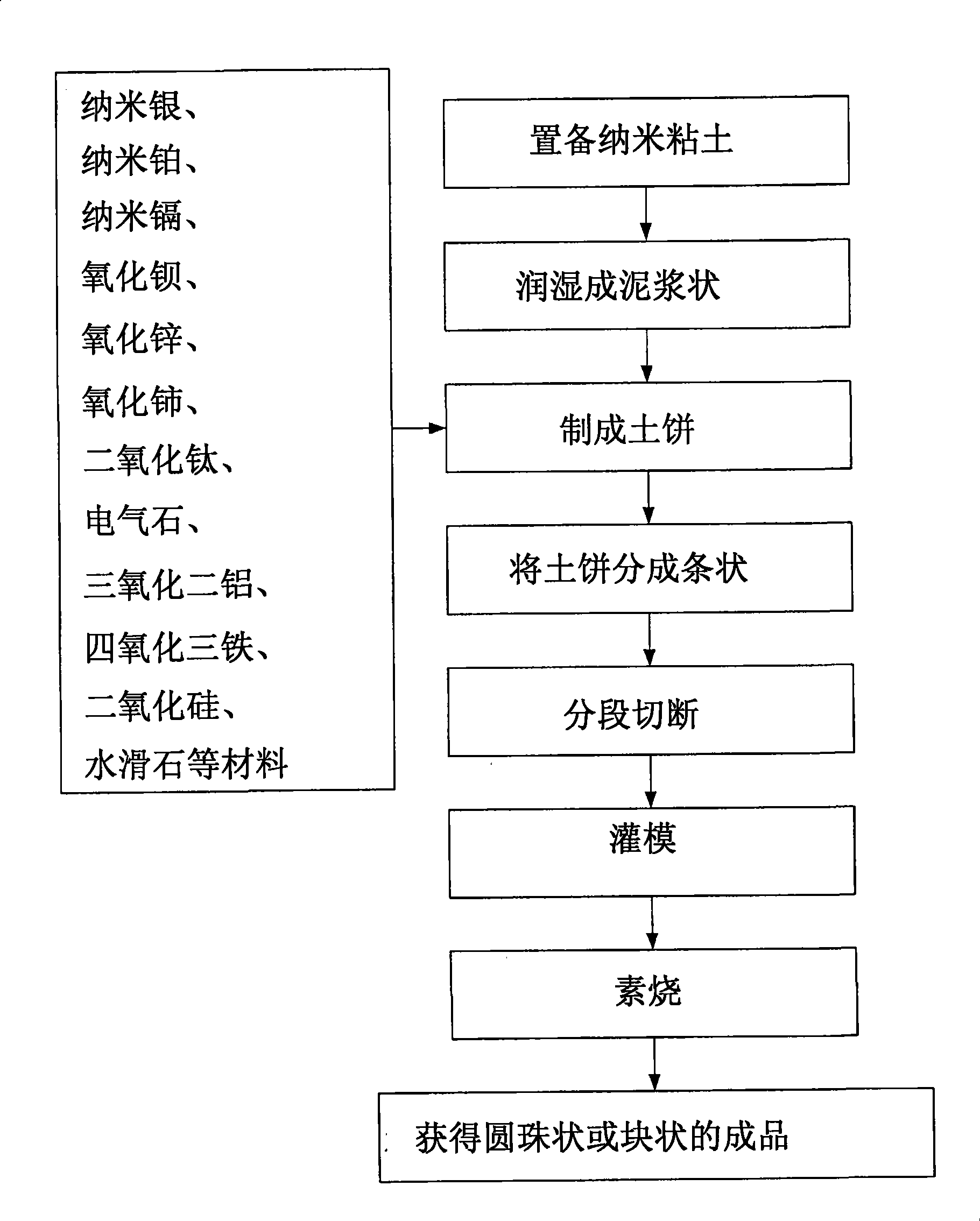

[0012] see figure 1 Shown is the main manufacturing flow chart of the preferred embodiment of the present invention. It can be clearly seen from the figure that the present invention is mainly composed of far-infrared substances mixed in nano-clay, and fired according to the following steps:

[0013] Moisten and beat the prepared nanoclay into mud;

[0014] Mixed with far-infrared substances to make nano-clay cakes;

[0015] The nanoclay cake is cut into multiple nanoclay blocks;

[0016] Nanoclay blocks are poured into the mold and bisque fired;

[0017] Shaped economizer after bisque firing.

[0018] The above-mentioned far-infrared substances can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com