Production equipment for continuous preparation of combustible gas using biomass fuel

A technology of biomass fuel and production equipment, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of combustible gas with many impurities, achieve the effects of improving production yield, ensuring regional stability, and solving blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

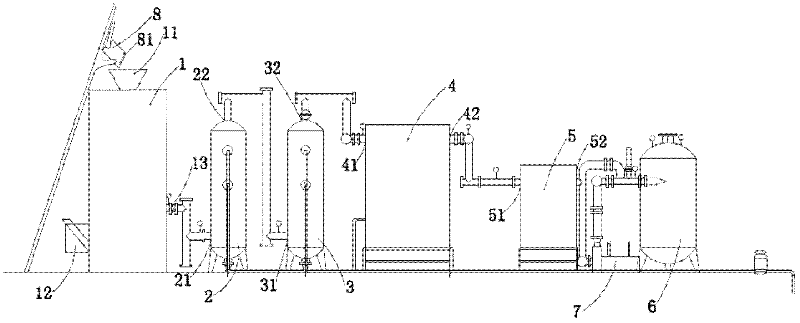

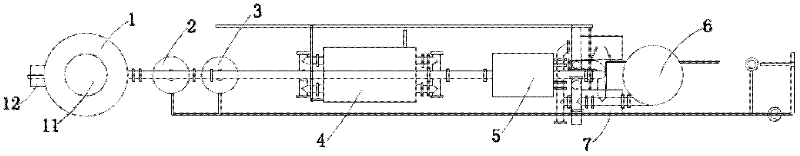

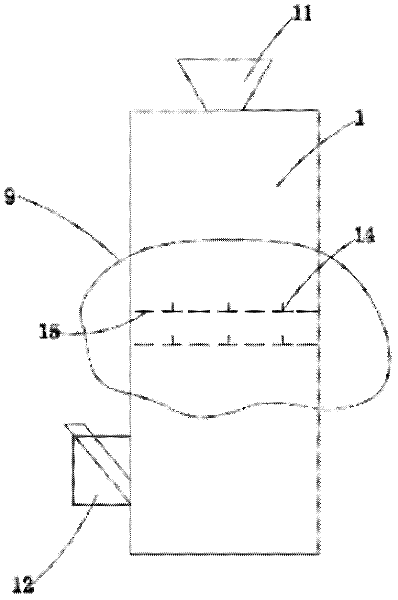

[0017] Such as figure 1 , figure 2 As shown, the production equipment for continuously preparing combustible gas provided by the present invention includes a biomass gasification furnace 1, a two-stage cooling dust removal spray tower, a tar purifier 4, a gas-water separator 5 and a buffer tank 6, The upper feed port 11 of the biomass gasification furnace 1 is provided with a feeding device 8, the biomass gasification furnace 1 is provided with a fire grate 9, and the lower end of the biomass gasification furnace 1 is provided with an ash discharge device 12. The gas outlet 13 of the biomass gasifier at the lower end of the other side of the furnace 1 communicates with the air inlet 21 of the first cooling and dust removal spray tower at the lower end of the first cooling and dust removal spray tower 2 through a pipe, and the top of the first cooling and dust removal spray tower 2 The air outlet 22 of the first cooling and dedusting spray tower is communicated with the air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com