Preparation method of superfine rhenium powder

A technology of rhenium powder and ammonium rhenate, which is applied in the field of manufacturing metal powder, can solve the problems of great environmental hazards of reduction products, discontinuous process, and high requirements for equipment materials, so as to achieve superior product performance, good fluidity, and lower requirements for equipment materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

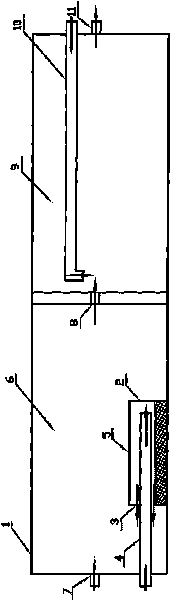

[0023] like figure 1 As shown, the reactor 1 is heated by a resistance furnace, and its outer diameter is φ90mm. One end of the volatilizer 2 is provided with a ventilation hole 3 for inserting an oxygen pipe 4, and this hole doubles as an escape hole for volatile products, and an escape hole can also be provided at the other end, or on the cover plate 5 of the volatilizer 2. escape hole.

[0024] Weigh ammonium rhenate and load it into the volatilizer 2, place it in the decomposition zone 6, and insert the oxygen delivery pipe 4 into the vent hole 3 of the volatilizer 2. The carrier gas is introduced through the carrier gas pipe 7, and nitrogen gas is first introduced after charging, and the air in the reactor is exhausted through the through hole 8 and the exhaust hole 11, and then the temperature is raised, and the temperature of the decomposition zone 6 is set at 350-700 °C Set and control; the temperature of reduction zone 9 is set and controlled within the range of 600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com