Cvd film forming method and cvd film forming apparatus

A film-forming method and a film-forming device technology, which are applied in the direction of gaseous chemical plating, coating, electrical components, etc., and can solve the problems of poor step coverage of PVD method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be specifically described below with reference to the drawings.

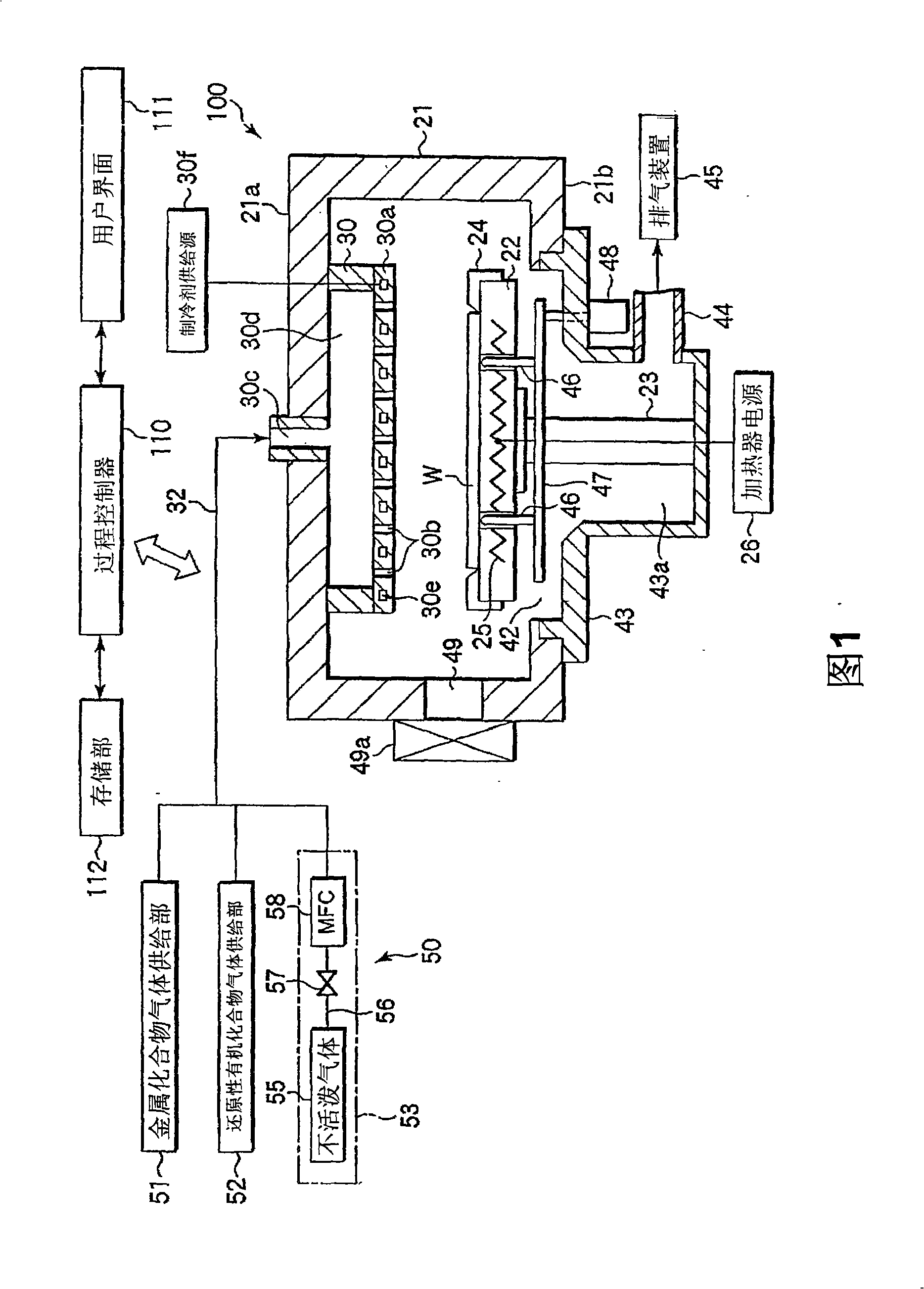

[0030] FIG. 1 is a cross-sectional view schematically showing a film forming apparatus for carrying out a CVD film forming method according to a first embodiment of the present invention.

[0031] The film forming apparatus 100 has a substantially cylindrical chamber 21 that is airtight. A circular opening 42 is formed at the center of the bottom wall 21b of the chamber 21, and an exhaust chamber 43 communicating with the opening 42 and protruding downward is provided on the bottom wall 21b. A susceptor 22 for horizontally supporting a wafer W as a semiconductor substrate is provided in the chamber 21 . The base 22 is supported by a cylindrical support member 23 protruding upward from the center of the bottom of the exhaust chamber 43 . A guide ring 24 for guiding the wafer W is provided on the outer edge of the susceptor 22 . A resistance heating type heater 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com