A method for manufacturing hot-dip galvanized steel sheet without strip zinc dust and bright spot defects on the surface

A hot-dip galvanized steel sheet, bright spot defect technology, applied in hot-dip plating process, coating, metal material coating process and other directions, can solve problems such as exposed iron defects in strip steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

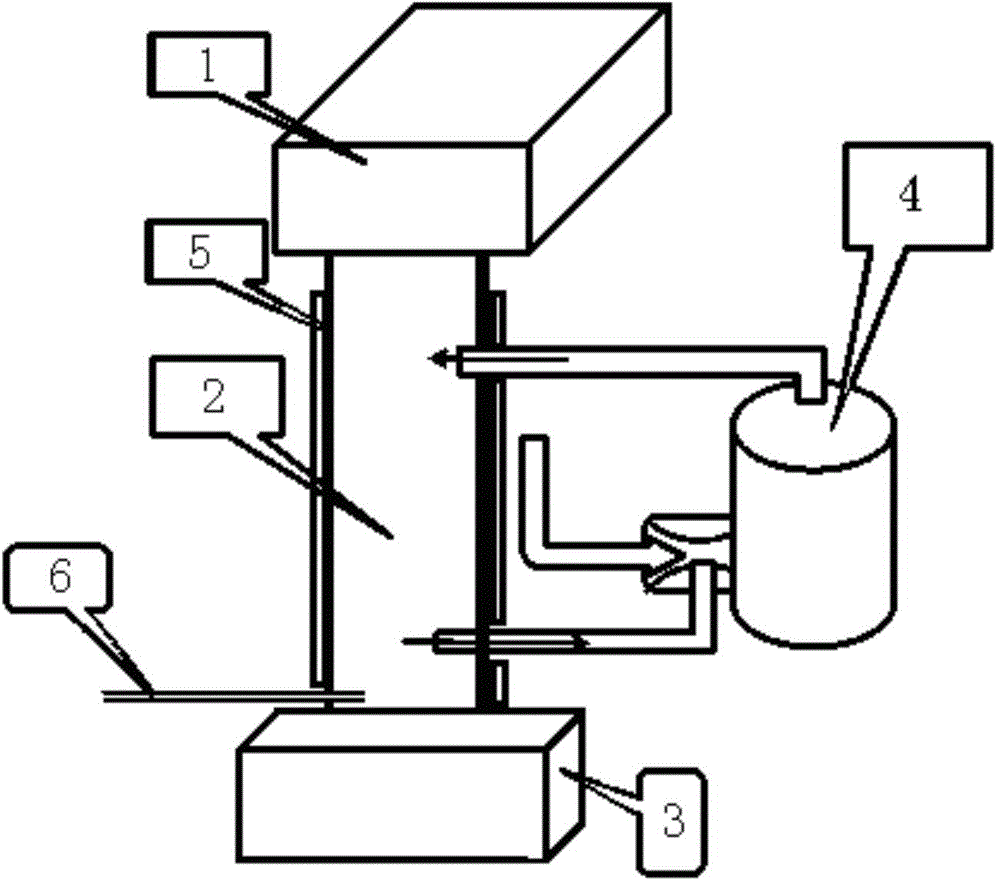

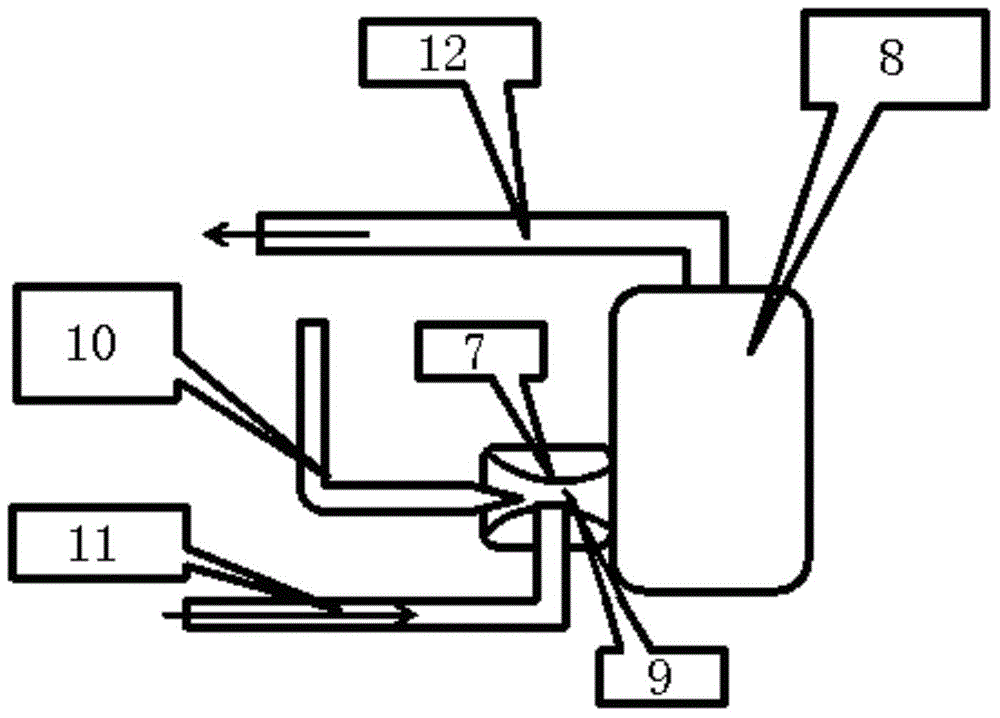

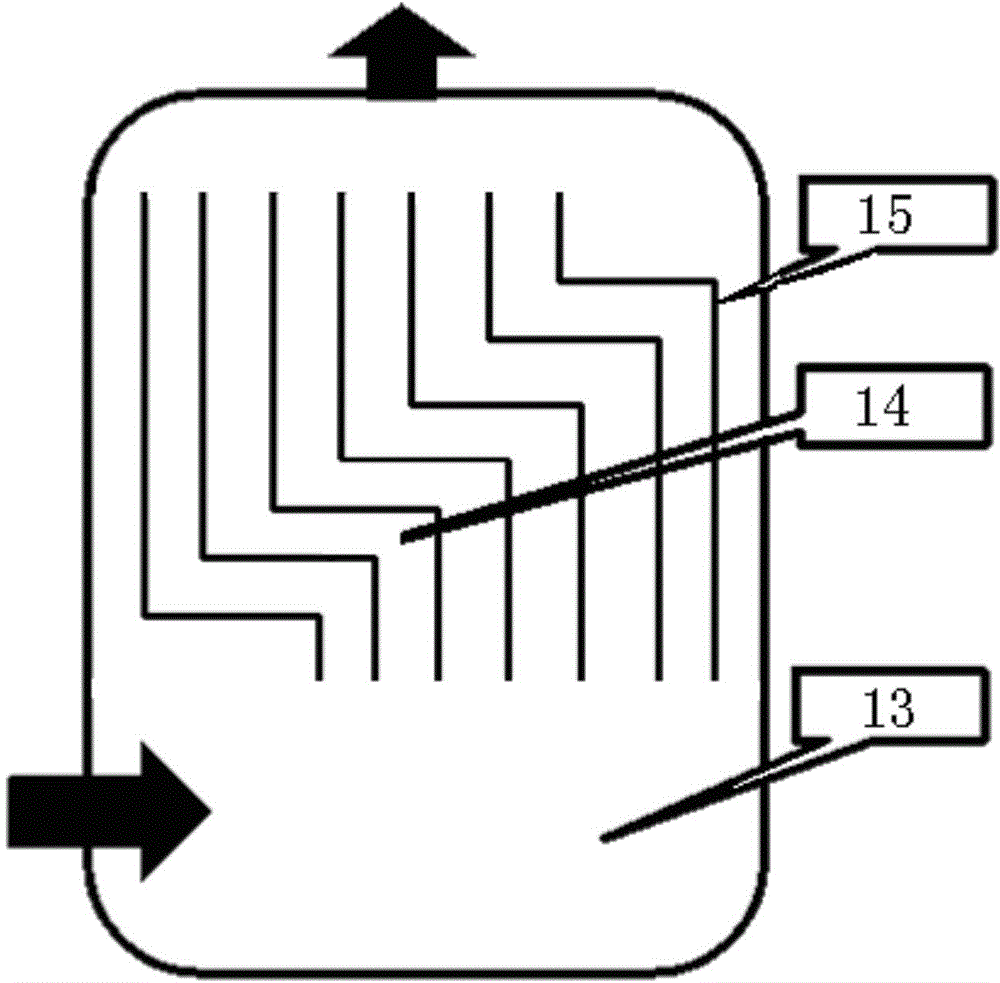

[0019] See figure 1 , is a structural schematic diagram of the implementation state of a hot-dip galvanized steel sheet manufacturing method without strip-shaped zinc ash and bright spot defects on the surface of the present invention. The annealing furnace 1 is connected to the zinc pot 3 through the furnace nose 2, and a condensation precipitation precipitation device is installed outside the furnace nose 2. 4. Create a negative pressure in the side area of the zinc pot in the furnace nose 2, and at the same time use a heater 5 on the side wall of the furnace nose to increase the temperature of the side wall of the furnace nose to 450-550°C, so that the zinc vapor above the zinc pot 3 is continuously sucked It cannot accumulate on the side wall of this area. The dew point range of nitrogen and hydrogen protective gas in the furnace nose 2 is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com