Efficient rotary hearth furnace direct reduction treatment process for zinc-containing dust and sludge in iron and steel plant

A treatment process and technology of rotary hearth furnace, which is applied in the field of direct reduction treatment process of high-efficiency rotary hearth furnace containing zinc dust and sludge in iron and steel plants, can solve the problems of lack of large-scale popularization and application, affecting the forward running and life of blast furnace, and high production cost, Achieve the effect of improving reduction efficiency and metallization rate, low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

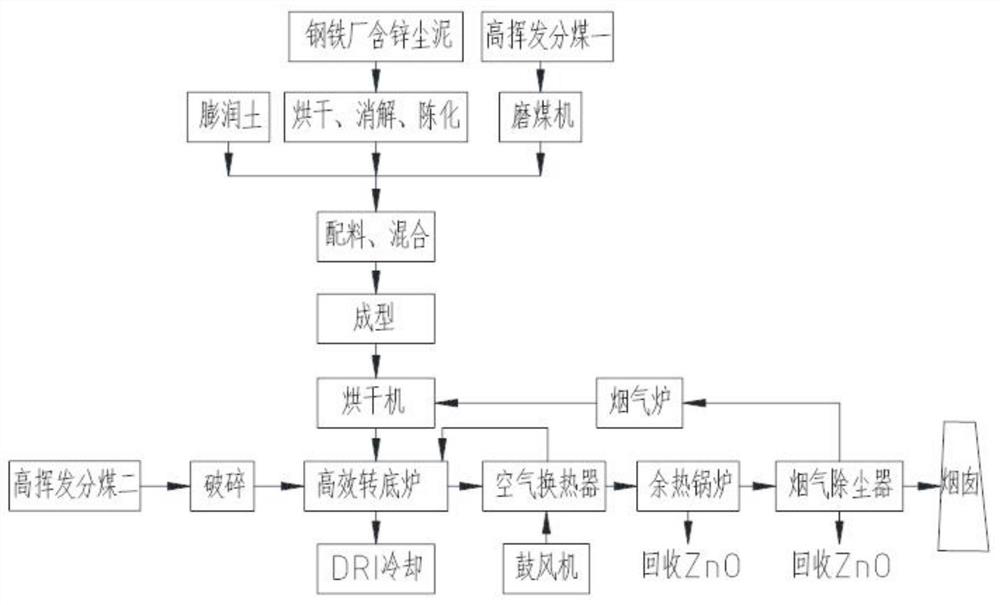

[0039] The zinc-containing dust contains 41.51wt% of TFe, 13.09wt% of C, 2.84wt% of Zn, 5.2wt% of SiO2, 8.84wt% of CaO and 0.59wt% of Cl. see figure 1 Shown, a kind of high-efficiency rotary hearth furnace direct reduction treatment process of zinc-containing dust sludge in iron and steel plant, comprising:

[0040] (1) Raw material treatment: Send the sludge to the dryer to dry until the water content is about 10%. The dried sludge is mixed with zinc-containing dust and then sent to the batching room silo for digestion and aging. Select high-volatile coal with a volatile content of 30-50% and an ash content <10%, and divide it into two parts, grind the high-volatile coal to a particle size of 100-200 mesh, and crush the high-volatile coal to a particle size of 5-25mm .

[0041](2) Batching and mixing: select 100 parts of zinc-containing dust, 12 parts of high-volatile coal, and 2 parts of bentonite, and mix them evenly after proportioning.

[0042] (3) Forming: prepare the...

Embodiment example 2

[0048] The zinc-containing dust contains 41.51wt% of TFe, 13.09wt% of C, 2.84wt% of Zn, 5.2wt% of SiO2, 8.84wt% of CaO and 0.59wt% of Cl. see figure 1 Shown, a kind of high-efficiency rotary hearth furnace direct reduction treatment process of zinc-containing dust sludge in iron and steel plant, comprising:

[0049] (1) Raw material treatment: Send the sludge to the dryer to dry until the water content is about 10%. The dried sludge is mixed with zinc-containing dust and then sent to the batching room silo for digestion and aging. Select high-volatile coal with a volatile content of 30-50% and an ash content <10%, and divide it into two parts, grind the high-volatile coal to a particle size of 100-200 mesh, and crush the high-volatile coal to a particle size of 5-25mm .

[0050] (2) Batching and mixing: select 100 parts of zinc-containing dust, 15 parts of high-volatile coal, and 3 parts of bentonite, mix according to the proportion of ingredients.

[0051] (3) Forming: pre...

Embodiment 3

[0057] The zinc-containing dust contains 41.51wt% of TFe, 13.09wt% of C, 2.84wt% of Zn, 5.2wt% of SiO2, 8.84wt% of CaO and 0.59wt% of Cl. see figure 1 Shown, a kind of high-efficiency rotary hearth furnace direct reduction treatment process of zinc-containing dust sludge in iron and steel plant, comprising:

[0058] (1) Raw material treatment: Send the sludge to the dryer to dry until the water content is about 10%. The dried sludge is mixed with zinc-containing dust and then sent to the batching room silo for digestion and aging. Select high-volatile coal with a volatile content of 30-50% and an ash content <10%, and divide it into two parts, grind the high-volatile coal to a particle size of 100-200 mesh, and crush the high-volatile coal to a particle size of 5-25mm .

[0059] (2) Batching and mixing: select 100 parts of zinc-containing dust, 15 parts of high-volatile coal, and 3 parts of bentonite, mix according to the proportion of ingredients.

[0060] (3) Forming: pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com