Low NOx combustor allowing cross-load regulation and used for biomass or pulverized coal

A load regulation and biomass technology, applied in combustion equipment, lighting and heating equipment, etc., can solve the problems of complex combustion devices and consumption of external fuels, and achieve the effects of maintaining combustion efficiency, promoting reduction reactions, and reducing NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

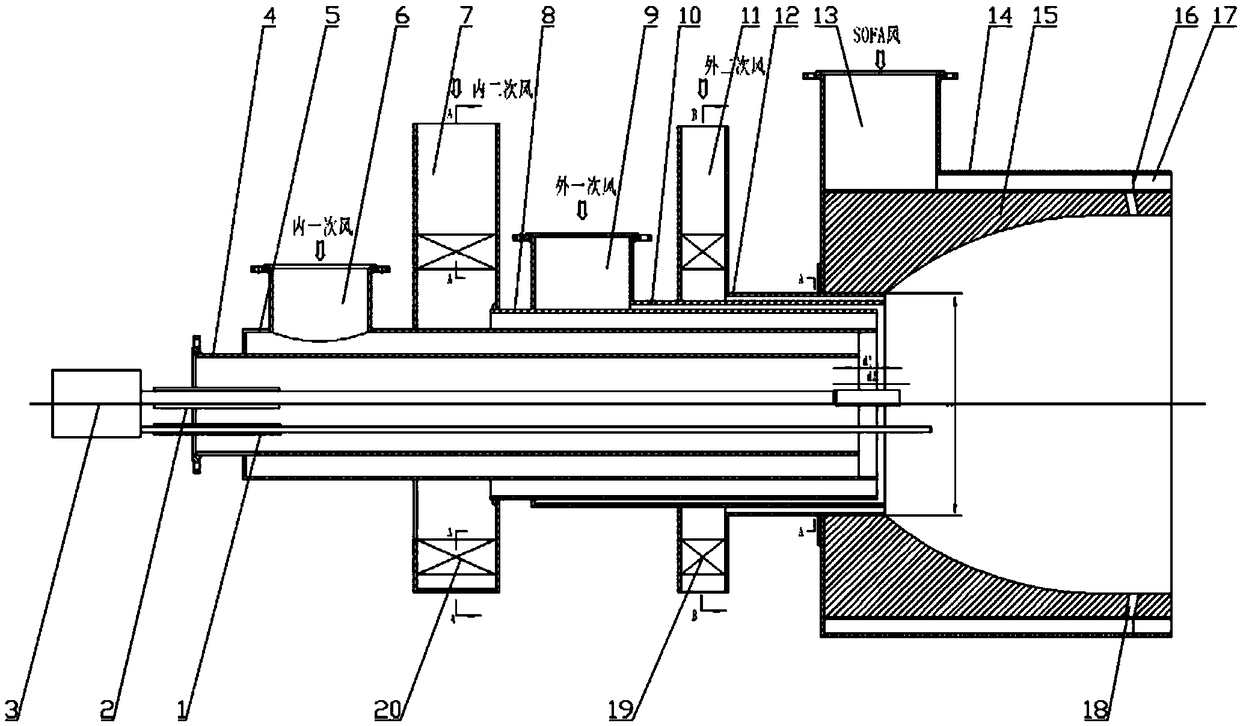

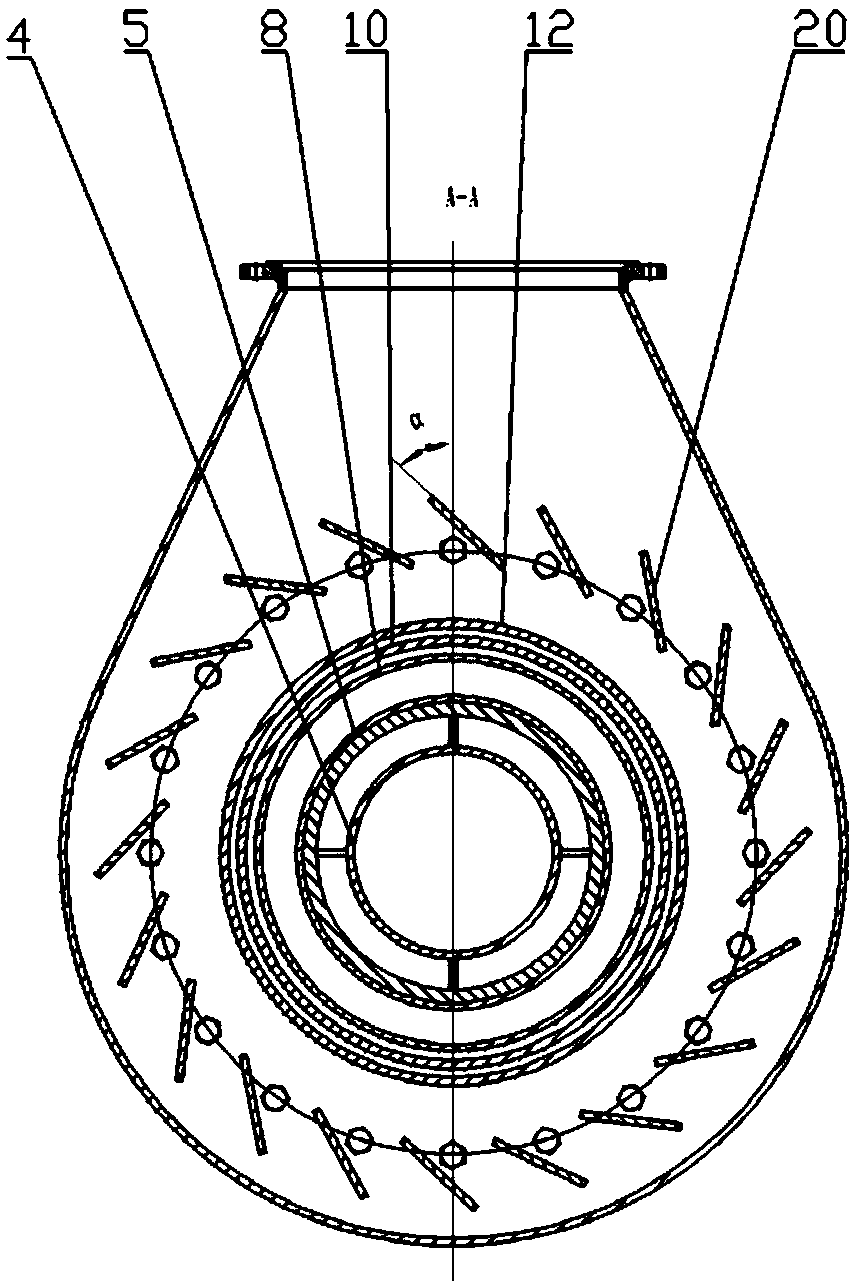

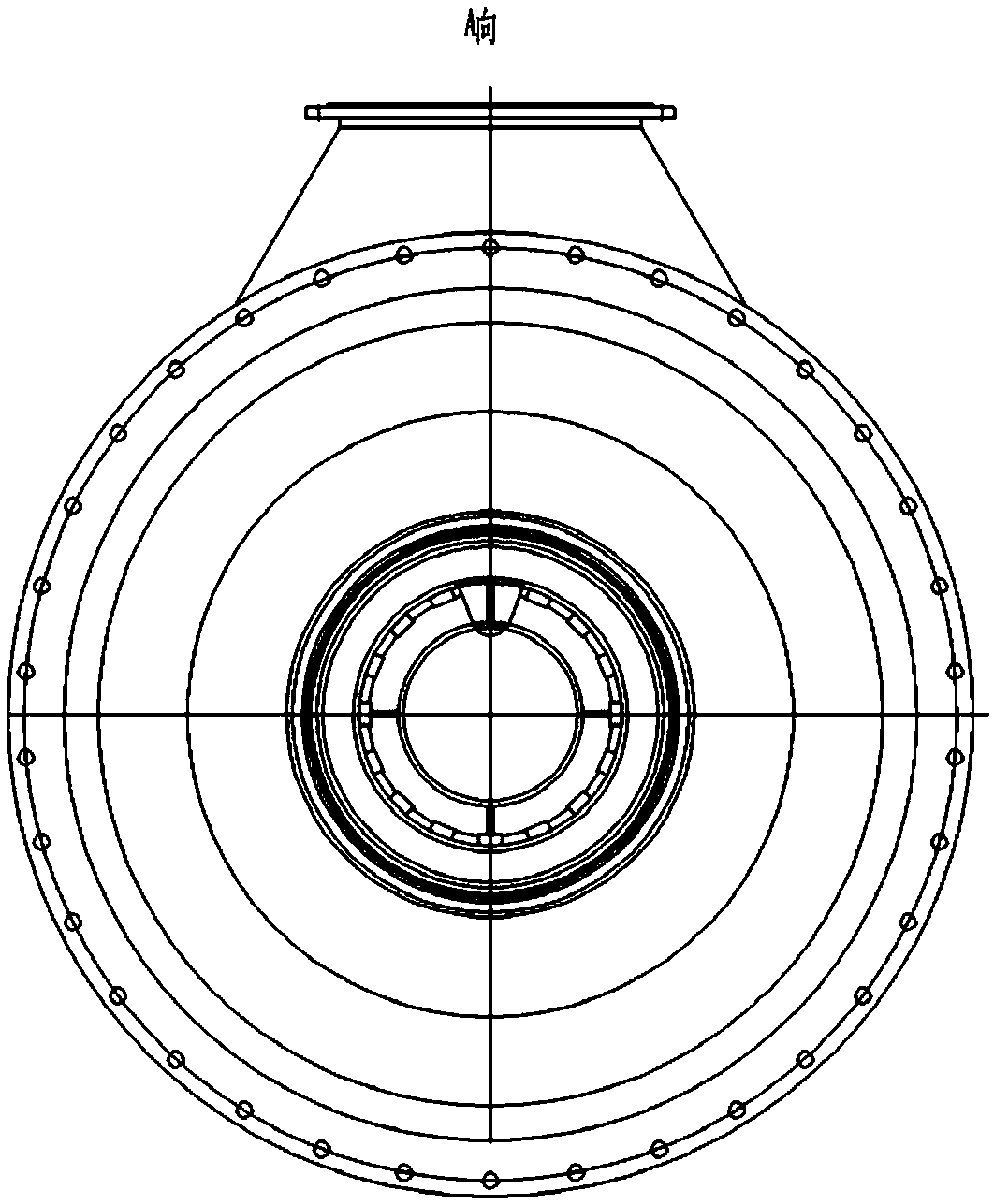

[0035] see Figure 1-Figure 5 , the invention can be used for low NO with biomass or pulverized coal adjustable across load x The burner includes a pre-combustion chamber surrounded by a pre-chamber housing 15, and the periphery of the combustion chamber is connected to an outer secondary air sleeve 12; the outer side of the pre-chamber housing 15 is covered with a SOFA air sleeve 14, and the The outer edge of the end of 15 is provided with 12 SOFA air flow nozzles 17 and 12 SOFA air swirl flow nozzles 18 symmetrically along the circumference of the outlet axis of the pre-combustion chamber. The entrance of the pre-chamber is fitted with a central pipe 4 , an inner primary air sleeve 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com