Method and computer unit for determining fill level of exhaust gas component in catalytic converter

A technology of filling level and calculation unit, which is applied in the direction of electric control of exhaust treatment device, diagnostic device of exhaust treatment device, exhaust treatment, etc., to achieve the effect of effective combustion process and effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

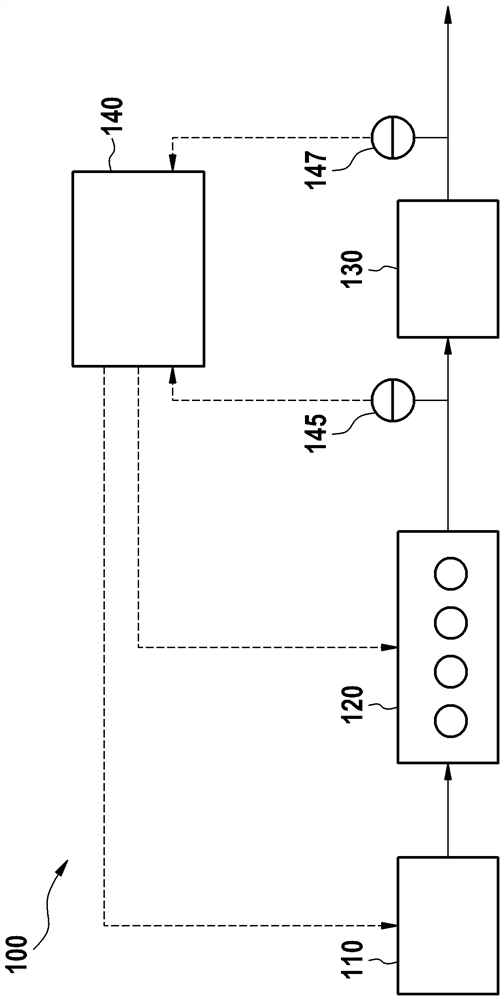

[0025] exist figure 1 In , a device is shown schematically and designated generally by 100 , which is set up to carry out an advantageous embodiment of the method according to the invention and which can be arranged, for example, in a vehicle.

[0026] The device 100 comprises: an internal combustion engine 120, such as a diesel engine or a gasoline engine; a fuel treatment device (Kraftstoffaufbereitungsvorrichtung) 110; an exhaust gas catalytic converter 130, which can be configured, for example, as a three-way catalytic converter; a computing unit 140, such as an engine control unit equipment (ECU); and sensors 145, 147 provided for example in the form of lambda sensors, thermocouples, pressure sensors and / or measuring devices for concentration, temperature, pressure or other physical or chemical variables , the additional physical or chemical variable may describe or influence the state of the exhaust system.

[0027] In particular, the invention makes use of the modeling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com