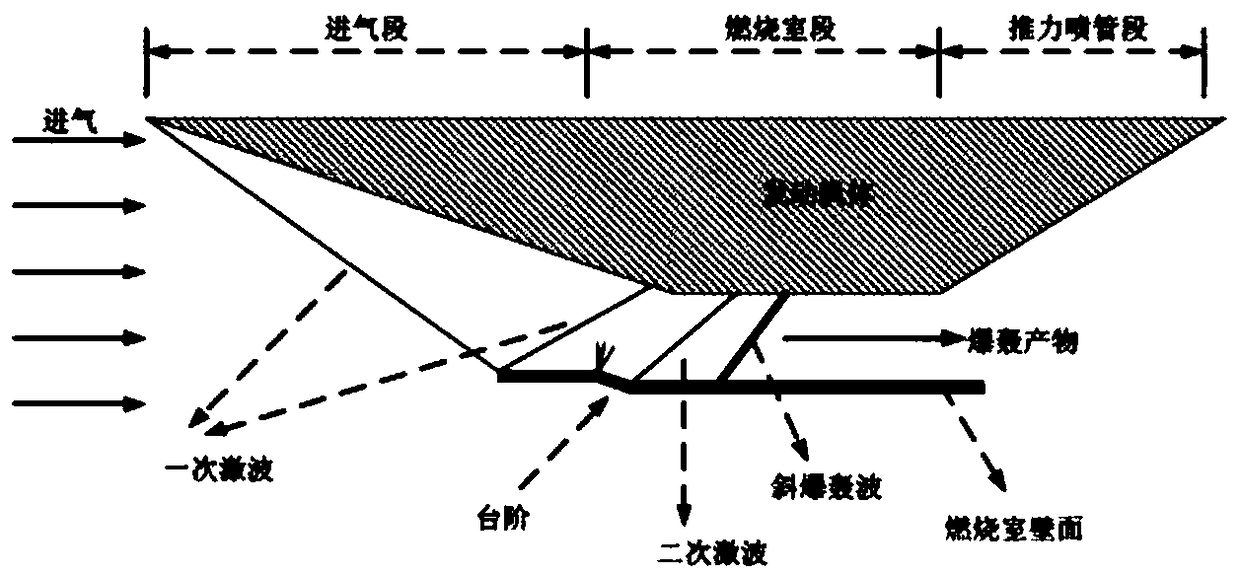

Combustion chamber for controlling detonation initiation position in oblique detonation engine

A combustion chamber and detonation technology, applied in the field of combustion chambers, can solve the problems of unfavorable stable detonation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

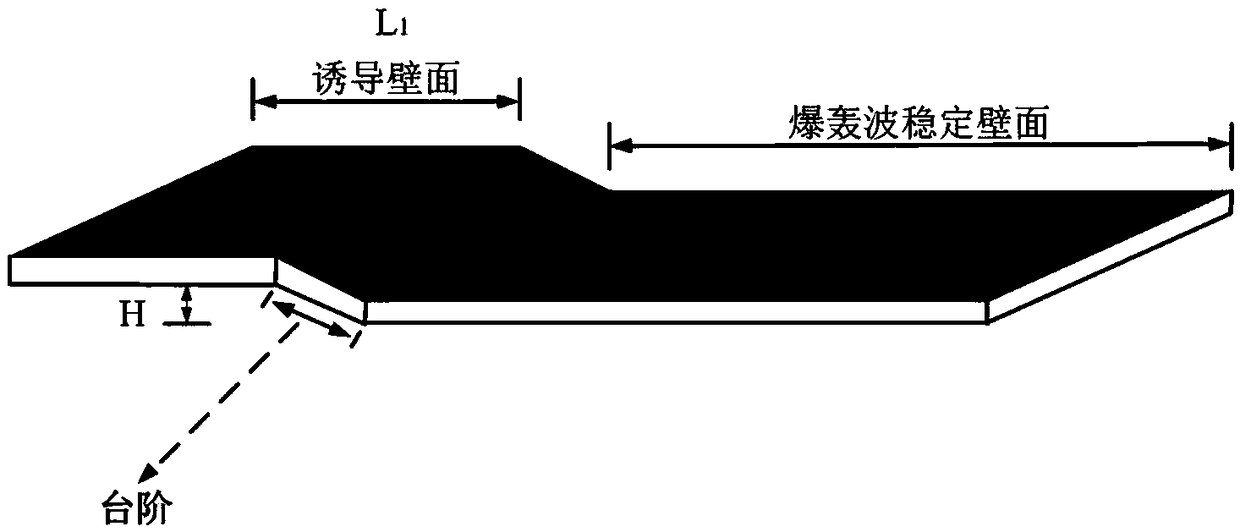

[0015] A combustion chamber for controlling the initiation position of the internal detonation in oblique detonation. The combustion chamber is applied to an oblique detonation engine. The wall of the combustion chamber is provided with slope steps extending outward along the circumference. The front side of the step is an induced wall surface and the rear The side is a detonation stable wall, and the slope slides along the plane where the wall of the combustion chamber is located. figure 1 The left side of the middle step is the front side of the step.

[0016] The included angle between the induced wall and the step, and the included angle between the step and the detonation stable wall are determined according to the overall design of the actual engine.

[0017] The length of the induced wall and the length of the step are determined according to the overall design of the actual engine.

[0018] The way the steps slide along the detonation stable wall is determined by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com