A method for improving the heat uniformity of pre-sintering process

A pre-sintering and process technology, applied in the field of improving the thermal uniformity of the pre-sintering process, can solve the problems of unevenness, different macroscopic moisture content, and the inability to fundamentally improve the permeability of the sintering process, and achieve improved quality, obvious quality, and fuel consumption. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

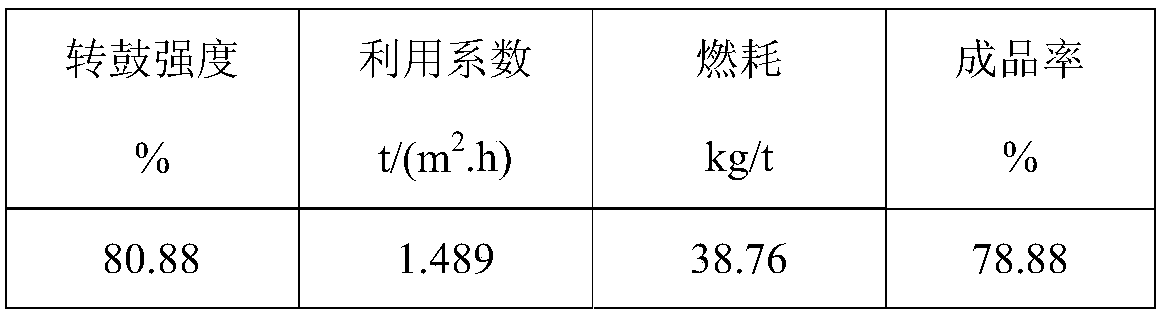

[0018] During the sintering production process, the sintering mixture is distributed twice, the first distribution is the lower layer sintering mixture distribution, the second is the upper layer sintering mixture distribution, first the lower layer sintering mixture distribution is carried out, and the thickness of the distribution is 600mm, the water content of the lower layer of sintering mixture is controlled at 6.3%, ignited, after pre-sintering for 12min, on the surface of the sintered ore being sintered, the second upper layer of sintering mixture is laid out, the thickness of the cloth is 500mm, the The water content of the upper sintering mixture is controlled at 8.2%; then ignition and sintering is carried out again, the sum of the thickness of the total material layer is ≥1000mm, and the finished sintered ore is obtained until the end of sintering. The indicators of the sintering test in Example 1 of the present invention are shown in Table 1.

[0019] The upper and...

Embodiment 2

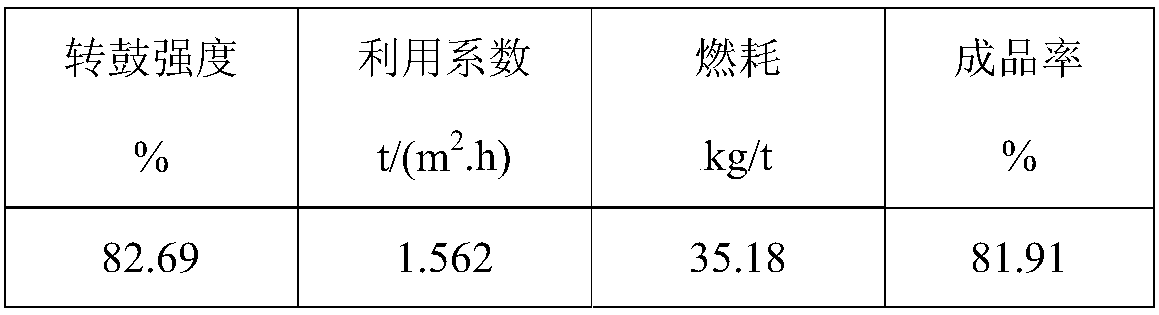

[0024] During the sintering production process, the sintering mixture is distributed twice, the first distribution is the lower layer sintering mixture distribution, the second is the upper layer sintering mixture distribution, first the lower layer sintering mixture distribution is carried out, and the thickness of the distribution is 800mm, the water content of the lower layer of sintering mixture is controlled at 6.6%, ignited, after pre-sintering for 12 minutes, on the surface of the sintered ore being sintered, the second upper layer of sintering mixture is distributed, and the thickness of the cloth is 400mm. The water content of the upper sintering mixture is controlled at 7.2%; then ignition and sintering is carried out again, the sum of the thickness of the total material layer is ≥1000mm, and the finished sintered ore is obtained until the end of sintering. The indicators of the sintering test of Example 2 of the present invention are shown in Table 2.

[0025] The u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com