Pole piece and isolating membrane thermal compounding equipment

A separation film and thermal lamination technology, which is applied to electrical components, non-aqueous electrolyte batteries, circuits, etc., to achieve the effect of improving the quality of thermal roll lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

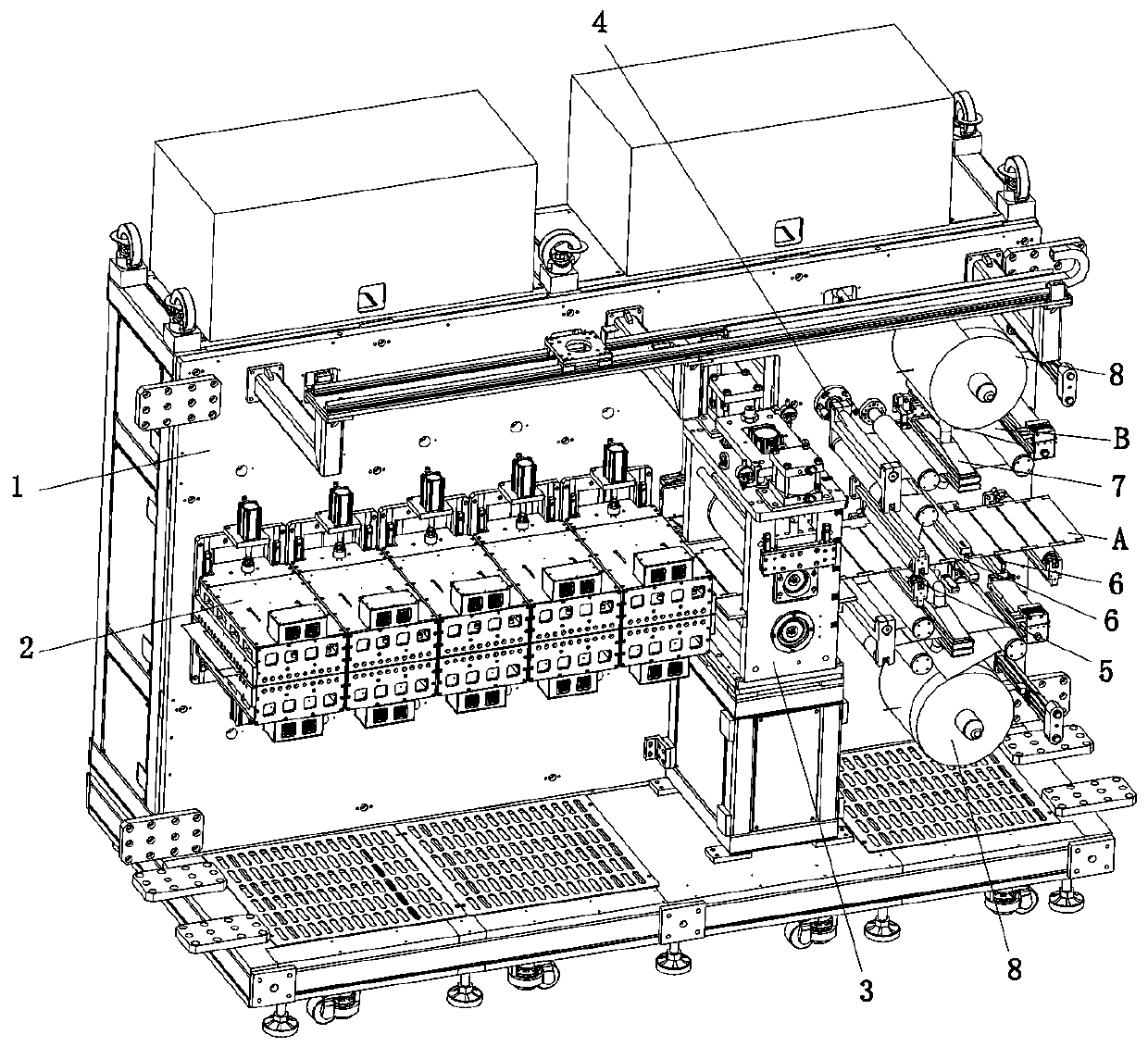

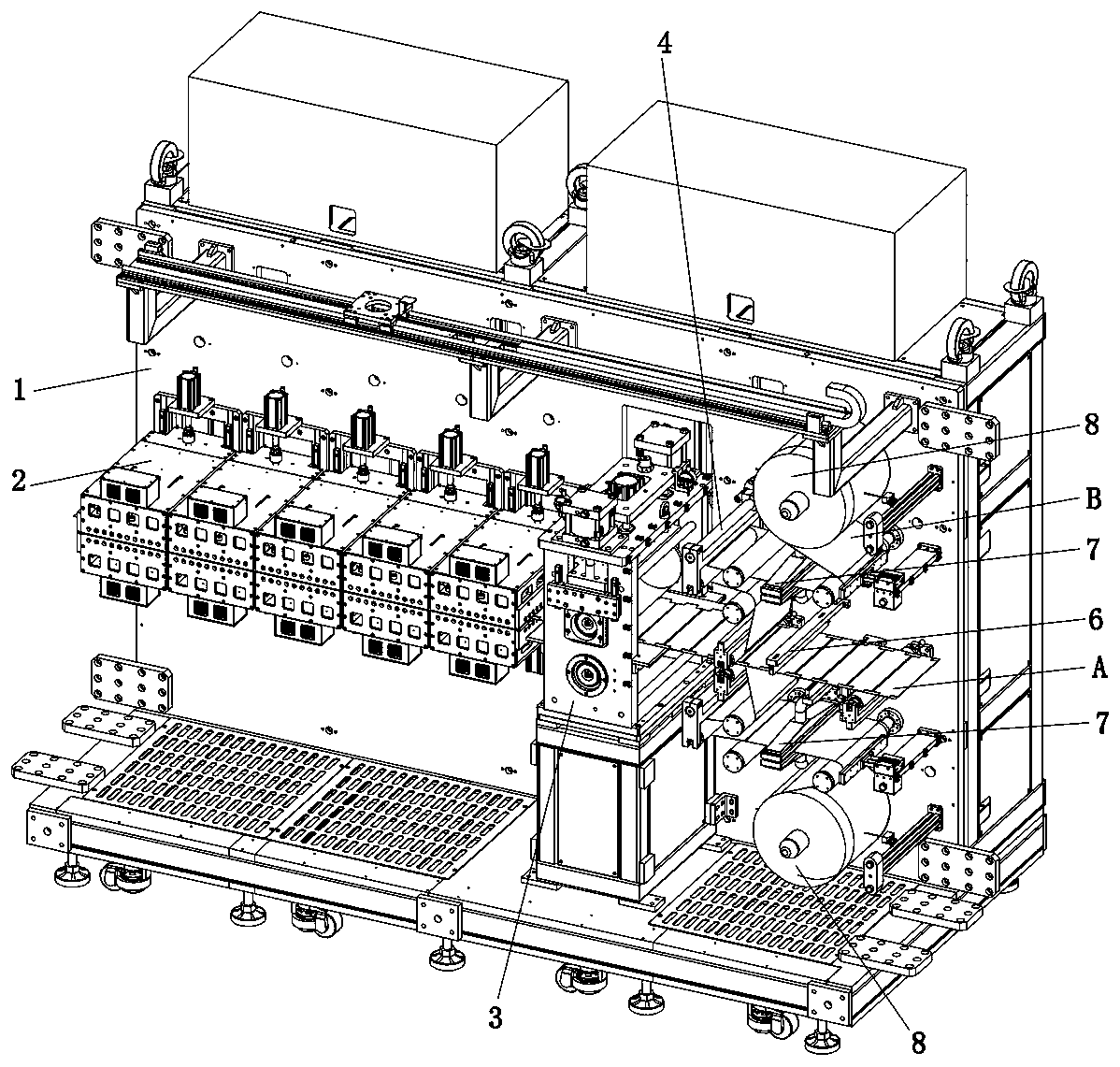

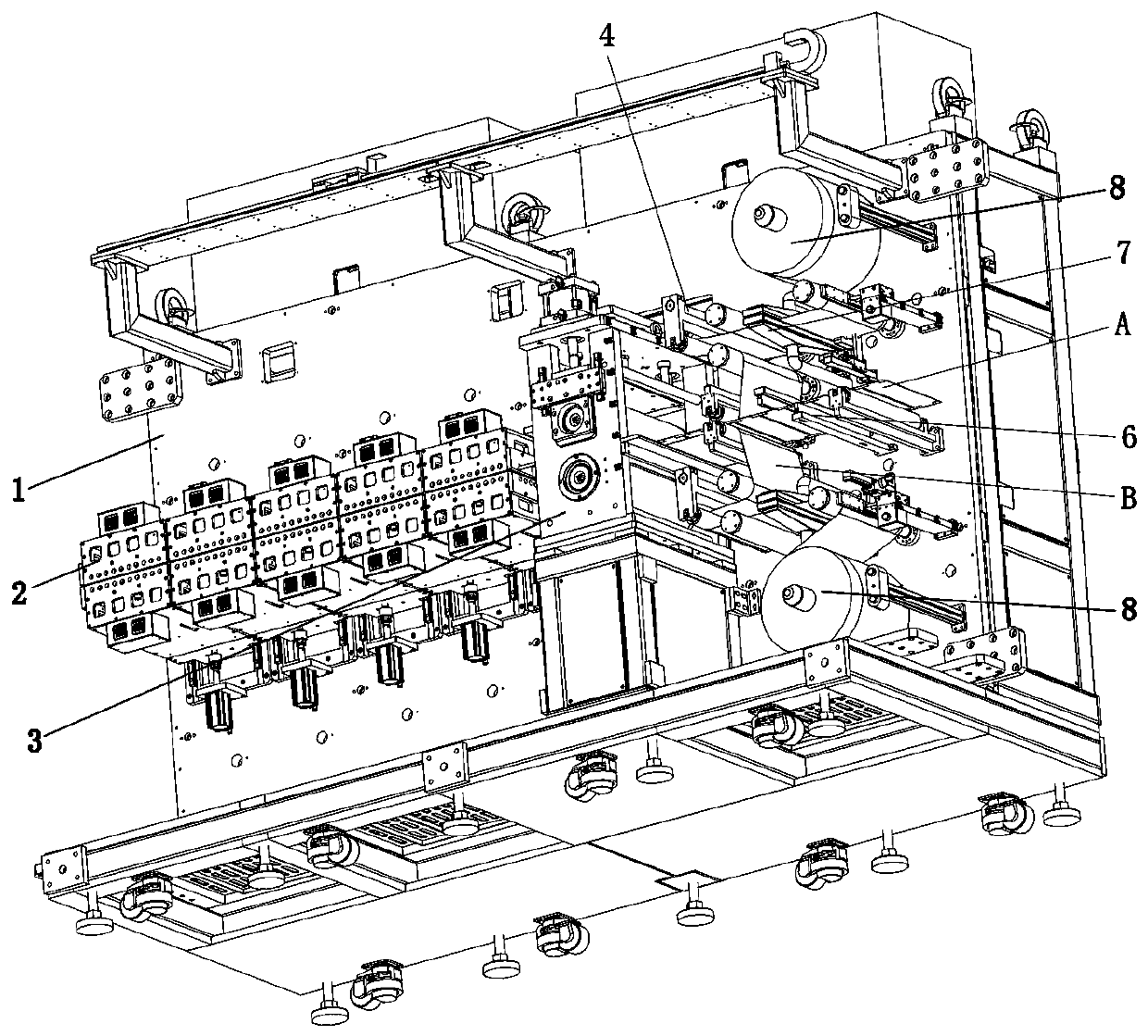

[0034] The present invention will be further described below in conjunction with accompanying drawing:

[0035] Such as Figure 1 to Figure 10 As shown, the technical solution adopted by the present invention is as follows: a pole piece and separator thermal compound equipment, including a preheating mechanism 2, a hot rolling mechanism 3, a connecting rod tensioning mechanism 4, a shaping roller 5, a magnetic strip 6, a suction The dust chamber 7 and the rewinding volume 8, wherein, the above-mentioned preheating mechanism 2 includes at least two sets, and the preheating mechanisms 2 are arranged side by side on the side wall of the frame 1 in sequence, and a horizontal preheating gap is formed in the preheating mechanism 2. The film-coated pole piece A moves forward linearly through the preheating gap; the above-mentioned hot rolling mechanism 3 is arranged on the side of the preheating mechanism 2, and when the preheated film-coated pole piece A passes through the hot rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com