Built-in tire pressure sensor

A tire pressure sensor, built-in technology, applied in tire measurement, tire parts, transportation and packaging, etc., can solve the problems of low product versatility, inability to meet assembly requirements of different arc assembly interfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

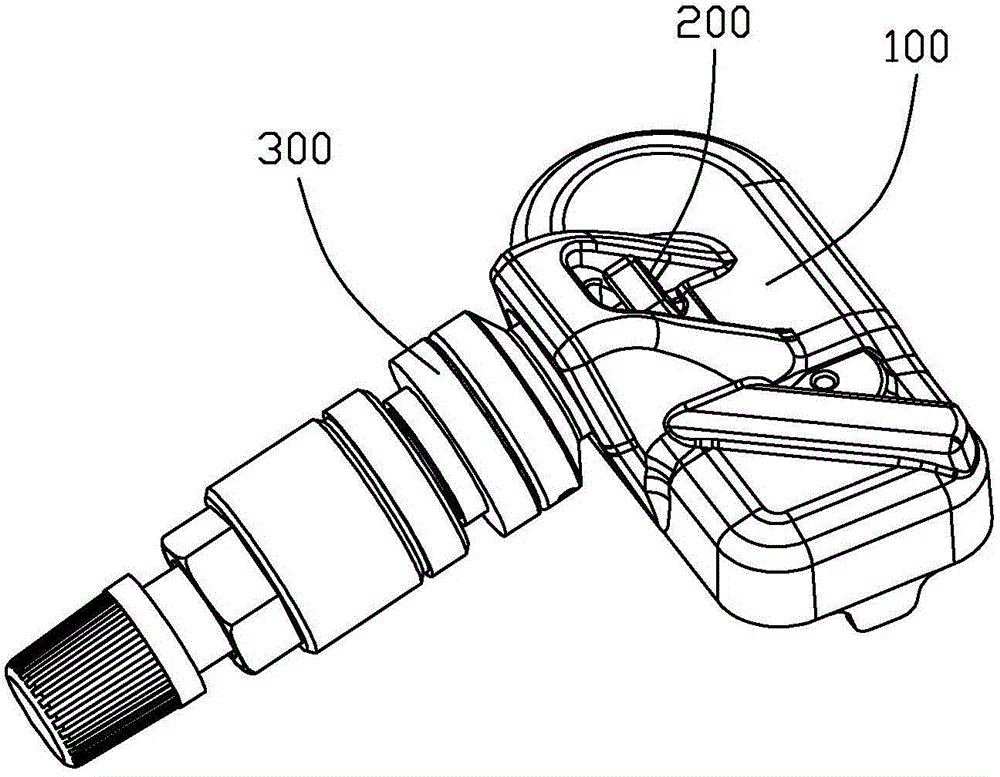

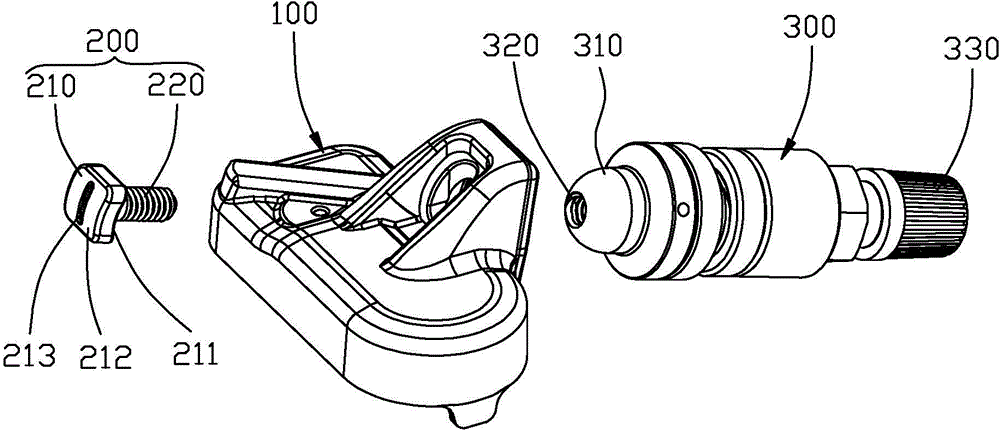

[0016] Such as figure 1 and figure 2 As shown, the built-in tire pressure sensor 100 of the present invention is installed in the vehicle tire and is fixedly connected with the valve 300 on the tire through a fixing member 200, and can be rotated relative to the valve 300 to adjust the installation angle, so as to adapt to different vehicle tires. Installation requirements.

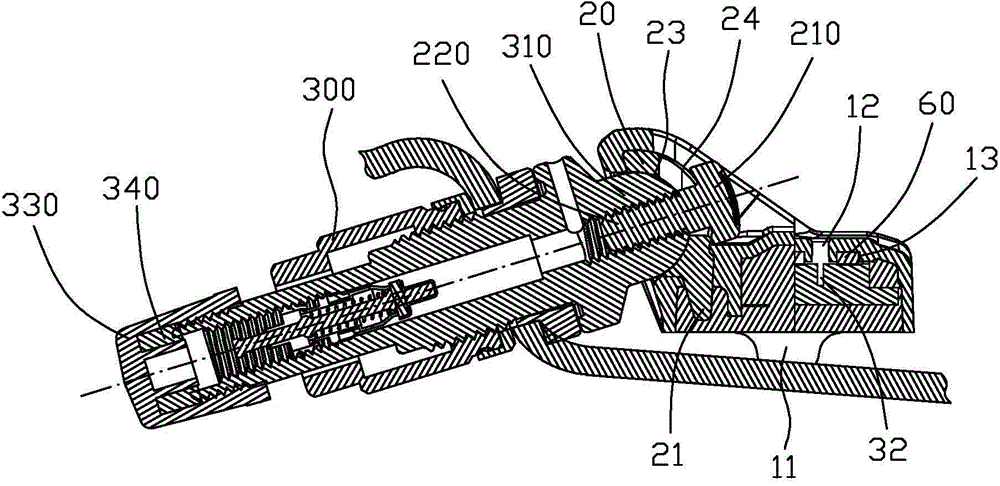

[0017] Please also see image 3 , the valve 300 is generally a hardware product, the inner end 310 of the valve 300 is connected to the tire pressure sensor 100 , the inner end 310 is hemispherical, and a fixing hole 320 is formed on the inner end 310 to connect with the fixing member 200 . In this embodiment, the fixing part 200 is a non-standard part, including a head 210 and a screw 220 extending outward from the center of the head 210, the fixing hole 320 is a sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com