System and method for testing local resistance loss coefficient of flame arrester

A technology of local resistance and loss coefficient, which is applied in the testing of machines/structural components, testing of mechanical components, instruments, etc., and can solve problems such as the inability to measure local resistance loss and data errors of test gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

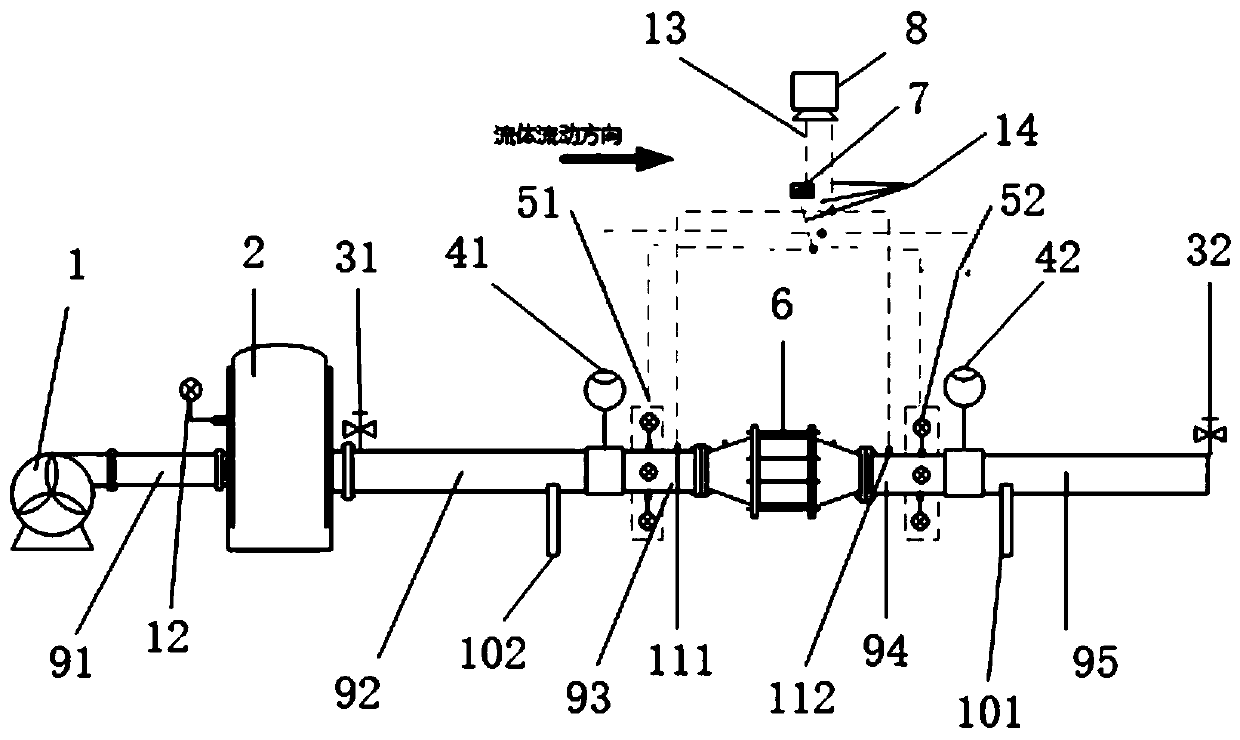

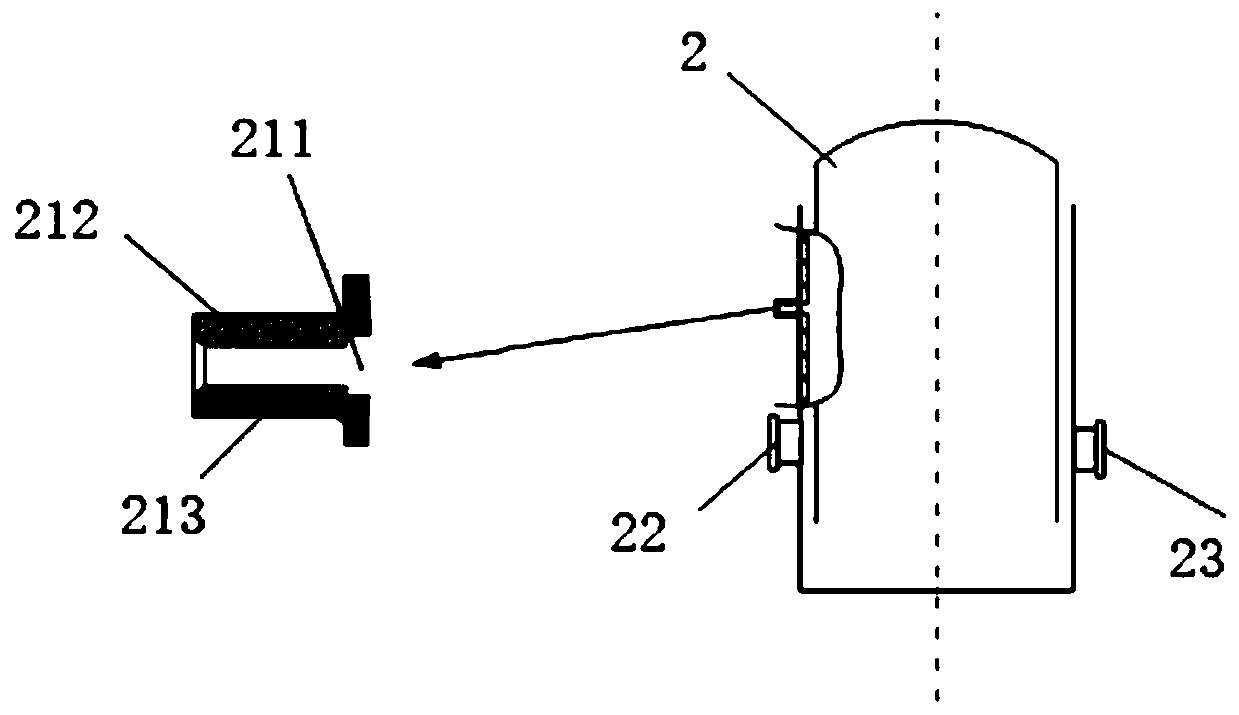

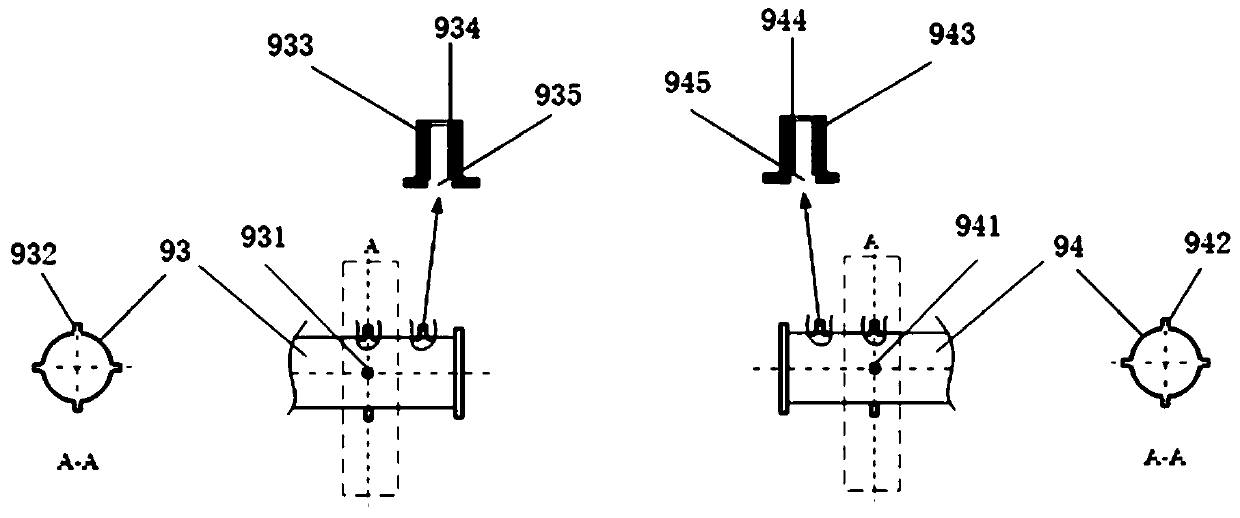

[0050] A test system for the local resistance loss coefficient of a flame arrester according to the present invention includes a mechanical structure unit and an electronic control data acquisition unit; the mechanical structure unit includes a fan 1, an air storage tank 2, a pipeline on-off valve 31, a flow regulator Valve 32, flame arrester 6, brackets 101, 102, test pipes 91, 92, 93, 94, 95 with the same diameter, unprotected side temperature sensor 111, protected side temperature sensor 112; the electronic control data acquisition unit includes unprotected Side flow meter 41, protection side flow meter 42, unprotected side pressure sensor 51, protection side pressure sensor 52, communication module 7, data processing server 8, gas tank positive and negative pressure gauge 12, network cable 13, signal shielding line 14;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com