Electric breast pump for pressure feedback control based on flexible pressure sensor

A pressure sensor and feedback control technology, applied in breast pumps, medical devices, and other medical devices, can solve problems such as poor accuracy, complicated structural settings of electric breast pumps, and insufficient sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

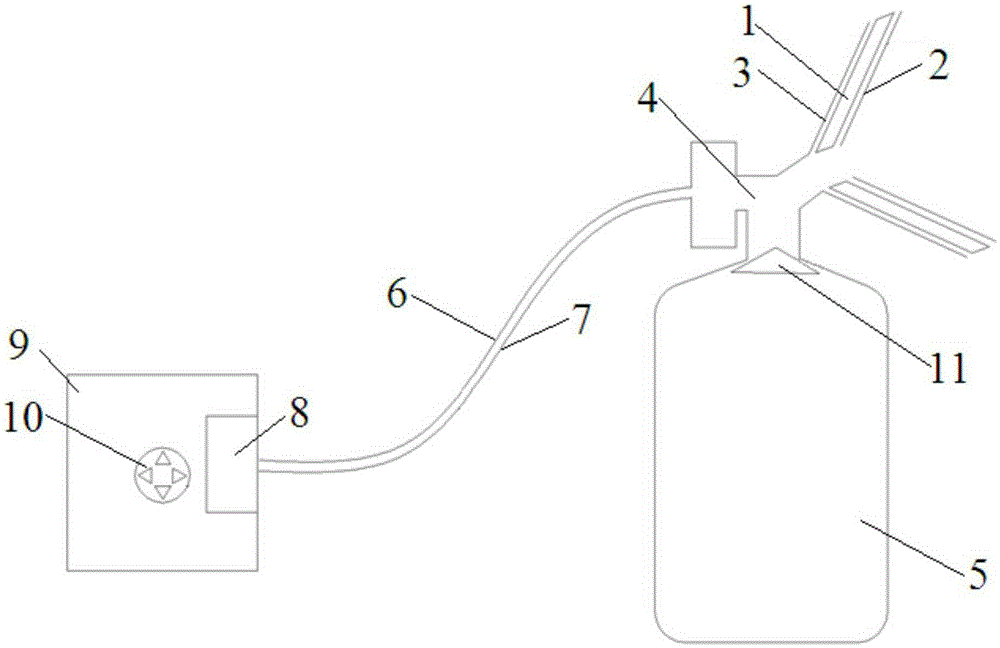

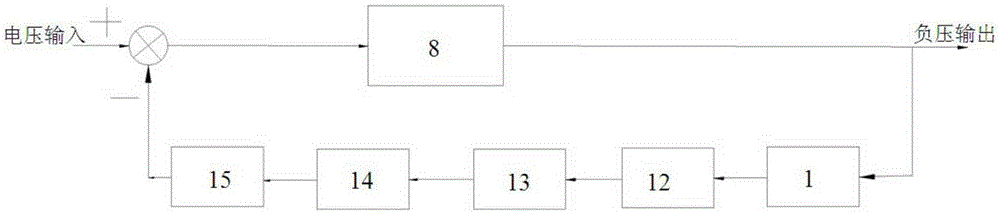

[0040] Such as figure 1 As shown, an electric breast pump based on a flexible pressure sensor for pressure feedback control includes a breast shield 3, a main body 4, an air suction pipe 6, a vacuum pump 8 and a control host 9, and the breast shield 3 is connected to the main body 4 , the main body 4 is connected to the vacuum pump 8 through the suction pipe 6, the vacuum pump 8 is set in the control host 9, the lower end of the main body 4 is used to connect the receiving container 5, and a piezoelectric film sensor 1 and a feedback unit are also provided, and the piezoelectric film sensor 1 is set In the inner side of the breast shield 3, the feedback unit is arranged inside the control host 9, and the piezoelectric film sensor 1 is connected with the feedback unit, and the piezoelectric film sensor 1 detects the negative pressure borne by the breast body surface tissue, and transmits it to the feedback unit, The feedback unit controls the suction force of the vacuum pump 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com