Spring pressurization closed type hydraulic oil tank with volume, pressure and leakage detecting function

A leakage detection and hydraulic oil tank technology, which is applied in the field of pressurized hydraulic oil tanks, can solve the problem of lack of closed oil tanks, and achieve the effect of less space and compact structure of the oil tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

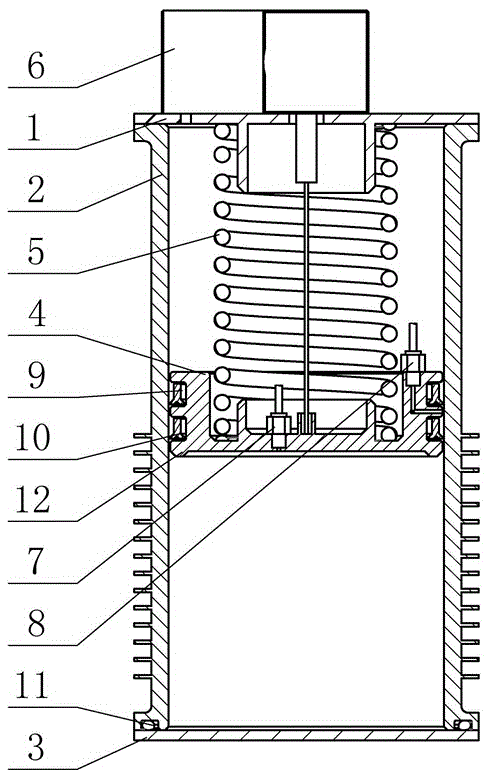

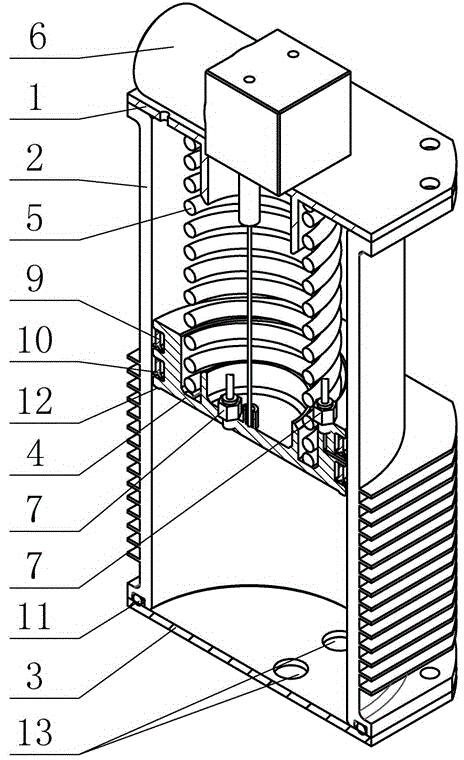

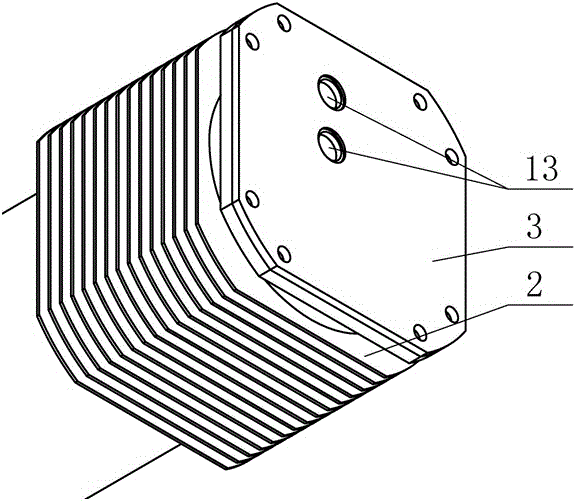

[0021] Such as figure 1 As shown, the present invention includes an upper plate 1, an oil tank barrel 2, a base plate 3 and a piston 4 assembled in the oil tank barrel 2, the top of the oil tank barrel 2 is connected to the upper plate 1, and the bottom end of the oil tank barrel 2 is connected and sealed with the base plate 3, and the piston A spring 5 is installed between 4 and the upper plate 1, and the fuel tank barrel, the bottom plate, the piston assembled in the fuel tank barrel and the corresponding sealing ring form a closed cavity to accommodate the hydraulic medium.

[0022] Such as figure 1 and figure 2 As shown, it also includes a pull wire sensor 6, the first miniature pressure sensor 7, the second miniature pressure sensor 8, the first piston seal ring 9, the second piston seal ring 10 and the bottom plate static seal ring 11; There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com