On-line monitoring system of substation low-oil equipment

A technology for monitoring systems and substations, applied to measuring devices, instruments, etc., can solve problems such as changes in operating parameters and less dissolved hydrogen monitoring technology, and achieve the effect of comprehensive parameters, convenient assembly process, and reliable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

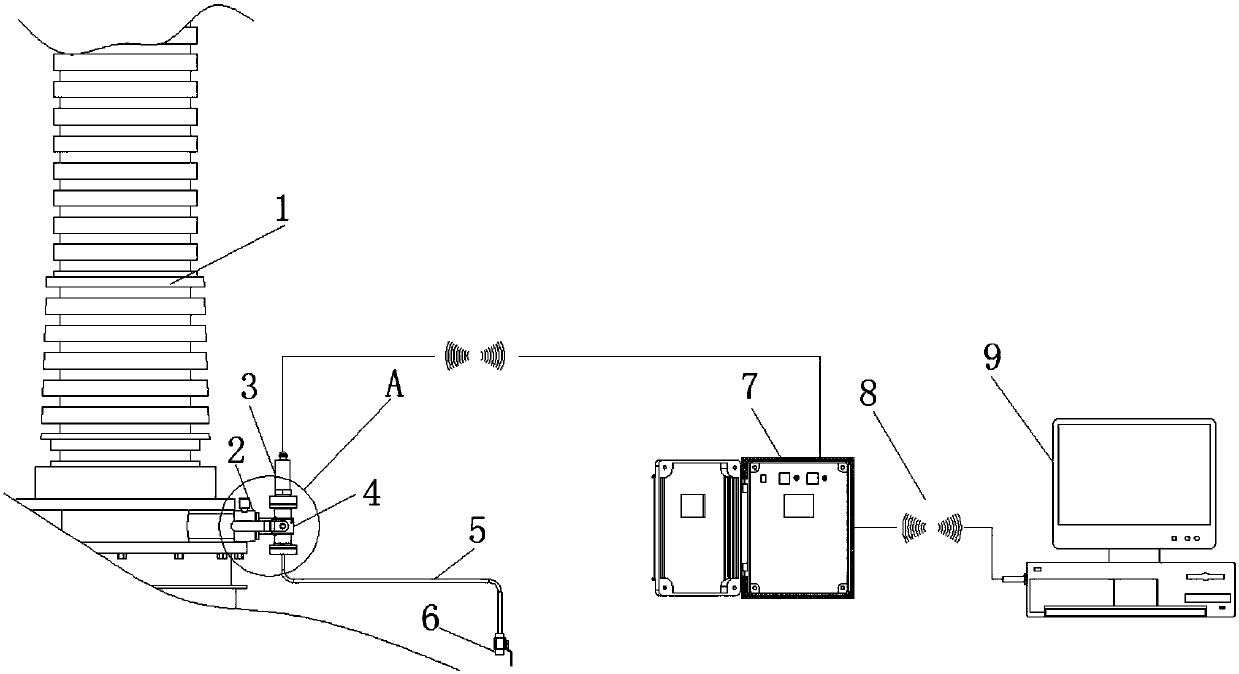

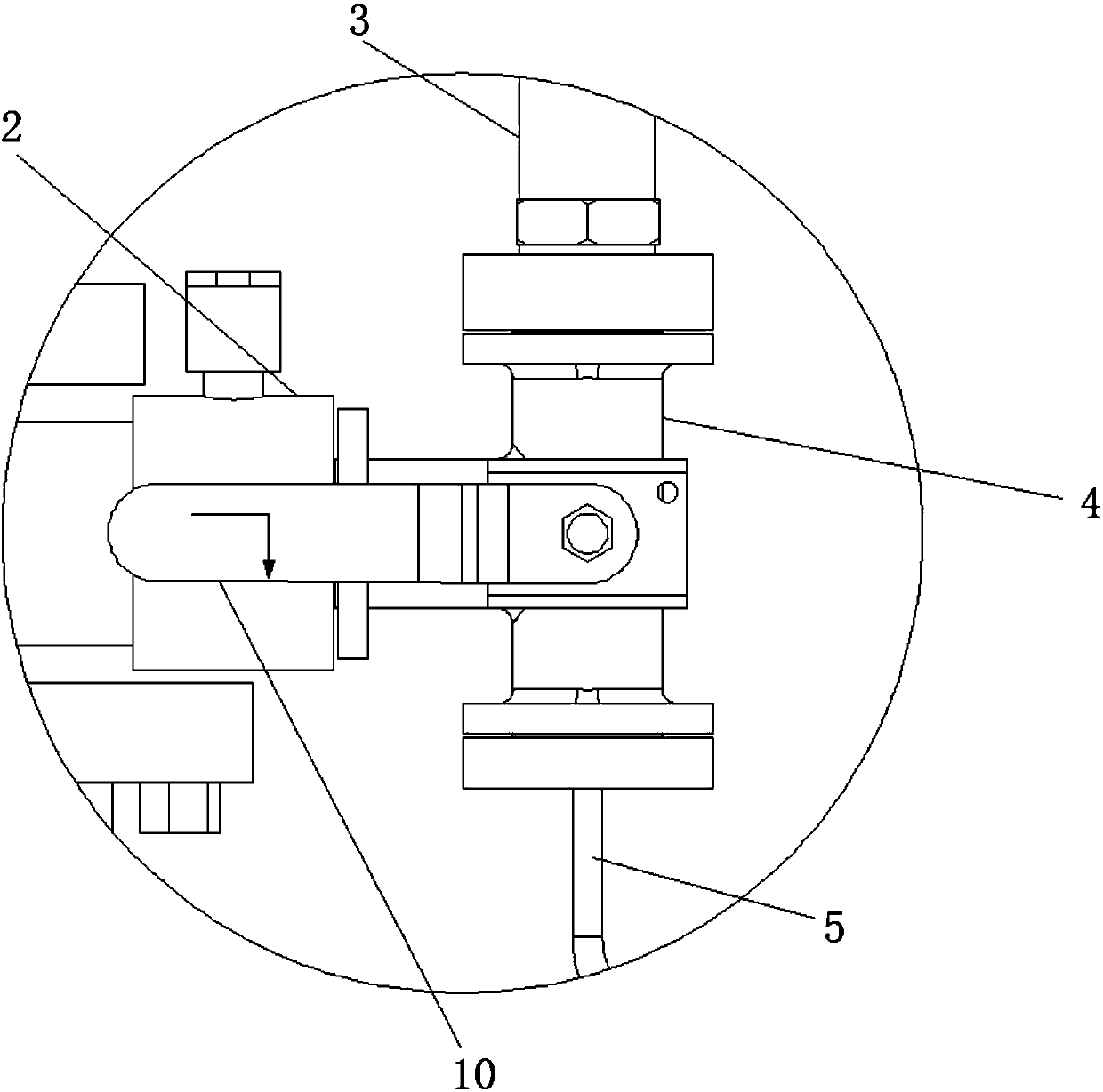

[0048] Such as Figure 1-14 As shown, it shows the specific implementation of the present invention, as shown in the figure, the online monitoring system of the substation oil-reducing equipment disclosed by the present invention, the oil-reducing equipment includes an oil discharge port, and includes an oil discharge port installed on the oil discharge port A tee 4; an inlet of the tee is connected with the oil discharge port (through the flange), and a monitoring sensor 3 and a down sampling pipe 5 are respectively installed on two outlets of the tee; the down sampling pipe is downward Extend, and install a sampling valve 6 at the end of the down-leading sampling pipe; a switching valve 10 for switching the inlet and the two outlets is installed on the tee;

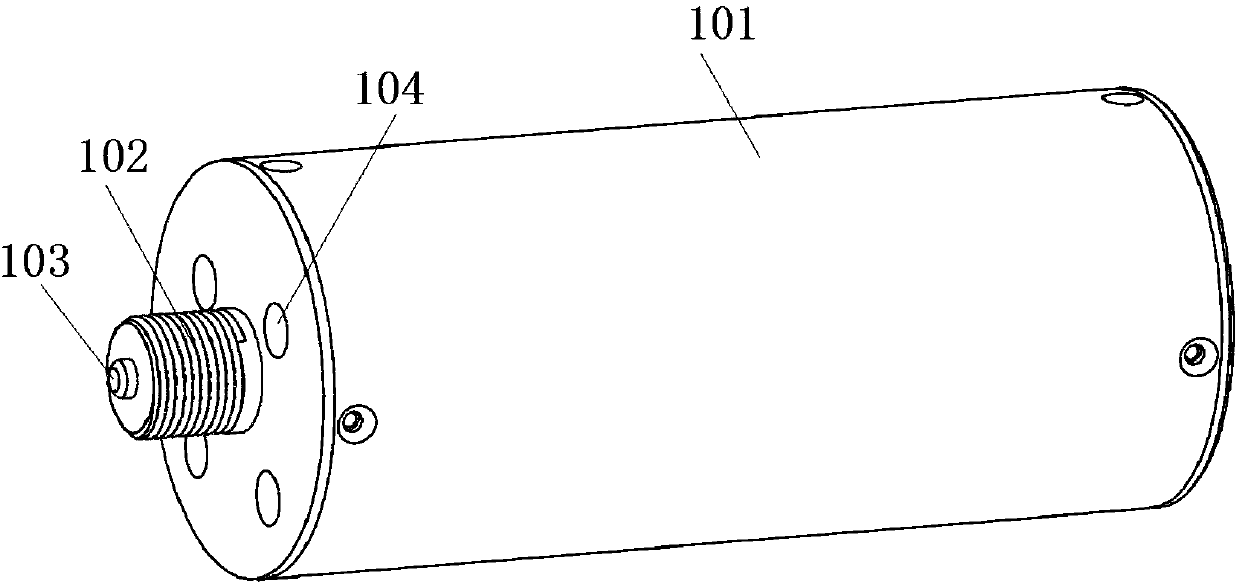

[0049] The monitoring sensor comprises a shell 101 of cylindrical structure, a bottom cover 112 is installed on the bottom of the shell, a top cover 113 is installed on the top of the shell, and the center of the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com