Automatic sampling detection device for pH meters of desulfurizing absorption towers in thermal power plants

A technology for desulfurization absorption towers and thermal power plants, applied in sampling devices, measuring devices, instruments, etc., can solve problems such as easy blockage of the pH meter measurement system, easy damage to electrodes, and inaccurate measurement, so as to prevent the abnormal influence of pH value Desulfurization efficiency, improve desulfurization efficiency, improve the effect of gypsum quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

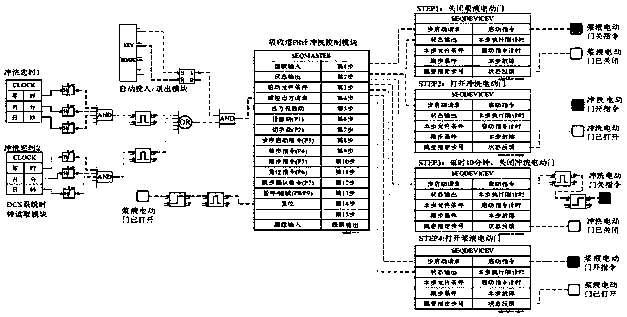

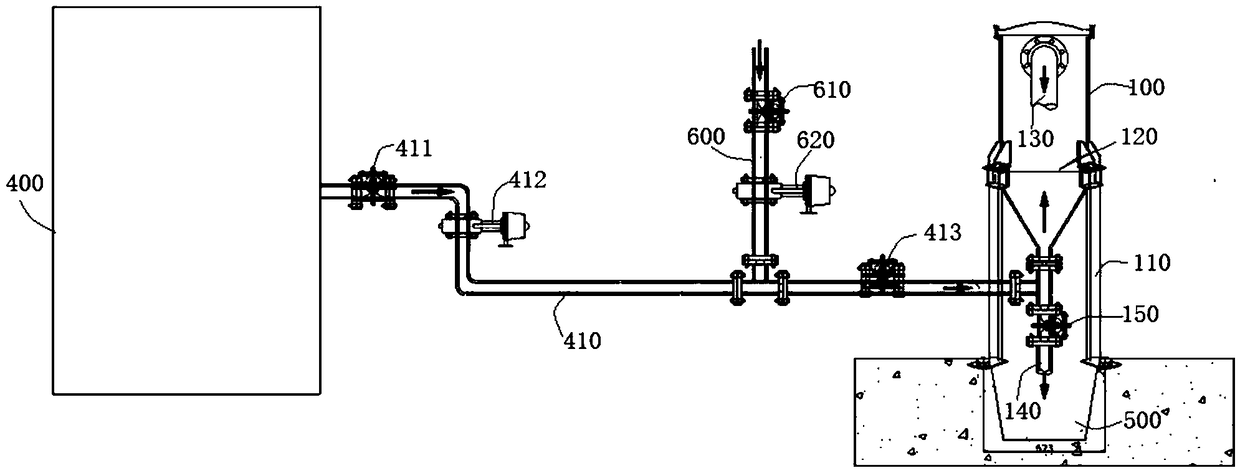

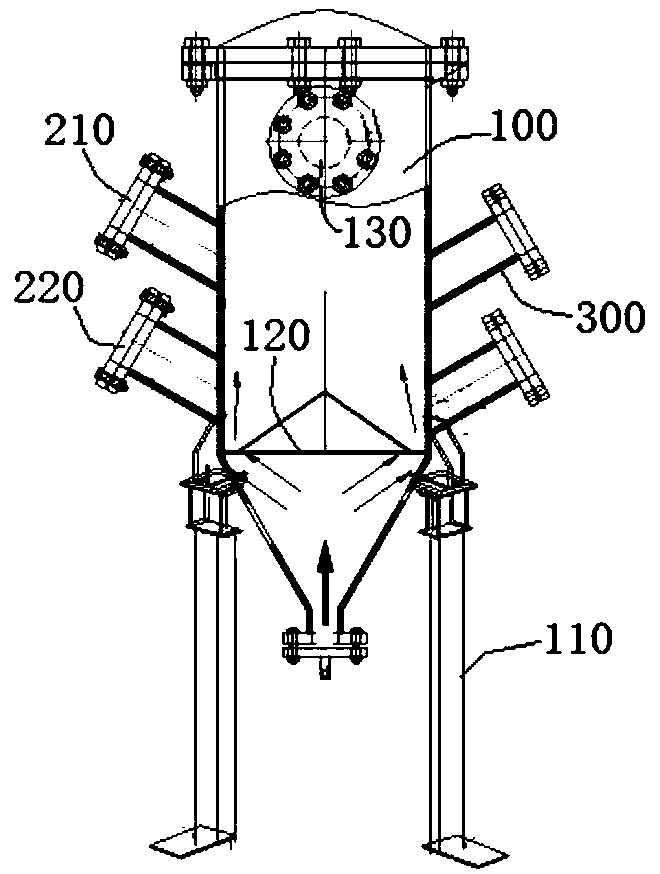

[0037] Such as Figure 1-Figure 5 As shown, a thermal power plant desulfurization absorption tower pH meter automatic sampling detection device of this embodiment includes a buffer tank 100 connected to the absorption tower 400 through a slurry inlet pipe 410, and the side wall of the buffer tank 100 is provided with an inclined insertion tank The first pH meter 210, the second pH meter 220 and the differential pressure transmitter 300 are integrated, the filter unit 120 is arranged in the lower part of the buffer tank 100, and the overflow pipe 130 is arranged on the upper side wall of the buffer tank 100. In this embodiment, the buffer tank 100 is made of anti-corrosion plastic material to prevent the slurry in the absorption tower 400 from corroding the buffer tank 100, and the bottom of the buffer tank 100 is a truncated cone whose cross-sectional area gradually increases from bottom to top type structure, the upper part of which is a cylindrical tank; the connection betwe...

Embodiment 2

[0043] A kind of thermal power plant desulfurization absorption tower pH meter automatic sampling detection device of this embodiment, the basic structure is the same as embodiment 1, further, as Figure 4 As shown, in this embodiment, the filter unit 120 includes a flat filter section 121 arranged horizontally at the inlet end of the lower part of the buffer tank 100, and a conical filter section 122 and a conical collection section 123 are arranged successively above the flat filter section 121. The cross-sections of the section 122 and the cone collecting section 123 gradually decrease from bottom to top, and the bottom cross-sectional area of the cone filter section 122 is smaller than the area of the flat filter section 121, and filter holes are provided on the circumferential side walls of the cone filter section 122 , The circumferential side wall of the cone collecting section 123 is a solid side wall. In the present embodiment, the area of the flat filter sectio...

Embodiment 3

[0046] A kind of thermal power plant desulfurization absorption tower pH meter automatic sampling detection device of this embodiment, the basic structure is the same as embodiment 2, furthermore, this embodiment also includes vent pipe (not drawn in the figure), and this vent pipe is set On the side of the pulp inlet pipe 410 and communicated with the pulp inlet pipe 410, a manual valve and an electric valve are also arranged on the vent pipe. A heating device can also be installed, and a variety of conventional heaters in the industry can be used to slightly heat the gas used for flushing. The ventilation pipe can be used in conjunction with the flushing pipe 600 to ventilate synchronously during flushing, which helps to increase the flushing flow rate and enhance the flushing effect. In order to dry the pipeline in time, prevent the slurry or cleaning fluid from depositing in the pipeline and prevent the pipeline from being blocked.

[0047] In this embodiment, the first p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com