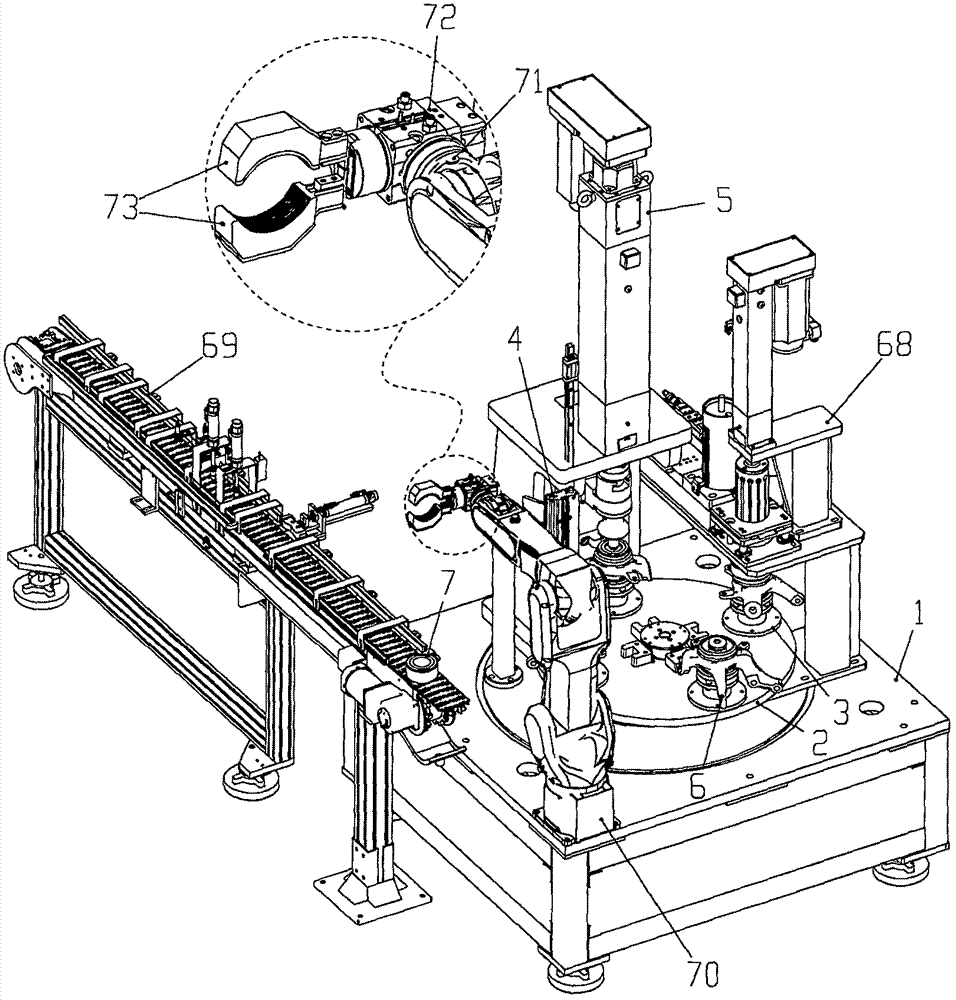

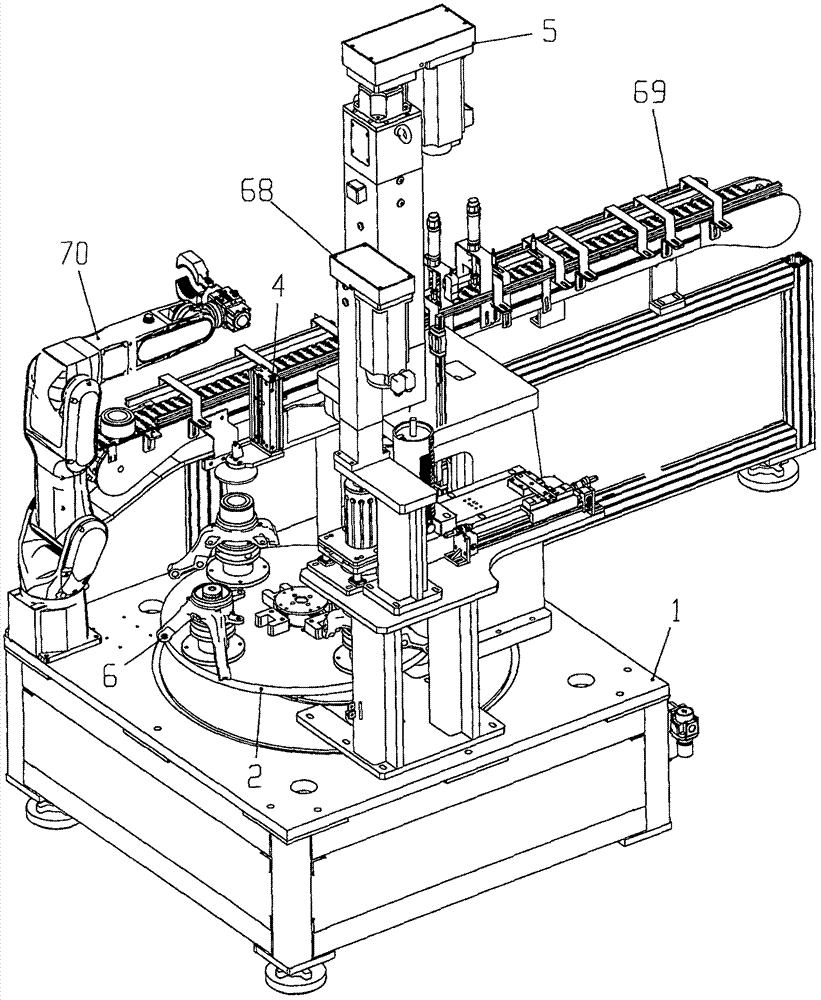

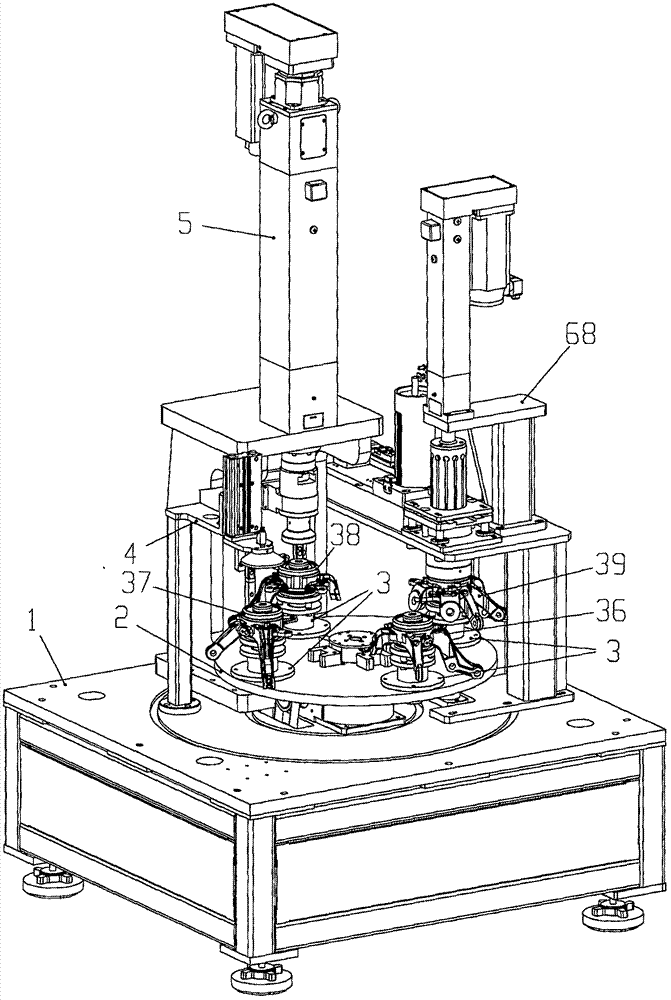

Industrial robot assisted intelligent flexible manufacturing production line

An industrial robot and flexible manufacturing technology, applied in manufacturing tools, assembly machines, metal processing equipment, etc., can solve the problems of inability to grasp the extrusion force of bearings, inner circlips and steering knuckles in real time, and low assembly quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As mentioned above, the present invention provides an industrial robot-assisted intelligent flexible manufacturing production line. During the automatic assembly production process of motor vehicle parts, the robot structure is used to grab the bearing from the conveyor chain and place it on the steering knuckle. Use the turntable mechanism to realize the automatic conversion of multiple stations, use the lubrication system to reduce the internal frictional resistance in the assembly process, use the flexible fixture to effectively avoid the pressure on the turntable mechanism during the extrusion process, and use the extrusion mechanism to press the bearing into the In the steering knuckle, use the circlip assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com