Volume fluctuation-based biomass continuous flash explosion and in situ alloying method and device

An in-situ blending and biomass technology, applied in the field of composite material processing, can solve the problems of uneven dispersion of biomass and plastic blending, inability to continue synchronously, fiber length reduction, etc., to achieve continuous automated industrial production, structure Simple, improve the effect of contact exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

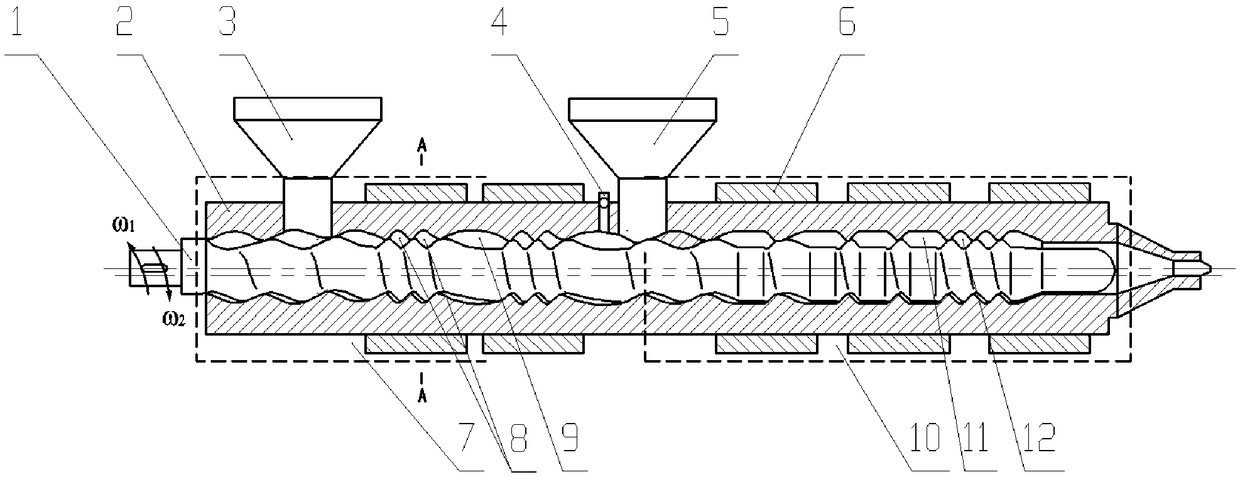

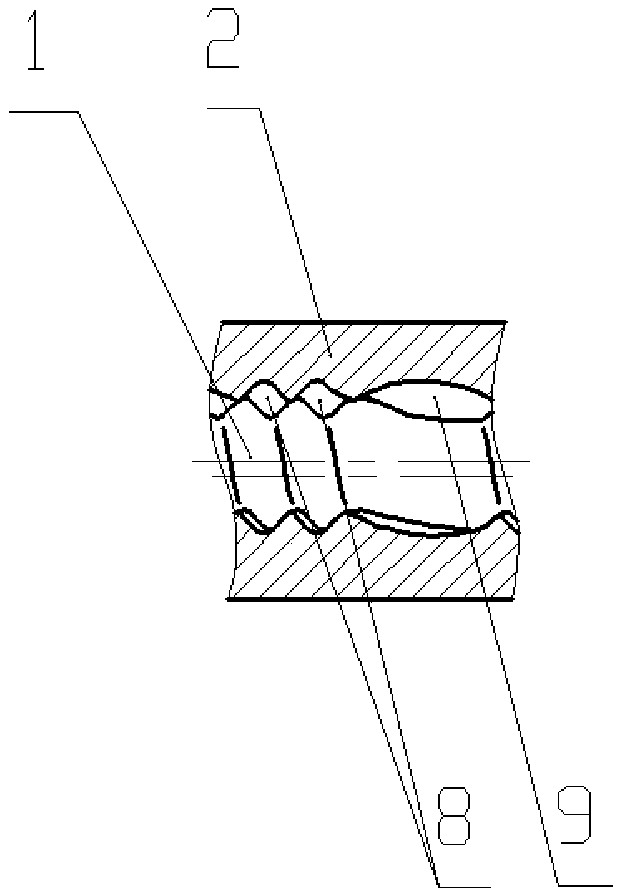

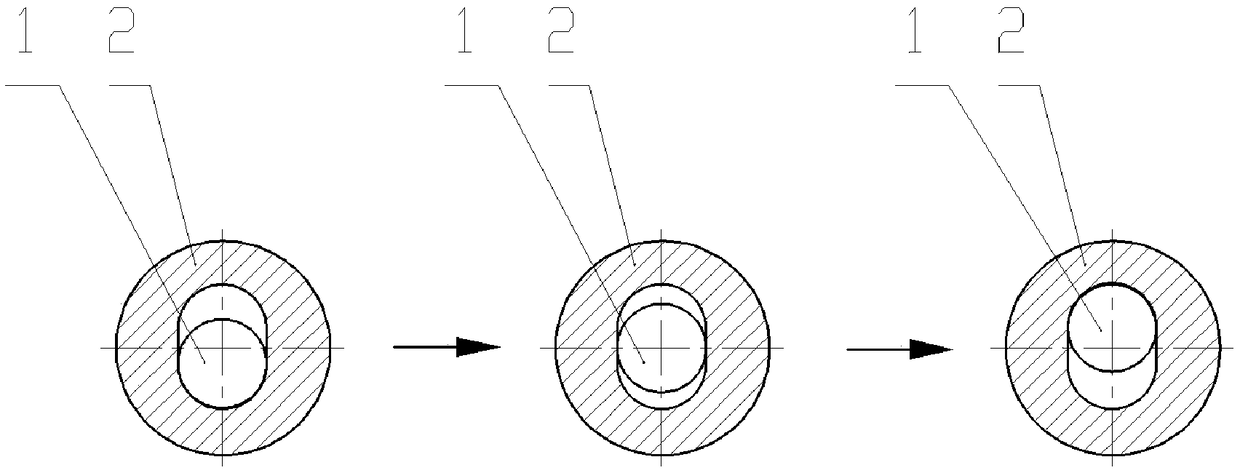

[0029] Such as figure 1 As shown, this embodiment is based on the continuous flash explosion and in-situ blending equipment of biomass with volume pulsation. The flash explosion part and the blending part are successively arranged along the material transportation direction, and both the flash explosion part and the blending part are eccentric rotors. The device, the eccentric rotor device includes an eccentric rotor and a stator, and the volume of the cavity between the eccentric rotor and the stator compresses and releases periodic pulsation changes. The power of the flash explosion part and the blending part is provided by a unified power source.

[0030]The outer sides of the stators of the flash explosion part and the blending part are equipped with heating devices for providing heat for flash explosion and blending, and the heating devices are heaters....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com