Construction method of mobile type bracket subsection cast-in-situ continuous beam

A construction method and a mobile technology, which is applied in the construction field of small and medium-span prestressed concrete continuous beams, and can solve the difficulties of using the mobile formwork method and jacking method, affecting navigation, flood discharge and road traffic, and large investment in temporary facilities. problem, to achieve the effect of reducing the disassembly and installation of the bracket, the construction is fast, convenient and flexible, and the amount of steel is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

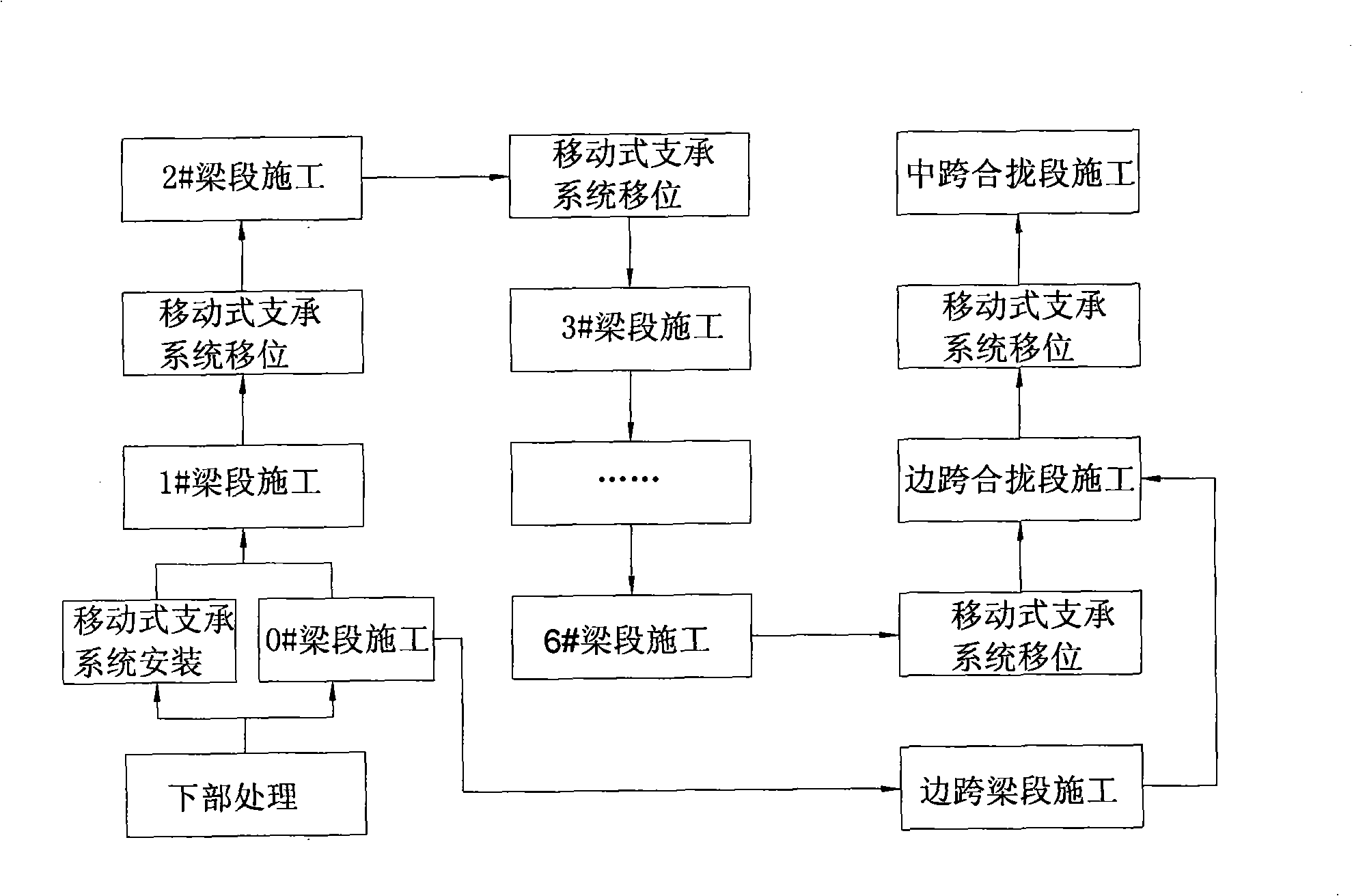

Method used

Image

Examples

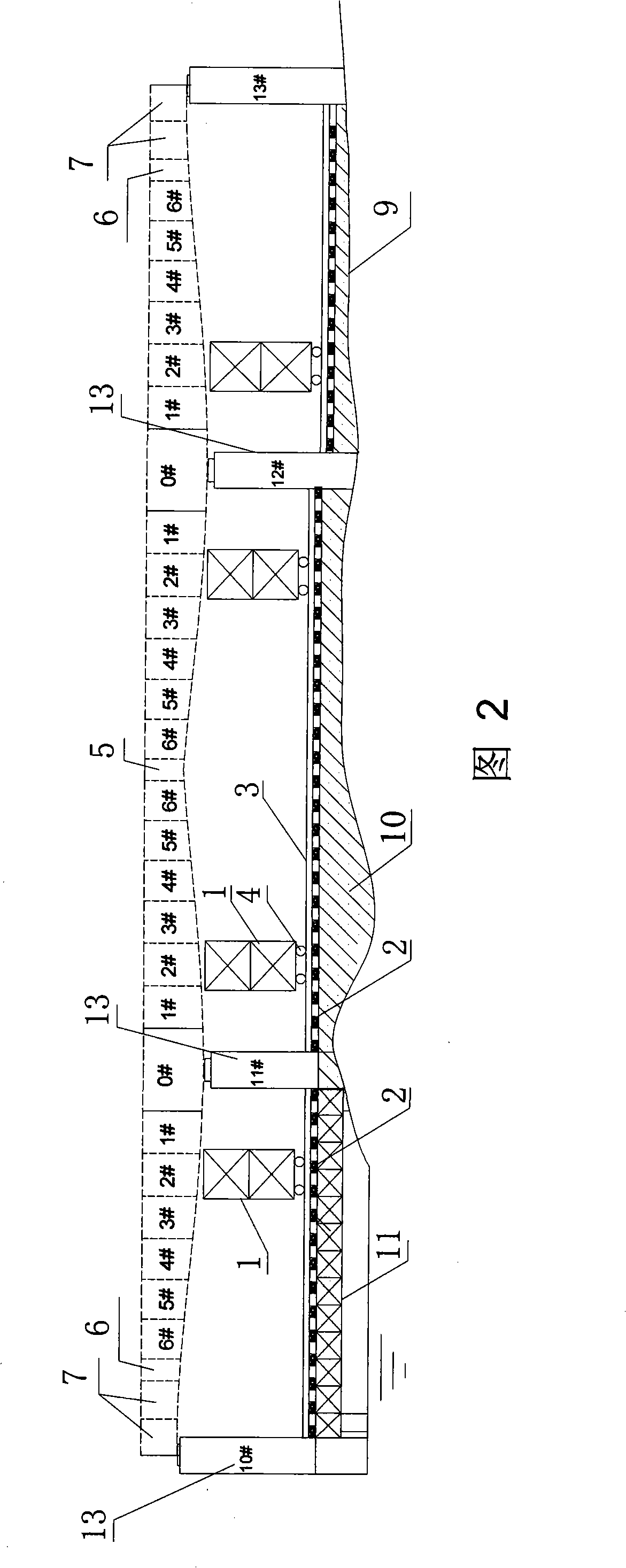

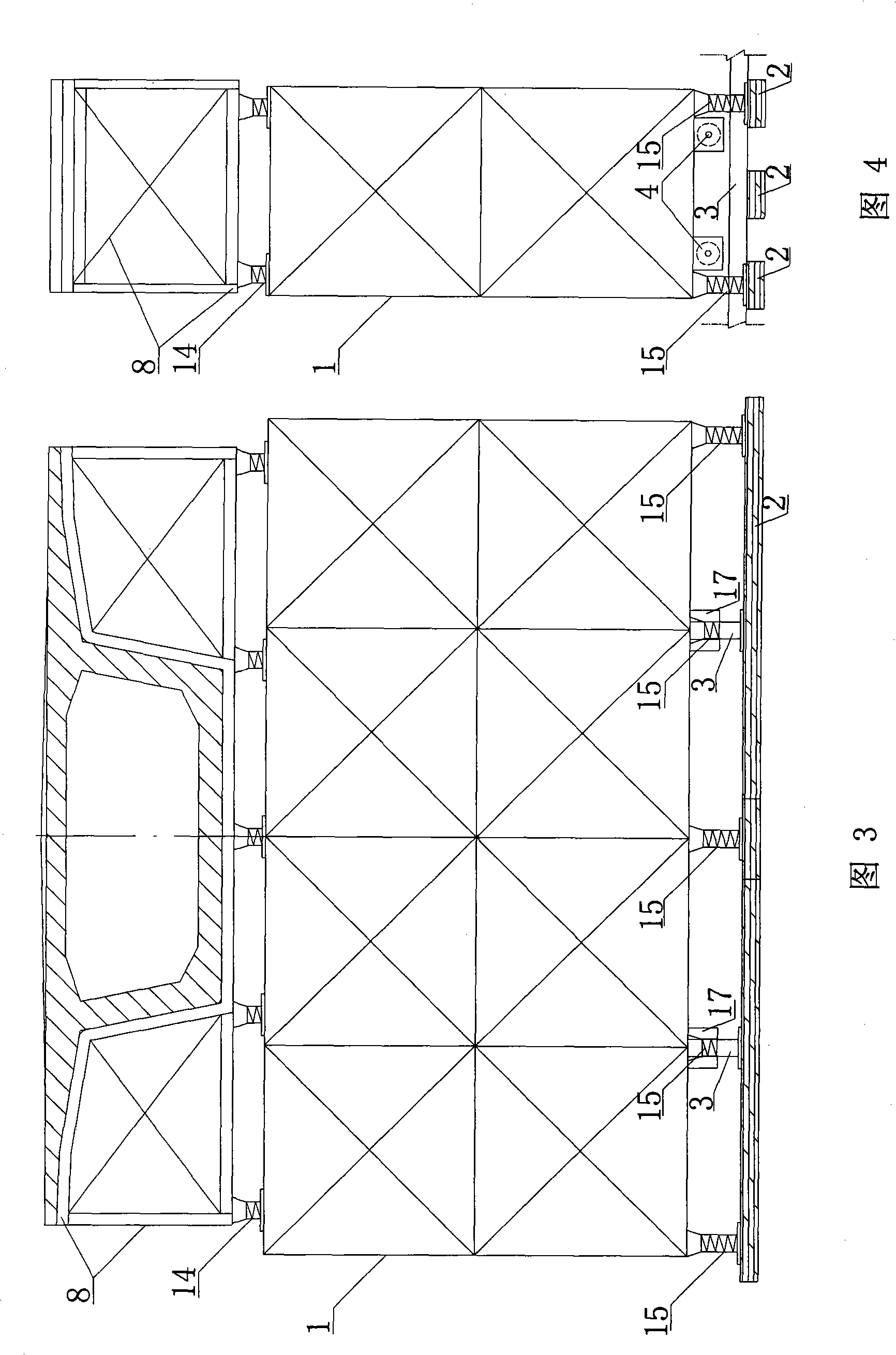

Embodiment Construction

[0042] A certain super-large bridge is a railway passenger-dedicated bridge across the urban development zone. The bridge is 1564.9 meters long and 13.4 meters wide. The 10#~13# piers of the bridge are (32+48+32)m prestressed concrete continuous beam. Piers 10# and 11# are located in the middle of the river, with a main span of 48m spanning Jiangbin Avenue, the main road of the urban development zone, and the embankment of the river. The height is 3.4m, the height of the mid-span girder is 2.8m, the top width of the box girder is 13.4m, the thickness of the top plate is 34-60cm, the thickness of the web is 40-70cm, the local widening is 95cm, and the thickness of the bottom plate is 30-90cm; There are 5 transverse diaphragms in the mid-span; the distance from the center line of the side support to the end of the beam is 0.55m, the distance from the center of the transverse bridge of the side support is 4.8m, and the distance from the transverse bridge of the middle support is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com