Numerical control processing method for corner of groove cavity

A processing method, the technology of turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

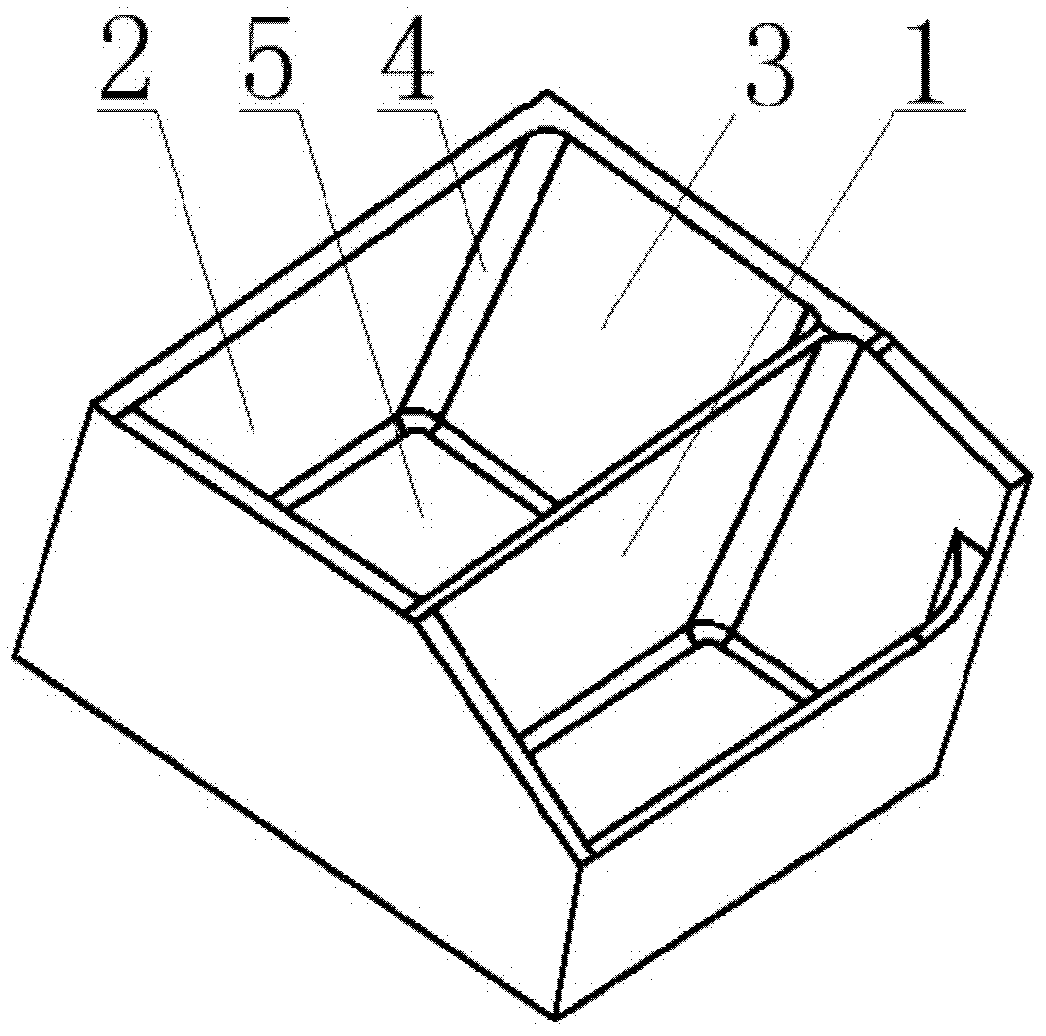

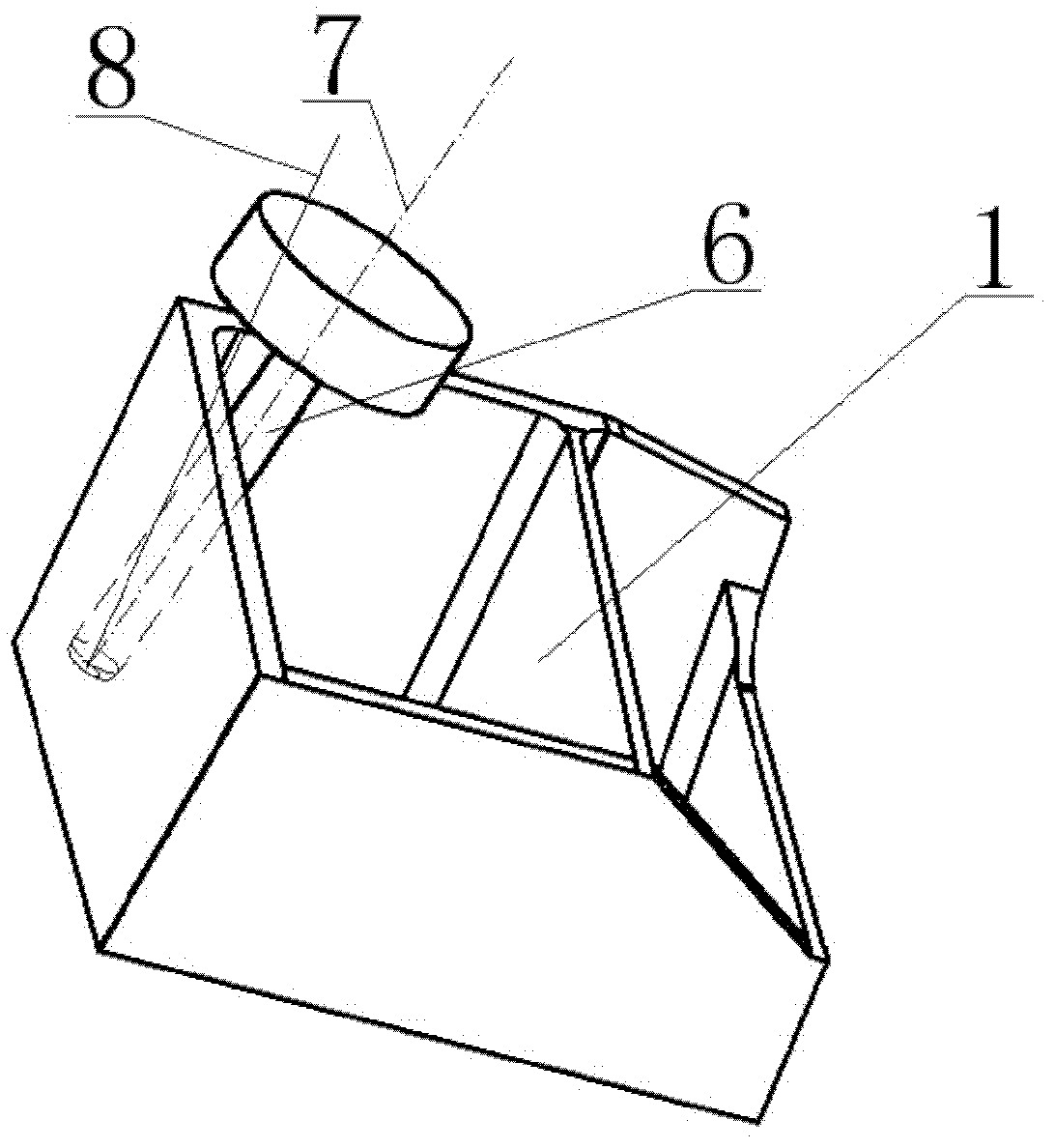

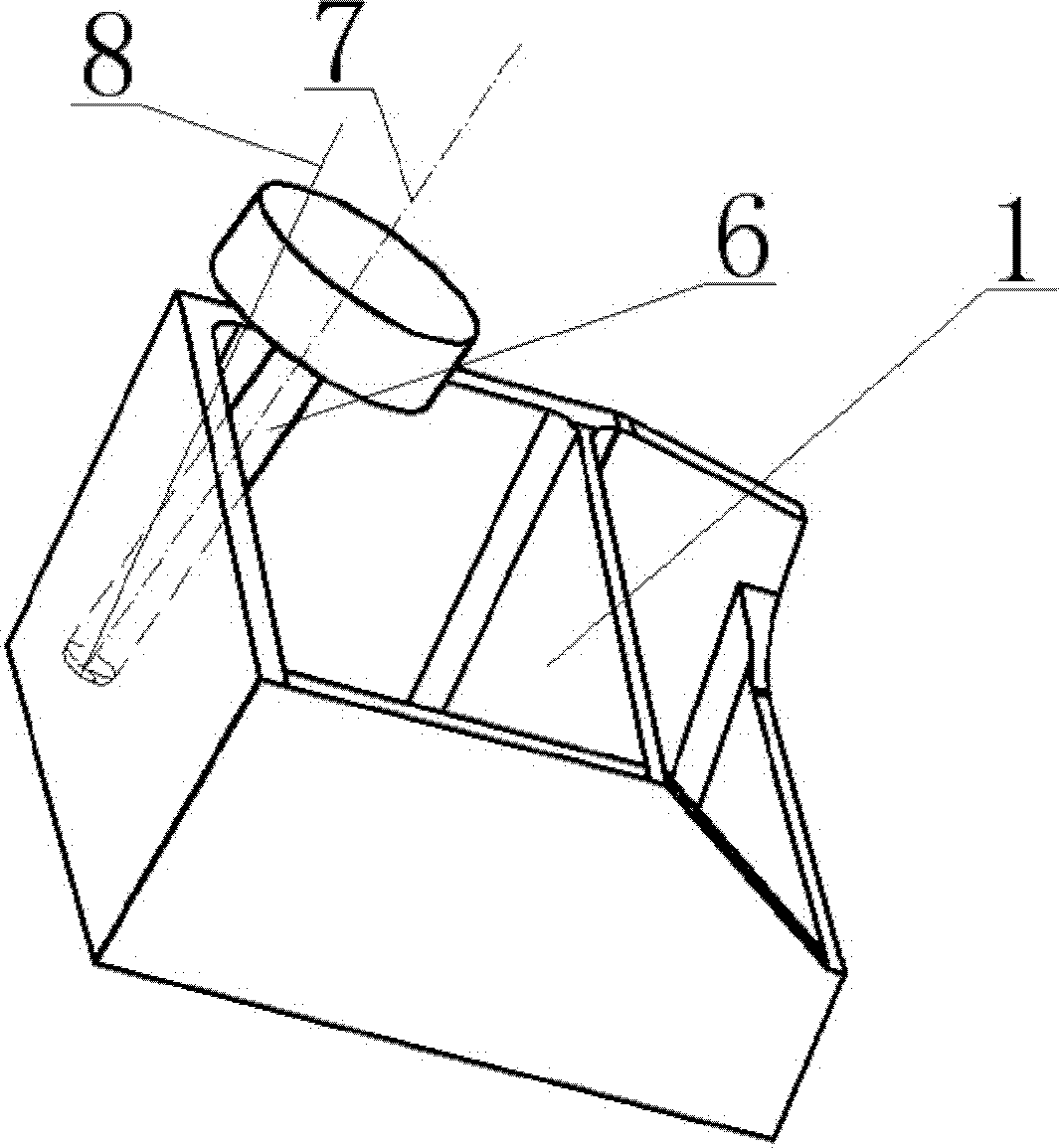

[0010] After analyzing the structural features of many products, the processing method of the present invention has advantages for the processing of the corner structure of the cavity, especially for the small absolute value of the corner, the angle between one side of the corner and the bottom surface of the cavity is less than 90 degrees, and the tool is long. When the diameter ratio is greater than 5, it has obvious advantages.

[0011] as attached figure 1 Shown: the body 1 of the box-shaped part to be processed shown in the embodiment is a cavity part with a corner, and the first side 2 of the cavity and the second side 3 of the cavity are not perpendicular to the bottom surface 5 of the cavity (the included angles are respectively 83 degrees and 102.9 degrees); the value of the groove corner 4 is R10.5mm, and the groove depth is 132mm.

[0012] The first step is to carry out rough machining of the cavity according to the bottom surface and side wall of the part with 3mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com