Mine hard alloy tooth

A cemented carbide tooth and mining technology, which is applied in the field of cemented carbide teeth, can solve the problems of limited change, fast wear of alloy teeth, and low service life of drilling tools, and achieves the effect of improving height and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

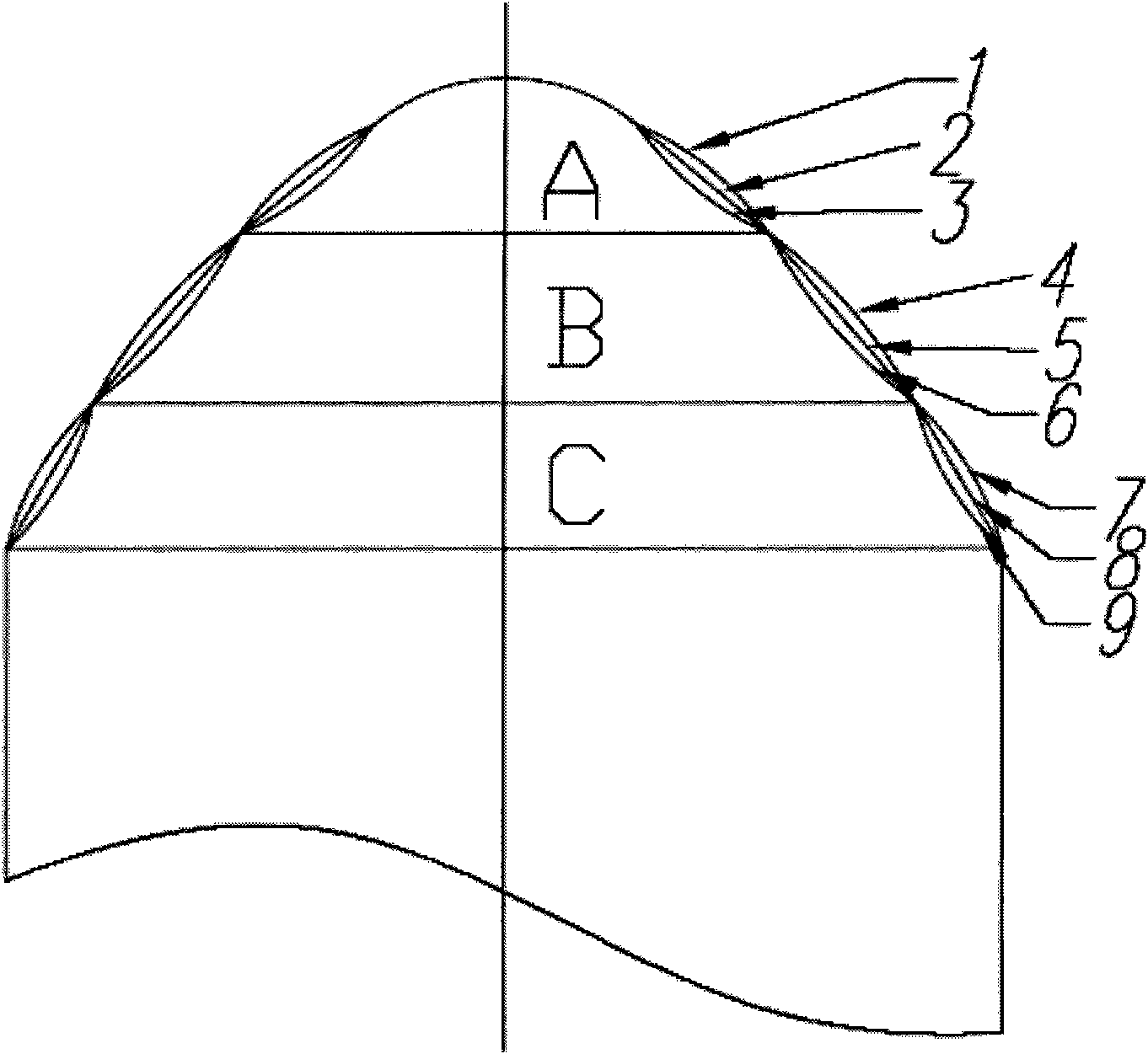

[0020] The cemented carbide mining tooth composed of a multi-layer tooth crown can not only avoid the wear interface of the single-layer tooth during use, the wear interface of the tooth is getting larger, and the friction force at the contact interface between the alloy tooth and the broken rock formation is too large, The drill had to be taken out of service. At the same time, it can also avoid the defect that the double-layer teeth contact the broken rock formation at the beginning because the interface area is too small, and the alloy teeth wear quickly during the use of the drilling tool, resulting in a short service life of the drilling tool.

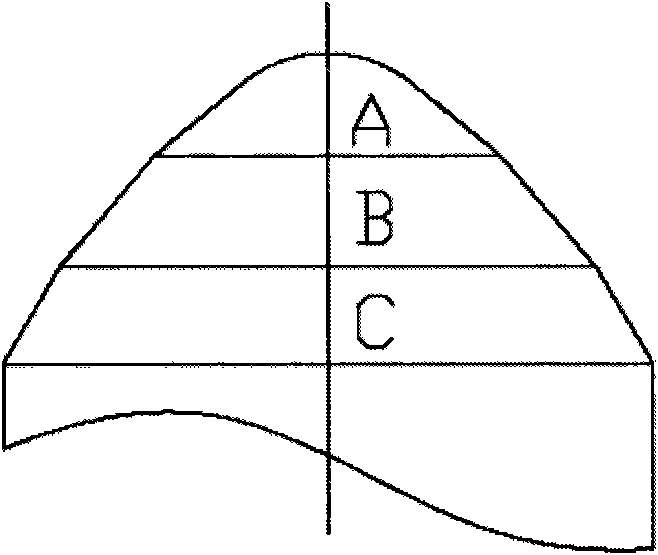

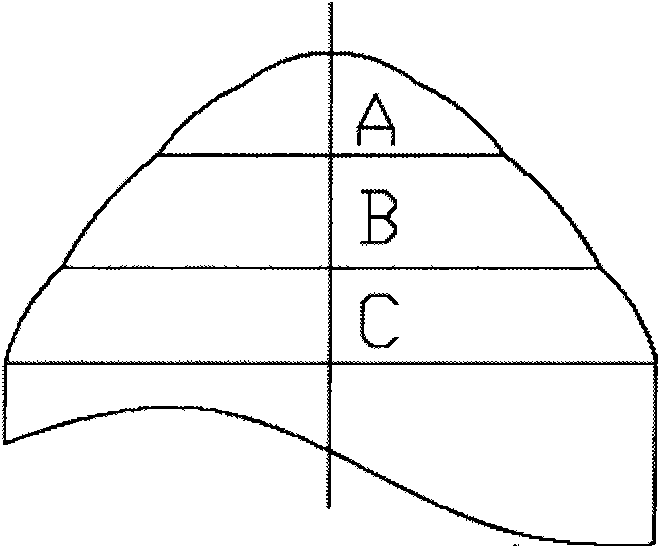

[0021] Cemented carbide teeth for mining mainly include a tooth body and a tooth crown. The shape of the tooth body is cylindrical, and a tooth crown is set on the upper end of the tooth body, such figure 1 As shown, the tooth crown includes top and side parts, and the profile of the top of the tooth crown is a convex arc; the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com