High-precision rail base for automobile production line

A technology for automobile production lines and track bases, which is applied to conveyor objects, conveyors, mechanical conveyors, etc., can solve the problems of inability to convey the inertia impact buffer of the track, reduce the control accuracy of the conveying track, and reduce the stability of the conveying track. Applicability, avoid continuous delivery, improve the effect of buffering and disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

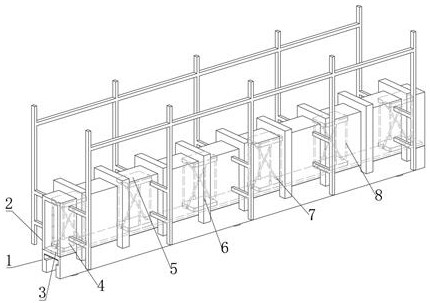

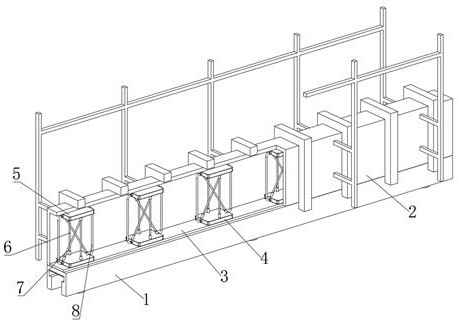

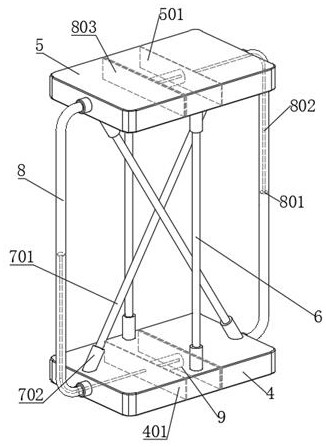

[0043] see Figure 1-8 , a track base of a high-precision automobile production line, including a transport track body 1 and a track base frame 2, the upper end of the transport track body 1 is fixedly connected with a transfer gasket 3, and the front and rear sides of the transfer gasket 3 are fixed to the inner wall of the track base frame 2 Connection, the upper end of the transmission gasket 3 is fixedly connected with a plurality of flexible buffer bottom blocks 4, and the lower inner wall of the track base frame 2 is fixedly connected with a plurality of flexible blocking top blocks 5, between the flexible buffer bottom block 4 and the flexible blocking top block 5 A pair of load-bearing connecting rods 6 arranged front and back are fixedly connected, and a pair of diagonal buffer assemblies 7 arranged diagonally across are fixedly connected between the flexible buffer bottom block 4 and the flexible blocking top block 5;

[0044] see Figure 1-4 and Figure 8 , a bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com