Oil brushing device of full-automatic electronic inspection machine for condoms

A fully automatic, condom technology, used in devices and coatings that apply liquid to the surface, which can solve the problems of secondary damage to condoms, surge in labor costs, and contamination, reducing the risk of oil-carrying and precise control. With oil volume, the effect of evenly brushing oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

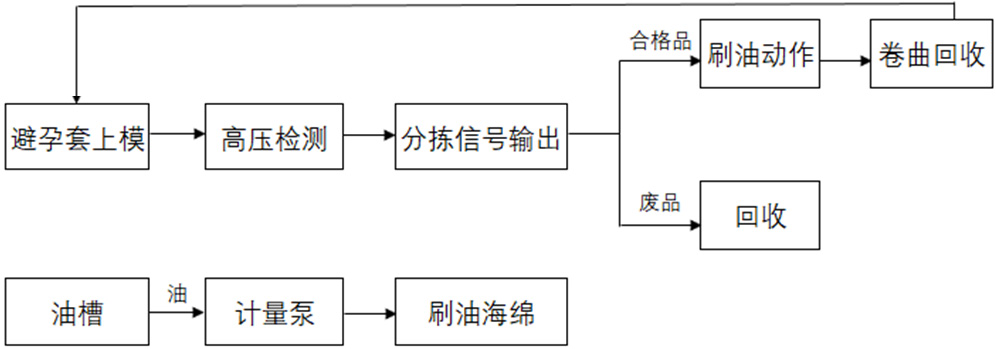

[0024] First, the condom lubricant in the oil tank 6 is pre-added to the oil brushing sponge 3 quantitatively by the control system through the metering pump 7 before starting the machine, and the amount of oil contained in the condom lubricant is about 10%-30%. During the subsequent normal start-up production process, when the control system automatically calculates that the lubricant content of the condom in the sponge 3 is lower than the required range, the signal is fed back, and the condom lubricant is quantitatively replenished through the metering pump 7, so that the lubricant in the sponge 3 The content is maintained at 10%-30%.

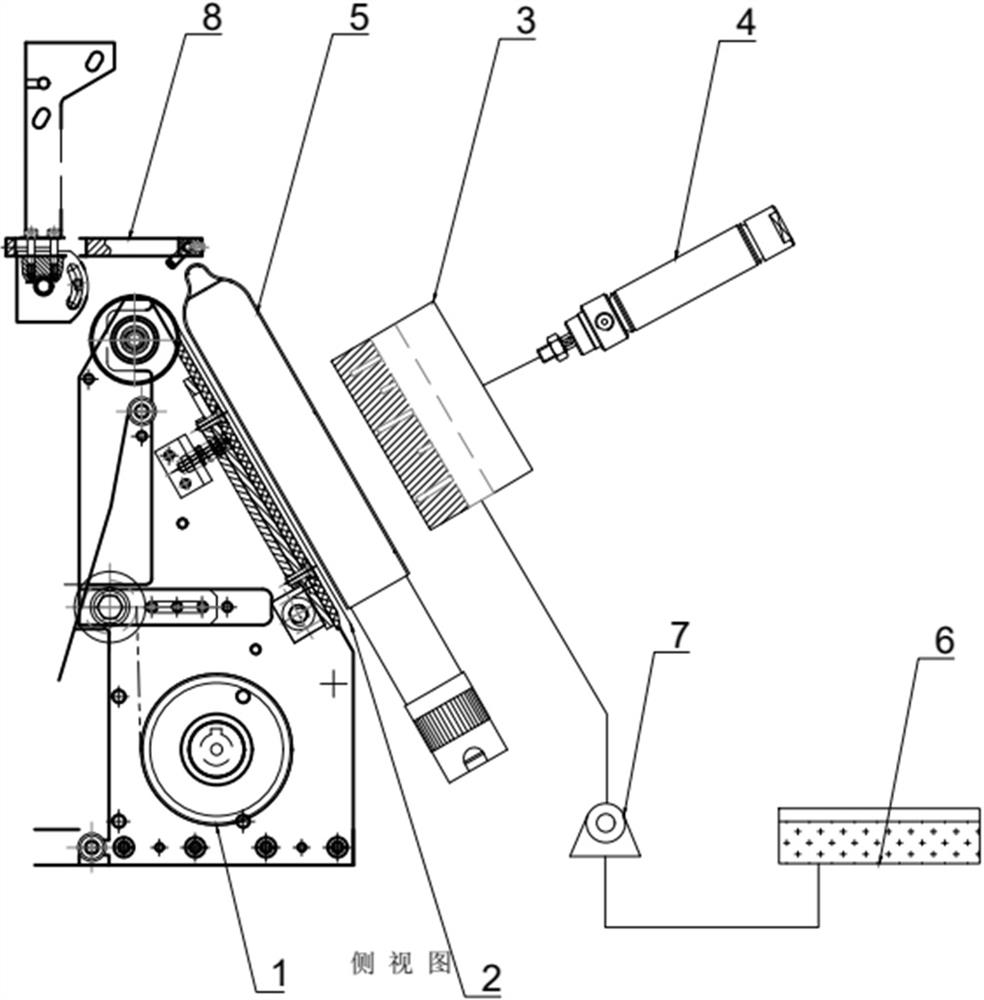

[0025] Then, the operator on duty normally operates the full-automatic electronic inspection machine. After the condom to be inspected is covered with the detection mold 5, the detection mold 5 does the normal detection task with the large disk under the control of the large disk rotating motor. When the condom to be inspected passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com