Porous solid material with micro nano-sized circulation pore diameter and preparation method thereof

A porous solid, micro-nano technology, applied in nanotechnology, metal material coating process, ceramic products, etc., can solve the problems of high price, long template manufacturing cycle, difficult to obtain flow pore size, etc., to reduce production costs and achieve consistent size Good performance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

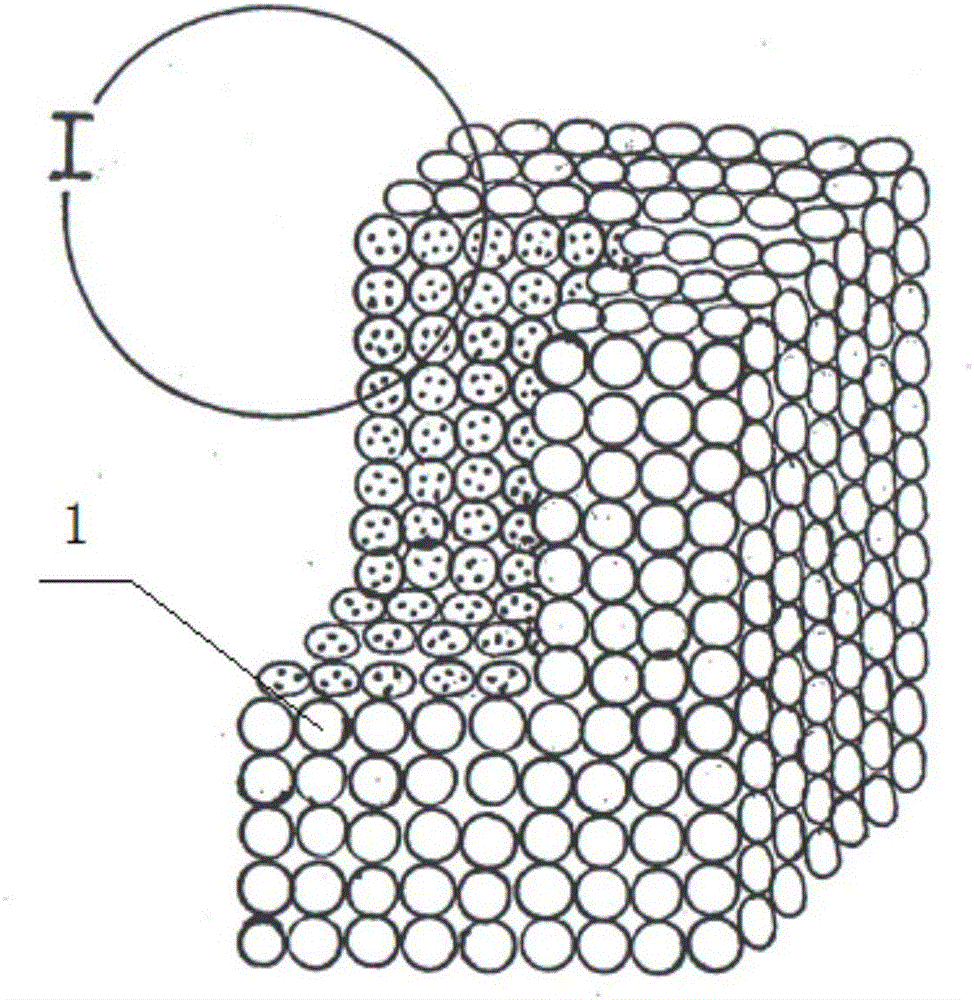

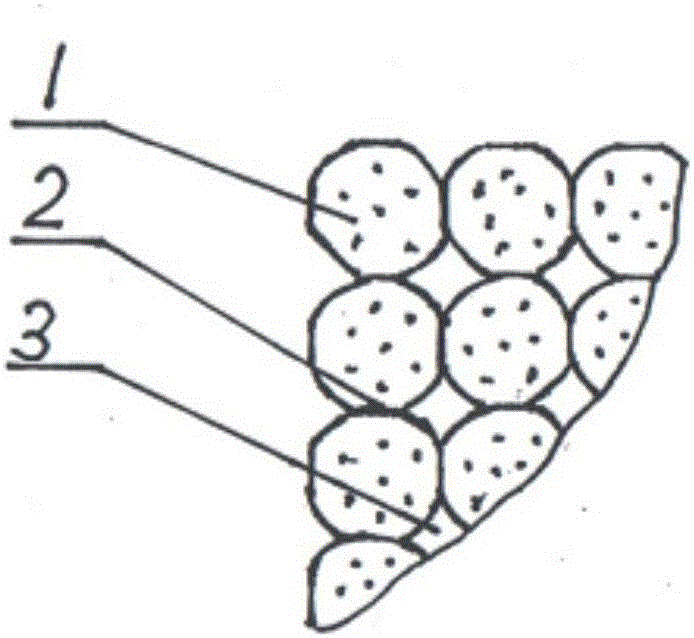

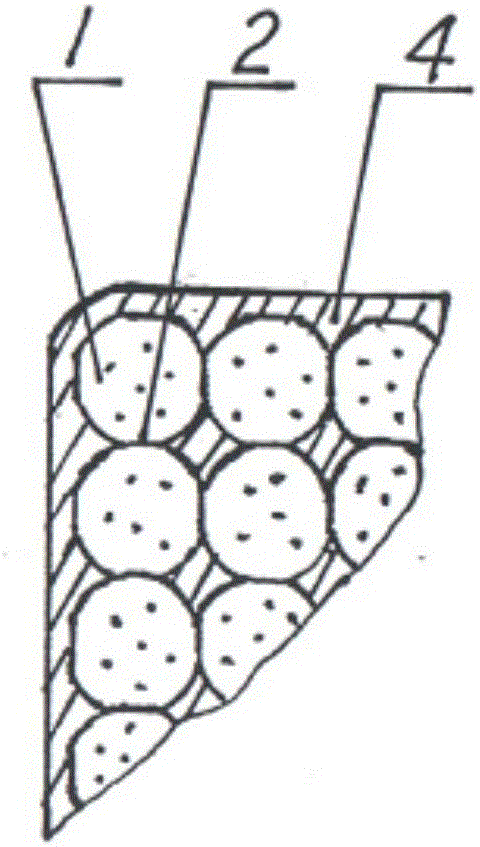

[0038] First, the surface of spherical calcium carbonate particles 1 with a diameter of 6 μm is dip-coated with a thin layer of water-soluble dilute binder, and when the surface of the binder starts to feel sticky, pour the calcium carbonate particles 1 into the cavity of the steel mold , the length of the cavity is 150mm, the width is 100mm, and the depth is 50mm. Cover the mold cover, operate the pressing device on the mold cover, and apply a pressure of 0.6MPa to make the adjacent calcium carbonate particles in the mold squeeze each other slightly to form an average diameter The contact area is 2 μm.

[0039] Next, the mold was put into a heating furnace to heat up, and the temperature in the furnace was controlled at 80° C. After heating for 20 minutes, the mold cover was opened. At this moment, the binding agent is completely dry, and the spherical particles 1 have been adhered to each other to become a cuboid, which is taken out, such as figure 1 shown. The binder make...

Embodiment 2

[0043] First, dip-coat a thin layer of water-soluble dilute binder on the surface of spherical aluminum particles with a diameter of 500nm. When the surface of the binder starts to feel sticky, pour the aluminum particles into the cavity of the steel mold. The length of the cavity is 100mm, width 80mm, depth 1.5mm, cover the mold cover, operate the pressing device on the mold cover, apply a pressure of 0.2MPa, make the adjacent particles in the mold slightly contact with each other, and form a contact area with an average diameter of 100nm.

[0044] Next, the mold was put into a heating furnace to heat up, and the temperature in the furnace was controlled at 70° C. After heating for 10 minutes, the mold cover was opened. At this point, the binding agent is completely dry, and the spherical particles have mutually adhered to a thin cuboid (this thin cuboid and figure 1 Similar, the difference is that the height of the thin cuboid is reduced), take it out. The binder makes the ...

Embodiment 3

[0048] First, if Figure 6 As shown, apply a thin layer of dilute adhesive on a flat and smooth paraffin wax plate. When the adhesive no longer flows and its surface is dry, use another flat plate to gently press the upper surface of the adhesive. Use a thickness gauge to measure the thickness of the adhesive. When the thickness reaches 3 nanometers, stop pressing the plate. At this time, use a 30mm*50mm rectangular frame 8 made of paraffin to surround the adhesive, and the inside of the rectangular frame 8 forms a thin block of adhesive 7. At this time, spherical particles 1 with a diameter of 6 nm are embedded in the thin block of binder 7 and arranged in a single layer (with the aid of a high-power microscope, the particles are arranged). After the binder is completely dry, the paraffin wax plate and the rectangular frame 8 are melted away, leaving the bonded single-layer granule and the binder thin block 7, such as Figure 7 shown.

[0049] Then, the single-layer partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com