Water circulation device for plastic extruder stock mould

A plastic extruder and shaping die technology, applied in the field of plastic processing machinery, can solve the problems of slow shaping and cooling, affecting product quality, unsatisfactory profile dimensional accuracy and surface quality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

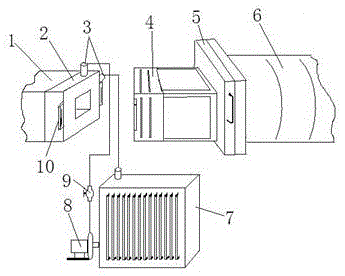

[0007] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: Further description will be made below in conjunction with the accompanying drawings.

[0008] As shown in the accompanying drawing, the water circulation device of the plastic extruder stereotypes consists of a cooler, a water pump and a water tank. There is a cross-sectional shape between the forming die 4 connected to the connecting plate 5 on the extruder 6 and the setting die 1, which is the same as them, and the extruded profile around the die forms an annular, hollow inner cavity, and a belt on the shell. There is the cooler 2 of water inlet and outlet 3, forming die, cooler and setting die are connected and fixed into one by connecting ear 10.

[0009] Described cooler has a radiator water tank 7, forms water circulation device by water pump 8 through pipeline. This water circulation device blocks the heat transfer from the forming die to the calibrating die.

[0010] On the pipeline that cooler is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com