Combined hammer head and manufacturing process thereof

A composite hammer and manufacturing process technology, applied in grain processing and other directions, to achieve the effects of considerable economic benefits, good wear resistance and good impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

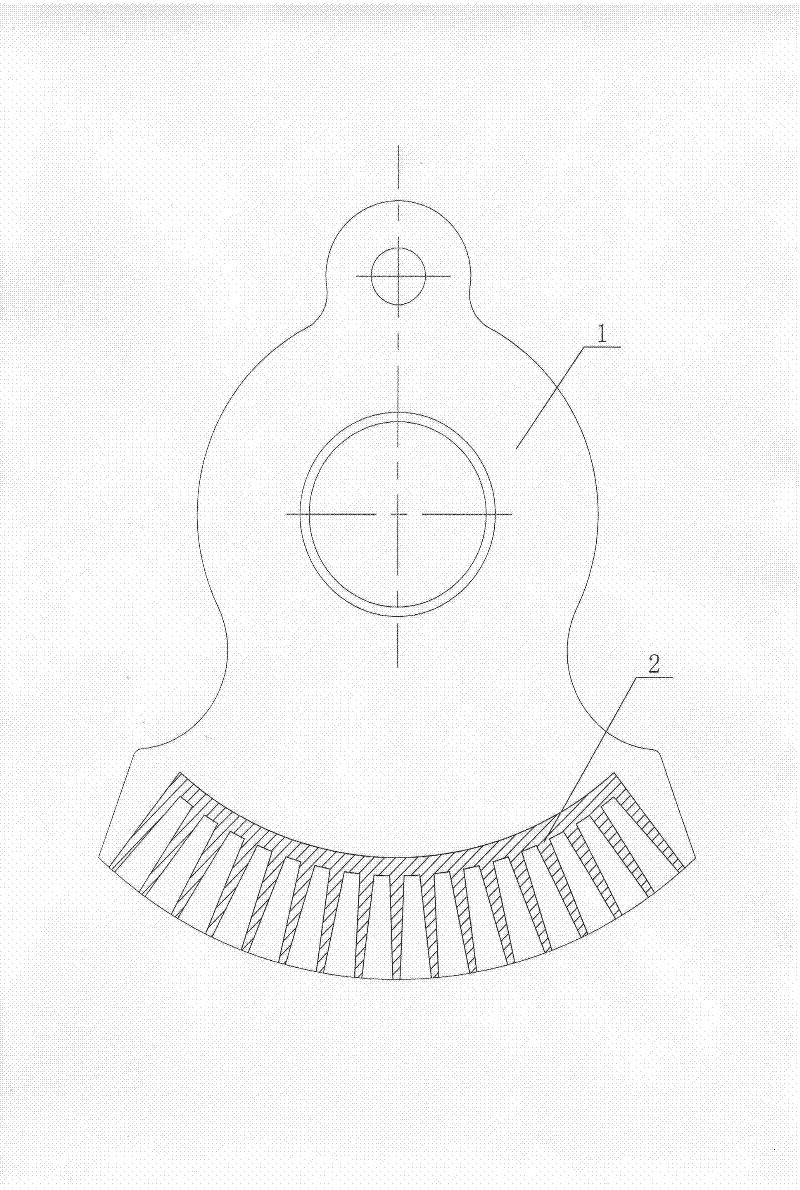

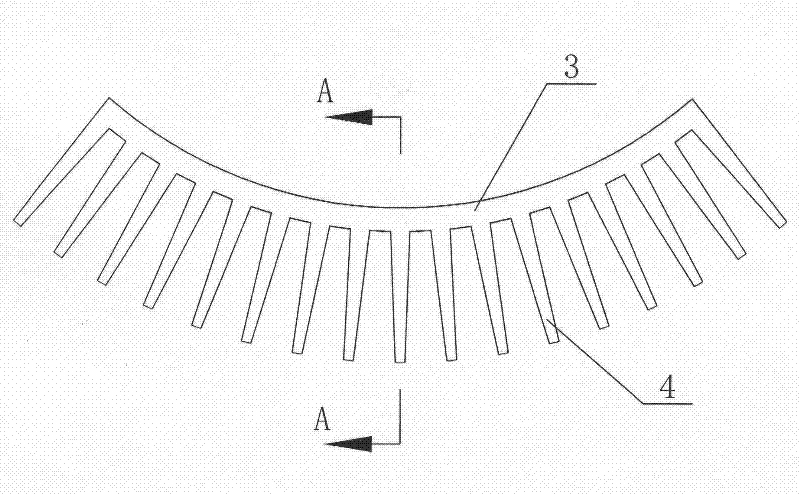

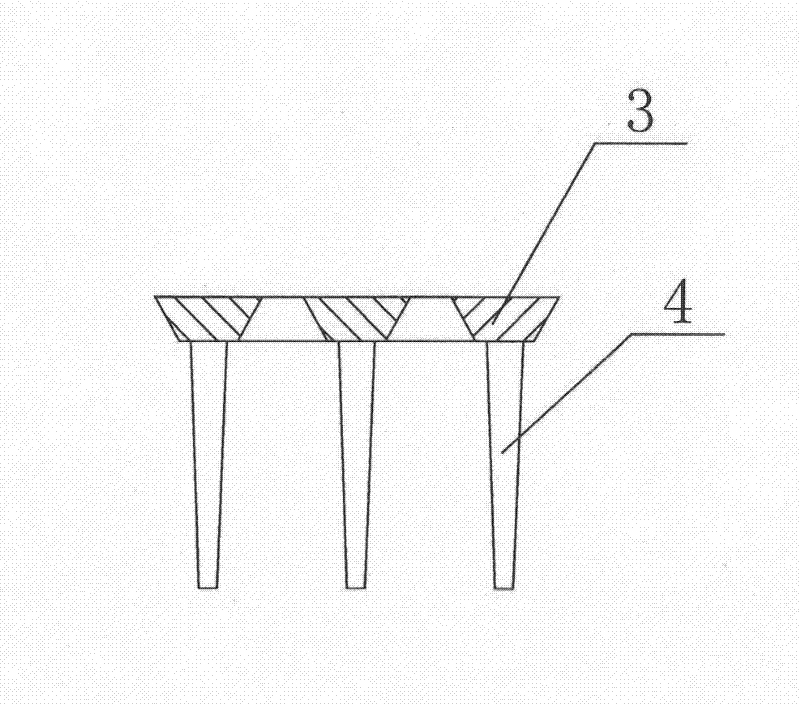

[0064] Such as figure 1 , figure 2 , image 3 As shown, a composite hammer head includes a hammer body 1 and a skeleton 2. The skeleton 2 is arranged in the hammer body 1 and is close to the front end of the hammer body 1. The skeleton 2 is a high chromium cast iron skeleton, which includes a frame 3 , The frame 3 is arc-shaped, the frame 3 is provided with cone rods 4, the cone rods 4 are equally spaced on the arc-shaped bottom surface of the frame 3, the larger diameter end of the cone rod 4 is connected to the frame 3, the diameter The small end faces the front end of the hammer body 1; the cross section of the frame is trapezoidal, the length of the upper bottom side is less than the length of the lower bottom side, and the upper bottom side is connected with a cone rod 4. The hammer body 1 is a low-carbon multi-element low-alloy steel hammer body.

[0065] The framework of high chromium cast iron is hypereutectic high chromium cast iron, and the weight percentage of each ch...

Embodiment 2

[0098] Such as Figure 4 , Figure 5 As shown, a composite hammer with a mass of 300 kg is produced, in which the mass of the skeleton 2 is 6% of the mass of the composite hammer, that is, the mass of the skeleton 2 is 18 kg. According to the shape and size of the hammer, the frame 3 of the skeleton 2 is designed as Four rows, each row has nineteen cone rods4.

[0099] The manufacturing process is as follows:

[0100] The first step is the preparation of skeleton 2;

[0101] a. Ingredients

[0102] According to the chemical composition of the high chromium cast iron framework, the weight percentage of raw materials is determined as: scrap steel: 25%; pig iron: 35%; ferrochrome: 35%; ferromanganese: 1.6%; ferromolybdenum: 1.5%; ferro-titanium: 0.8%; Copper: 1%; Aluminum: 0.1%;

[0103] b, shape

[0104] The high chromium cast iron skeleton is cast in lost foam. First, the model of skeleton 2 is made of polystyrene plastic, and the outer surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com