Apparatus for manufacturing a fine porous film for a separation film of a battery and method for manufacturing a film using same

A manufacturing method and a manufacturing device technology, which are applied in the field of microporous membrane manufacturing, can solve the problems of difficult uniform cooling, difficult adjustment of microporous membrane pore size or pore size, and difficult adjustment of cooling speed, so as to achieve low equipment cost and structural The effect of simple, uniform porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

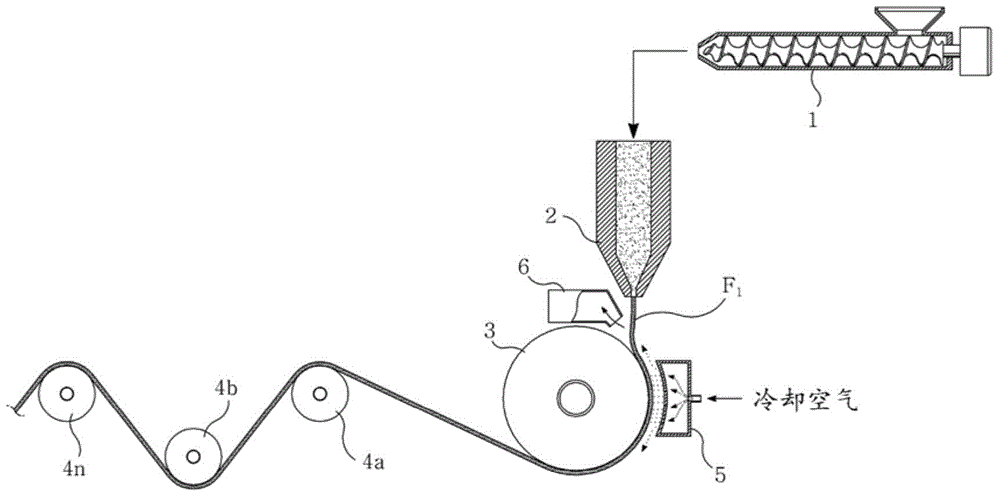

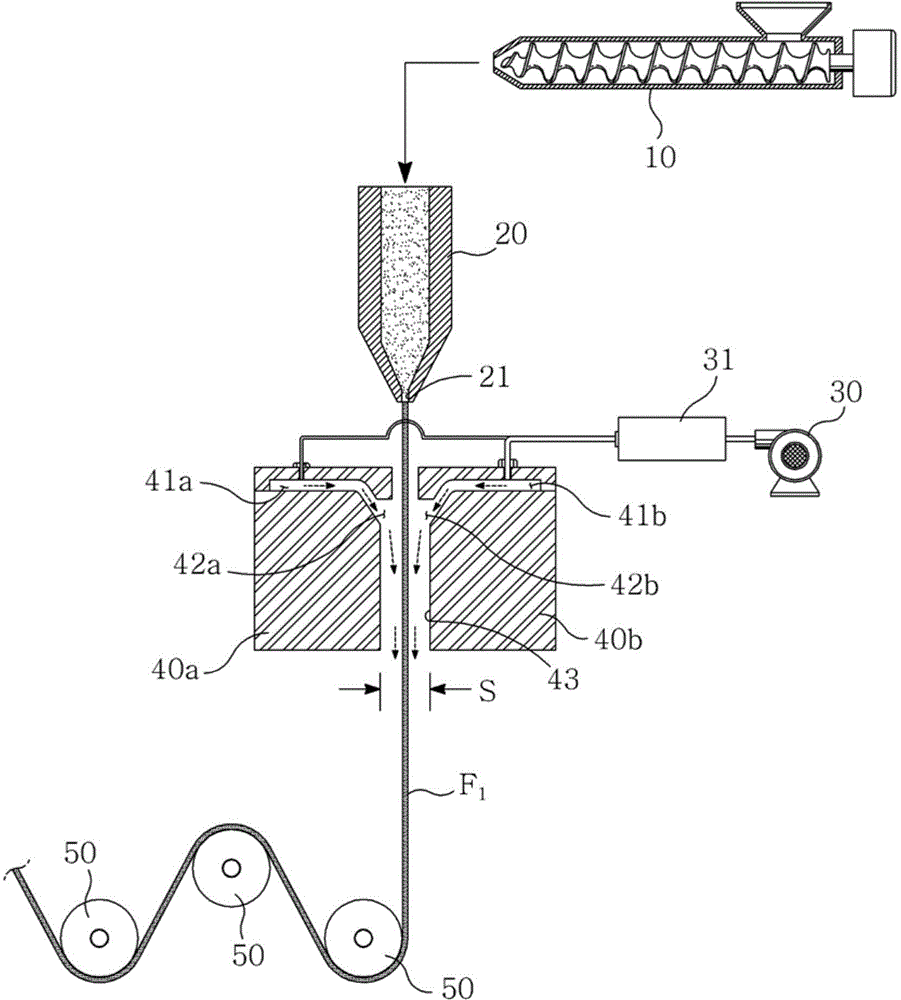

[0031] If refer to figure 2 When the apparatus for manufacturing a microporous membrane according to the present invention is first described, the apparatus for manufacturing a microporous membrane according to the present invention includes a T-shaped die 20, and a nozzle tip 21 is used to apply a constant pressure to the melted film in the press 10 Partially crystalline resin is pressed to form a precursor film F1; a guide roller 50 is arranged on the downstream side of the pressing direction of the T-shaped die and guides the precursor film to stretch to a predetermined draft ratio; a precursor film cooling device 40, A cooling gas flow is provided on either side of the front / back side of the precursor film F1 or on both sides along the movement direction of the precursor film F1 to cool the precursor film; and a film stretching device, which is mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com