Device and method for cooling welded rail section

A technology of track welding and cooling method, which is applied in the direction of track, track maintenance, track laying, etc., can solve the problem that the residual stress of the track welding part cannot be reduced, and achieve the effects of improving fatigue strength, precise temperature control, and reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

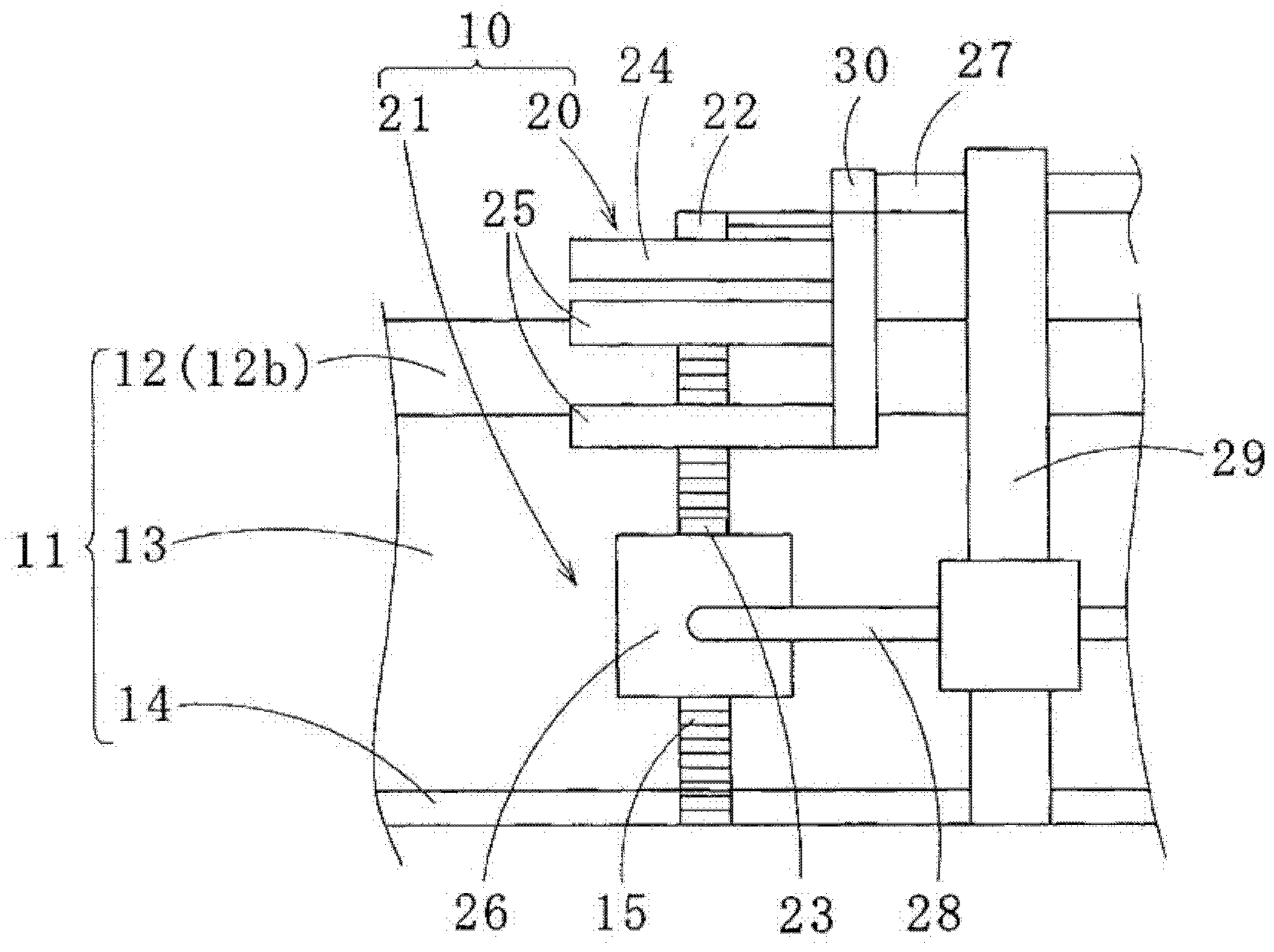

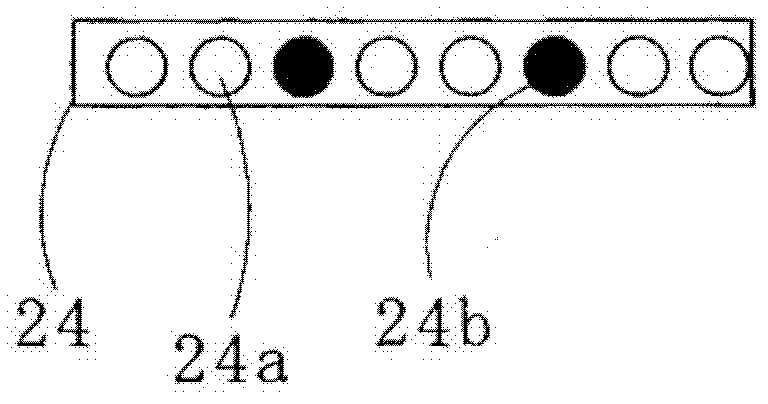

Method used

Image

Examples

Embodiment

[0093] [Cooling test of orbital welded part]

[0094] Next, a cooling test of an orbital welded portion performed using the cooling device 10 will be described. Table 1 shows the examples of the present invention, and Table 2 shows the respective cooling conditions of the comparative examples. The numerical values in the table are cooling rates, and except for Comparative Example 2, different cooling rates were set at 500° C., which is the pearlite deformation point, as a boundary. Also, when the center temperature of the target portion is less than 200°C, the effect of reducing residual stress is small even if the target portion is subjected to accelerated cooling, so accelerated cooling is performed up to 200°C.

[0095] [Table 1]

[0096]

[0097] [Table 2]

[0098]

[0099] In Examples 1 to 3, accelerated cooling was performed only on the head portion and column portion of the orbital welded portion, and in Comparative Example 1, the accelerated cooling was perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com