Patents

Literature

35results about How to "Flat temperature distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

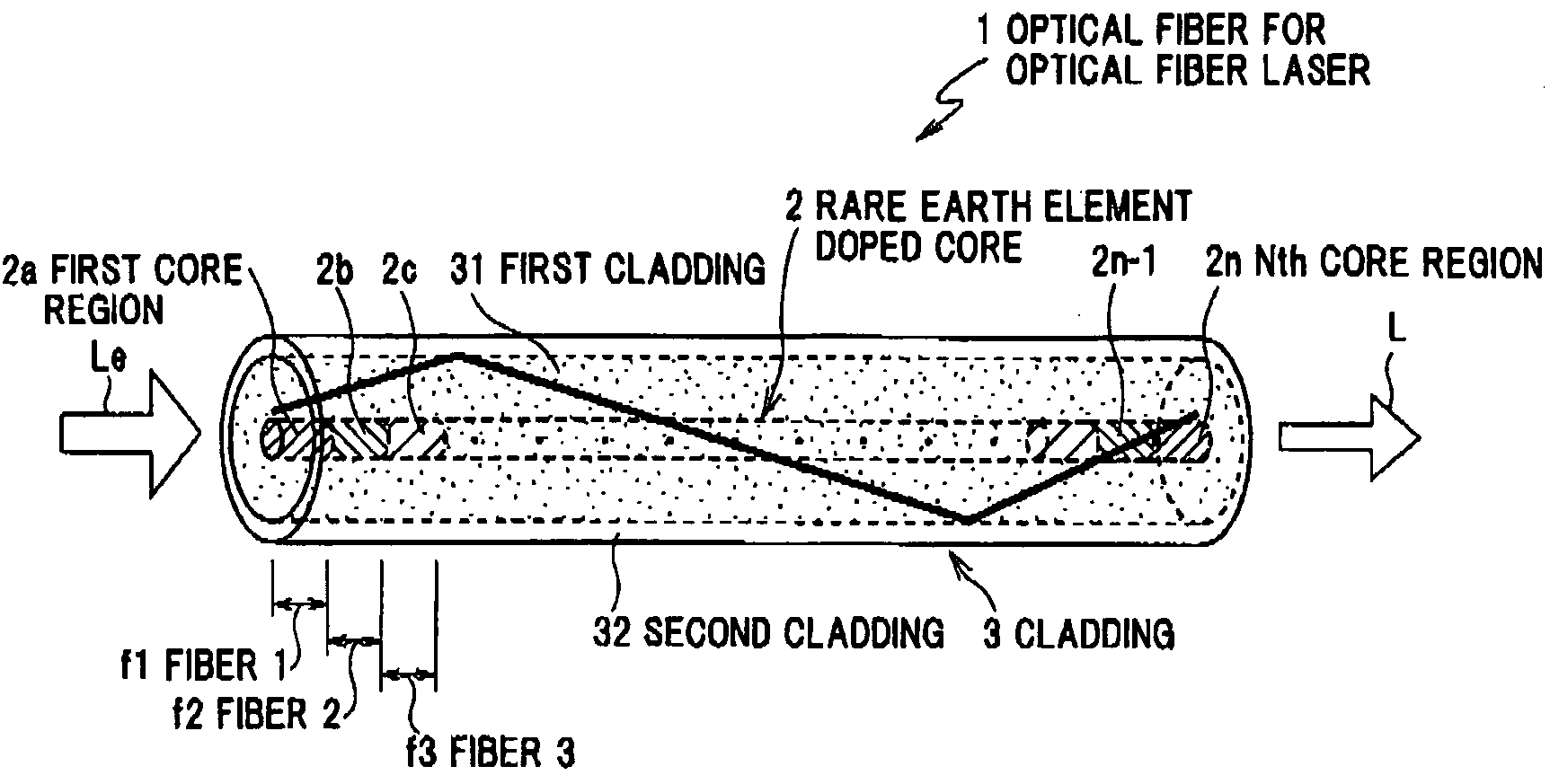

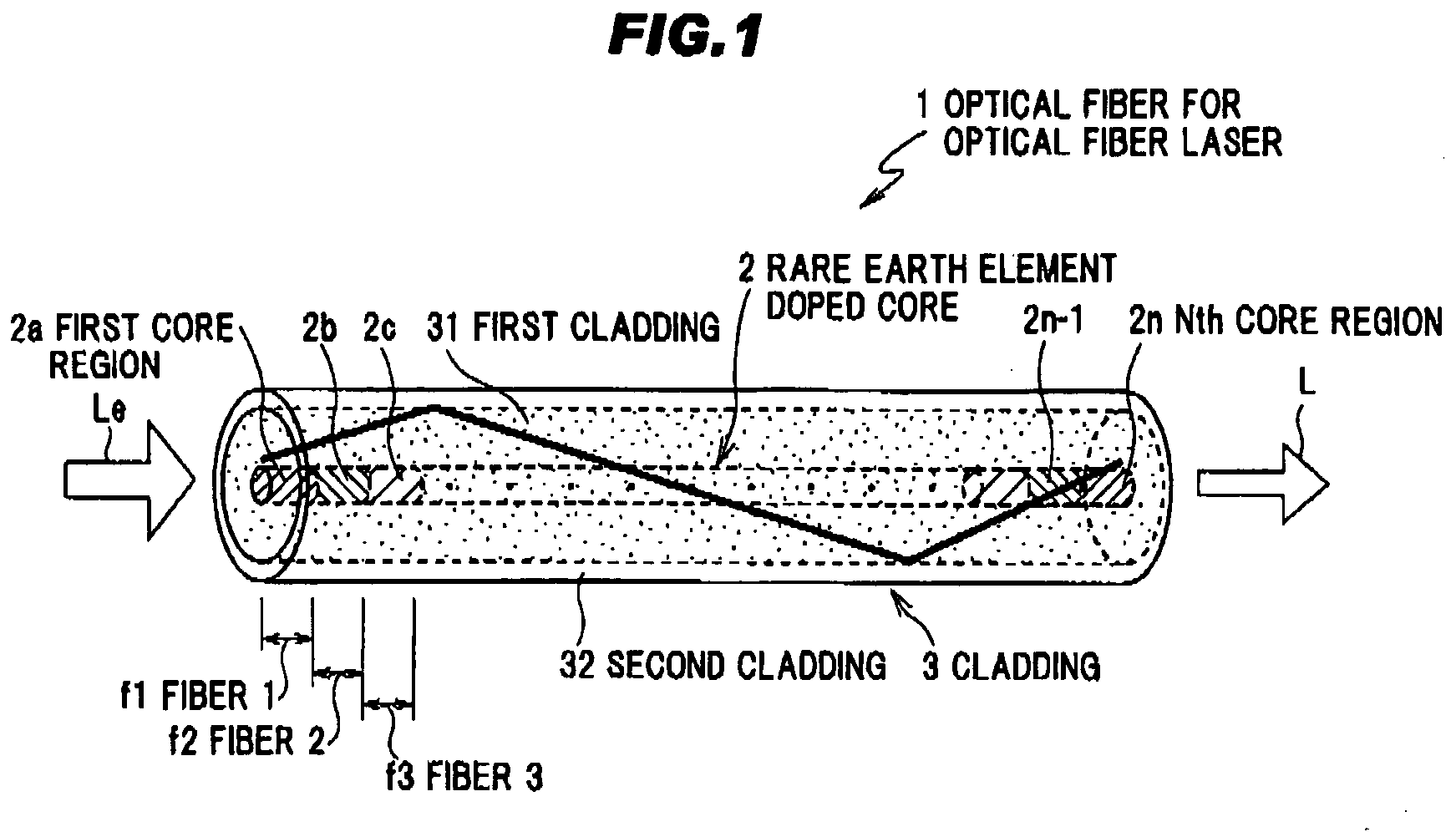

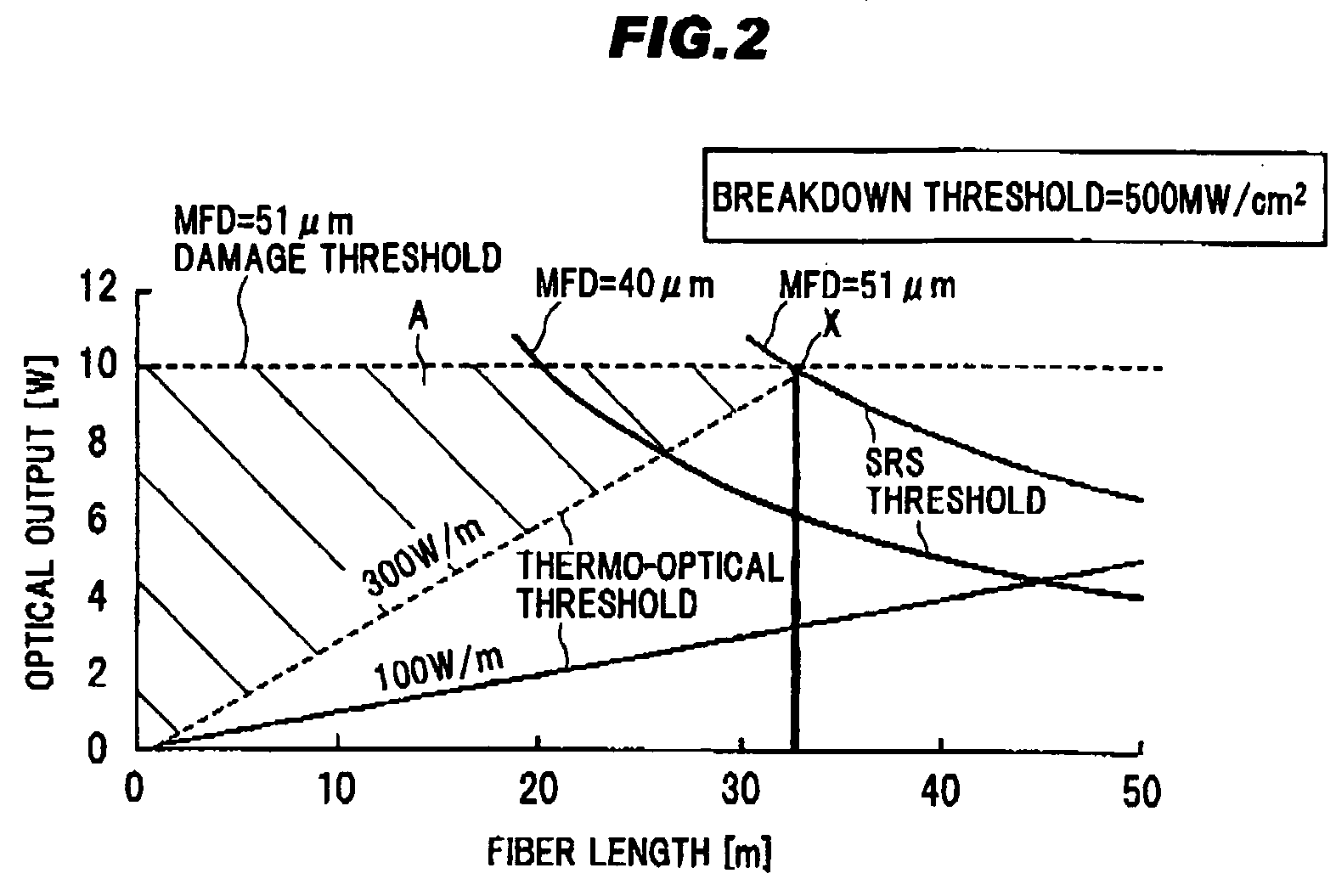

Optical fiber for an optical fiber laser, method for fabricating the same, and optical fiber laser

InactiveUS20090080472A1Easy to controlFlat temperature distributionLaser using scattering effectsOptical fibre with multilayer core/claddingRare-earth elementMaterials science

Owner:HITACHI CABLE

Method for drying automobile glass printing ink

InactiveCN101746174AReduce labor intensityReduce cost inputPrinting after-treatmentPrinting press partsProduction linePulp and paper industry

The invention relates to a method for drying automobile glass printing ink, which comprises the following steps: carbon midwave tubes and common midwave tubes are arranged in an printing ink drying machine, and heating zone of the drying machine is divided into a plurality of regions; after finishing printing, the glass flows into the drying machine through the production line and passes through a baking zone, and heat of the heating pipe pair is radiated onto the ink, so that the glass is quickly heated and the moisture is evaporated; and when the glass passes through the baking zone, the surface temperature can falls quickly, thereby achieving the design requirement. Compared with the prior art, the invention has the advantages of high output, low labor intensity, low investment and the like.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

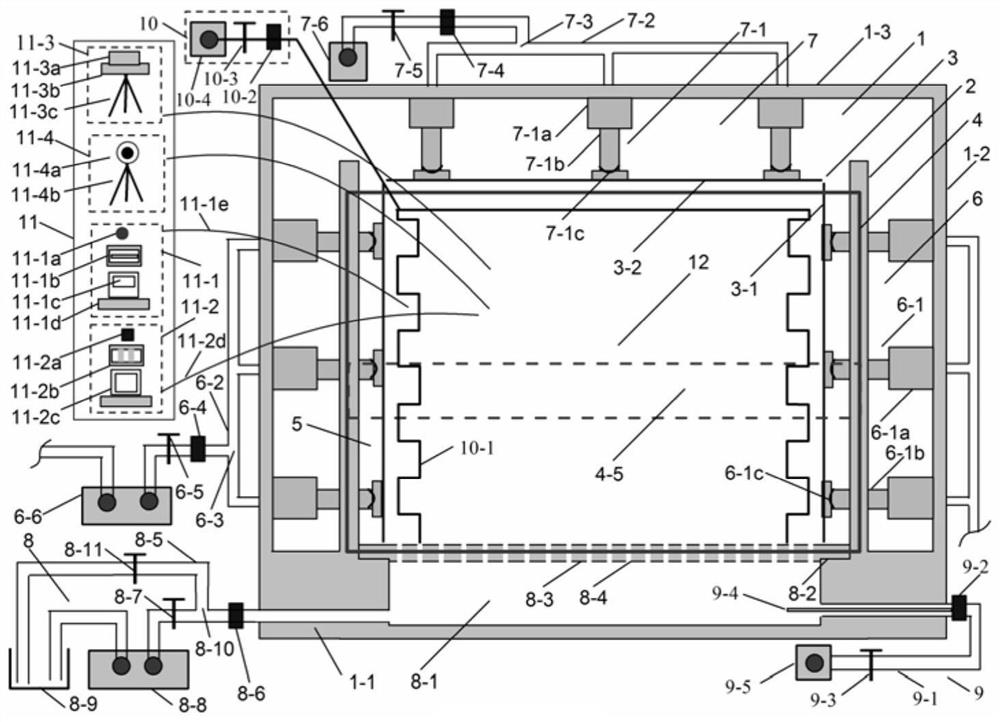

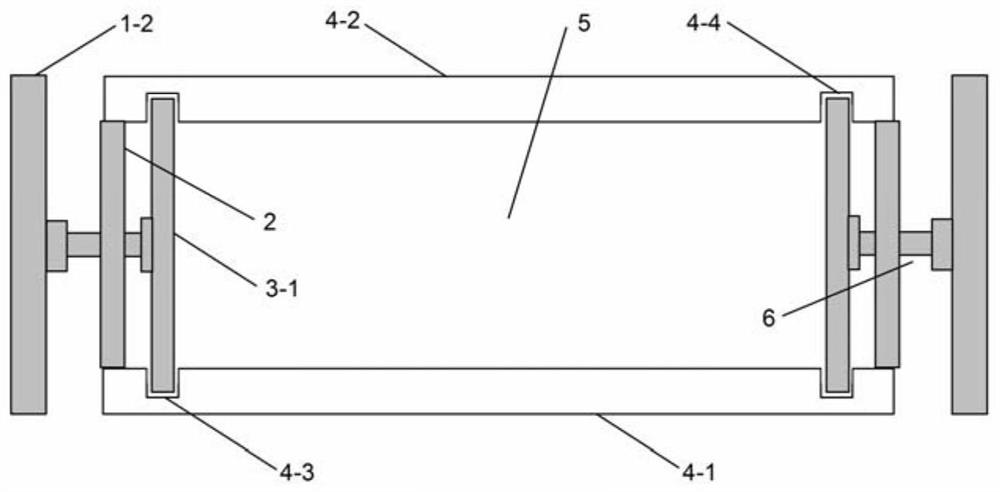

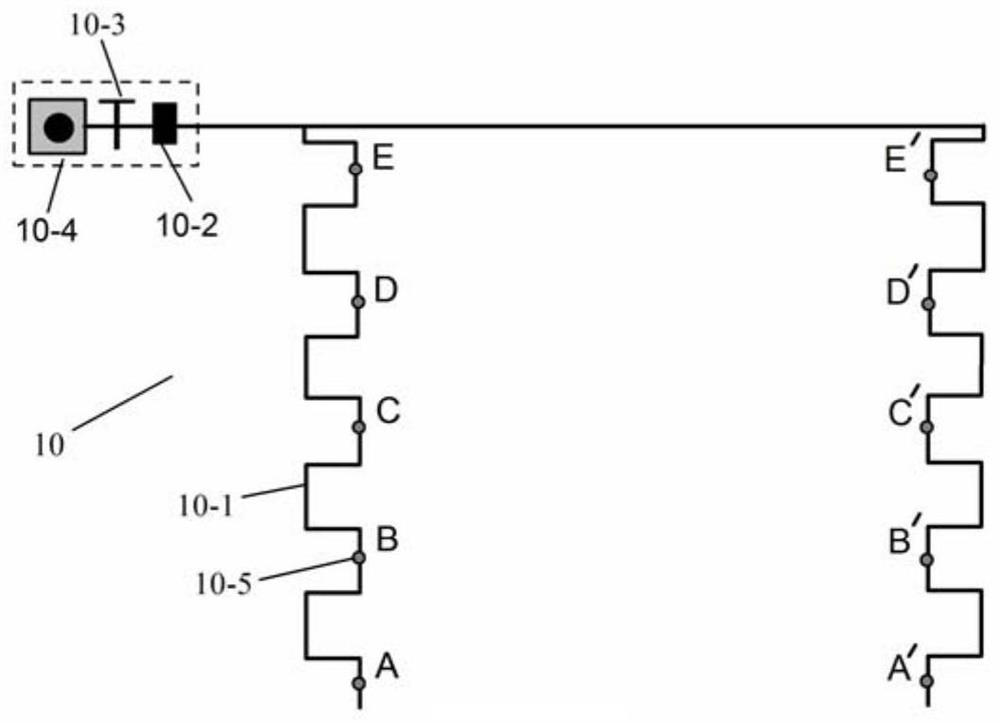

Deep confined water mining fault water inrush multi-field precursor information evolution similarity test device and method

ActiveCN111398564AReveal wellConducive to true reproductionEarth material testingCoal measuresSoil science

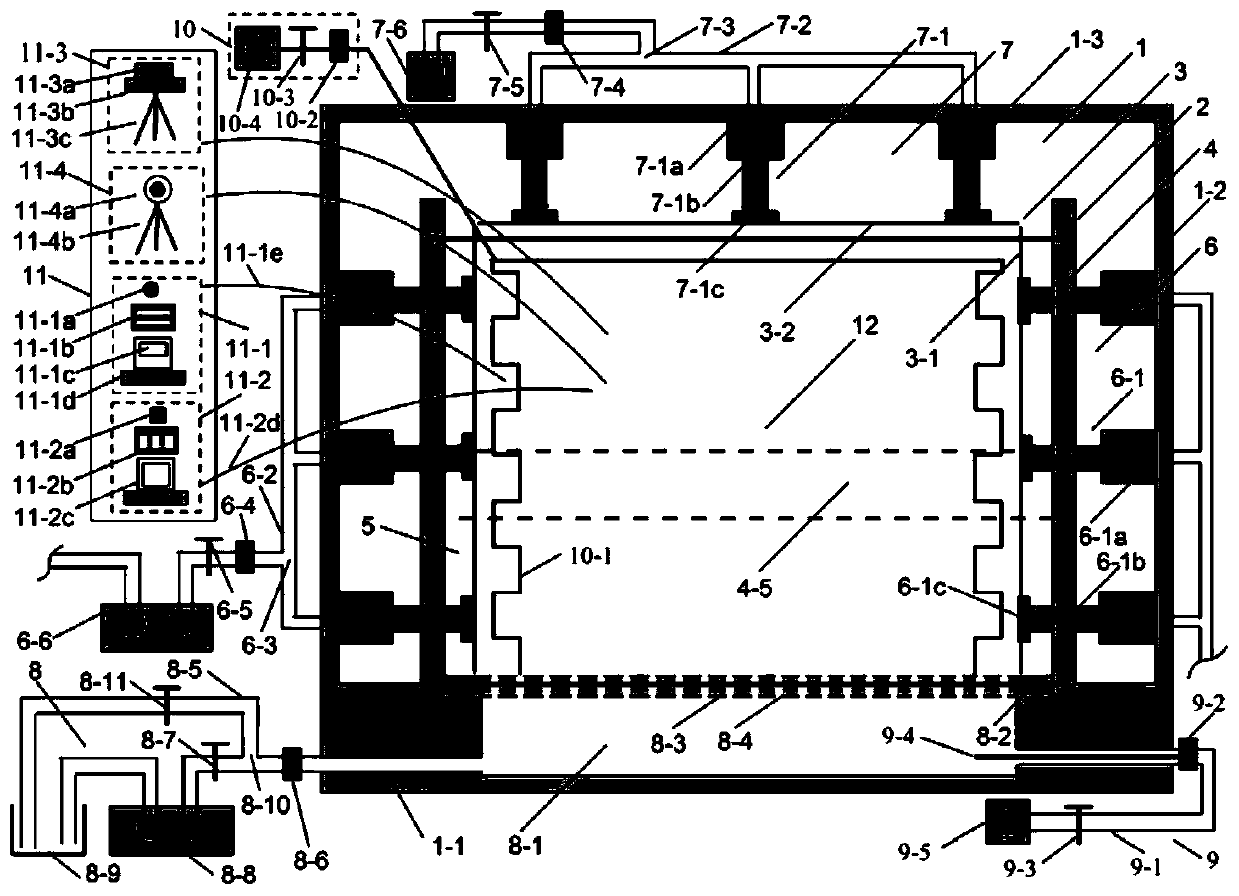

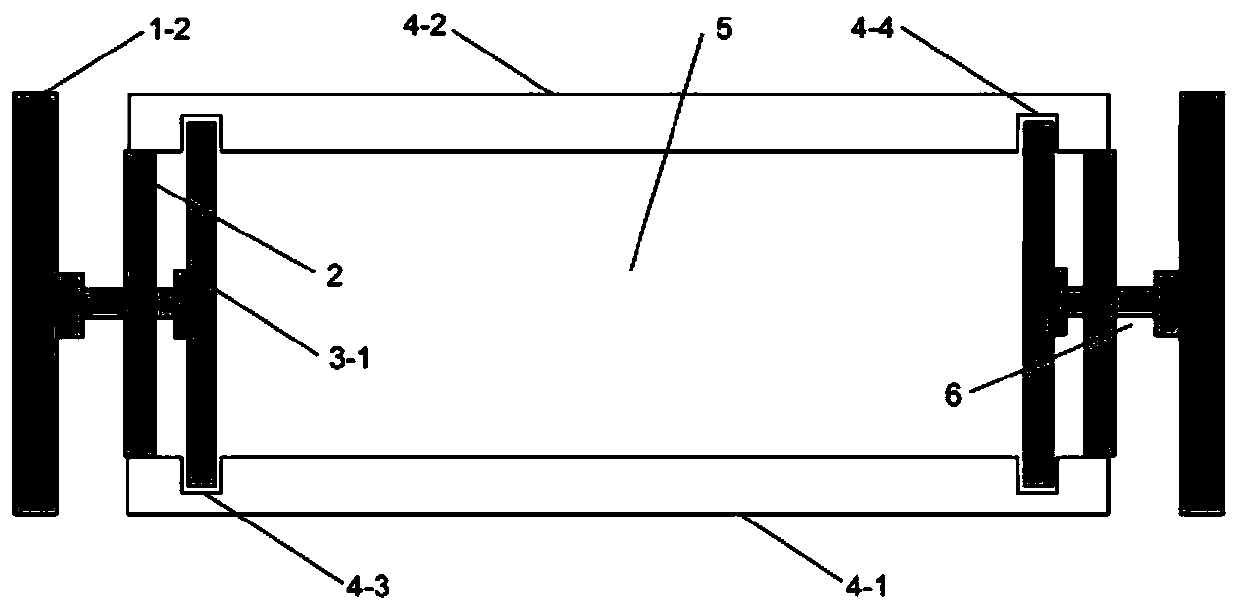

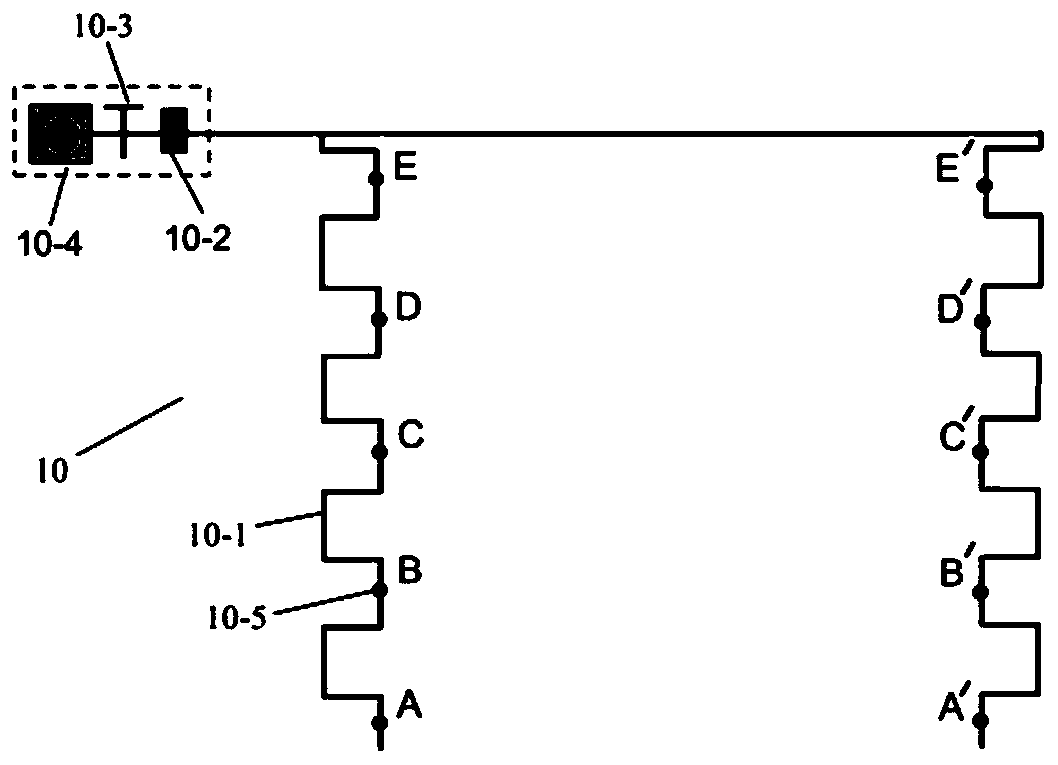

The invention discloses a deep confined water mining fault water inrush multi-field precursor information evolution similarity test device and method, and relates to the field of formation temperatureand similar simulation tests. The test device comprises a test bracket, a lateral baffle plate, a loading plate, a transparent glass plate, a model storage cavity, a lateral pressure loading system,a vertical loading system, a water pressure loading system, a water temperature adjusting system, a ground temperature adjusting system, a signal acquisition and processing system and a test model. The water pressure loading system, the water temperature adjusting system and the ground temperature adjusting system of the test device can provide stable high-temperature and high-pressure water and gradient formation temperature for the test model; the real geomechanical environment of the deep confined water fault-containing coal measure strata can be well simulated; real reproduction of multi-field precursor information of deep confined water mining fault water inrush is facilitated, and the evolution rule, coupling characteristics and influence factors of multi-field precursor informationsuch as fault surrounding rock stress, displacement, cracks, seepage and temperature in the deep confined water mining fault water inrush process are inversely analyzed.

Owner:ANHUI UNIV OF SCI & TECH

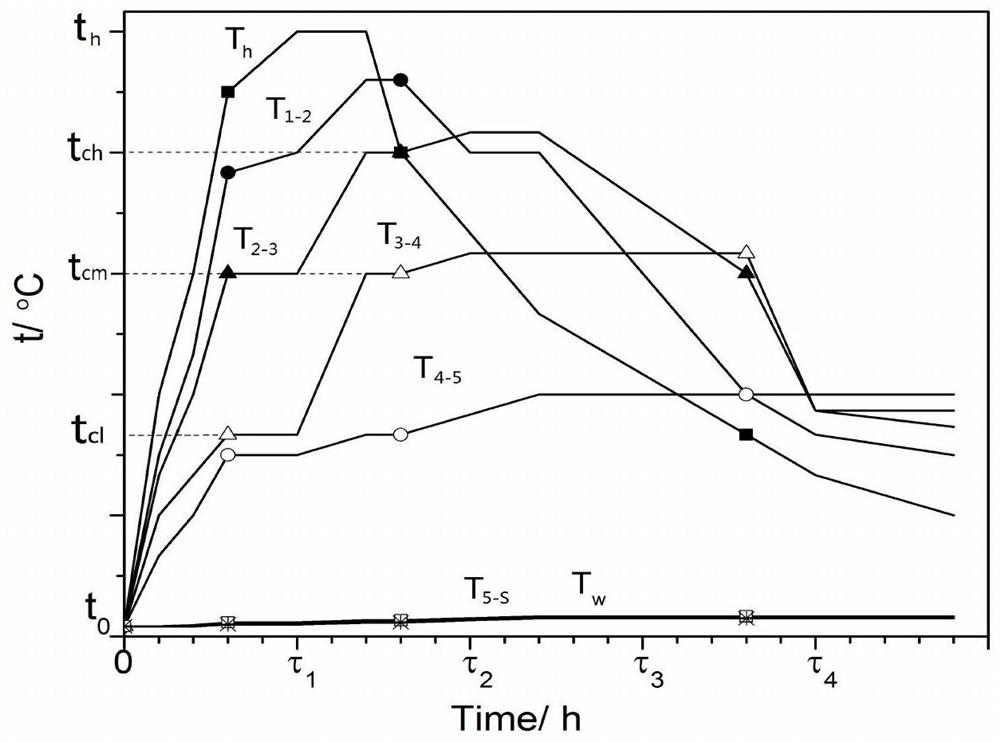

Intermittent operation high-temperature kiln near-zero heat loss refractory material lining body and preparation method thereof

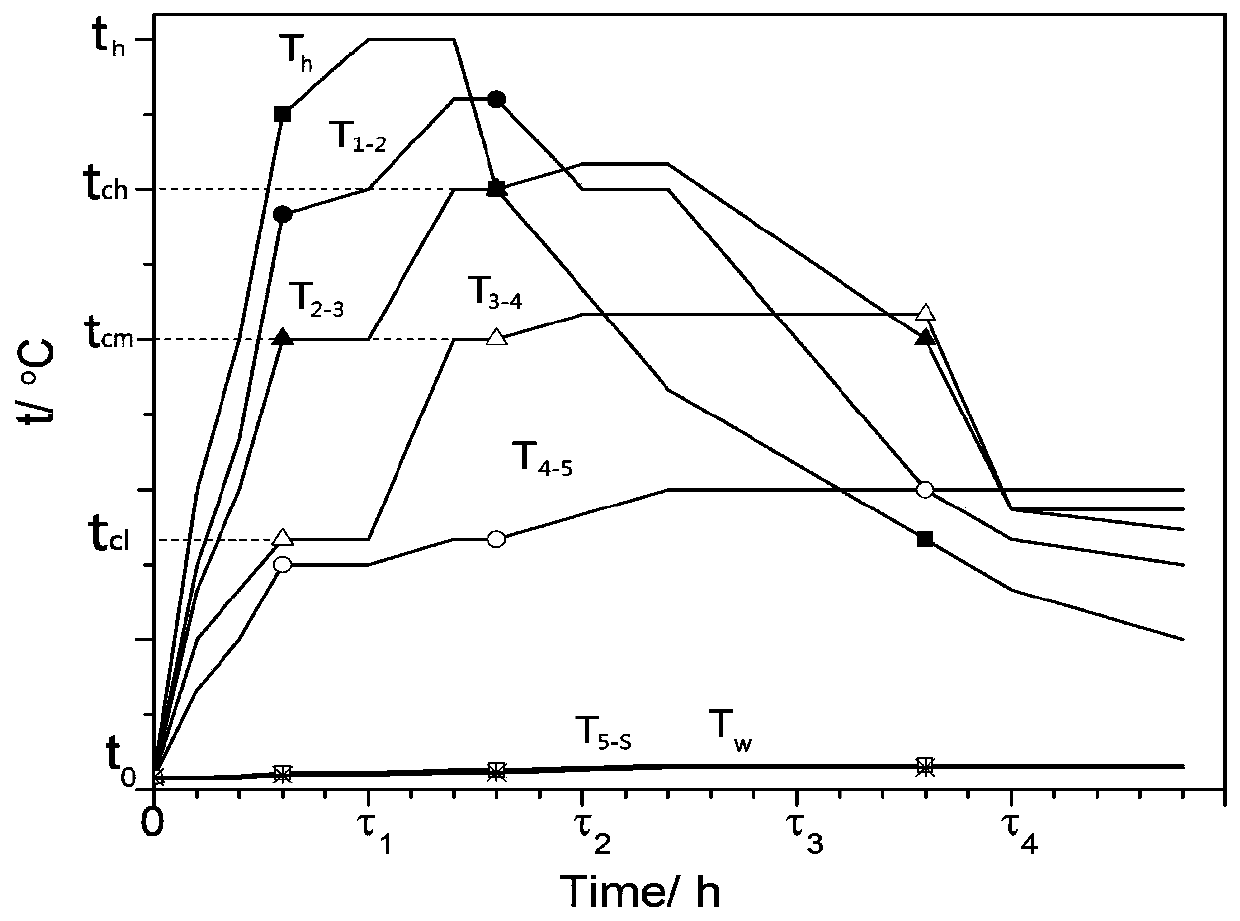

ActiveCN111205099ASmall temperature fluctuationsFlat temperature distributionSilicon alloyCarboxylic acid

The invention relates to an intermittent operation high-temperature kiln near-zero heat loss refractory material lining body and a preparation method thereof. According to the technical scheme, a permanent lining refractory material of the refractory material lining body is a phase-change heat-storage refractory material, namely a high-temperature phase-change heat-storage refractory material, a medium-temperature phase-change heat-storage refractory material and a low-temperature phase-change heat-storage refractory material are sequentially formed from inside to outside. The phase-change heat-storage refractory material is prepared by adding water into alloy-ceramic large capsules, alloy-aluminum oxide microcapsules, alpha-Al2O3 micro powder, silicon micro powder, calcium aluminate cement and polycarboxylic acid, mixing the substances with water, and carrying out molding, demolding and drying. During preparation, an aluminum-silicon-nickel alloy-ceramic large capsule, an aluminum-silicon-iron alloy-ceramic large capsule and an aluminum-silicon alloy-ceramic large capsule in the alloy-ceramic large capsules are respectively proportioned with a corresponding aluminum-silicon-nickelalloy-aluminum oxide microcapsule, an aluminum-silicon-iron alloy-aluminum oxide microcapsule and an aluminum-silicon alloy-aluminum oxide microcapsule in the alloy-aluminum oxide microcapsules. Theheat loss is approximate to zero, and the service life of the furnace lining refractory material is long.

Owner:WUHAN UNIV OF SCI & TECH

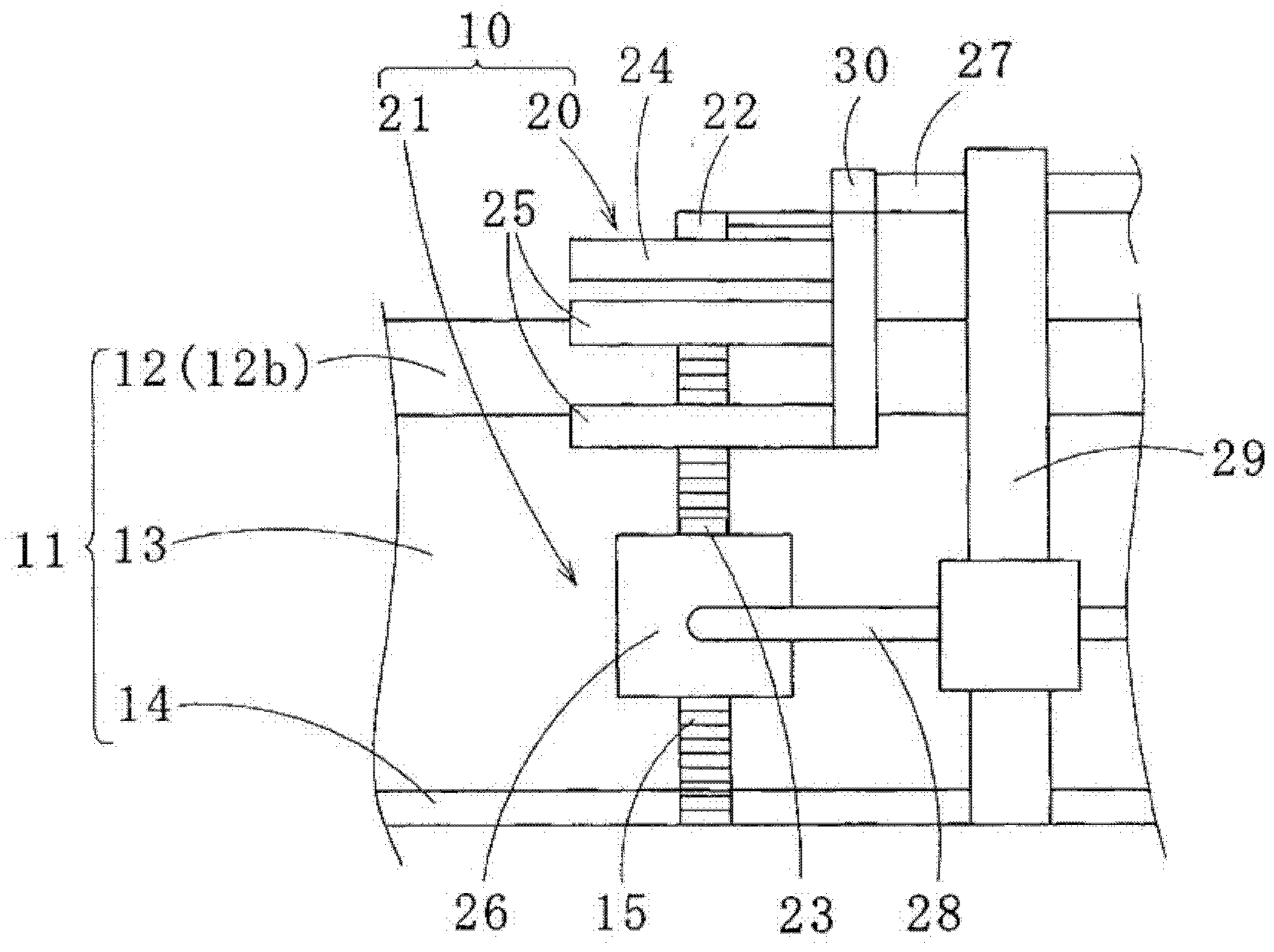

Device and method for cooling welded rail section

InactiveCN102361725AReduce residual stressImprove fatigue strengthRailsFurnace typesCooling fluidControl unit

A device for cooling a welded rail section is provided with a first cooler for cooling a head section of the welded rail section, a second cooler for cooling a column section of the welded rail section, and a control unit for controlling the first cooler and the second cooler. The first cooler is provided with a first temperature detection section for detecting the temperature of the head section, and also with a first discharge section for discharging a first cooling fluid toward the head section. The second cooler is provided with a second temperature detection section for detecting the temperature of the column section, and also with a second discharge section for discharging a second cooling fluid toward the column section. The control section individually changes the kind, amount, and flow speed of the first cooling fluid and the second cooling fluid when the head section and the column section are cooled.

Owner:NIPPON STEEL CORP

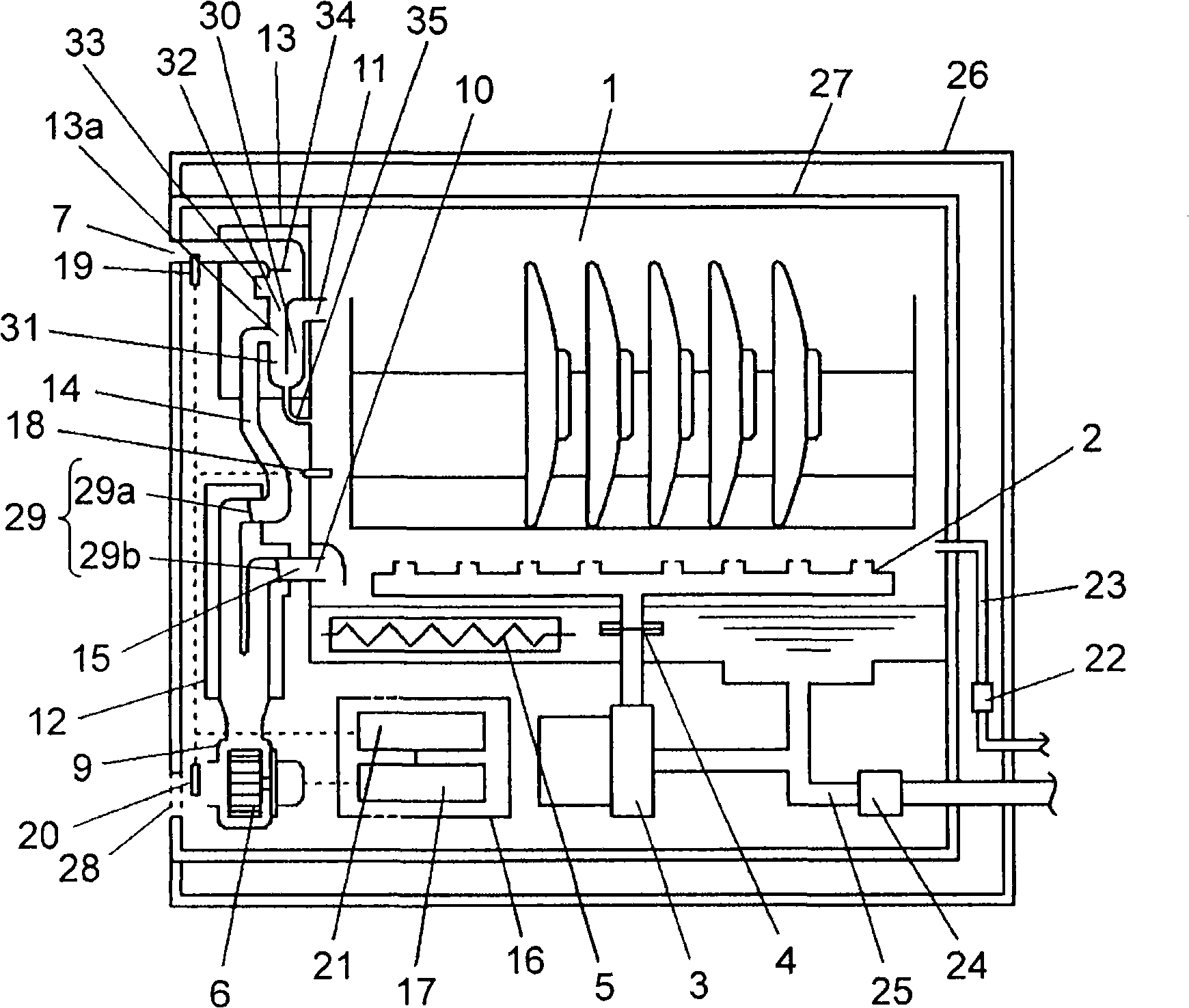

Cleaning and drying machine for tableware

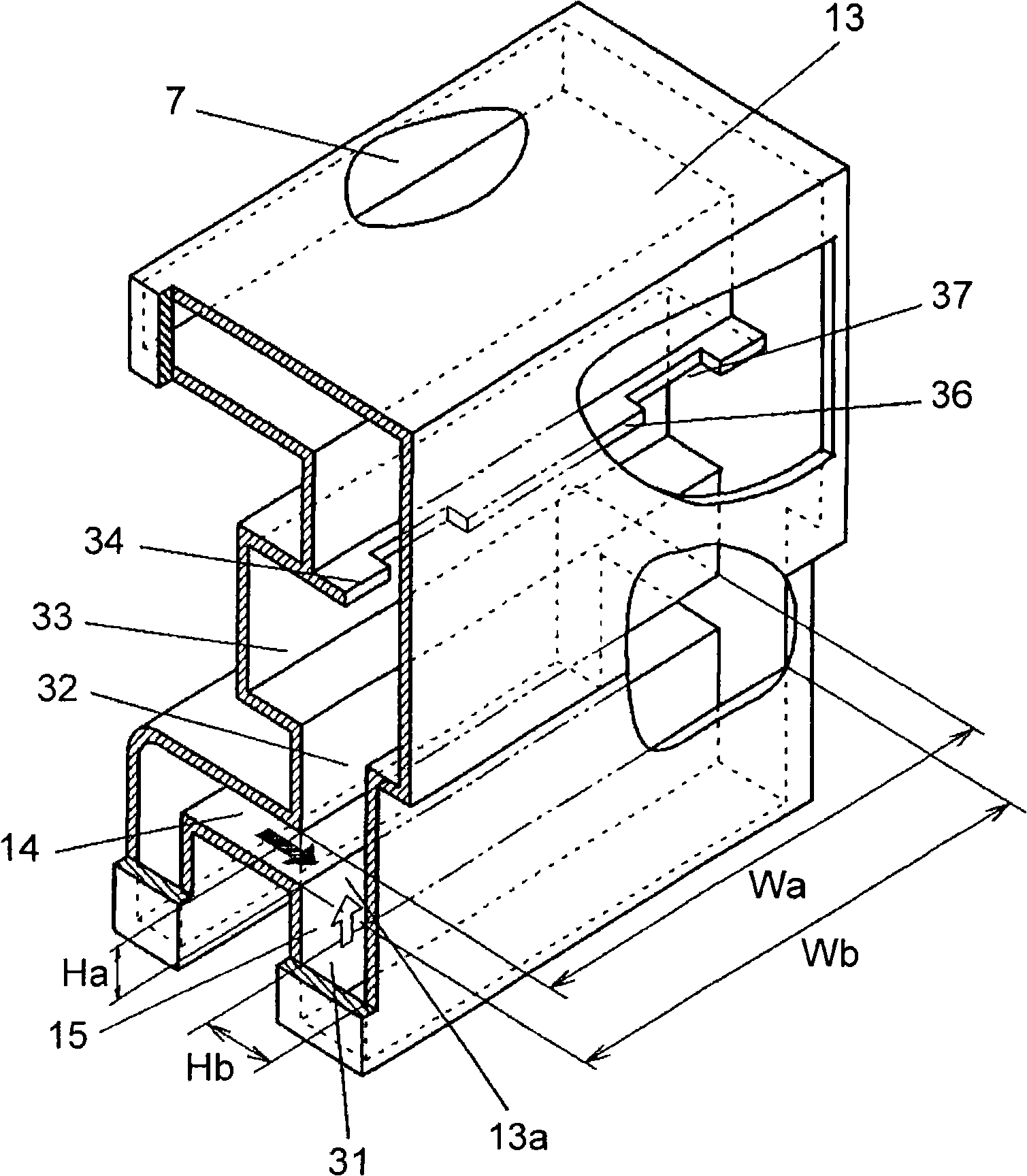

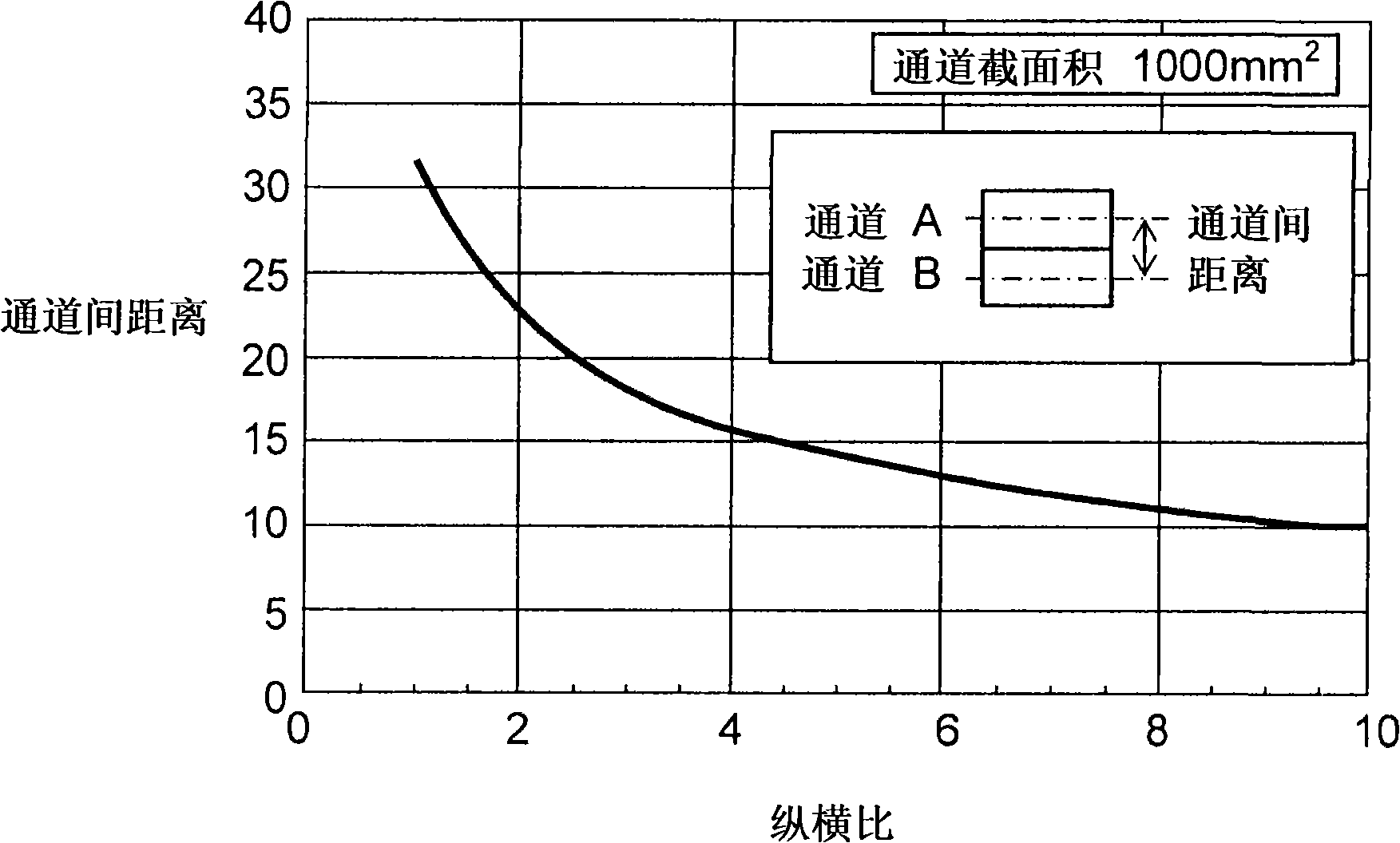

InactiveCN101278826APrevent hot airFlat temperature distributionTableware washing/rinsing machine detailsMiniaturizationCooling down

The present invention provides a tableware washing and drying machine in dry operation which can mix enough outer gas during a wash tank discharging gas for promoting temperature reduction of discharged gas and decreasing moisture in discharged gas, in which a drying device (9) having a vent (7) for discharging humidity inside of the wash tank (1), a blast engine (6) and a mixing device (13).The mixing device is mounted at the upstream side of the vent to mix outer gas from outside of the machine into the wash tank inner gas from the wash tank for cooling down inner gas of the wash tank. The wash tank inner gas channel (15) of the mixing device and outer gas channel (14) have rectangular section shapes with big aspect ratio respectively, and longer edging of the channels are connected each other for processing interflow.Outer gas flowing in the mixing device and inner gas of the wash tank can be mixed in minor space to cool down inner gas of the wash tank, thereby reducing air discharging humiture, preventing hot air feel reliably, implementing miniaturization of the device.

Owner:PANASONIC CORP

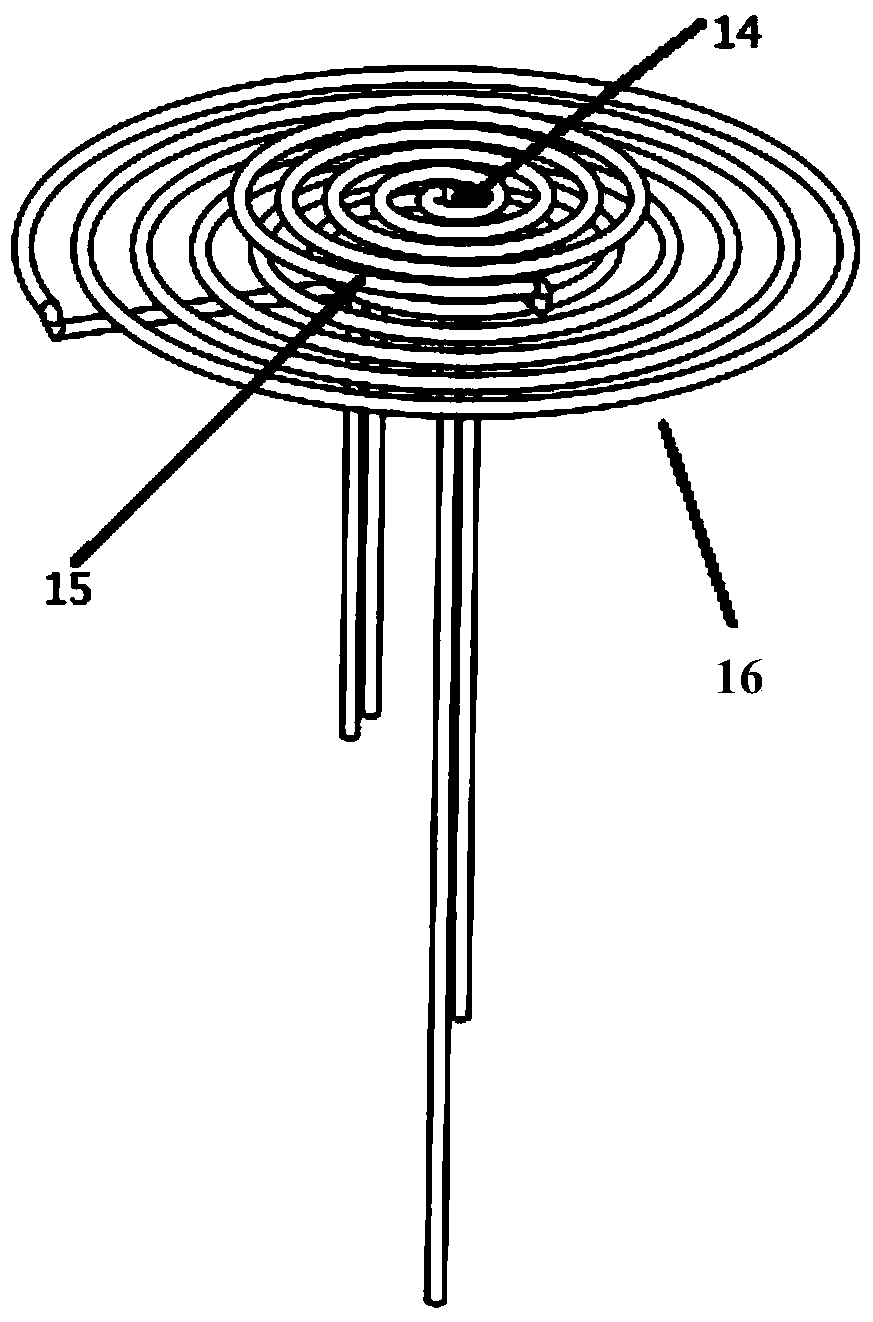

Heating device for hydride vapor phase epitaxy (HVPE) growth

InactiveCN104264218AIncrease volumeMaintain temperatureFrom chemically reactive gasesVapor phaseInternal temperature

The invention relates to a heating device for hydride vapor phase epitaxy (HVPE) growth. The heating device comprises five heating temperature regions, an in-furnace heating module, a heating furnace body and a heating furnace shell, wherein the heating furnace body is divided into an auxiliary heating temperature region and a material growing heating constant-temperature region; each heating temperature region is provided with a plurality of heating modules and internal temperature sensors thereof. With the adoption of the heating device, each heating module and an internal temperature sensor thereof are respectively connected with an automatic temperature controlling circuit, heating power of each heating module is reasonably regulated by the automatic temperature controlling circuit, and combined with a type and a heating mode of each heating module set in the each heating temperature region, temperature of each temperature region is independently and precisely controlled in a preset temperature range, thus realizing uniform and stable temperature distribution in an in-furnace temperature field. The heating device is particularly suitable for growth of materials in large-area region.

Owner:SINO NITRIDE SEMICON +1

Production method of catalyst dilution loading oxalate

InactiveCN103772197AImprove conversion rateGood choicePreparation by carbon monoxide or formate reactionOxalatePalladium catalyst

The invention relates to a production method of catalyst dilution loading oxalate, which mainly solves the problems of low raw material per-pass conversion and low oxalate selectivity in the prior art. With the adoption of the technical scheme that CO and nitrite at a mole ratio of (1-5):1 are introduced to a fixed bed reactor as raw materials at the feed temperature of 60-160 DEG C, and perform contact reaction with a palladium-bearing catalyst at the pressure of 0-1.5MPa, heat generated by the reaction is removed by heat exchange timely, the reactor comprises at least two catalyst bed layers, the height of each catalyst bed layer is Hn, Hn / H1 is equal to (1-5):1 by taking the height H1 of the first bed layer at the upper part as a reference, a volume ratio of inert filler without catalyst activity to a catalyst is (0-4):1, and the volume ratios of the catalyst in the bed layers from the top down are gradually increased, the problems are better solved, and the method can be used for industrial production of oxalate.

Owner:CHINA PETROLEUM & CHEM CORP +1

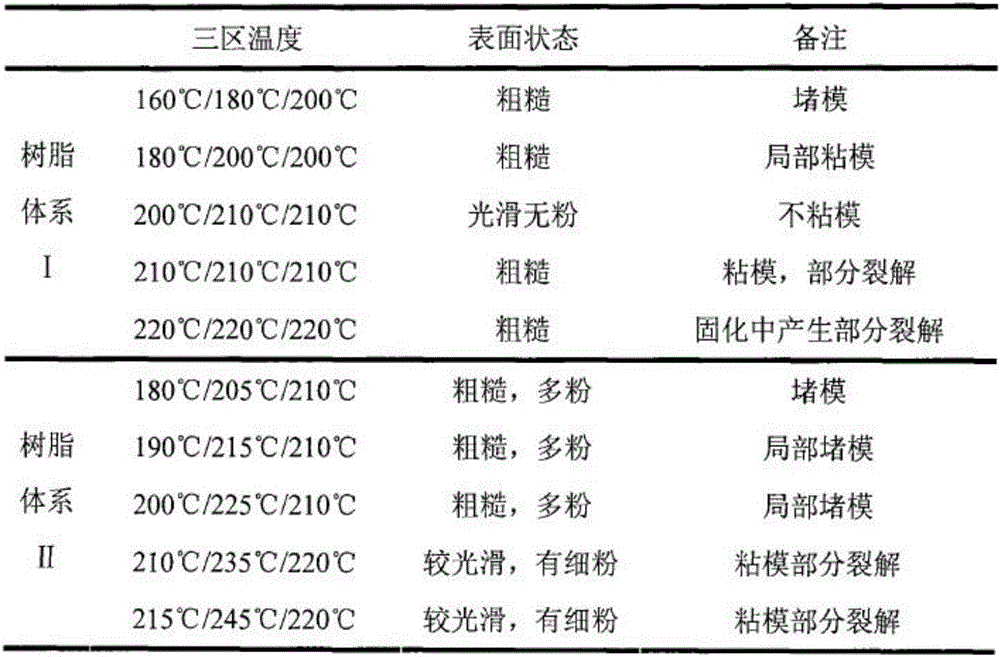

Preparation method for composite cable core

InactiveCN106393740ATimely supplementTimely replacementCable/conductor manufactureAccelerantMaterials science

The invention provides a preparation method for a composite cable core. The preparation method comprises the following steps that (1) continuous glass fibers are soaked in a solution of a resin system; (2) the soaked glass fibers are pulled and extruded by a pulling and extruding device comprising a pulling and extruding die, wherein the pulling and extruding speed is 20-40 cm / min, and the temperatures of three areas of the pulling and extruding die are respectively 180-200 DEG C, 210-215 DEG C and 210-215 DEG C; and (3) the resin system is furthered cured by a heating chamber, wherein the resin system comprises the following components in percent by weight: 100 parts of epoxy resin, 130-150 parts of a curing agent, 3-8 parts of a filler, 20-50 parts of a release agent and 2-5 parts of an accelerant. Through the adoption of the preparation method, the problem that during the pulling and extruding process, the surface of a composite is powdered, so that the surface of the composite is unsmooth is solved.

Owner:余姚市楷瑞电子有限公司

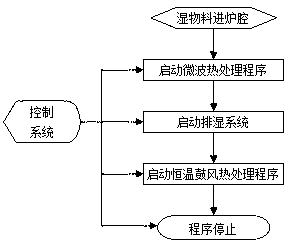

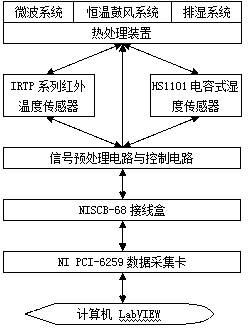

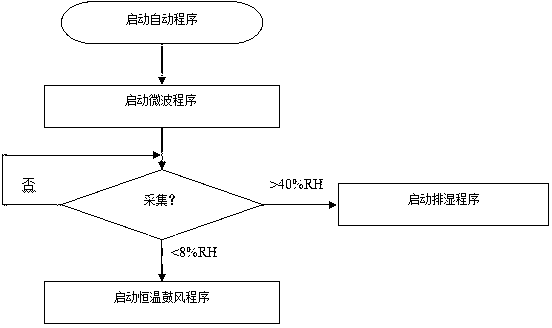

Blending heat treatment intelligent control method of microwave oven

InactiveCN103064446AReal-time acquisitionAchieving processing powerTemperature control using electric meansMicrowave ovenAmbient humidity

The invention discloses a blending heat treatment intelligent control method of a microwave oven. When wet materials enter an oven chamber, a microwave heat treatment processing procedure is started to dry the wet materials at first. When the ambient humidity in the oven chamber is higher than a preset value, a moisture exhaust system is started. Steam is discharged through the moisture exhaust system. When the ambient humidity in the oven chamber is lower than the preset value, the procedure switches to a constant temperature blast heat treatment condition. After constant temperature blast heat treatment operates for a certain time, drying and heat treatment are finished. The whole process of the heat treatment operates under the control of a control system. The blending heat treatment intelligent control method of the microwave oven takes advantages of high efficiency of high-temperature drying of the microwave and stable temperature distribution of the oven, greatly reduces time of the heat treatment, improves temperature uniformity, and increases production efficiency and heat treatment quality. Under the aegis of industrial control technology, a user can realize real-time collection, processing and display of data as long as on an operation interface and rapidly and accurately control the procedure of the heat treatment.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

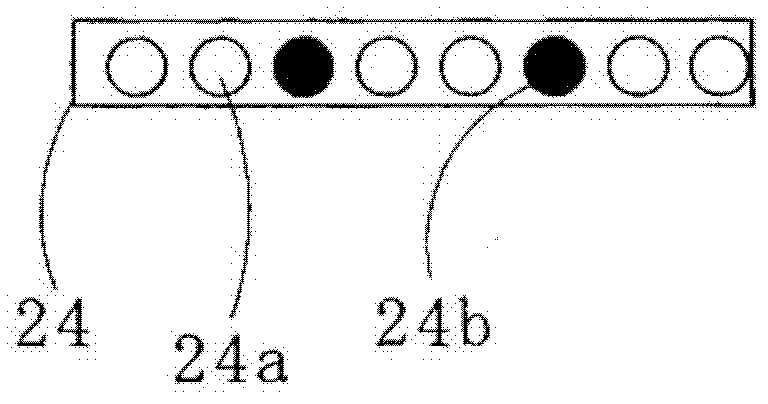

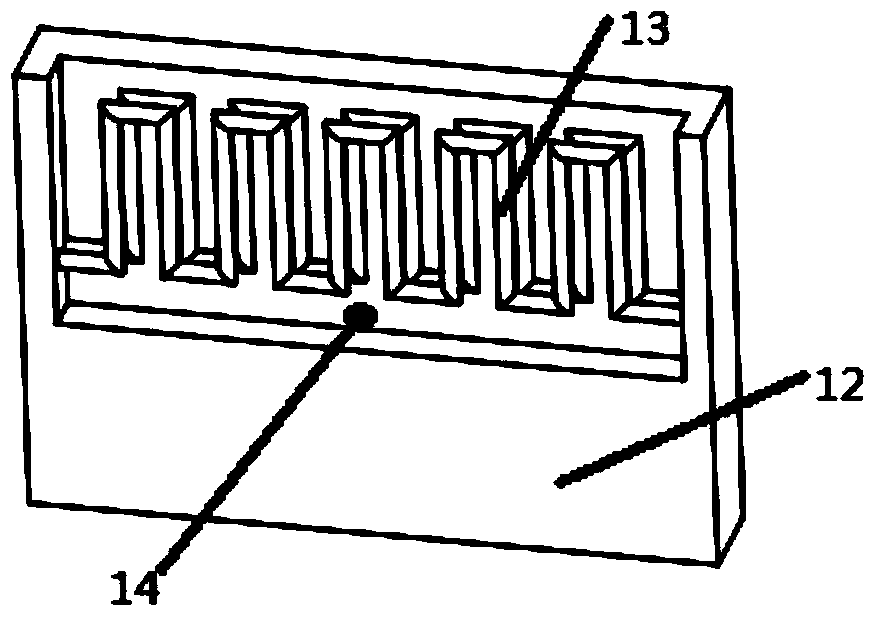

Low-voltage current limiting rapid fuse

InactiveCN104900460AUniform current distributionFlat temperature distributionEmergency protective devicesCurrent limitingCopper

The invention discloses a low-voltage current limiting rapid fuse which comprises a first connecting end, a fuse body and a second connecting end; wherein the first connecting end, the fuse body and the second connecting end are made of copper and are successively connected. The fuse body is elongated and is provided with a plurality of elongated slotted holes which are transversely and uniformly arranged in parallel. The fuse body of the copper low-voltage current limiting rapid fuse is set to a sheet-shaped member. Furthermore the fuse body is provided with the elongated slotted holes which are uniformly arranged in parallel, thereby improving stability and accuracy in operation of the low-voltage current limiting rapid fuse, and realizing a good fusing characteristic. Furthermore fusing time of the low-voltage current limiting rapid fuse is stable at a low overcurrent multiple and can satisfy a national requirement.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

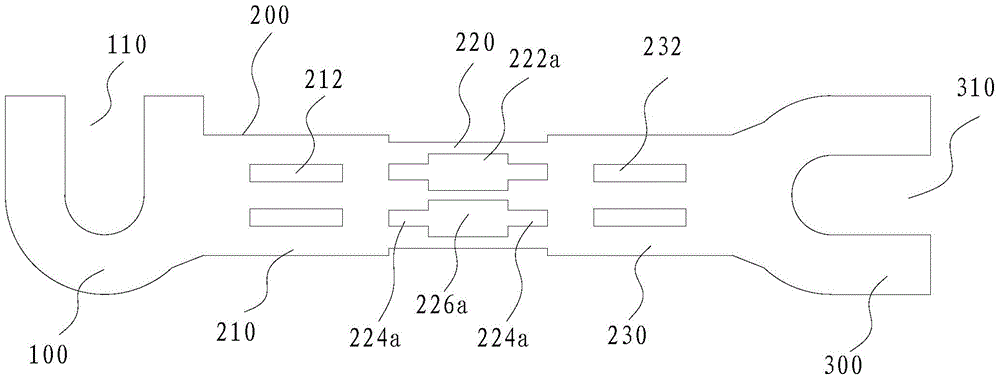

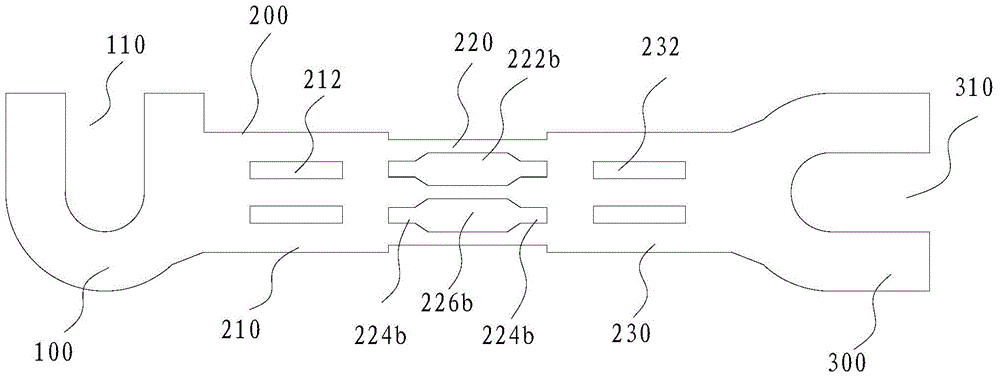

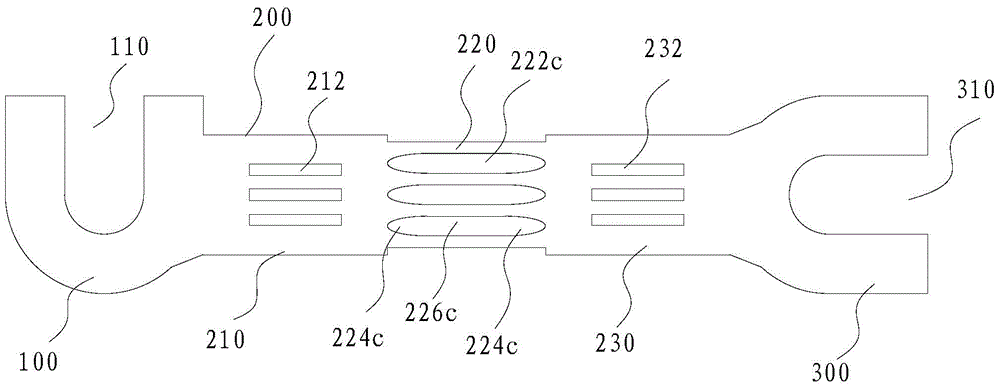

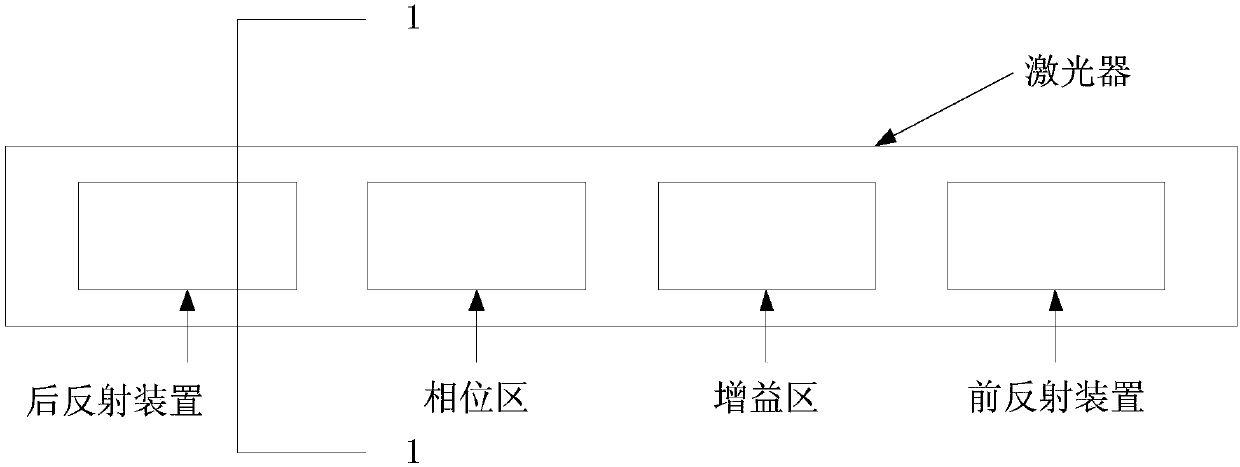

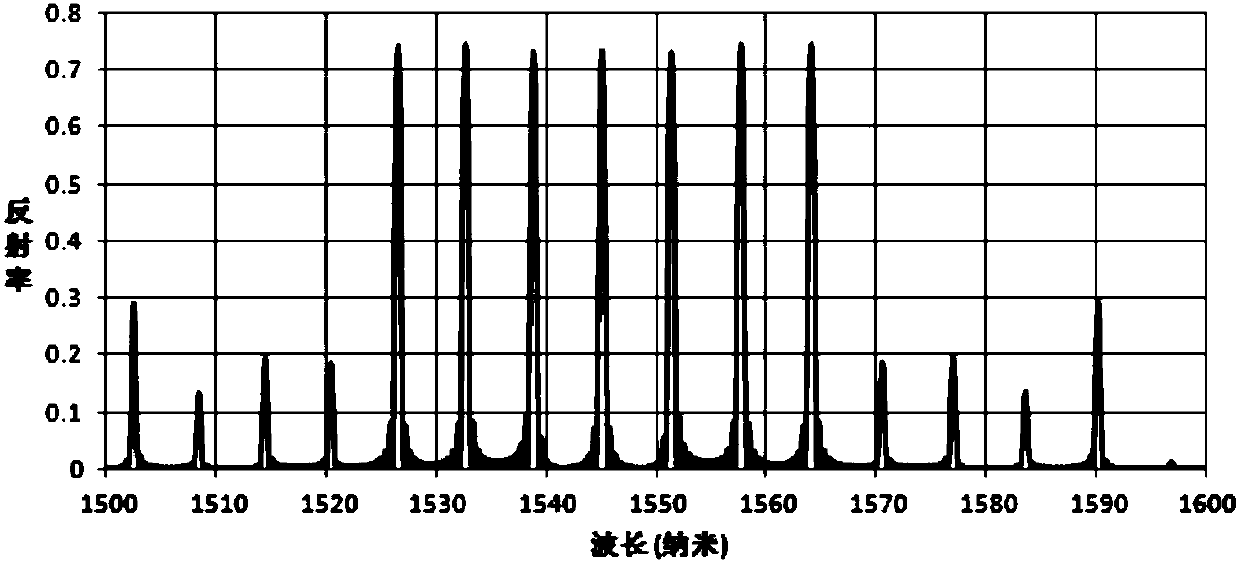

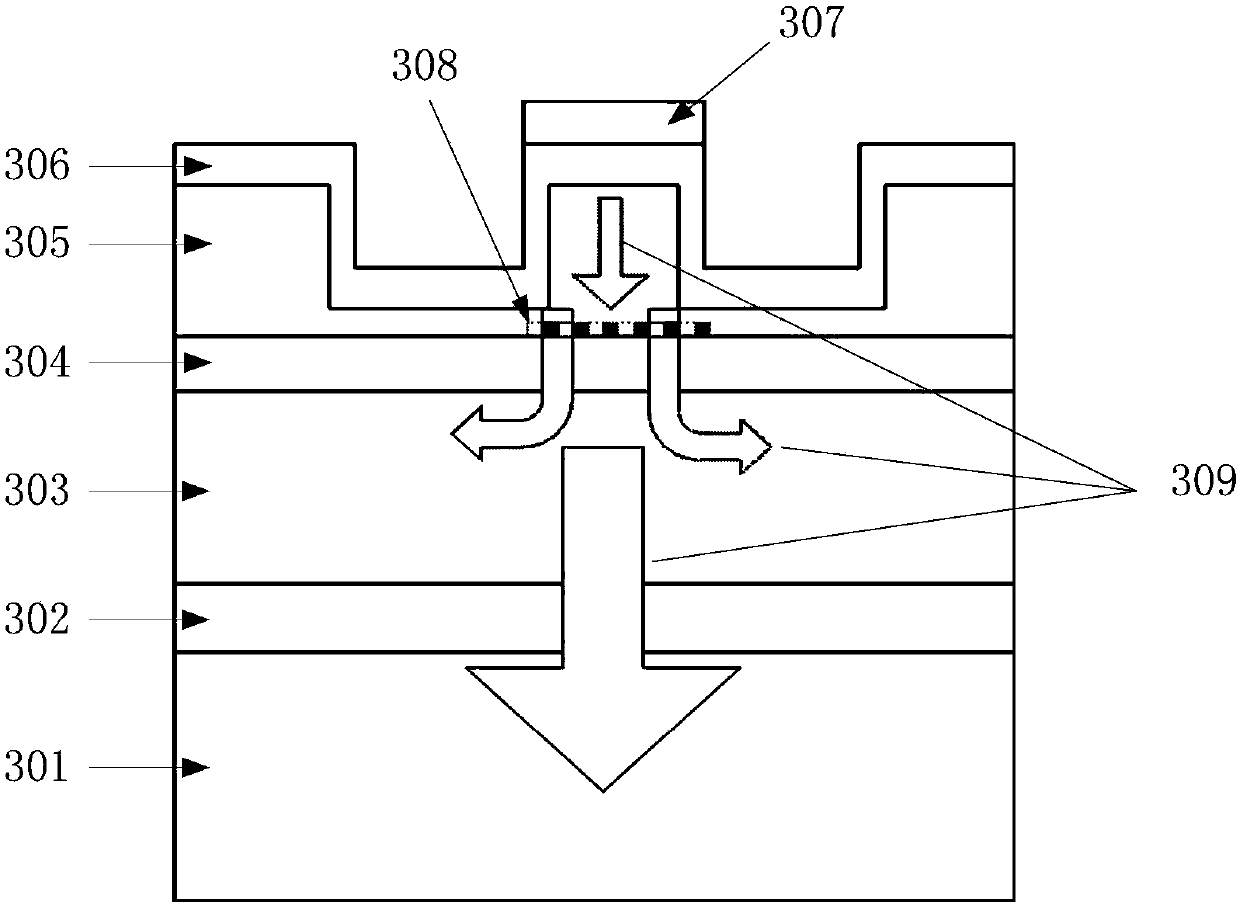

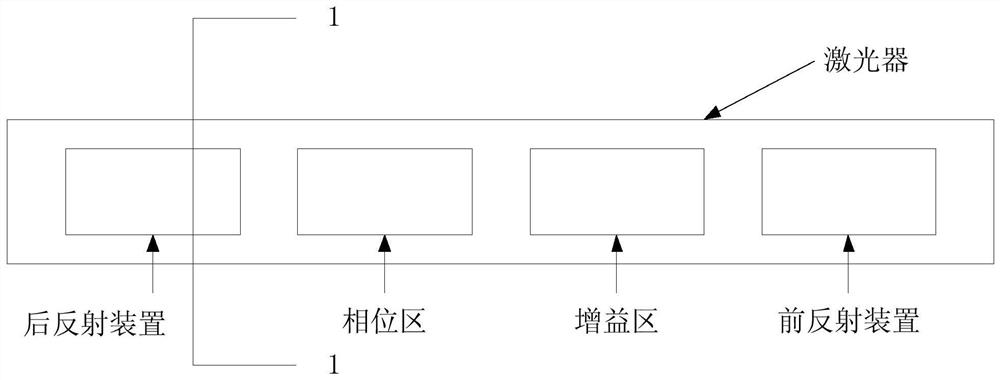

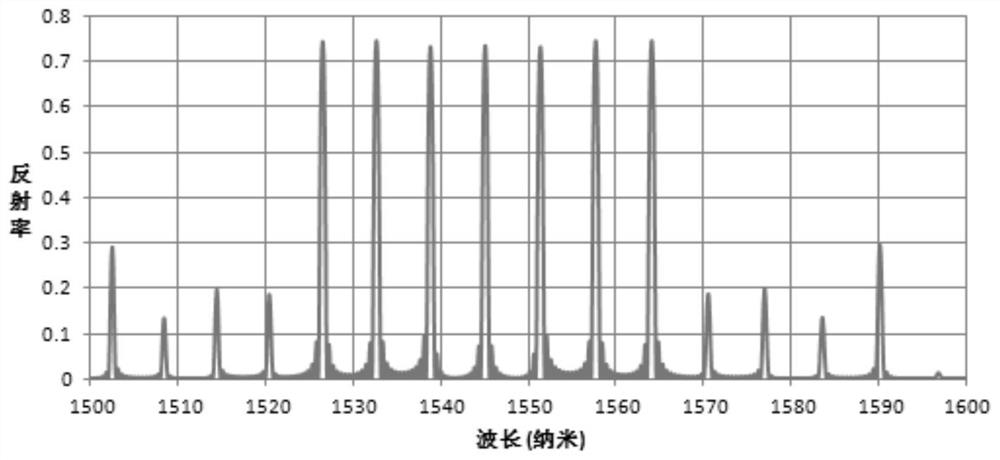

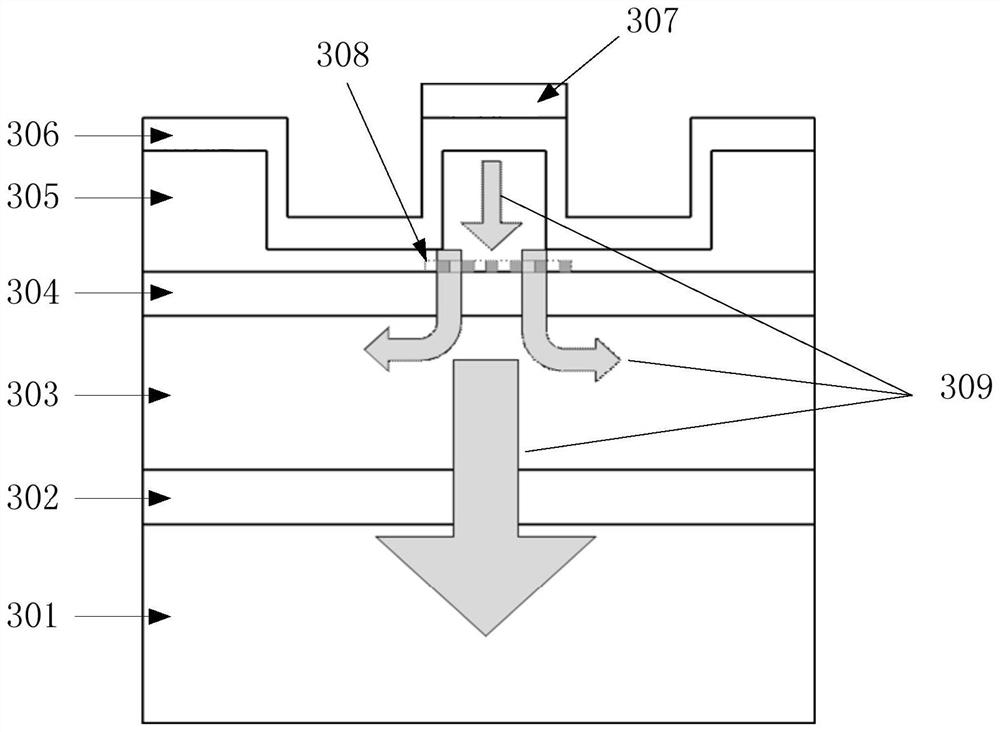

Reflecting device and tunable laser

ActiveCN110376766AFlat temperature distributionUniform temperature distributionOptical waveguide light guideNon-linear opticsLight transmissionTunable laser

The present application discloses a reflecting device and a tunable laser for ensuring uniform temperature distribution of the reflecting device during thermal tuning and improving the thermal tuningefficiency. The reflecting device comprises a light transmission layer and a ridge protruding from the light transmission layer; a first group of heaters and a second group of heaters isolated from each other are disposed on the surface of the ridge away from the light transmission layer; the light transmission layer on a first side of the ridge is provided with a first support arm and a second support arm isolated from each other, the end surface of the first support arm close to the ridge is a first end surface, the first end surface extends in a direction perpendicular to the ridge to forma first flat plate, and the first group of heaters is at least partially disposed in a region where the surface of the ridge away from the light transmission layer intersects the first flat plate; theend surface of the second support arm close to the ridge is a second end surface, the second end surface extends in a direction perpendicular to the ridge to form a second flat plate, and the secondgroup of heaters is at least partially disposed in a region where the surface of the ridge away from the light transmission layer intersects the second flat plate.

Owner:HISILICON OPTOELECTRONICS CO LIMITED

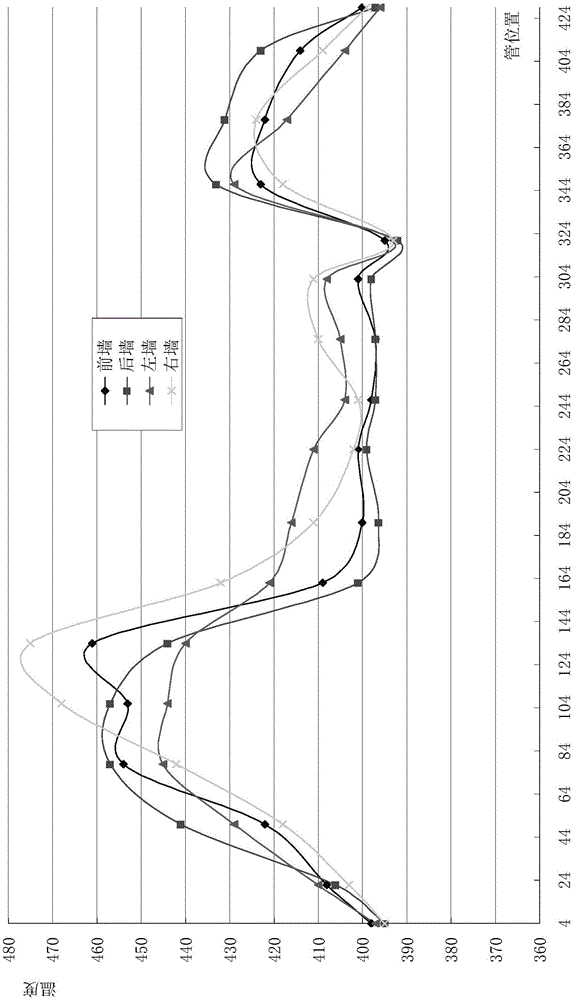

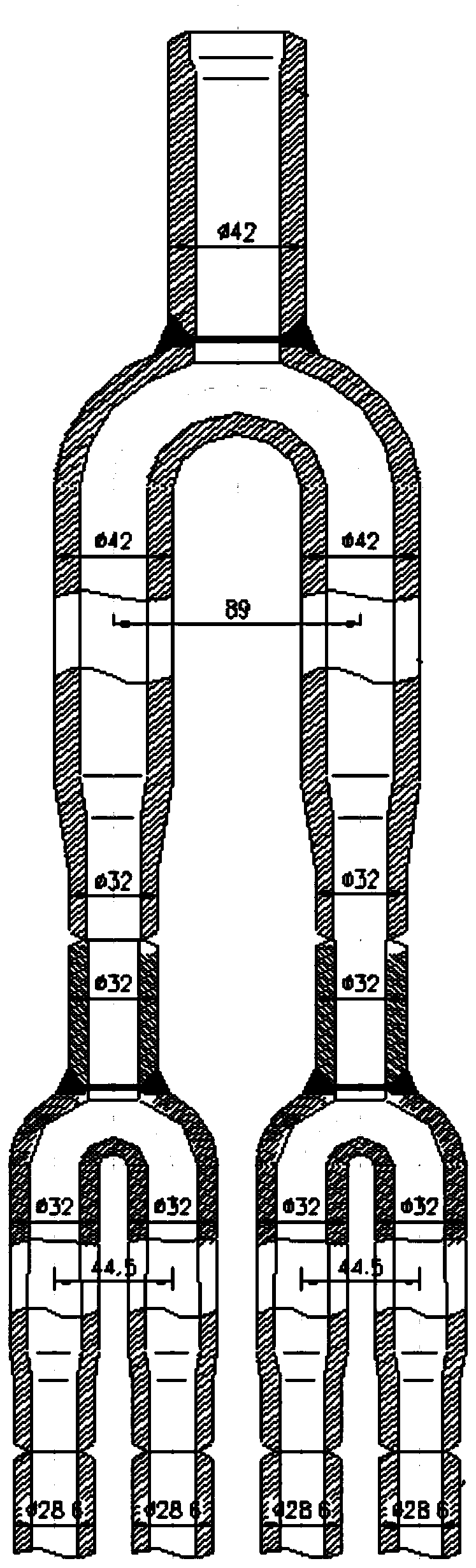

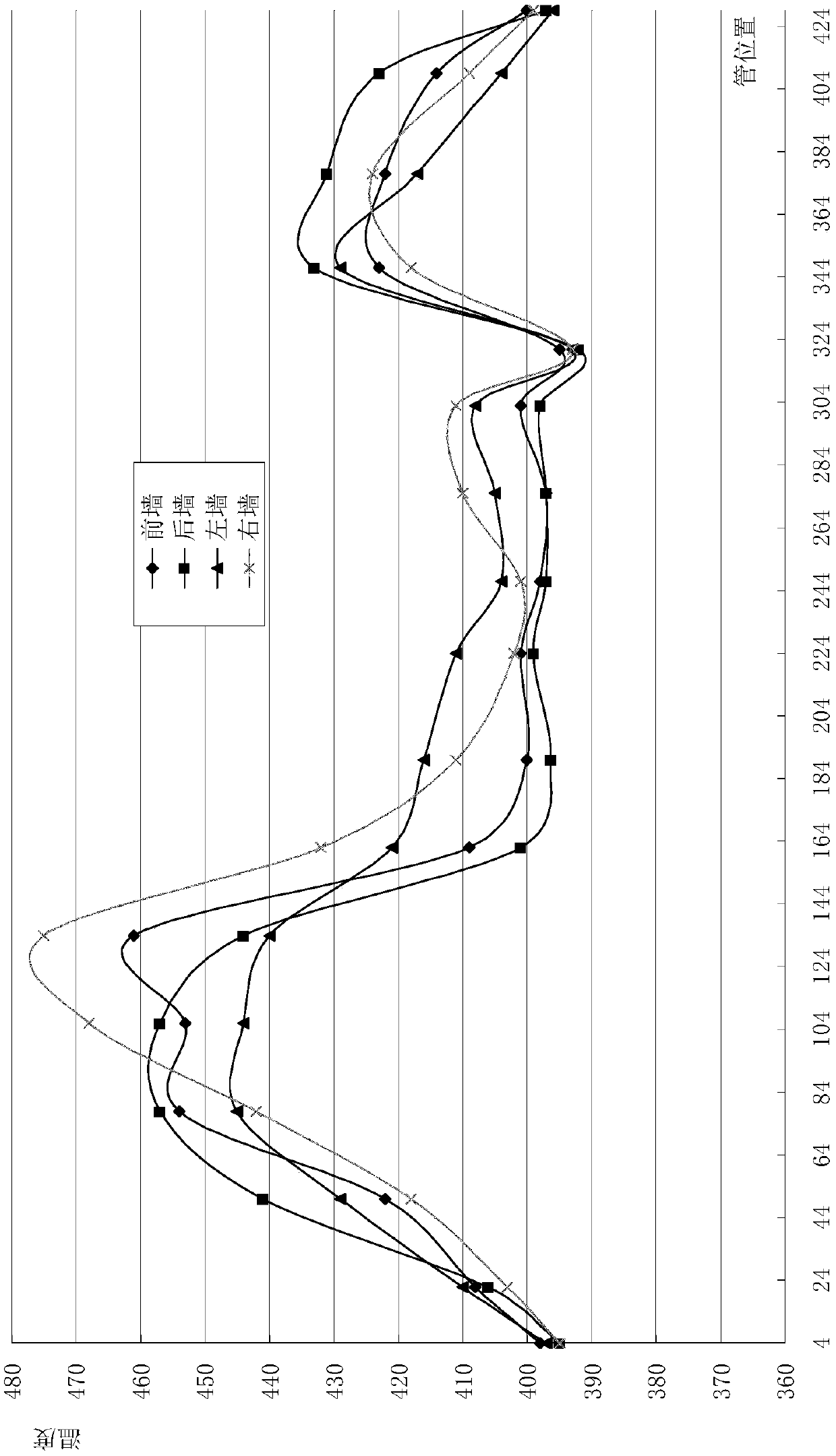

Method for decreasing occurrence rate of transverse cracks of boiler water walls

ActiveCN106439774AImprove securityReduce areaBoiler water tubesCasings/liningsEngineeringTemperature monitoring

The invention relates to a method for decreasing the occurrence rate of transverse cracks of boiler water walls. The method comprises the following steps, from wall temperature monitoring to hole expanding, that when a boiler and the water walls operate, the temperatures of the water walls on the four sides and water wall pipes are monitored correspondingly; a thermal deviation curve showing temperature distribution of the water wall pipes in the water walls on the four sides is drawn according to measured temperature data, and whether water wall pipes located in an overheat area exist or not is judged; and throttling holes corresponding to the water wall pipes located in the overheat area are expanded, wherein after hole expanding is conducted during one time of operation, wall temperature monitoring and overheat judging are conducted in the next time of operation, and throttling holes corresponding to the water wall pipes located in the overheat area are expanded after the water wall pipes located in the overheat area are judged to still exist. By adoption of the method for decreasing the occurrence rate of the transverse cracks of the boiler water walls, the occurrence area and probability of the transverse cracks of the water walls are substantially decreased, and the safety of the water walls is improved.

Owner:JIANGSU DATANG INT LUSIGANG POWER GENERATION

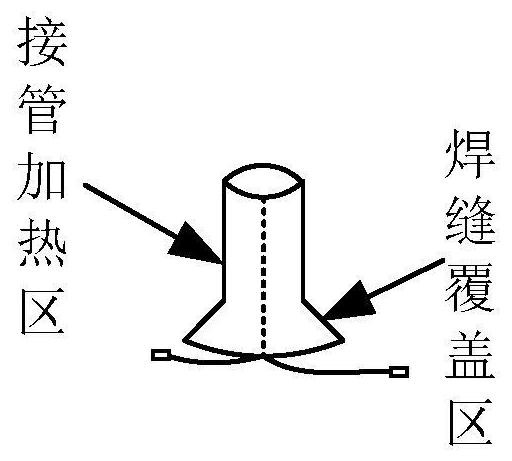

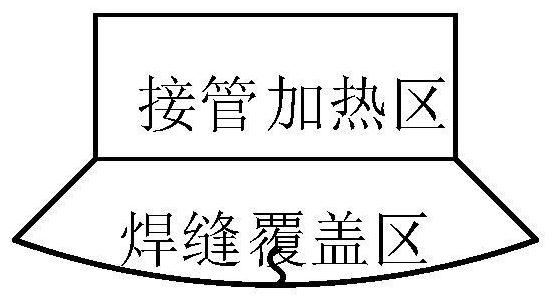

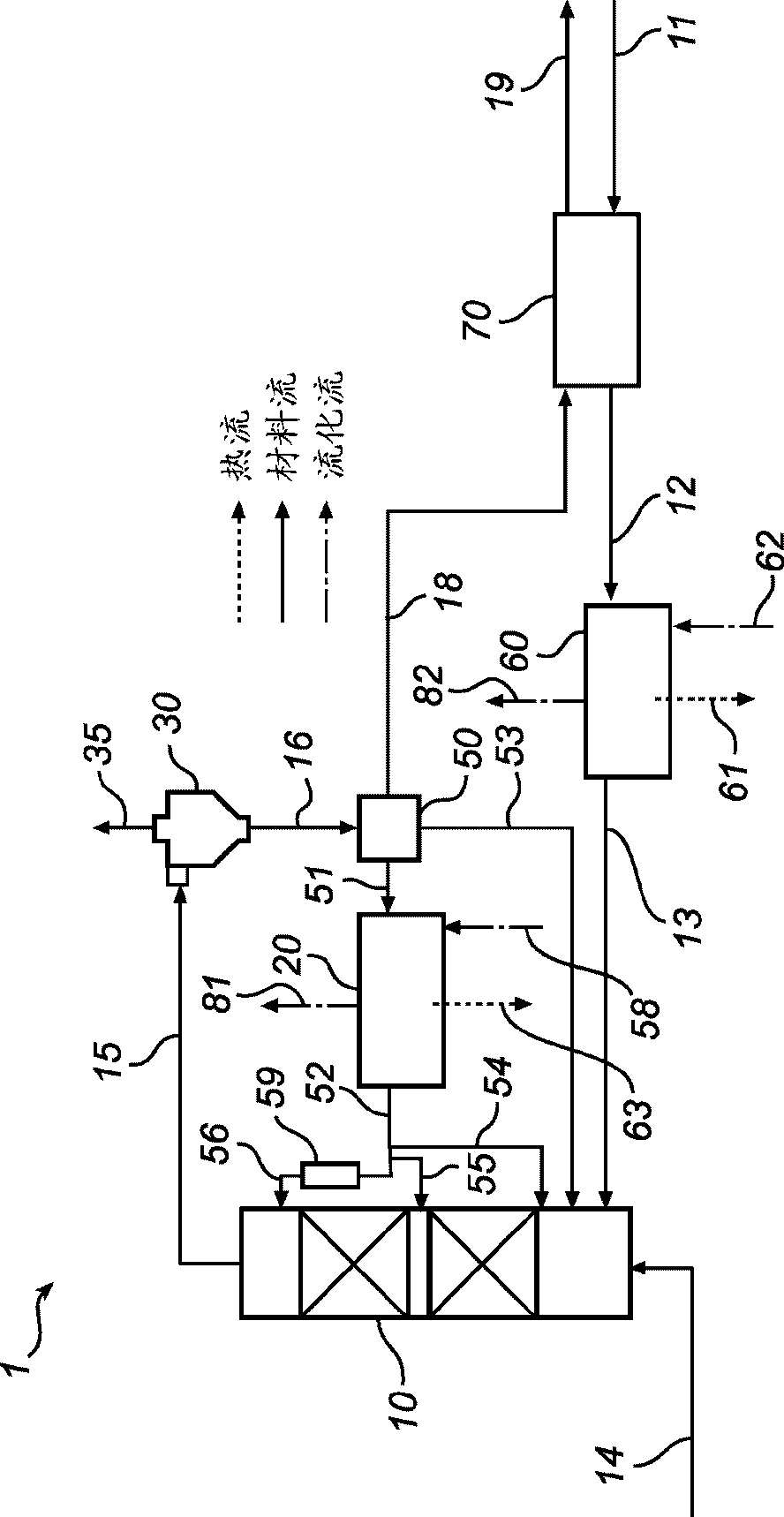

Armored heating sheet for heat treatment of fillet weld of small connecting pipe

PendingCN113106237ASimple structureEasy to useFurnace typesHeat treatment furnacesFillet weldMechanical engineering

The invention discloses an armored heating sheet for heat treatment of a fillet weld of a small connecting pipe. The heating sheet comprises ceramic chips, a heating wire and heating connectors; the ceramic chips are connected in series through the heating wire; and the heating connectors are installed at the two ends of the heating wire and used for being connected with heat treatment equipment. The armored heating sheet for the heat treatment of the fillet weld of the small connecting pipe provided by the invention is convenient in structure, simple to use, easy to mount, reusable, stable in heat treatment effect and uniform in temperature distribution.

Owner:XIAN THERMAL POWER RES INST CO LTD

A reflection device and tunable laser

ActiveCN110376766BFlat temperature distributionUniform temperature distributionOptical waveguide light guideNon-linear opticsEngineeringErbium lasers

Disclosed are a reflection device and a tunable laser, which are used for ensuring the uniform temperature distribution of the reflection device during thermal tuning and improving the efficiency of thermal tuning. The present application comprises: a light transmission layer and a ridge protruding from the light transmission layer, wherein a surface, away from the light transmission layer, of the ridge is provided with a first group of heaters and a second group of heaters, which are separated from each other; a part of the light transmission layer on a first side of the ridge is provided with a first supporting arm and a second supporting arm, which are separated from each other; an end face, close to the ridge, of the first supporting arm is a first end face that extends in a direction perpendicular to the ridge to form a first flat plate, and at least some of the first group of heaters are arranged in a region where the surface, away from the light transmission layer, of the ridge intersects with the first flat plate; and an end face, close to the ridge, of the second supporting arm is a second end face that extends in a direction perpendicular to the ridge to form a second flat plate, and at least some of the second group of heaters are arranged in a region where the surface, away from the light transmission layer, of the ridge intersects with the second flat plate.

Owner:HISILICON OPTOELECTRONICS CO LIMITED

Flame tube air inlet method of solid oxide fuel cell system and combustion chamber of solid oxide fuel cell system

ActiveCN114188578ASmall volumeAchieve combustionFuel cell auxillariesSolid electrolyte fuel cellsCombustion chamberFuel cells

The invention relates to a flame tube gas inlet method of a solid oxide fuel cell system, anode tail gas of a galvanic pile enters a flame tube from the head of the flame tube in a rotational flow mode, and cathode tail gas of the galvanic pile enters the flame tube in the following mode: 1) entering the flame tube from side wall through holes distributed in the side wall of the flame tube; (2) entering the flame tube from end wall through holes distributed in the head end wall of the flame tube; and (3) the tail gas enters the flame tube from the head of the flame tube in a rotational flow mode, and the cathode tail gas entering the flame tube in the rotational flow mode wraps the anode tail gas entering the flame tube in the rotational flow mode in the gas inlet direction. The invention further relates to the combustion chamber adopting the method. By means of rotational flow flame stabilization, flame multi-point arrangement, anode tail gas collection and distribution, unique distribution of the side wall through holes and the end wall through holes and the like, stable combustion of the combustion chamber under the conditions that gas composition changes are complex, residual gas coefficients are variable and the combustion heat value is extremely low is achieved, and the temperature distribution of an outlet of the combustion chamber is uniform.

Owner:北京有恒能动科技有限公司

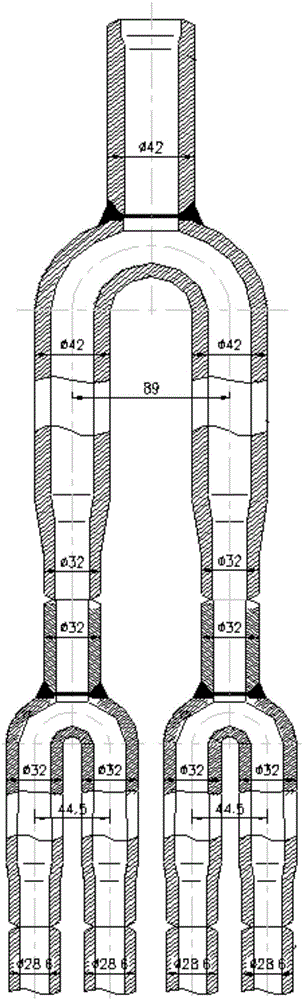

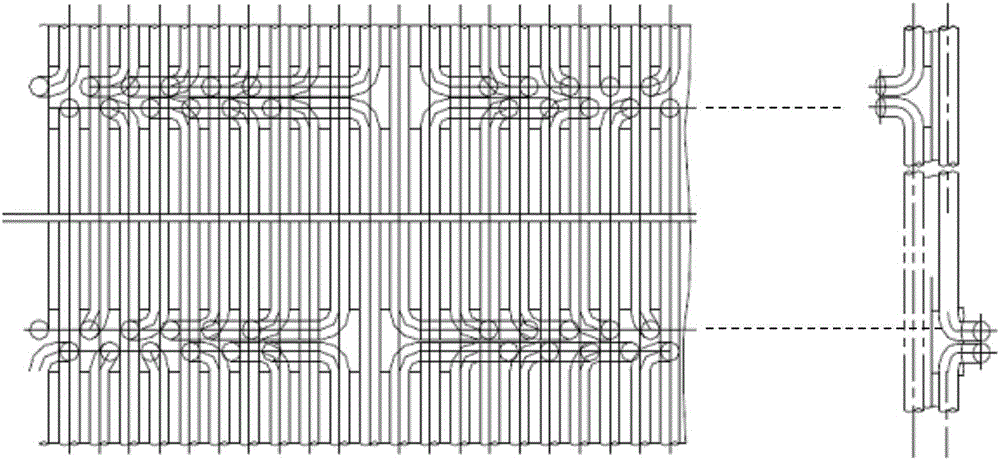

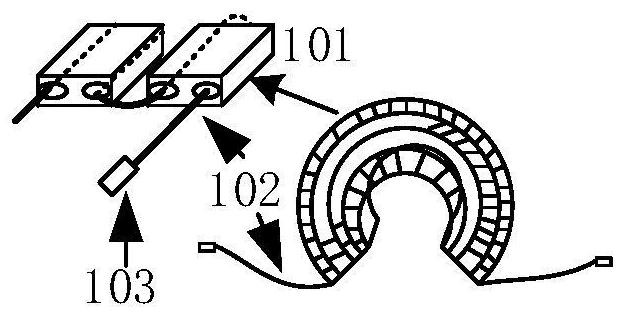

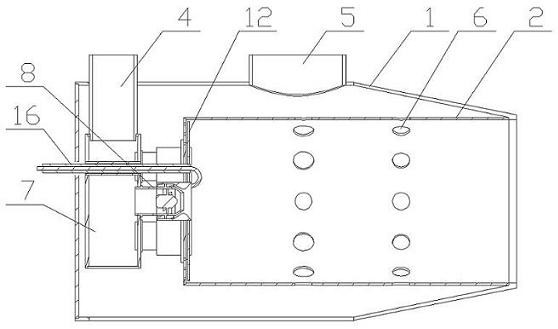

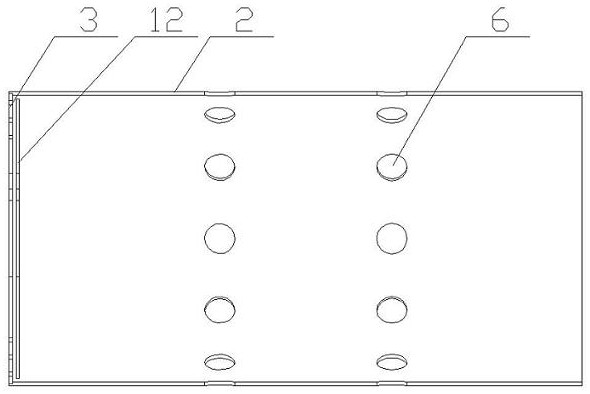

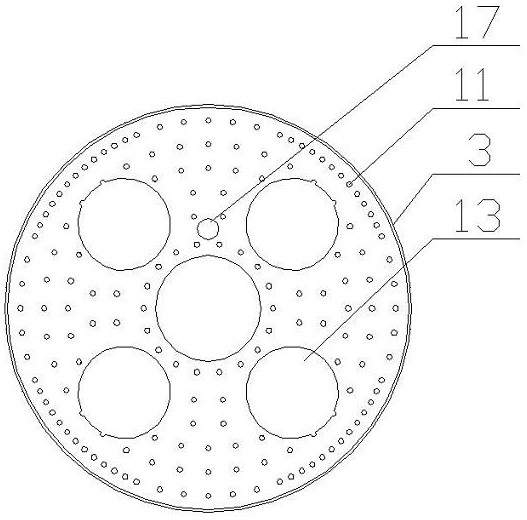

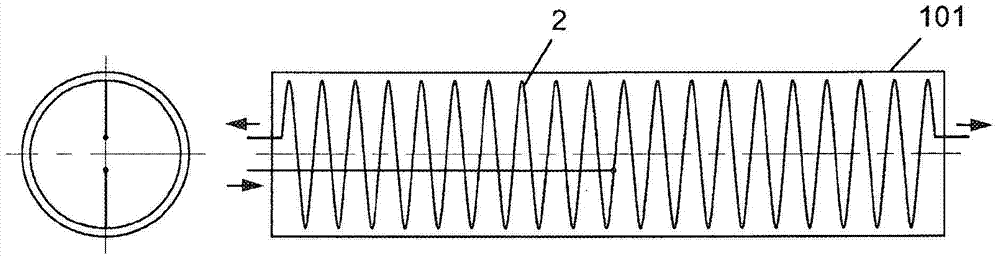

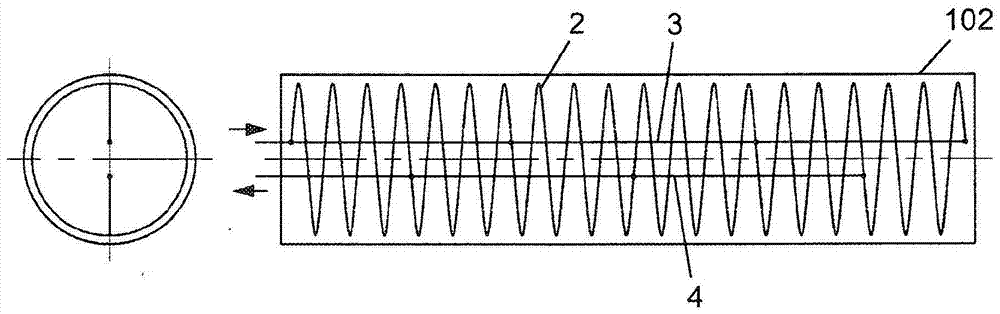

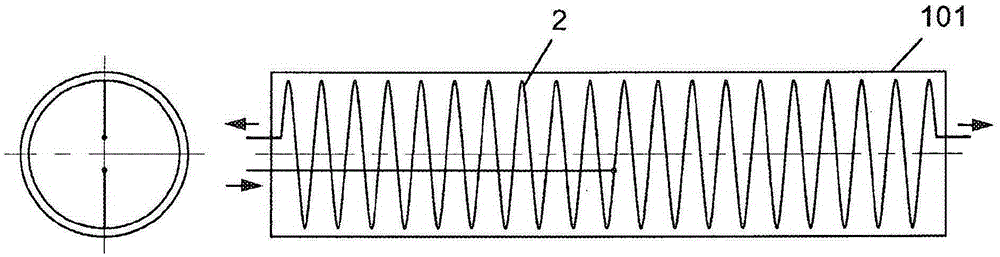

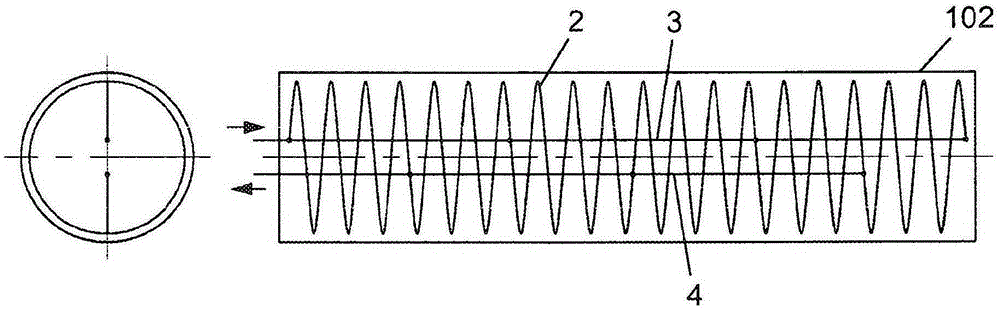

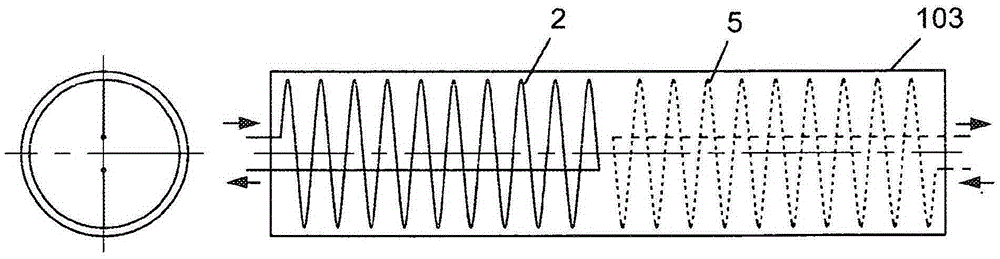

Heated or cooled deflection drum for pouring equipment

ActiveCN105263688BUniform temperatureFlat temperature distributionCoatingsEngineeringContinuous casting

The invention relates to a return pulley (101..110) for a continuous casting system, said return pulley comprising a drum-shaped main body and at least one heating pipe (2, 5, 6) laid underneath a cylindrical surface of the pulley (101..110). The heating pipe(s) (2, 5, 6) each has / have at least one input and at least one output offset in relation to said input, the sum of the inputs and outputs being at least three. The invention further relates to a continuous casting system having a return pulley (101..110) of the above type.

Owner:BERNDORF BAND GMBH

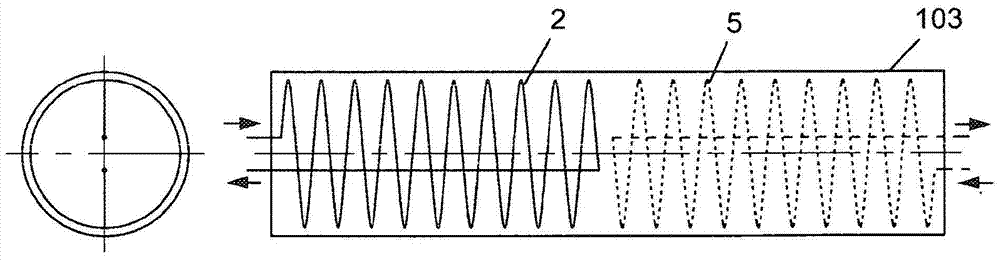

High solids flux circulating carbonation reactor

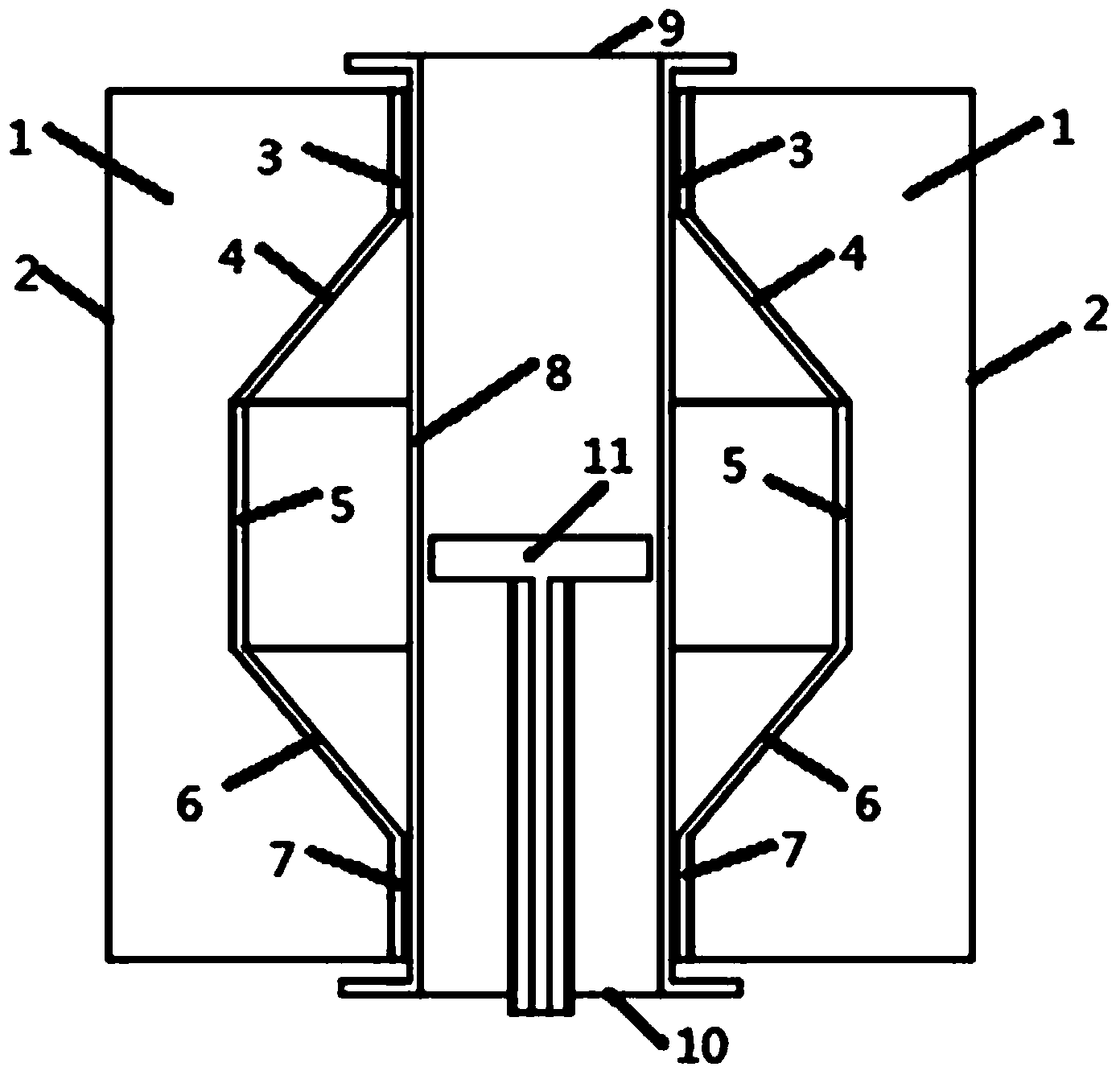

ActiveCN104185501AIncrease temperatureIncrease temperature distribution gradientCalcium/strontium/barium carbonatesProductsFluidized bedPhysical chemistry

The present invention relates to a method for capturing carbon dioxide CO 2 by carbonation in a circulating fluidized bed (CFB) carbonation reactor (10) wherein temperature profile is adjusted by recirculation of solid fractions of metal oxide MeO and metal carbonate MeCO 3 to the CFB carbonation reactor (10). Also a system (1) recirculating the metal oxide MeO and metal carbonate MeCO 3 is provided by the invention.

Owner:GENERAL ELECTRIC TECH GMBH

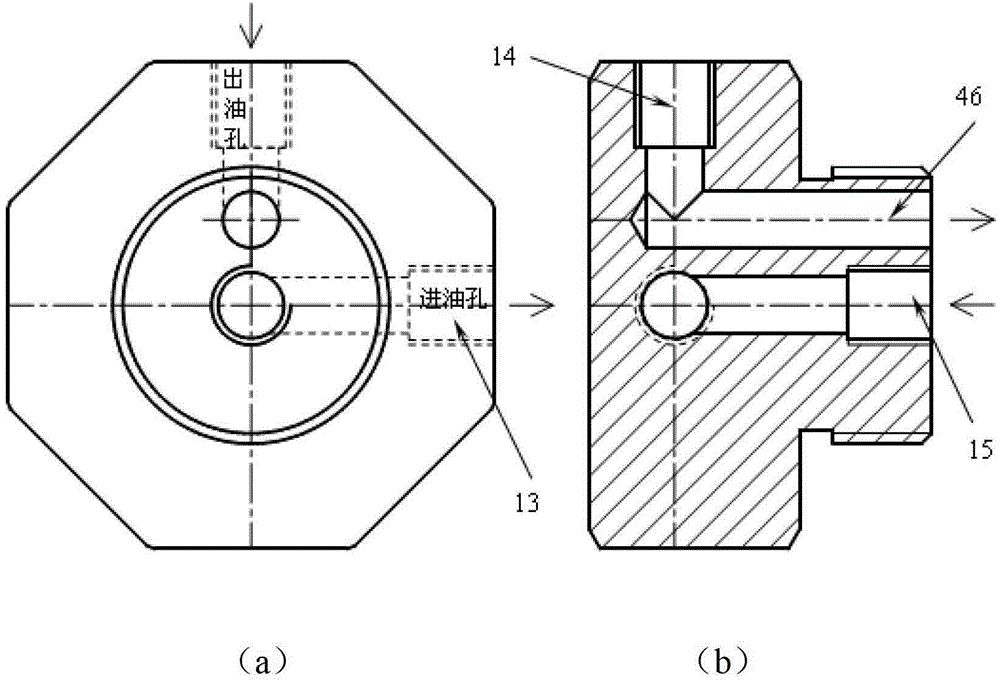

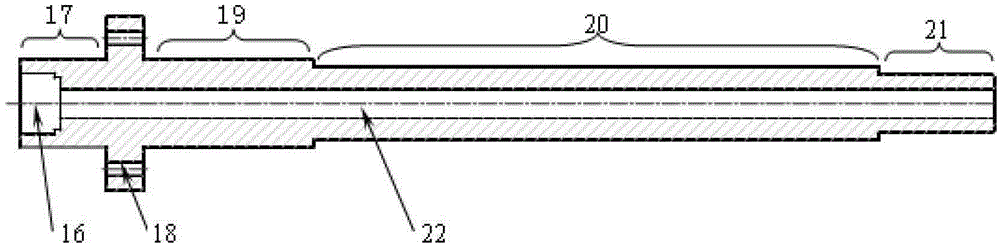

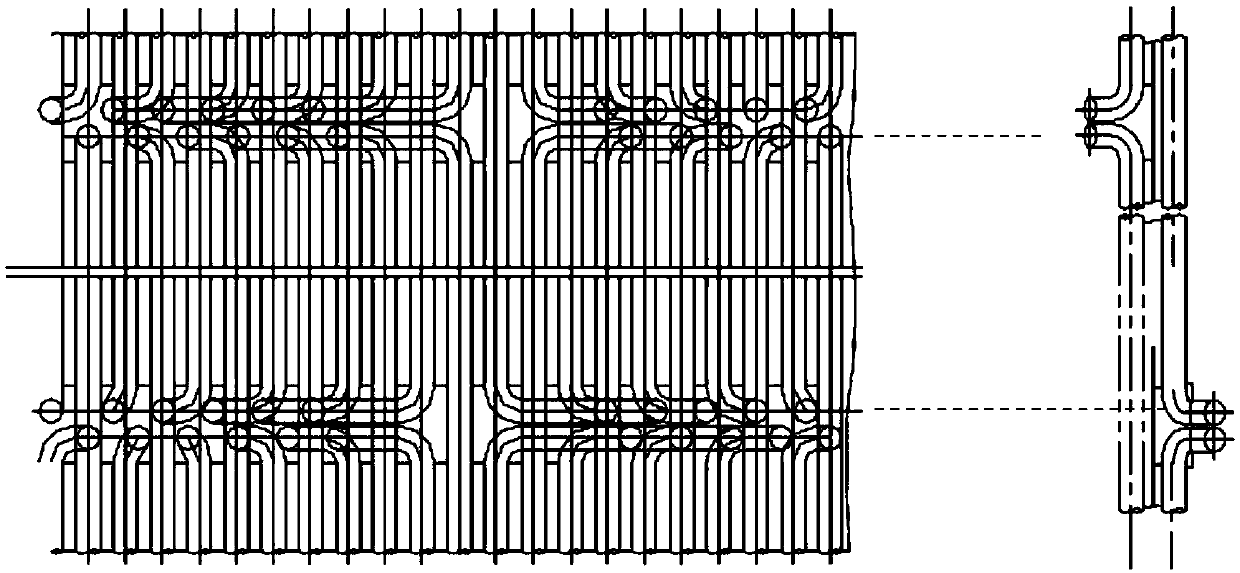

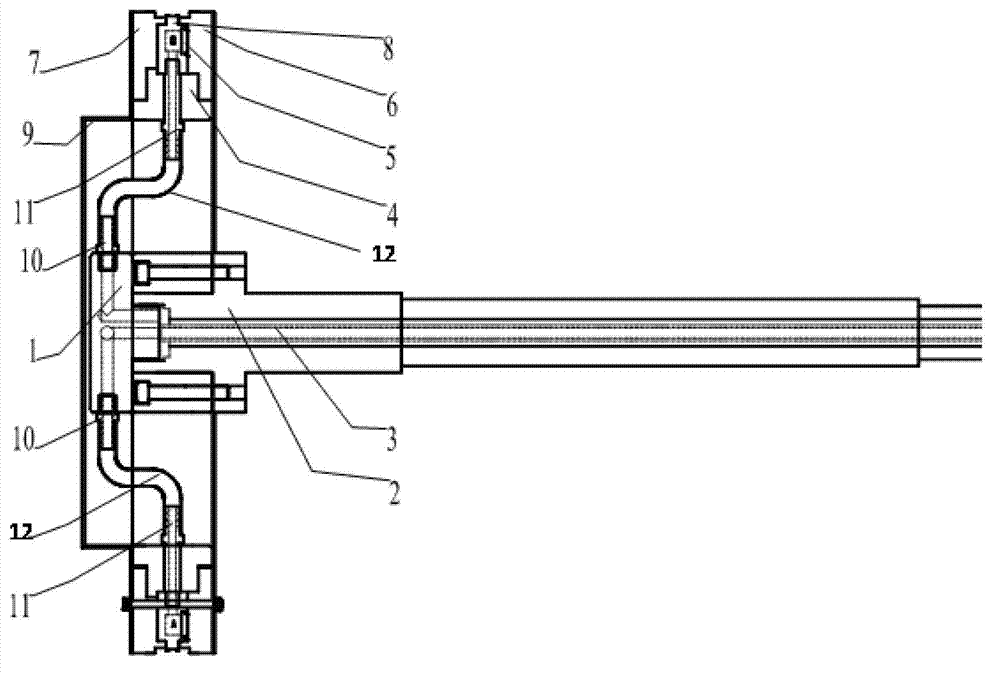

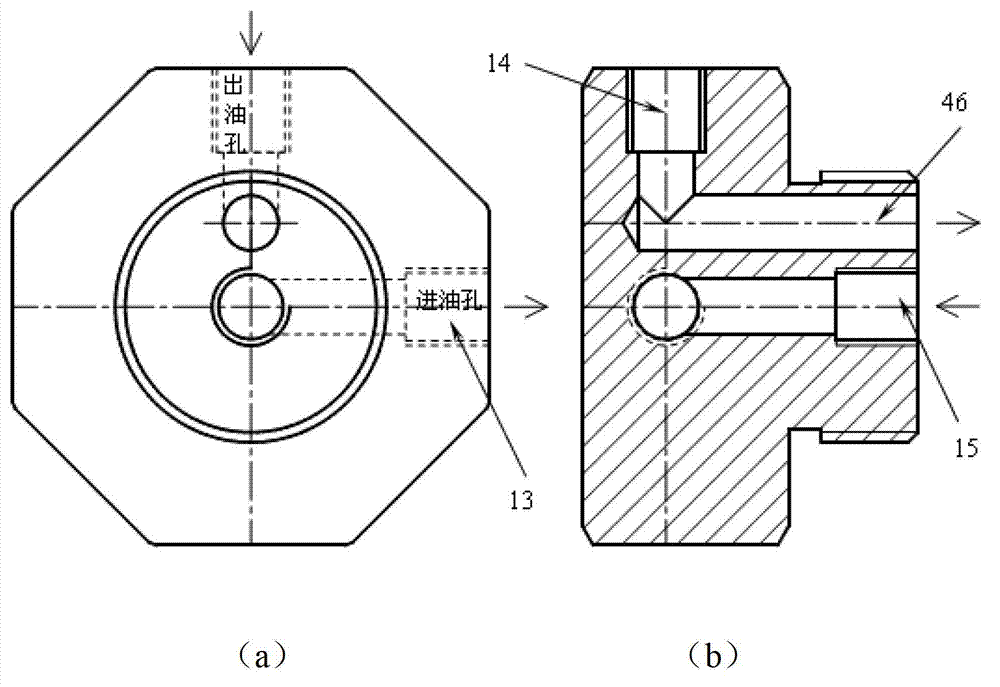

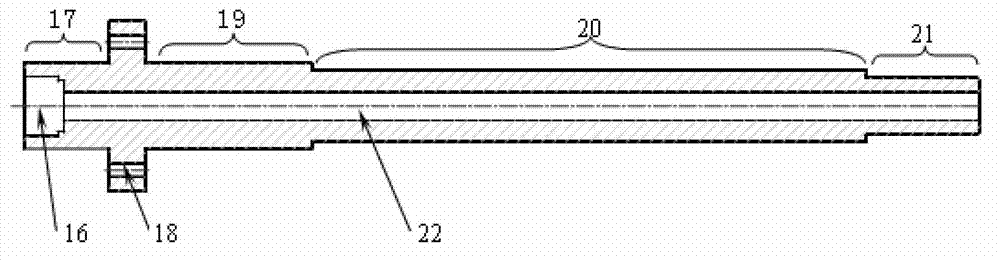

Thermocompression bonding wheel for drip irrigation belt

The invention discloses a thermocompression bonding wheel for a drip irrigation belt. The thermocompression bonding wheel of the drip irrigation belt comprises an oil supply and distributing joint, a central shaft, an oil feeding pipe, a wheel strake, an oil channel baffle plate, a right side wheel flange, a left side wheel flange, a heat sealing pressing wheel, an external stainless steel protecting plate, a first joint, a second joint and a hose; the oil supply and distributing joint is fixedly connected to one end of the central shaft, and the other end of the central shaft is connected with a motor; the oil feeding pipe is positioned into an internal chamber of the central shaft; one end of the oil feeding pipe is connected with the oil supply and distributing joint while the other end of the oil feeding pipe is connected with a temperature control device; the wheel strake is arranged outside the central shaft in a sleeving way and is fixedly connected with the central shaft; a left annular groove and a right annular groove are respectively arranged on the edges of both sides of the wheel strake; the left side wheel flange and the right side wheel flange are respectively arranged in the left annular groove and the right annular groove, and moreover, the heat sealing pressing wheel is mounted in a clearance formed between the left side wheel flange and the right side wheel flange; and the heat sealing pressing wheel is arranged outside the wheel strake in the sleeving way. The thermocompression bonding wheel of the drip irrigation belt disclosed by the invention integrates the heating function and the extruding function, therefore, good effect of heating is achieved; and a copper-made heat sealing pressing wheel is adopted, by which the surface layer of a film can be prevented from being adhered to other layers.

Owner:NORTHWEST A & F UNIV

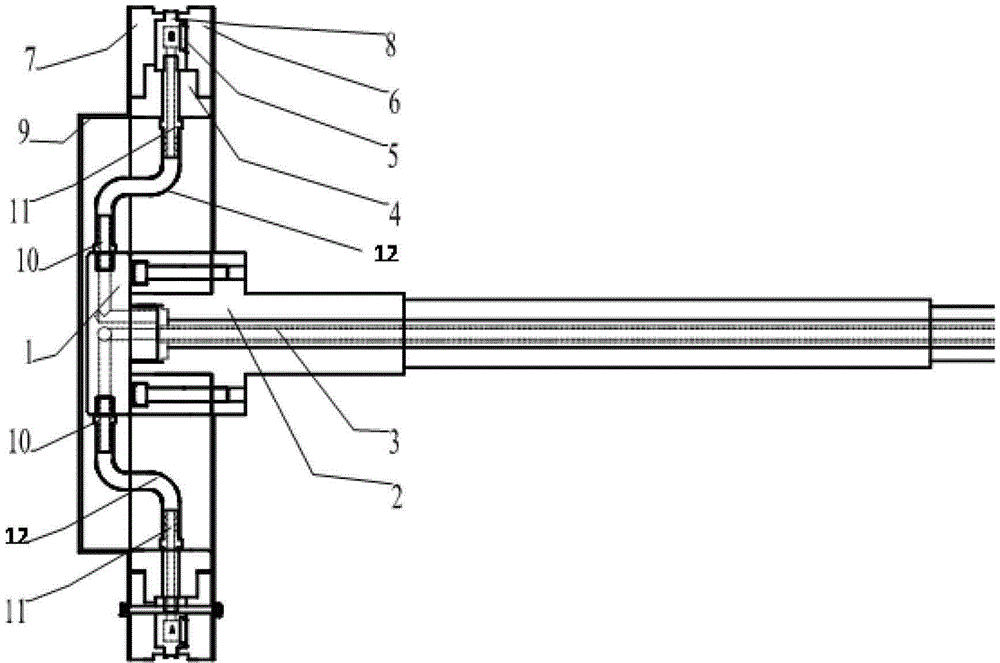

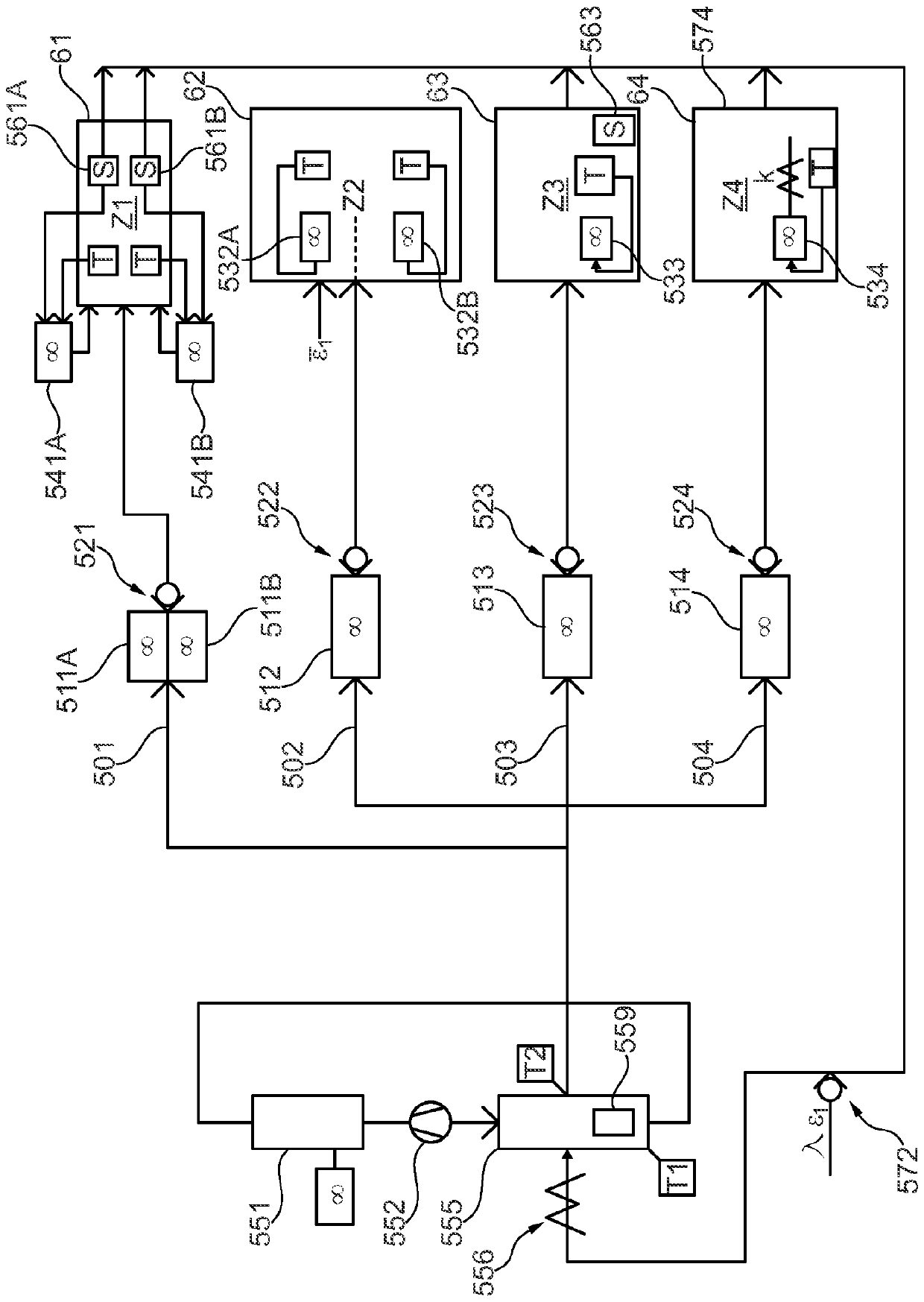

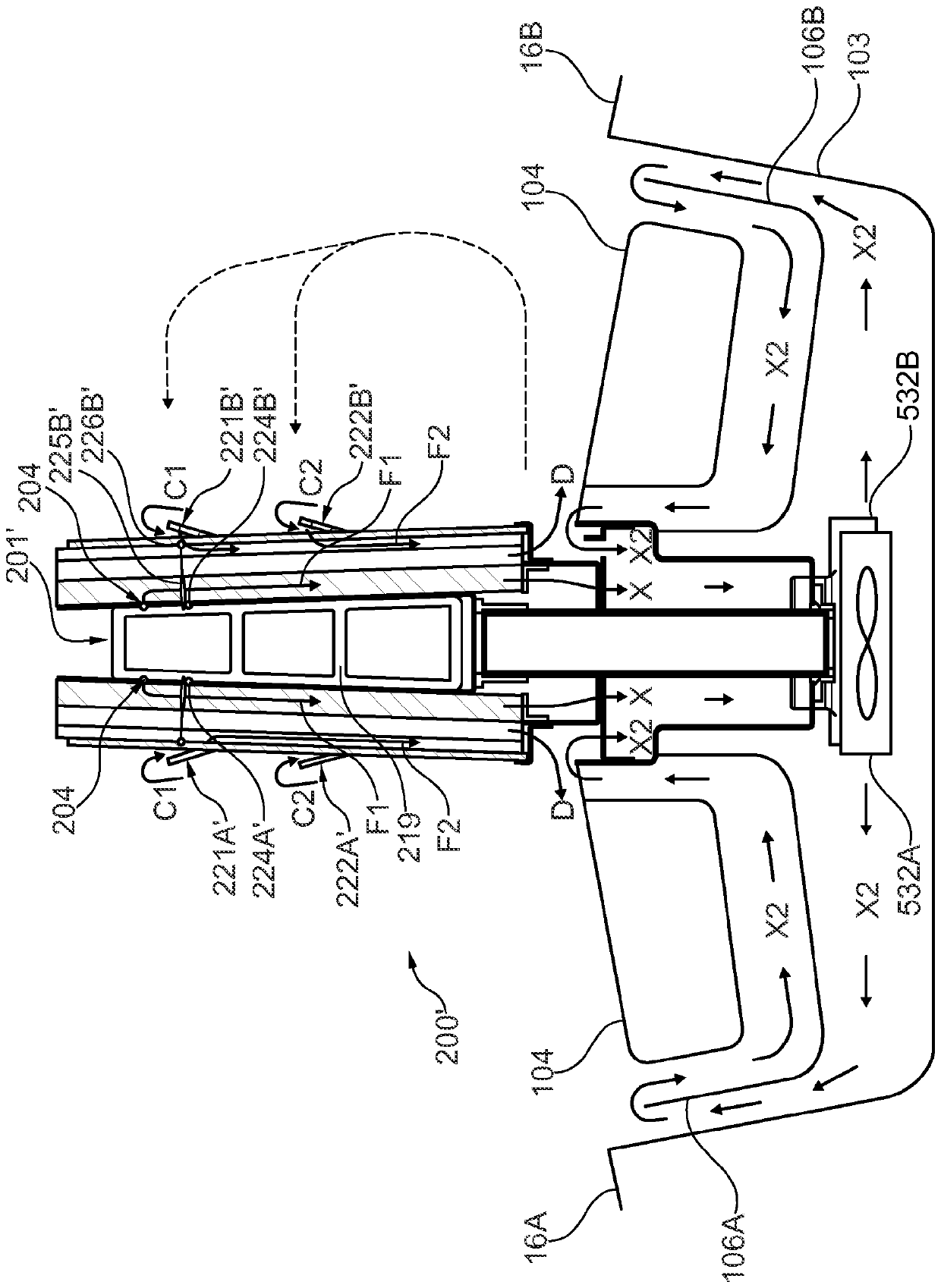

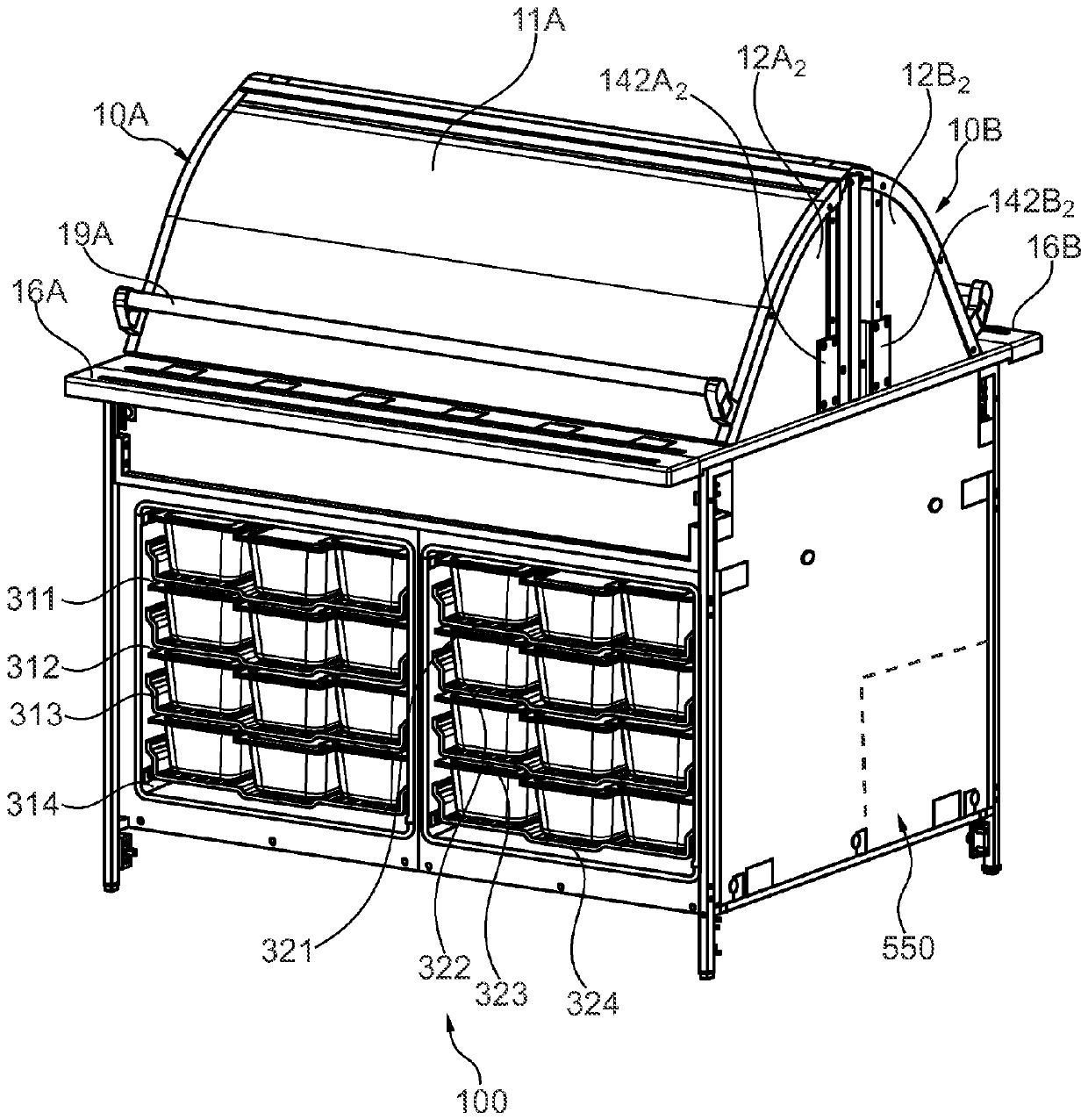

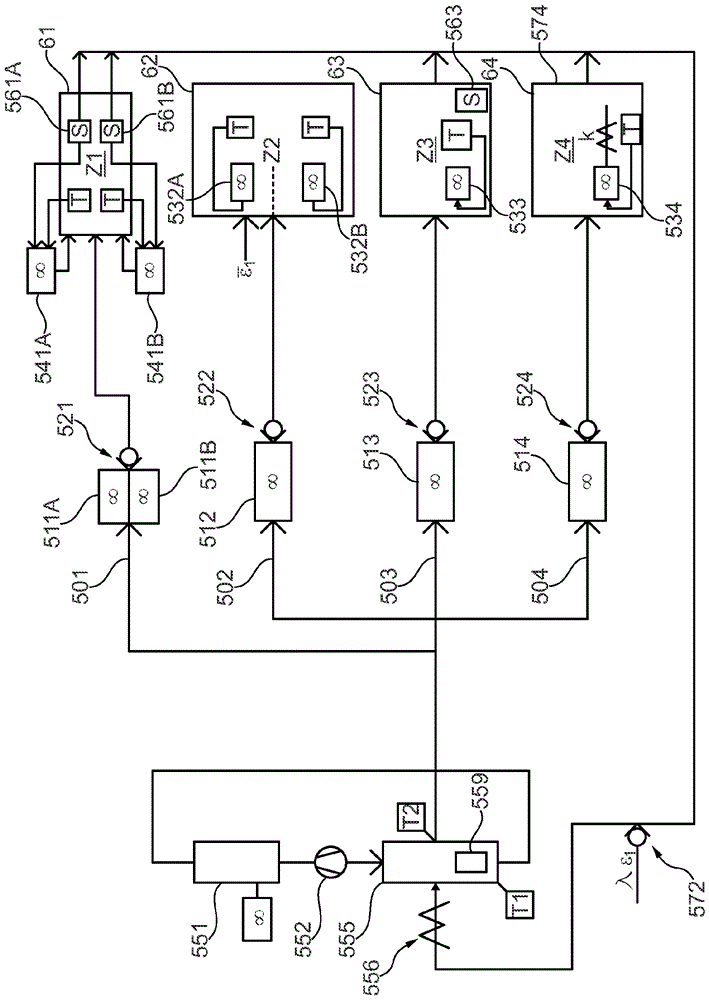

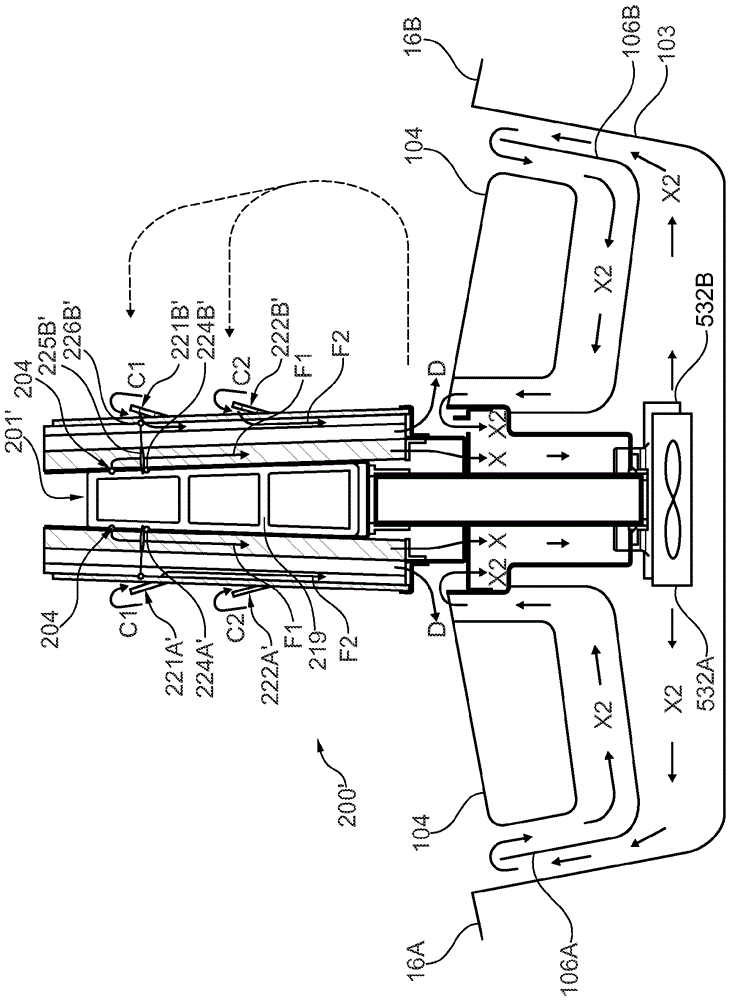

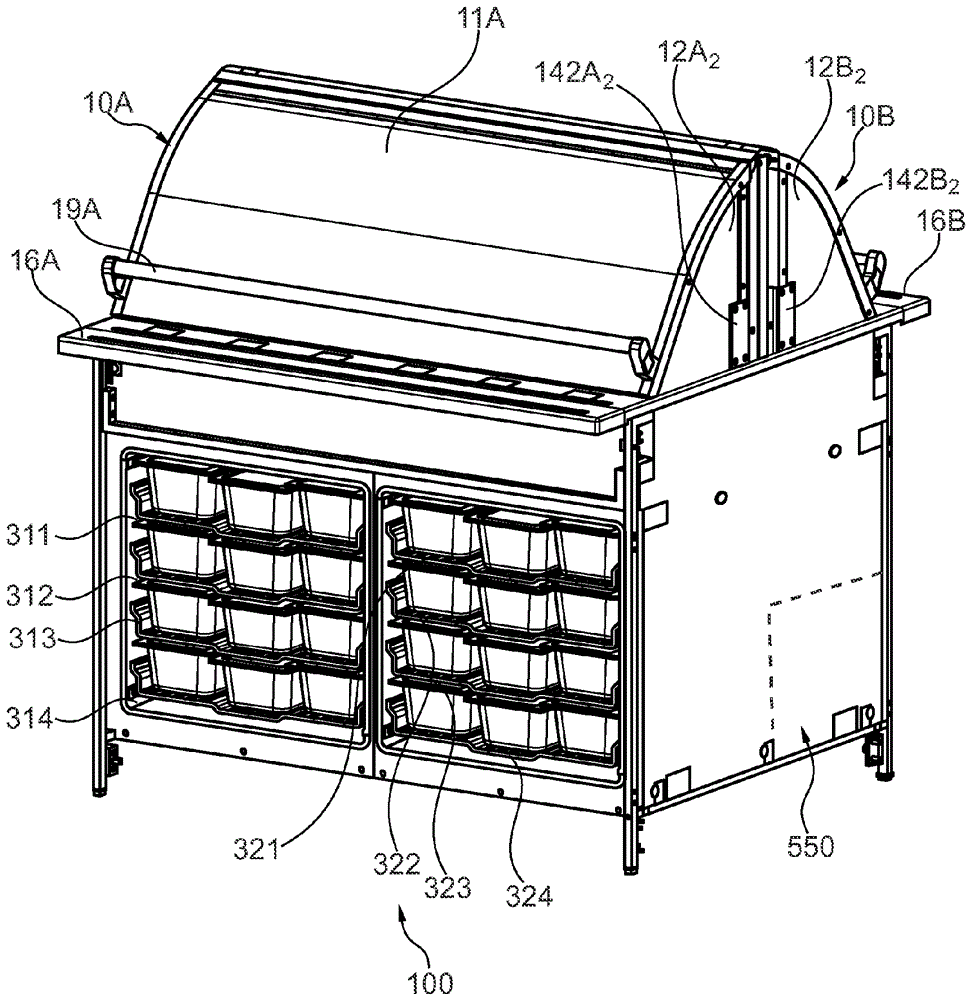

Improved refrigerated food station apparatus and cooling system for cooling the food station

ActiveCN106687012BFlat temperature distributionMeeting high hygiene requirementsShow cabinetsDomestic refrigeratorsClimate zonesRefrigeration

A food table device (100), for example, a salad table, the food table device (100) includes: a cooling system with a refrigeration device (550); a cabinet device (300) with a plate holding device (103), the table A plate (104) is arranged in said plate holder (103). The cooling system is adapted to cool the food table arrangement (100) so as to provide at least two different climate zones (Z1, Z2), the cooling of the at least two different climate zones (Z1, Z2) being individually controllable and the cooling system includes an evaporator (555), cooling device (200) arranged close to and above the back wall of the dinner plate and adjacent to the The pan covers the rear section of the device (110), so that the cooling air will flow out from the lower edge of the cooling device due to self-convection, out over the food product and upwards towards the upper edge of the cooling device, forming a first climate zone. Plate holder elements (106A, 106B) are arranged in said holding means (103) such that in said holding means, between said plate holder elements and said plate's bottom wall and transverse wall The second climate zone (Z2) is formed in between.

Owner:哌咖熟食公司

Similar test device and test method for multi-field precursory information evolution of water inrush from mining fault in deep confined water

ActiveCN111398564BReveal wellConducive to true reproductionEarth material testingCoal measuresSoil science

The invention discloses a similar test device and a test method for evolution of multi-field precursory information of water inrush from mining faults in deep confined water, and relates to the field of formation temperature and similar simulation tests. Glass plate, model storage cavity, lateral pressure loading system, vertical loading system, water pressure loading system, water temperature regulation system, ground temperature regulation system, signal acquisition and processing system, test model; the water pressure loading system and water temperature regulation system of the test device And the geothermal regulation system can provide stable high temperature, high pressure water and gradient formation temperature for the test model, which can better simulate the real geomechanical environment of the deep confined water-bearing fault-bearing coal measure strata, which is beneficial to the high water inrush of the deep confined water-mining faults. Real reproduction of field precursor information, inversion analysis of the evolution law, coupling characteristics and influencing factors of multi-field precursor information such as stress, displacement, fissure, seepage, temperature and other multi-field precursor information during the water inrush process of mining faults in deep confined water.

Owner:ANHUI UNIV OF SCI & TECH

Near-zero heat loss refractory lining for batch-operated high-temperature kiln and preparation method thereof

ActiveCN111205099BSmall temperature fluctuationsFlat temperature distributionCarboxylic acidKiln burner

The invention relates to a near-zero heat loss refractory lining of a high-temperature kiln operated intermittently and a preparation method thereof. The technical solution is: the permanent lining refractory material of the refractory lining body is a phase change heat storage refractory material, that is, a high temperature phase change heat storage refractory material, a medium temperature phase change heat storage refractory material and a low temperature phase change heat storage refractory material. composed in sequence. The phase change heat storage refractory material is composed of alloy@ceramic macrocapsule, alloy@alumina microcapsule, α‑Al 2 o 3 It is prepared by mixing micropowder, silica micropowder, calcium aluminate cement and polycarboxylic acid with water, forming, demolding and drying. When preparing: Al-Si-Ni alloy @ Ceramic Large Capsule, Al-Si-Fe Alloy @ Ceramic Large Capsule and Al-Si Alloy @ Ceramic Large Capsule and the corresponding Al-Si-Ni alloy @ Aluminum Oxide Microcapsule in Alloy @ Ceramic Large Capsule Microcapsules, aluminum silicon ferroalloy@alumina microcapsules and aluminum silicon alloy@alumina microcapsules are prepared separately. The heat loss of the present invention is close to zero and the furnace lining refractory material has a long service life.

Owner:WUHAN UNIV OF SCI & TECH

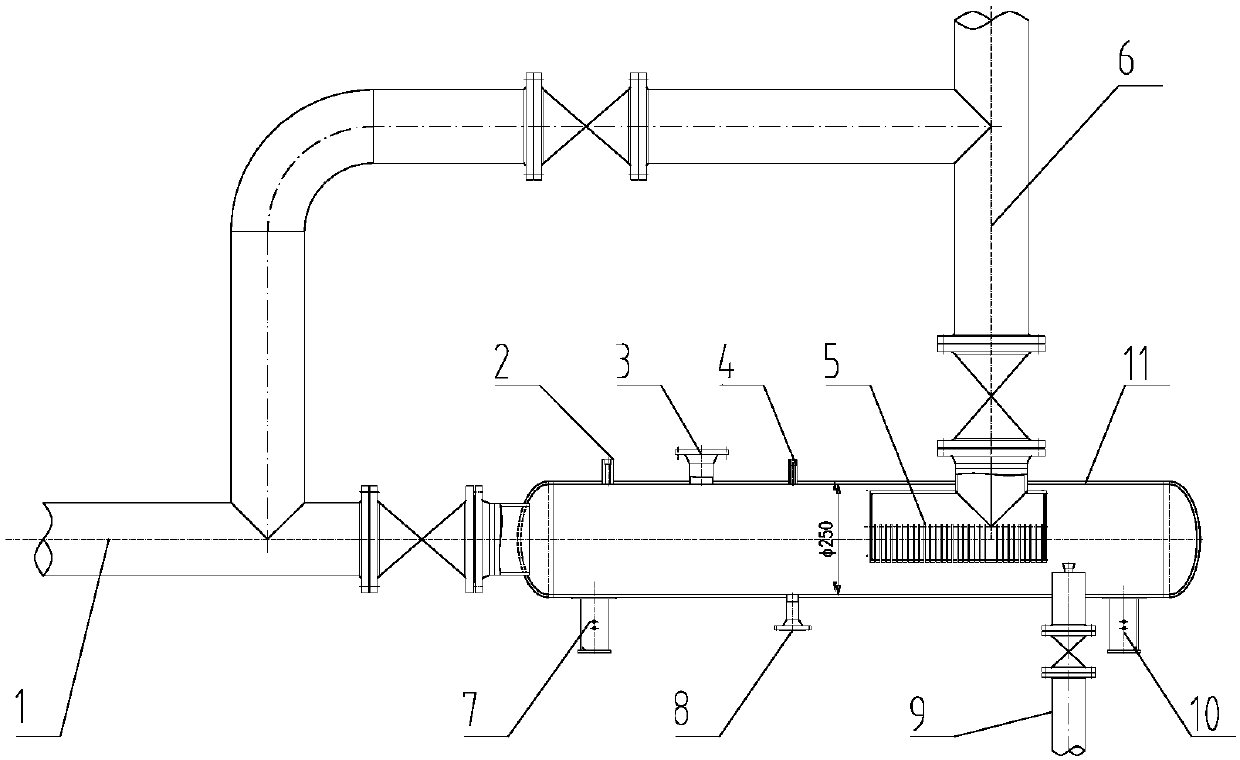

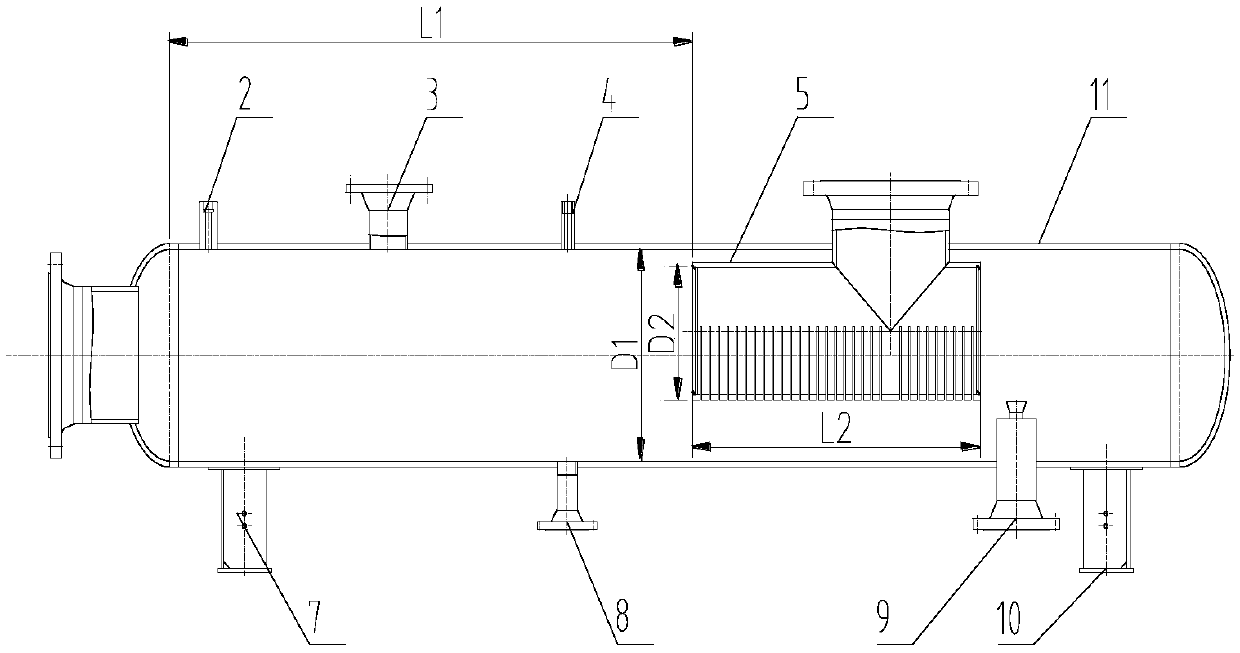

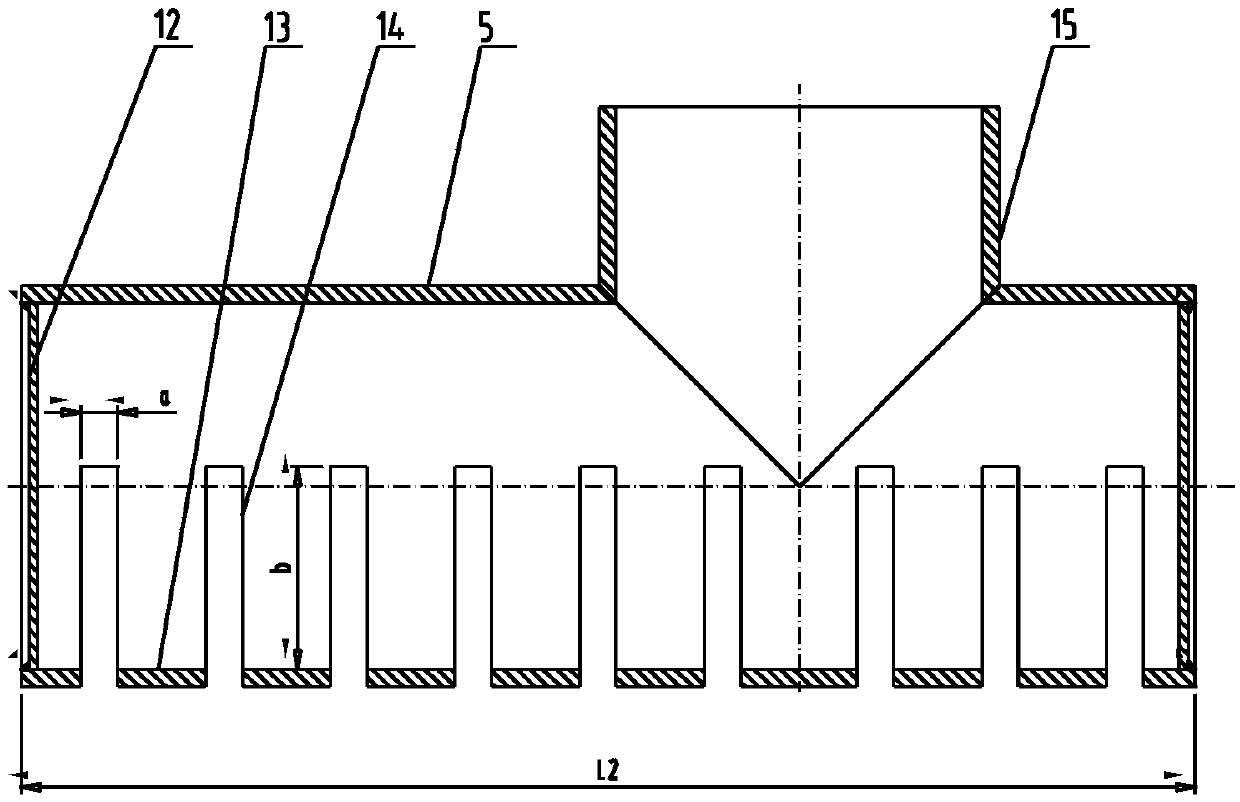

steam mixer

ActiveCN106139944BRelieve stress shockReduce pressure shockFlow mixersTransportation and packagingEngineeringGate valve

The invention discloses a steam mixer. The top of one end of the heater shell is connected to the main steam pipe through a flow regulating valve, the other end of the heater shell is connected to the mixed steam pipe through a gate valve or a cut-off valve, and the main steam pipe is passed through a gate valve or a cut-off valve. The valve is connected to the mixed steam pipe, and the bottom of the heater housing opposite to the inlet of the main steam pipe is connected to the heating steam pipe through a flow regulating valve. The steam distribution pipes are evenly distributed along the axial direction of the heater shell, and the heating steam pipes are extended into the heater shell with combined nozzles. Mix a large flow of saturated steam and a superheated steam in the equipment to form a slightly superheated steam with a certain degree of superheat; it has high heat exchange efficiency and can effectively reduce the generation of steam when the pipe network transports The impact of water hammer is powerful for the safe operation of the pipe network.

Owner:青岛康泰重工机械有限公司

An improved refrigerated food bar arrangement and a cooling system for such a food bar

ActiveCN106687012AFlat temperature distributionMeeting high hygiene requirementsShow cabinetsDomestic refrigeratorsEngineeringClimate zones

The invention discloses a food bar arrangement (100), e.g. a salad bar, comprising a cooling system with a refrigerating arrangement (550), a cabinet arrangement (300) with a pan holding arrangement (103) in which the pans (104) are arranged. The cooling system is adapted for cooling the food bar arrangement (100) such that at least two different climate zones (Z1,Z2) are provided, the cooling of which is separately controllable, and it comprises one evaporator (555), a cooling arrangement (200) arranged close to, and above, pan back walls and adjacent a rear section of a covering arrangement (110) adapted to cover pans and so that cooled air will flow from a lower edge thereof, outwards above the food products, and upwards, in towards an upper edge thereof due to self-convection, forming a first climate zone. Pan holder elements (106A,106B) are disposed in the holding arrangement (103) so disposed that in said holding arrangement, between said pan holder elements and the bottom and lateral walls of the pans, said second climate zone (Z2 )is formed.

Owner:哌咖熟食公司

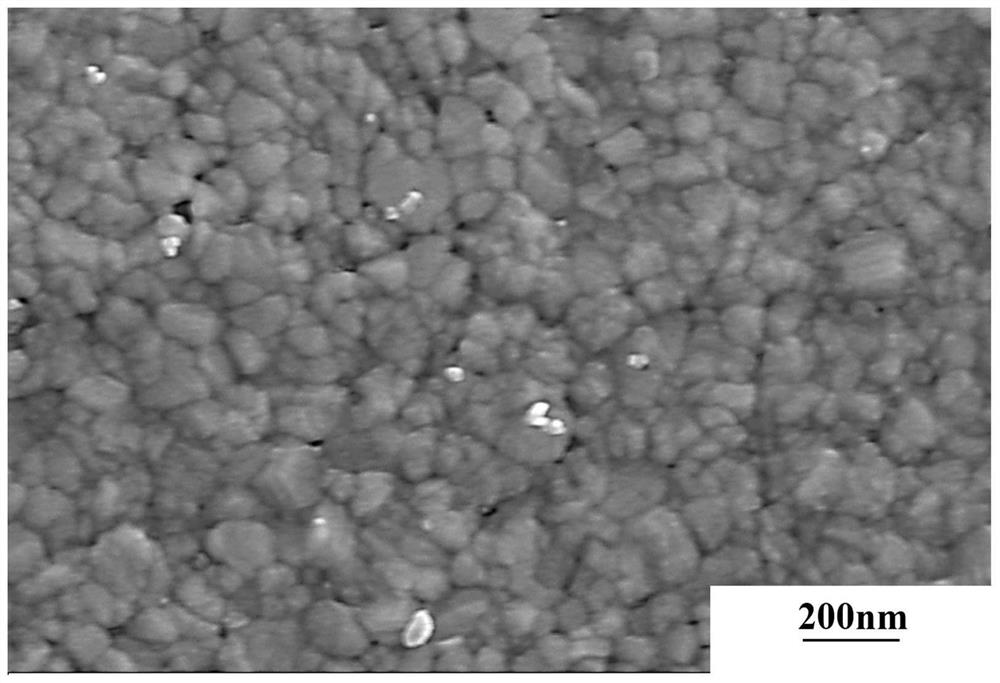

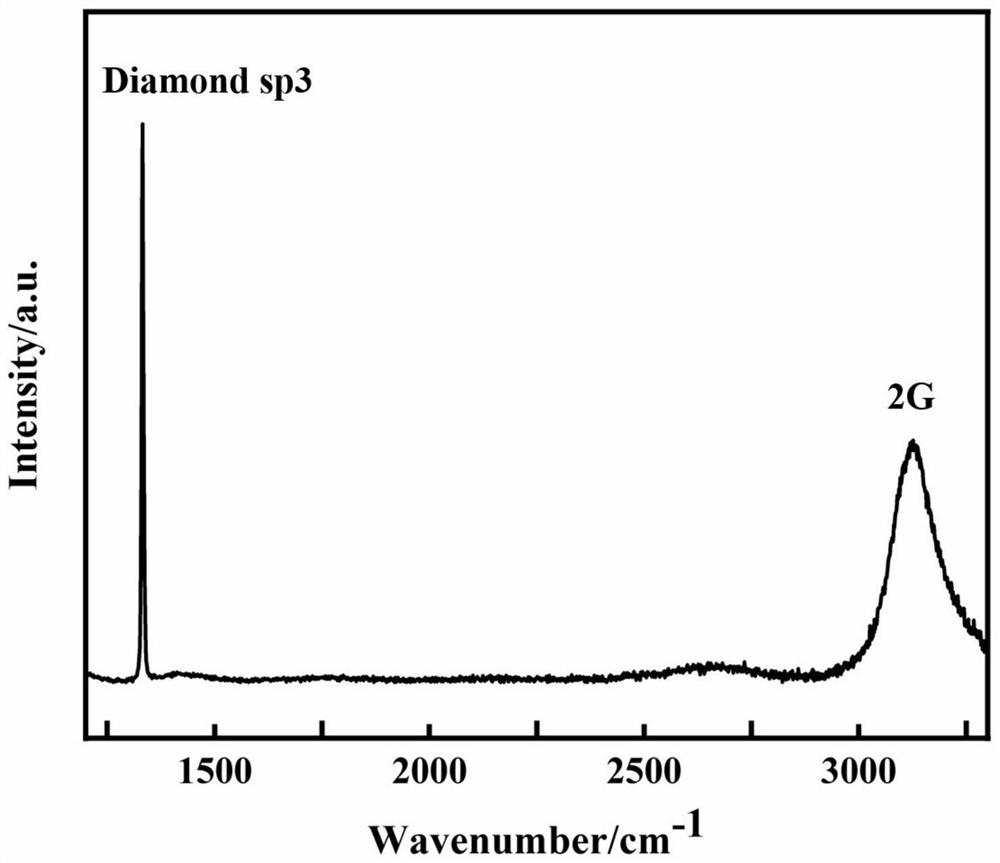

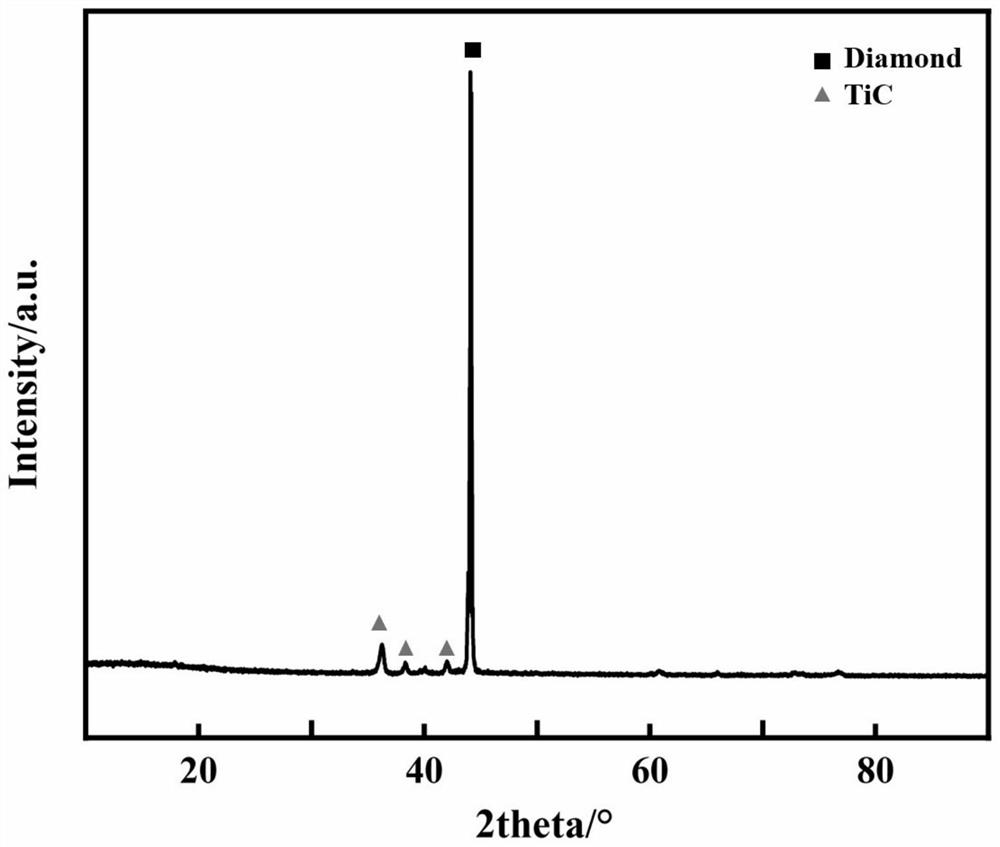

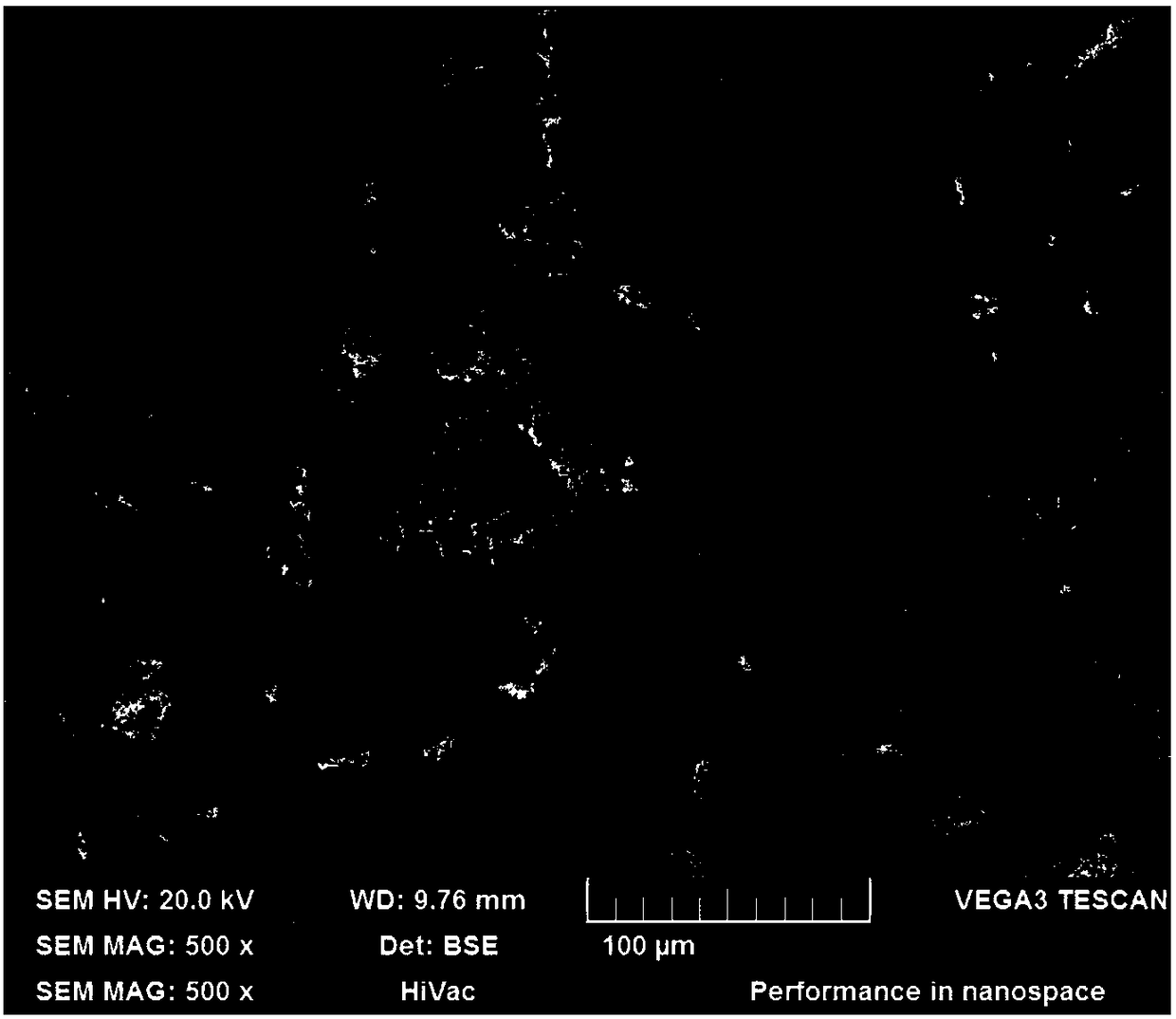

Method for preparing high-bonding-strength carbide coating on diamond surface by using thermal plasma

ActiveCN112981299AImprove bindingHigh chemical activityMolten spray coatingMetal coatingCarbide coating

The invention relates to a method for preparing a coating on a diamond surface, in particular to a method for preparing a high-bonding-strength carbide coating on the diamond surface by using thermal plasma, and aims at solving the problems that a carbide coating prepared on the diamond surface through an existing method is not uniform and compact, difficult in thickness control and low in bonding strength. The method comprises the following steps: weighing a certain mass of diamond powder with a metal coating, cleaning and drying the diamond powder, and conveying the diamond powder into a thermal plasma reactor for thermal plasma treatment. According to the method, the compact carbide coating can be generated on the diamond surface by using the hot plasma as a high-temperature heat source, the graphitization tendency of the diamond surface layer is inhibited, the coating coverage rate is greater than 95%, and the thickness of the carbide coating can be controlled by controlling the thickness of the metal coating. The method is suitable for preparing the carbide coating on the diamond surface.

Owner:HARBIN INST OF TECH

A method for reducing the occurrence of transverse cracks in boiler water wall

ActiveCN106439774BImprove securityReduce areaBoiler water tubesCasings/liningsCrazingTemperature monitoring

The invention relates to a method for decreasing the occurrence rate of transverse cracks of boiler water walls. The method comprises the following steps, from wall temperature monitoring to hole expanding, that when a boiler and the water walls operate, the temperatures of the water walls on the four sides and water wall pipes are monitored correspondingly; a thermal deviation curve showing temperature distribution of the water wall pipes in the water walls on the four sides is drawn according to measured temperature data, and whether water wall pipes located in an overheat area exist or not is judged; and throttling holes corresponding to the water wall pipes located in the overheat area are expanded, wherein after hole expanding is conducted during one time of operation, wall temperature monitoring and overheat judging are conducted in the next time of operation, and throttling holes corresponding to the water wall pipes located in the overheat area are expanded after the water wall pipes located in the overheat area are judged to still exist. By adoption of the method for decreasing the occurrence rate of the transverse cracks of the boiler water walls, the occurrence area and probability of the transverse cracks of the water walls are substantially decreased, and the safety of the water walls is improved.

Owner:JIANGSU DATANG INT LUSIGANG POWER GENERATION

Thermocompression bonding wheel for drip irrigation belt

The invention discloses a thermocompression bonding wheel for a drip irrigation belt. The thermocompression bonding wheel of the drip irrigation belt comprises an oil supply and distributing joint, a central shaft, an oil feeding pipe, a wheel strake, an oil channel baffle plate, a right side wheel flange, a left side wheel flange, a heat sealing pressing wheel, an external stainless steel protecting plate, a first joint, a second joint and a hose; the oil supply and distributing joint is fixedly connected to one end of the central shaft, and the other end of the central shaft is connected with a motor; the oil feeding pipe is positioned into an internal chamber of the central shaft; one end of the oil feeding pipe is connected with the oil supply and distributing joint while the other end of the oil feeding pipe is connected with a temperature control device; the wheel strake is arranged outside the central shaft in a sleeving way and is fixedly connected with the central shaft; a left annular groove and a right annular groove are respectively arranged on the edges of both sides of the wheel strake; the left side wheel flange and the right side wheel flange are respectively arranged in the left annular groove and the right annular groove, and moreover, the heat sealing pressing wheel is mounted in a clearance formed between the left side wheel flange and the right side wheel flange; and the heat sealing pressing wheel is arranged outside the wheel strake in the sleeving way. The thermocompression bonding wheel of the drip irrigation belt disclosed by the invention integrates the heating function and the extruding function, therefore, good effect of heating is achieved; and a copper-made heat sealing pressing wheel is adopted, by which the surface layer of a film can be prevented from being adhered to other layers.

Owner:NORTHWEST A & F UNIV

Heatable or coolable return pulley for a continuous casting system

ActiveCN105263688AFlat temperature distributionReduce temperature gradientCoatingsEngineeringMechanical engineering

The invention relates to a return pulley (101..110) for a continuous casting system, said return pulley comprising a drum-shaped main body and at least one heating pipe (2, 5, 6) laid underneath a cylindrical surface of the pulley (101..110). The heating pipe(s) (2, 5, 6) each has / have at least one input and at least one output offset in relation to said input, the sum of the inputs and outputs being at least three. The invention further relates to a continuous casting system having a return pulley (101..110) of the above type.

Owner:BERNDORF BAND GMBH

Surface coating for hydraulic motor and preparing method

InactiveCN108220950AReduce coefficient of frictionImprove thermal conductivityHeat inorganic powder coatingHydraulic motorCopper

The invention provides a surface coating for a hydraulic motor. The surface coating is prepared through following components including, by mass percent, 10%-12% of tin, 0.25%-2.0% of graphene and thebalance copper. The sheet layer thickness of the graphene ranges from 0.35 nm to 10 nm, and the width of the graphene ranges from 20 microns to 400 microns. The graphene is added in bronze, the thermal conductivity of a bronze coating can be obviously improved, the friction coefficient between friction pairs can be effectively reduced through the graphene, and heat and material losses generated due to friction are effectively reduced. Accordingly, the service life of a cylinder is effectively prolonged, and the using performance of the cylinder is effectively improved. The experiment result shows that the thermal conductivity of the coating is 84-170 W / <m.k>, compared with the prior art, the friction coefficient is reduced by 15%, the instant highest temperature of the friction pair interface is reduced to 160 DEG C from near 200 DEG C, and temperature distribution is smoother compared with the prior art. The invention further provides the surface coating for the hydraulic motor.

Owner:SEED TECH CORP LTD

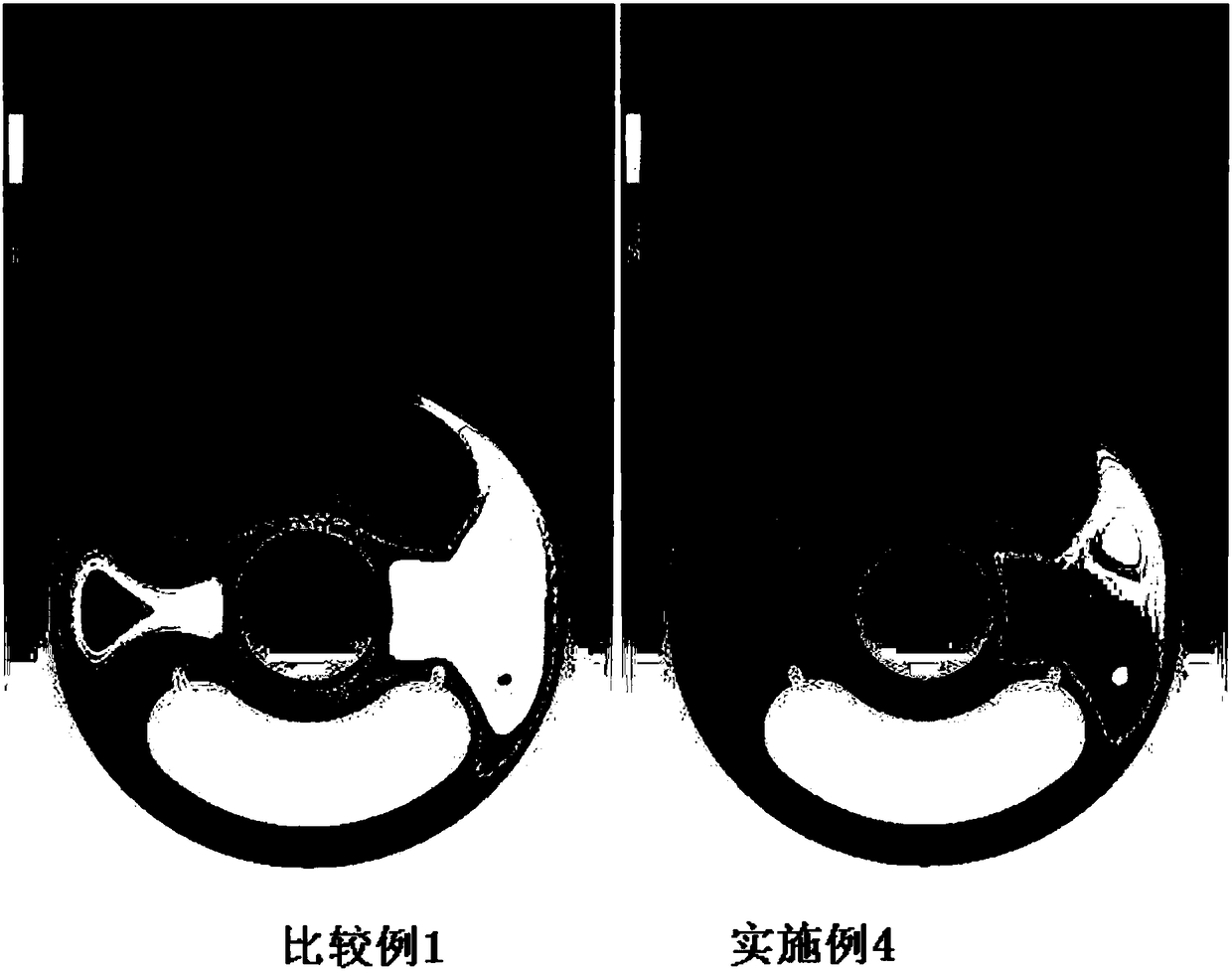

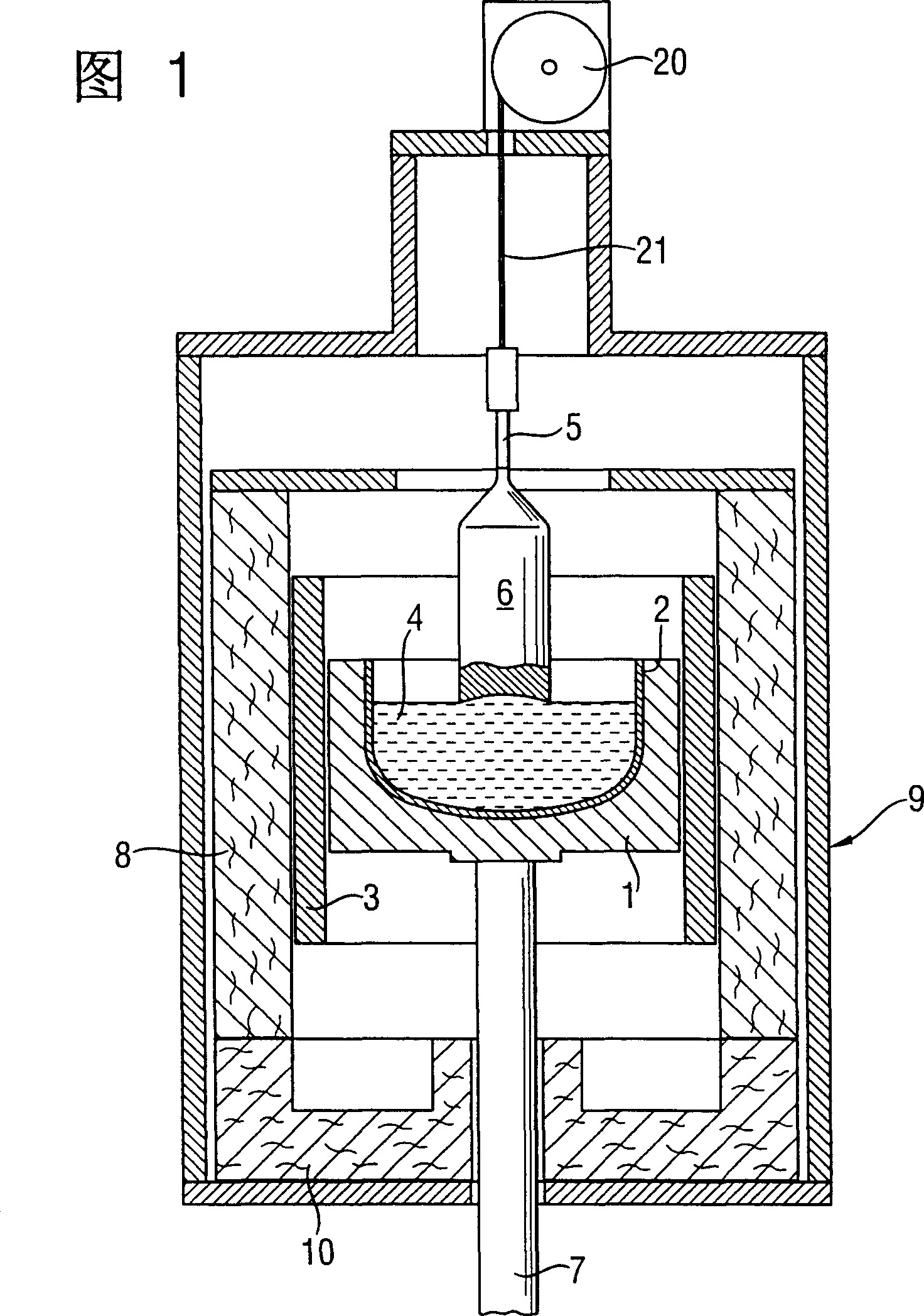

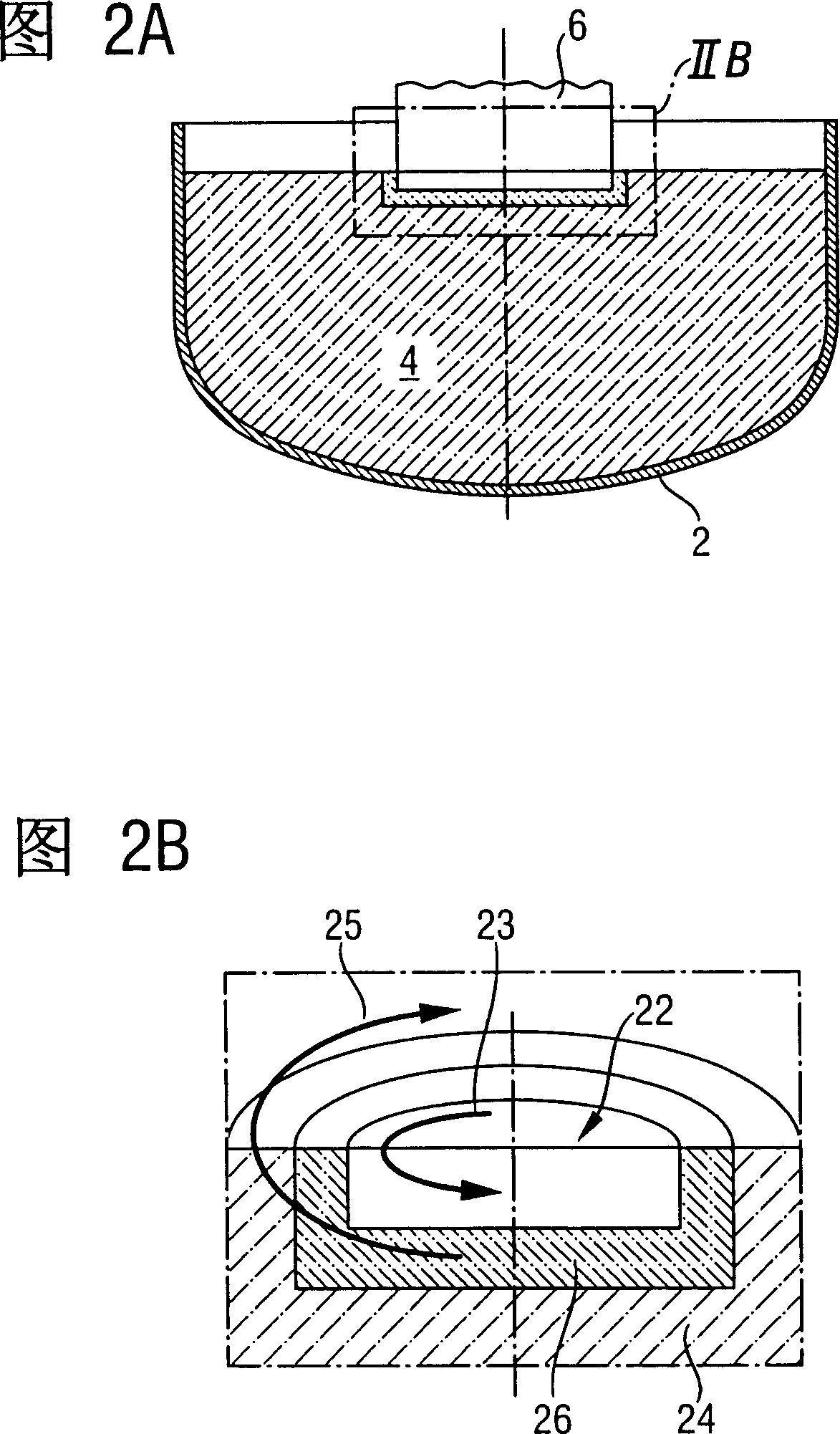

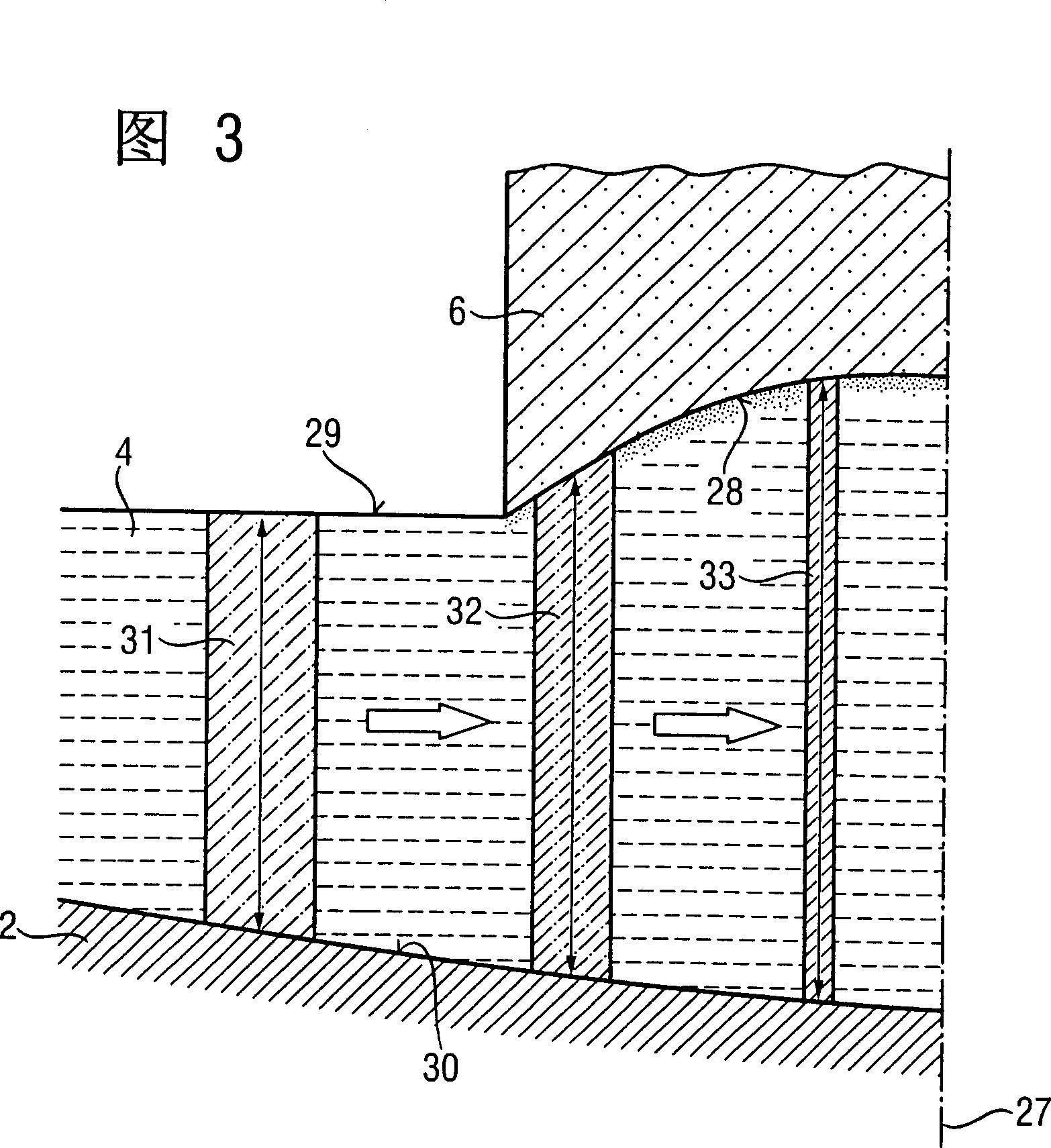

Crucible for the growth of silicon crystal and process for the growth of silicon crystal

InactiveCN1333116CImprove productivityImprove qualityPolycrystalline material growthBy pulling from meltProduction rateCrucible

The present invention is to provide a crucible for the growth of silicon crystal, which can enhance the productivity, yield and quality of crystal in the process of silicon crystal growth by Czochralski method, and a silicon crystal growing method by Czochralski method using said crucible. <??>A crucible for the growth of silicon crystal by Czochralski method having an inner bottom surface, the profile of which has at least a raised portion symmetrical about the rotary axis of the crucible wherein the periphery of the raised portion is positioned at a distance of from 0.4 to 1.2 times the radius of crystal to be grown from the rotary axis and the height of the raised portion is from not smaller than 7% to not greater than 100% of the radius of crystal to be grown.

Owner:SILTRONIC AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com