Surface coating for hydraulic motor and preparing method

A surface coating, hydraulic motor technology, applied in coating, metal material coating process, heating inorganic powder coating and other directions, can solve problems such as poor thermal conductivity, cylinder failure, etc., to reduce friction coefficient, improve thermal conductivity, The effect of reducing heat and material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing a surface coating for a hydraulic motor, comprising the following steps:

[0035] In terms of mass fraction, mix 10-12% tin powder, 0.25-2.0% graphene powder and the rest of the reduced copper powder, add ethanol, and perform ball milling, place the obtained ball mill on the surface of the cylinder, and press it Sintering is carried out under a reducing atmosphere to obtain surface coatings for hydraulic motors.

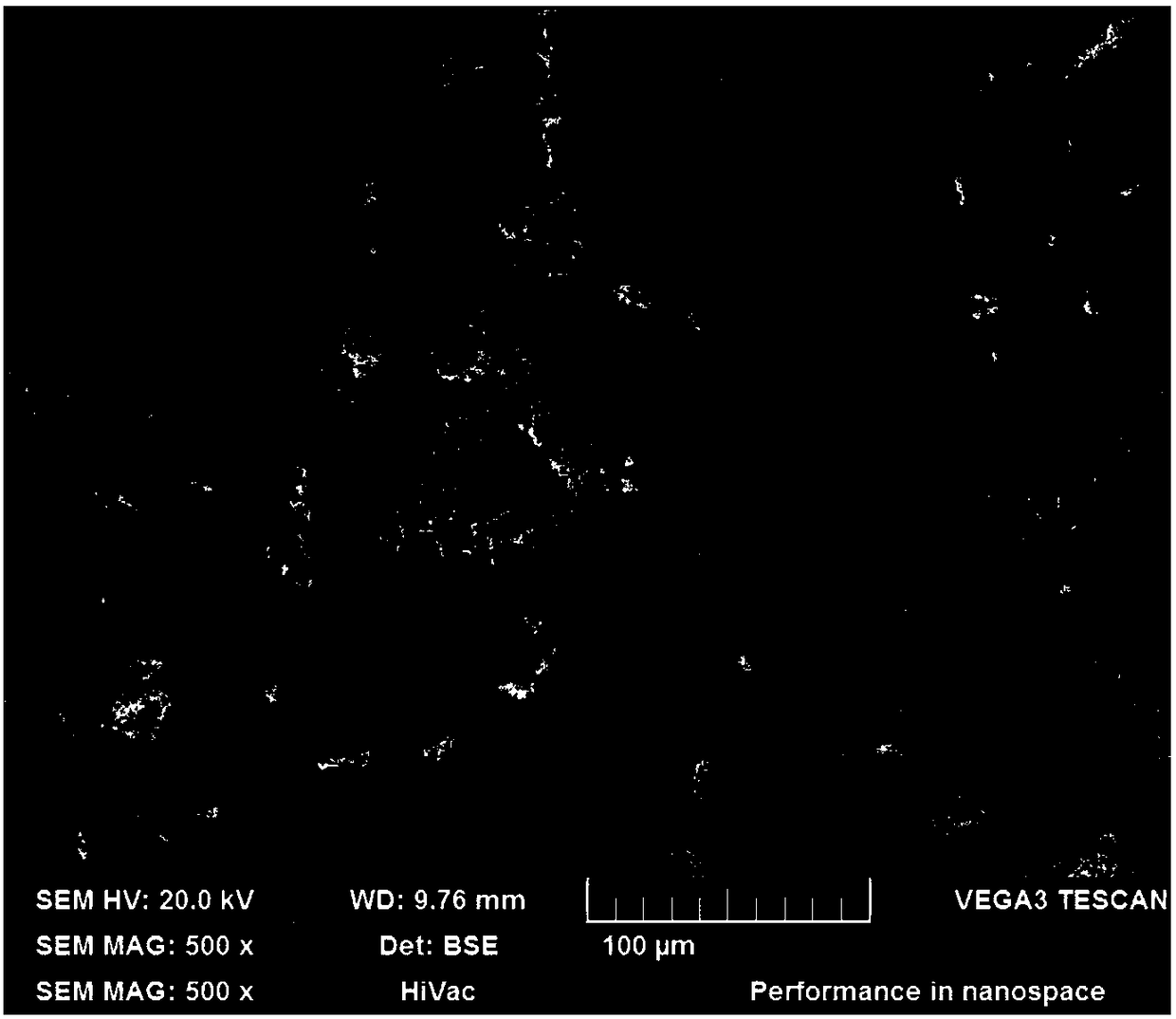

[0036] In the present invention, due to the unique two-dimensional structure of graphene, its specific surface area is 2630m 2 / g, more than carbon nanotubes, but the bulk density is extremely low (0.005g / cm 3 ), so it is difficult to prepare graphene-enhanced copper-tin alloys in conventional mixing.

[0037] In view of this, the present invention adopts the method of powder metallurgy to prepare the surface coating. Specifically, the powders of the raw materials can be mixed and then directly cover...

Embodiment 1

[0057] The proportioning of raw materials in this embodiment is shown in Table 1.

[0058] Mix the raw material powder, add ethanol, and use a horizontal planetary ball mill for ball milling for 2 hours at a speed of 50rpm. The ball milled powder is evenly placed on the surface of the hydraulic motor cylinder and the distribution plate, then pressed, and finally placed in a reducing atmosphere Sintering is carried out in a protected sintering furnace to obtain a graphene-enhanced copper-tin alloy coating.

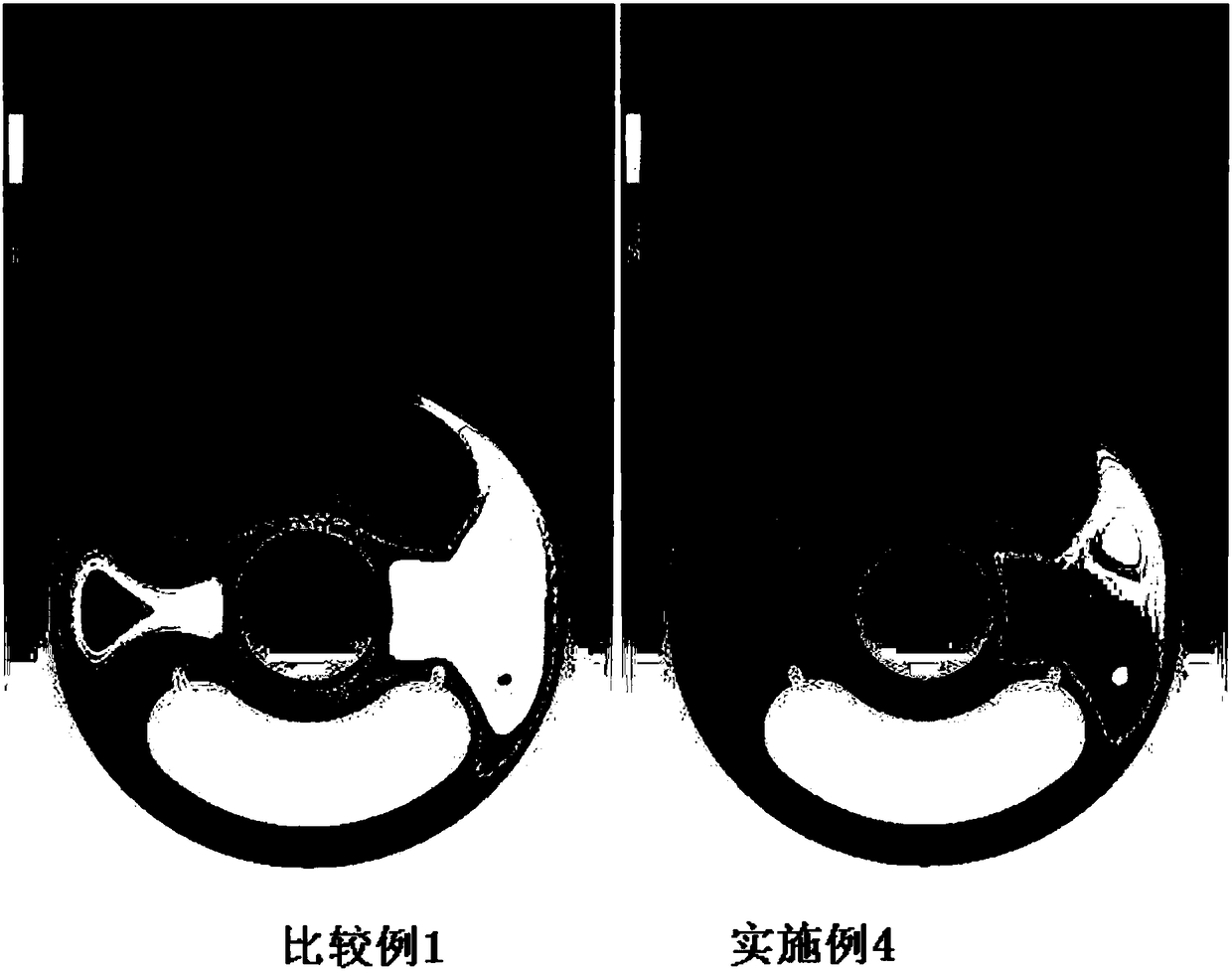

Embodiment 2~5

[0060] Using the corresponding formula in Table 1, a graphene-strengthened copper-tin alloy coating was prepared according to the method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com