Cleaning and drying machine for tableware

A tableware washing and drying machine technology, which is applied in the direction of tableware washing machine/rinsing machine parts, etc., can solve problems such as insufficient air volume, and achieve the effect of preventing hot air feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

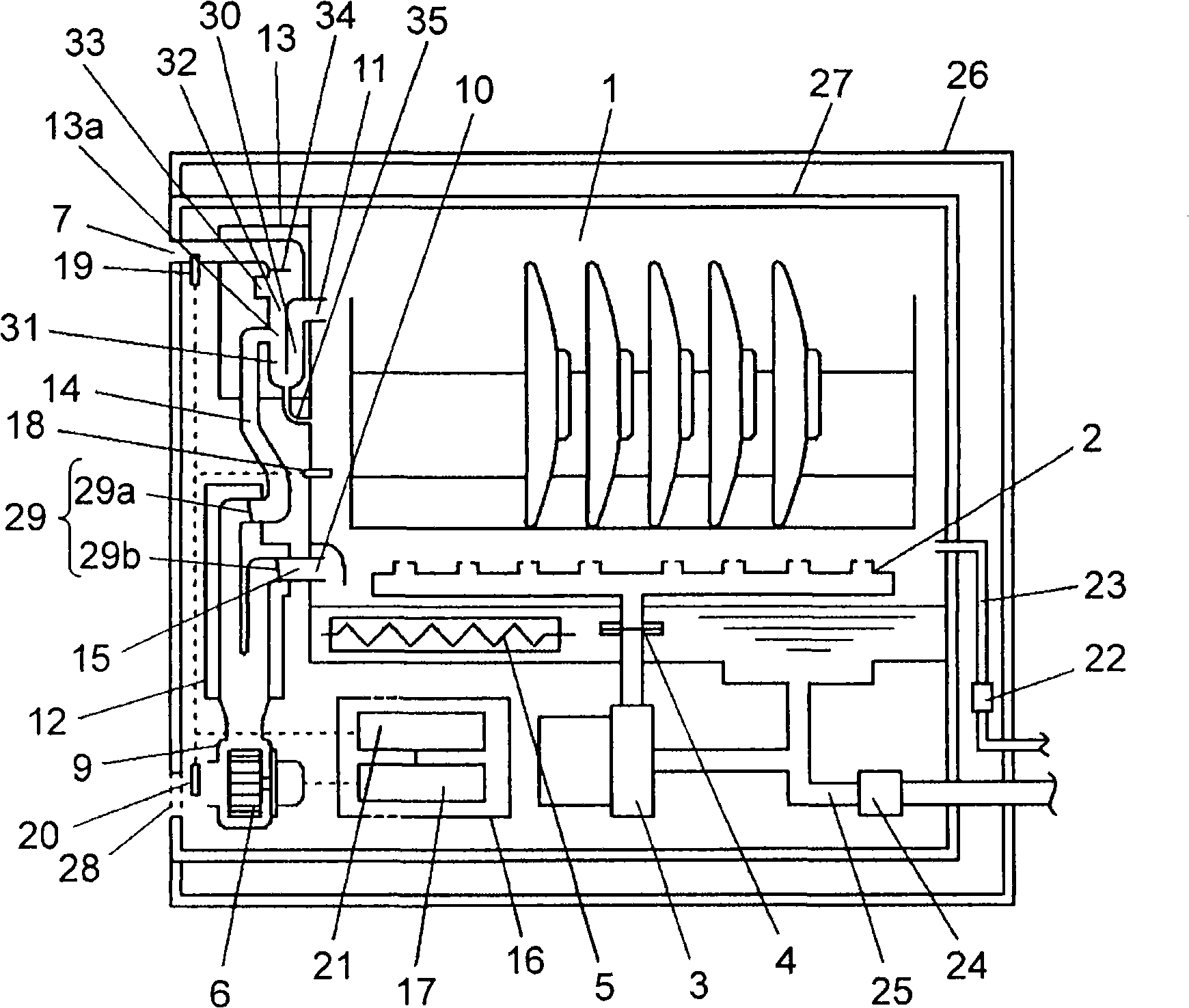

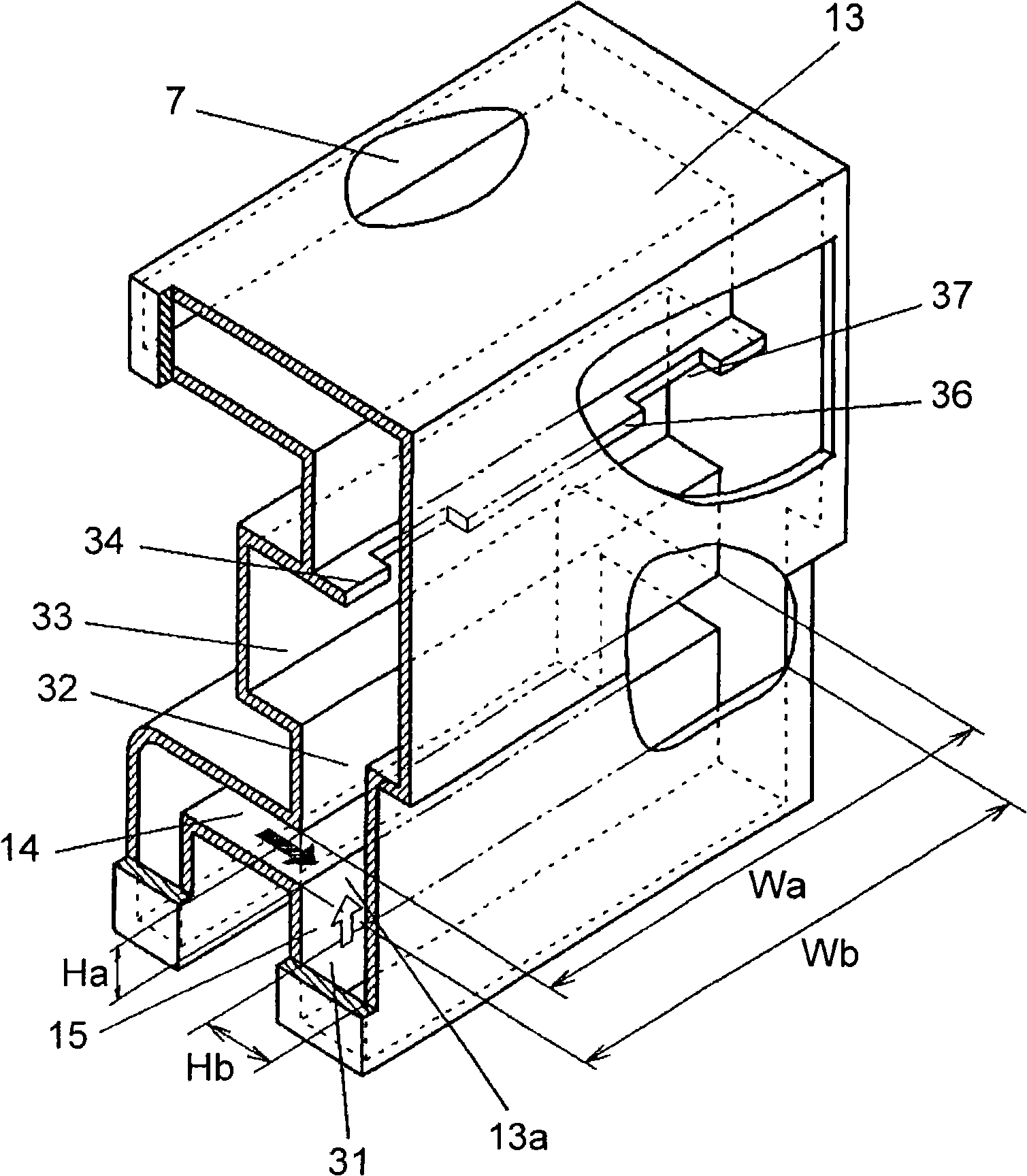

[0027] figure 1 It is a sectional view showing the configuration of the dish washer and dryer in Embodiment 1 of the present invention. Such as figure 1 As shown in , a cleaning device 4 and a heating device 5 are provided below the cleaning tank 1 for storing dishes and other objects to be cleaned. The cleaning device 4 is provided with a washing machine for spraying cleaning water to the objects to be cleaned and circulating the cleaning water. Nozzle 2, and washing pump 3 for pressurizing washing water. The heating device 5 heats the washing water to increase its temperature. In addition, the dish washing and drying machine of this embodiment is further provided with a blower 6 and a drying device 9 . The air blower 6 is used to blow in external air so as to discharge the moisture in the cleaning tank 1 and make the cleaning tank 1 dry. The drying device 9 is provided with an exhaust port 7 for discharging moisture in the cleaning tank 1 . The bottom of the cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com