Dishware cleaning and drying machine

A tableware cleaning and drying machine technology, which is applied to tableware washing machines/rinsing machines, tableware washing machines/rinsing and rinsing machine parts, and cleaning equipment. Reduce exhaust temperature and humidity, improve drying performance, and prevent hot air feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

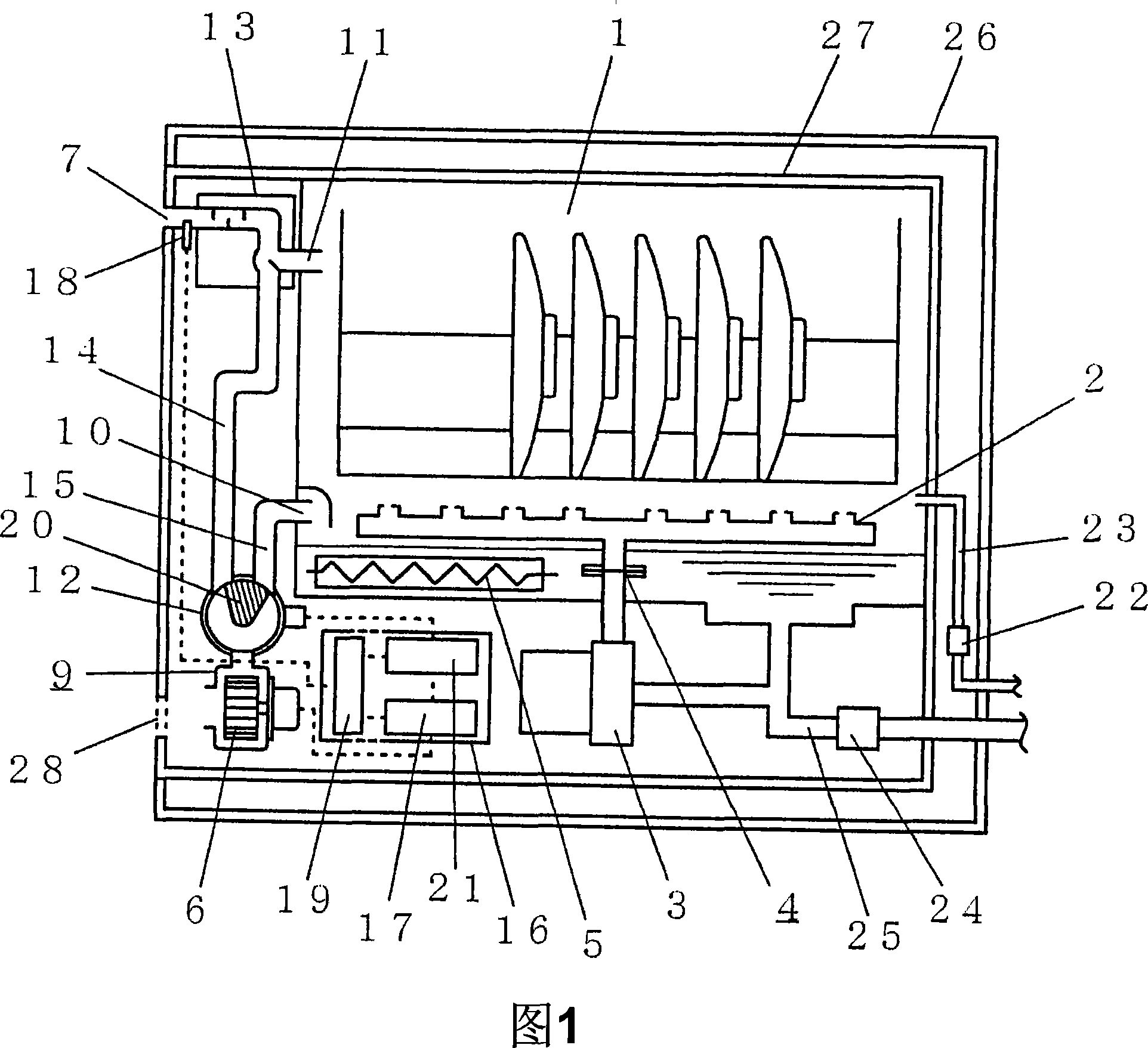

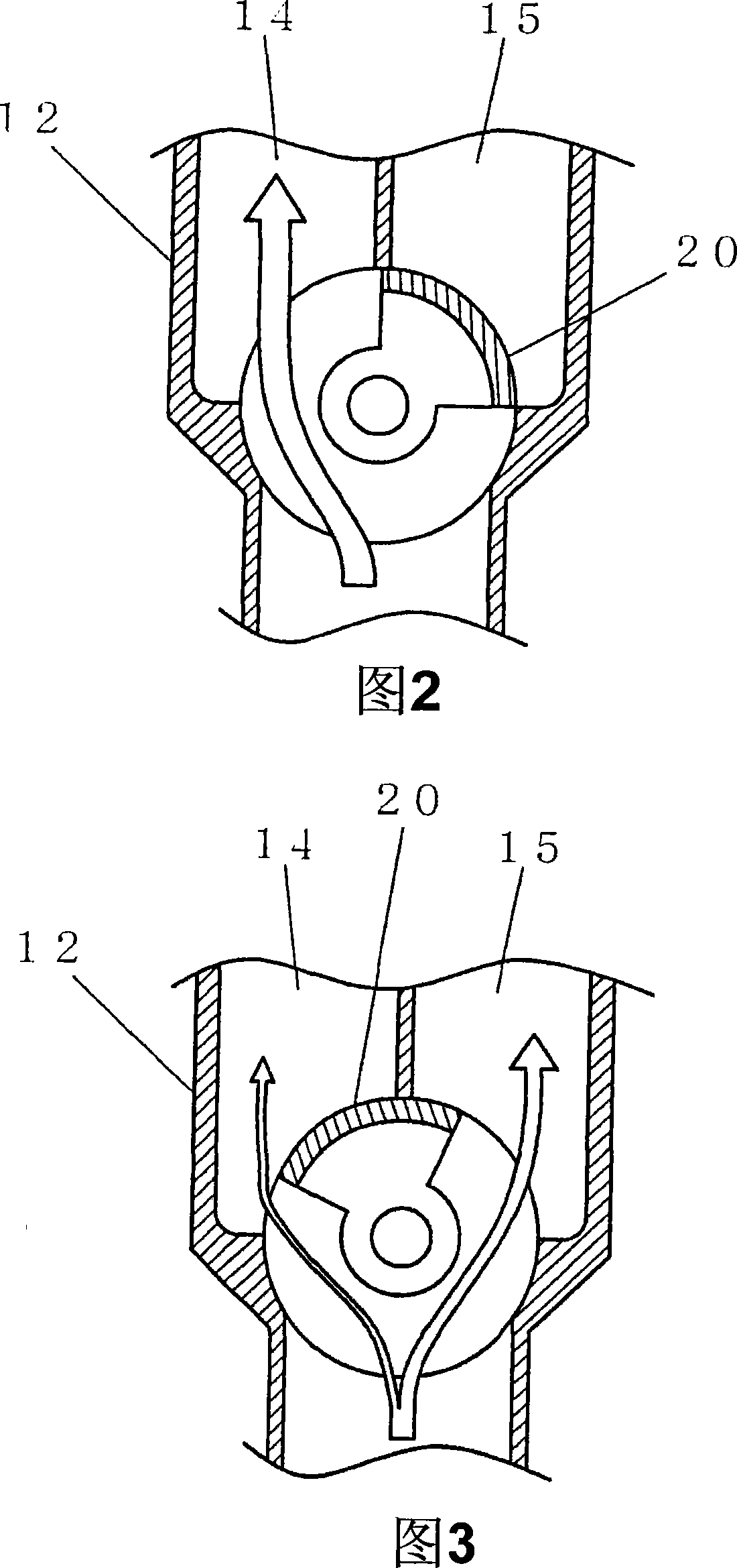

Embodiment 1

[0031] Fig. 1 is a cross-sectional view showing the structure of a dish washer and dryer in a first embodiment of the present invention. As shown in FIG. 1 , a cleaning device 4 and a heating device 5 are provided below the cleaning tank 1 for storing objects to be cleaned such as tableware. The cleaning device 4 is provided with a cleaning nozzle 2 for spraying cleaning water onto the object to be cleaned to circulate it, and a cleaning pump 3 for pressurizing the cleaning water. The heating device 5 is used to heat the washing water to increase its temperature. In addition, the drying device 9 is provided with a blower 6 for discharging the moisture in the cleaning tank 1, drying the cleaning tank 1 and blowing in outside air, and an exhaust gas for discharging the moisture in the cleaning tank 1. Mouth 7. The bottom of the cleaning tank 1 is provided with an air inlet 10 for external air to flow in, and the top is provided with an air outlet 11 for discharging the air in ...

Embodiment 2

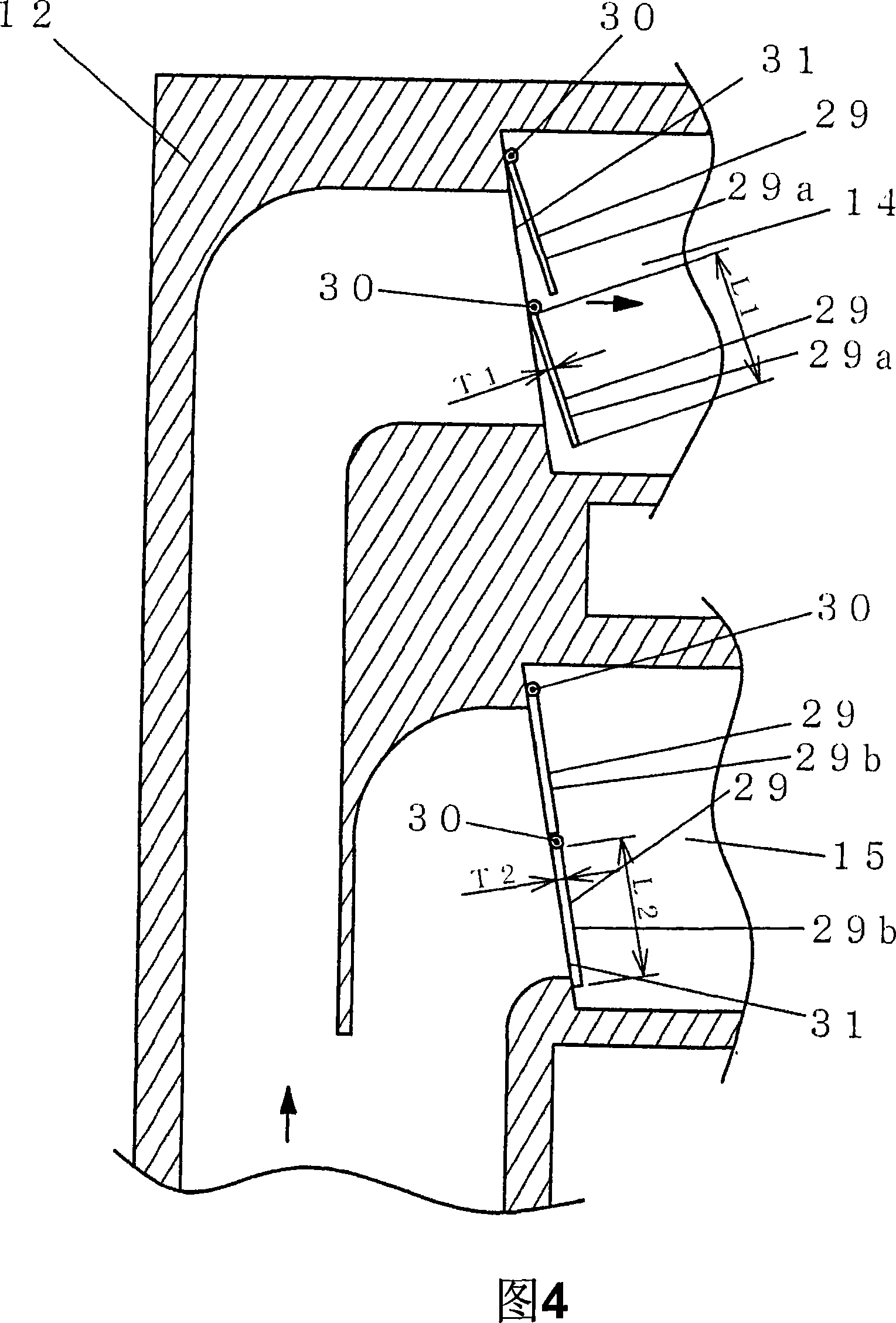

[0060] Fig. 4 is a schematic structural view of the air volume distribution device in the second embodiment of the present invention. The components and functions in FIG. 4 that are the same as those in the embodiment in FIGS. 1 to 3 are marked with the same symbols, and their detailed descriptions are omitted, but only the differences are described as the center.

[0061] The air volume distribution device 12 is a damping plate 29 that changes the opening according to the pressure of the flowing fluid (indicated by an arrow), specifically the wind pressure of the blower 6, and the air passage 15 in the external air passage 14 and the cleaning tank. Such devices are arranged at least in the air passage 15 in the cleaning tank in each passage. Moreover, the channel resistance on the side of the air passage 15 in the cleaning tank is greater than that on the side of the external air passage 14, so that the air volume flowing to the side of the external air passage 14 is more than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com