Dish washer/dryer

A tableware washing and drying machine technology, which is applied to tableware washing machines/rinsing machines, cleaning equipment, household utensils, etc., and can solve the problems of sufficient exhaust temperature drop and air mixing ratio outside the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, this invention is not limited to this embodiment.

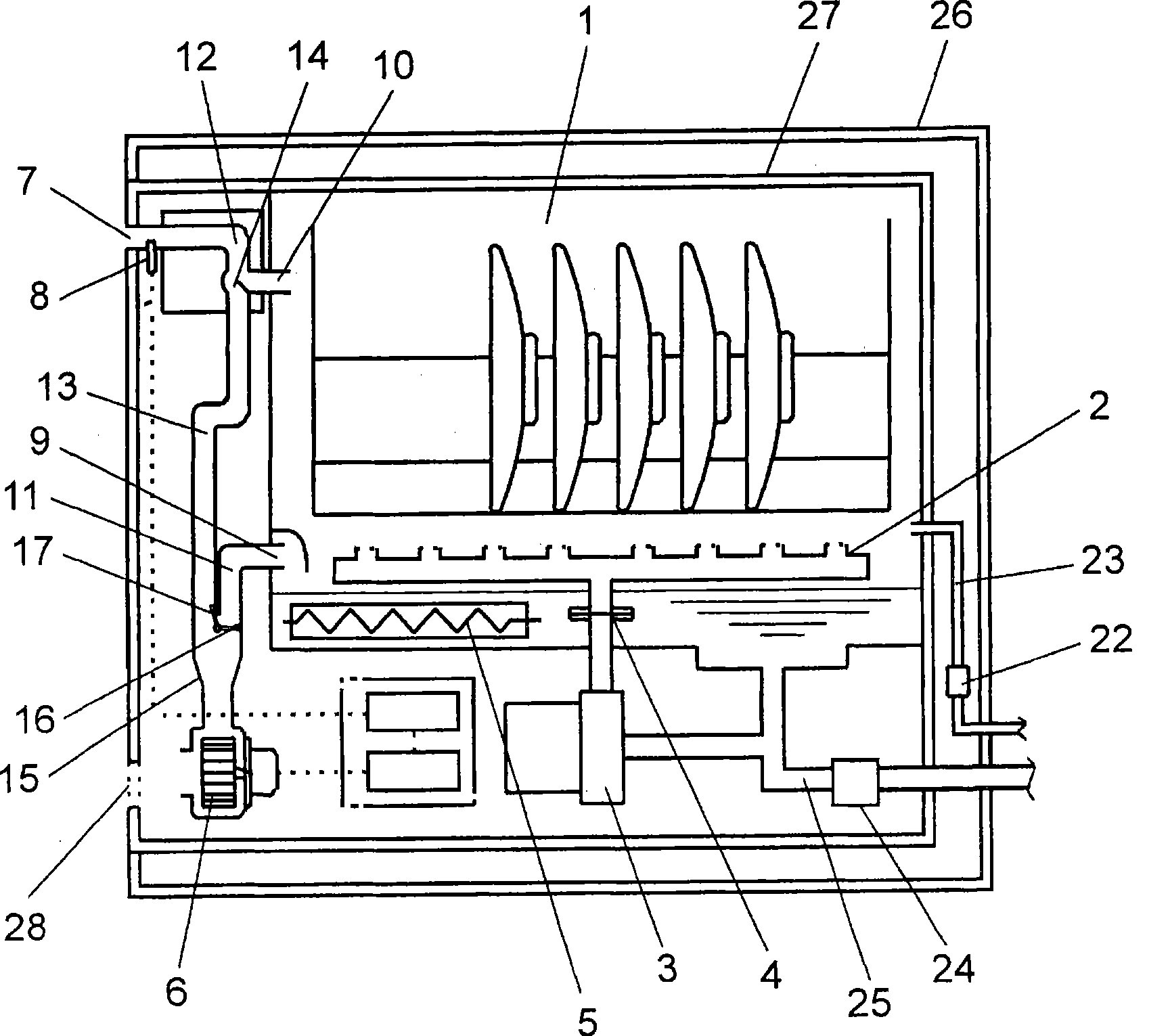

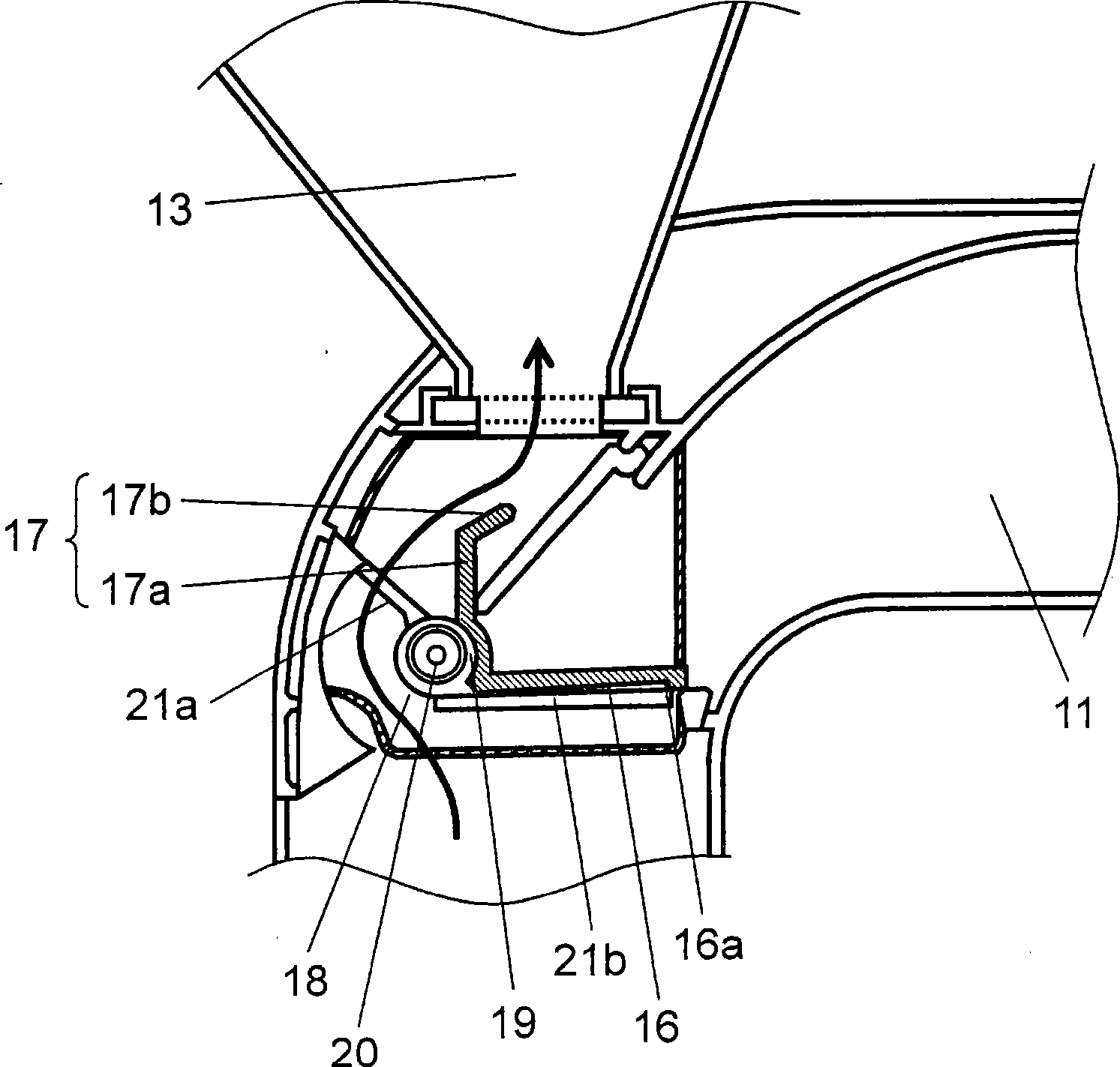

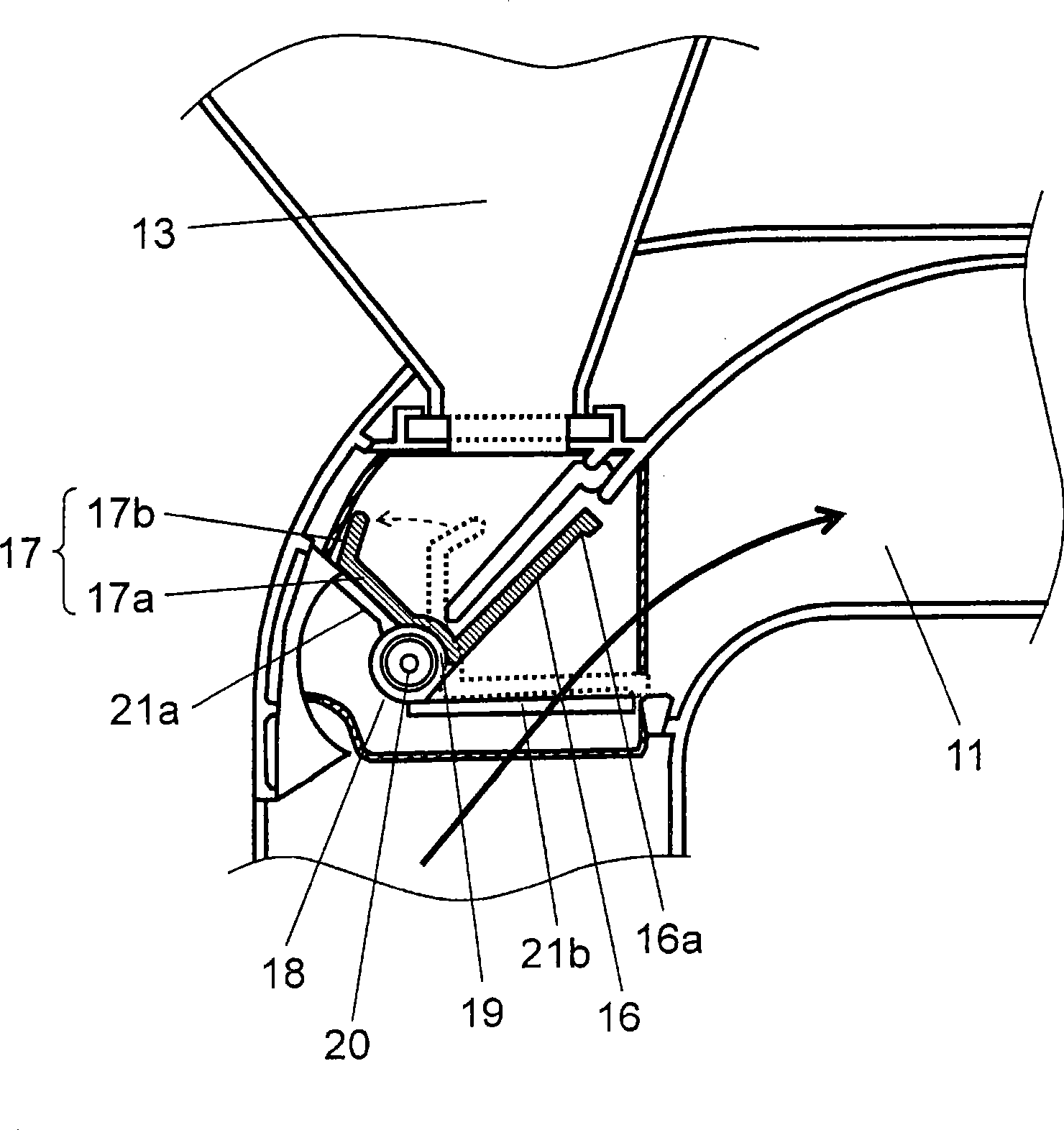

[0013] figure 1 It is a sectional view showing the structure of the dish washer and dryer according to the embodiment of the present invention, figure 2 yes figure 1 A cross-sectional view of the air volume distribution section in, image 3 yes means figure 2 A cross-sectional view of another state of the air volume distribution part in, Figure 4 yes figure 2 A perspective view of the air volume distribution part in .

[0014] First, use Figure 1 to Figure 4 The basic structure of the dish washer and dryer of this embodiment is demonstrated. The tableware washing and drying machine of this embodiment includes: a washing tank 1, which is used to store the objects to be cleaned; a heating part 5, which heats the washing water in the washing tank 1; Air discharge; the air supply part 6, which su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com